eISSN: 2574-9927

Research Article Volume 7 Issue 4

1Professional Graduate in Environmental and Health Engineering from the Popular University of Cesar, Colombia

2Environmental and Sanitary Engineering, University Professor and Master in Environment and Development at the National University of Colombia, Colombia

3Chemical engineer, University Professor and Master in Environmental Sciences from Sue Caribe, Colombia

4Environmental Engineer, Master in Environmental Engineering, Colombia

5Environmental and Sanitary Engineer. University Professor and Master of Management Systems Uniautonomous, Colombia

Correspondence: Karina Paola Torres Cervera, Environmental and Sanitary Engineering, University Professor and Master in Environment and Development at the National University of Colombia, Colombia, Tel +57 13165000

Received: December 06, 2023 | Published: December 13, 2023

Citation: Solís ACM, Velásquez DT, Cervera KPT, et al. Removal of heavy metals present in wastewater from oil and gas drilling wells through natural coagulants based on yuca almidon and Opuntia ficus indica in the municipality of Sahagún, Córdoba. Material Sci & Eng. 2023;7(4):210-215. DOI: 10.15406/mseij.2023.07.00225

The efficiency of Opuntia ficus indica and Cassava Starch as coagulants in treating wastewater associated with oil and gas production was evaluated. Laboratory-scale tests of coagulation, flocculation, and sedimentation were conducted with contact times of 1 minute (rapid mixing), 20 minutes (slow mixing), and 30 minutes, respectively. The samples were taken from wastewater associated with oil and gas extraction, with an initial turbidity value of 14500 NTU, from a well named Clarinete-5 under Sucre jurisdiction. Various concentrations were evaluated, considering parameters such as chemical oxygen demand (COD), turbidity, pH, and heavy metals (Mercury, Iron, and Lead). Opuntia ficus indica exhibited efficiency in removing Iron, turbidity, biochemical oxygen demand (BOD), and COD, with results exceeding 87%.

Keywords coagulation, flocculation, removal, Opuntia ficus-Indica, Yucca starch

The hydrocarbon industry is one of the most harmful sectors for water resources, analyzing the incidence that activities of the extractive industries have caused or generate as a potential risk in affecting the environment and especially water. Taking into account the importance of water as a natural resource that sustains life, all efforts must be directed to protect it and prevent its depletion, but they cannot be directed to stop progress, on the contrary, it is necessary to find formulas that allow a joint development that not only stimulates the growth of the industry, but also protects water sources.

Since the production generates a high pollutant load that causes the deterioration of the quality of life and regulatory non-compliance, forcing the industry to seek measures to minimize environmental impacts. Therefore, this research is necessary to reduce organic loads in the effluent to the oxidation pond and thus achieve compliance with current regulations (Resolution 0631 of 2015), using mechanisms in the coagulation processes such as natural coagulants that seek optimization in the removal of heavy metals.

Therefore, the behavior of parameters such as pH, turbidity, biological oxygen demand (BOD), chemical oxygen demand (COD) and heavy metals will be studied, seeking to provide an alternative solution to this type of water, using low-cost tools such as the implementation of natural coagulants based on cassava starch and Opuntia ficus indica.

Problem statement and justification

The oil industry has different processes for its exploitation, extraction, treatment and sale of its products. For its exploitation process, water is used, which is extracted together with the hydrocarbon and gas. After the extraction process, the water, hydrocarbon and gas are separated. The crude oil is stored until it is sold, the gas is burned in the TEA or flare, and the water is treated in an industrial wastewater treatment plant, where different solid materials that make up the sludge are retained; the water resulting from this treatment is recirculated to the system to be injected into other extraction wells. As a by-product of water treatment in the Industrial Wastewater Treatment Plant (WWTP), sludge impregnated with hydrocarbons is obtained, which must also be treated for its final disposal in an appropriate manner in the environment due to its content of different heavy metals and polluting substances.15

Crude oil contains toxic organic components, natural matter with radioactive residues and heavy metals such as cadmium, lead, mercury, arsenic, copper, among others, in addition, oil contains other associated compounds such as sulfur, heavy metals such as vanadium, inorganic salts and other toxic substances, some of them radioactive,4 which merits adequate planning, design and operational control at each stage, as this would minimize and mitigate the impacts. It is very important to understand that the procedures for managing the environmental repercussions of each stage of exploration and exploitation can be systematically evaluated before starting a project in order to take the necessary measures,12 however, there is currently no appropriate management to minimize the contamination caused by the water coming out of the well and the available alternatives are not very satisfactory, which is not a very favorable scenario for a country like Colombia, where, in short, it has a dependence on oil.1

Failure to provide adequate management to these industrial wastewaters would bring legal problems caused by the disposal of these in the environment, without prior treatment could cause different environmental impacts on the soil and water resources, failing to comply with its environmental responsibility. Being the company the generator of these, they must comply with the requirements of Resolution 0631 of 2015, which establishes the parameters and maximum permissible limit values in point discharges to surface water bodies and public sewage systems, as well as Decree 3930 of 2010 by which Title I of Law 9ª of 1979 is partially regulated, as well as Chapter II of Title VI - Part III - Book II of Decree-Law 2811 of 1974, It is for this reason that, faced with this problem, the need arises for economic and effective methods for the removal of these metals present in these waters, implementing the development of new technologies to achieve separation, for this purpose, chemical precipitation, oxidation, ion exchange, among others, have been implemented; Based on these problems, an alternative is proposed for the removal of heavy metals by means of an alternative adsorbent, based on cassava starch and Opuntia ficus indica, since previous studies have catalogued them as promising bioadsorbents for the removal of heavy metals.

General objective

Specific objectives

Theoretical reference

The oil industry is one of the fastest growing industries and plays a significant role in the economic development of developing countries, such as India.16 However, this industry generates wastewater containing a wide variety of pollutants, including petroleum hydrocarbons, mercaptans, oils, greases, and critically, heavy metals.14,16

Current techniques for the treatment of these wastewaters include bioreactor-based technologies such as stirred, membrane, packed bed and fluidized reactors.14 In addition, other techniques such as membrane technology, photocatalytic degradation, advanced oxidation processes, and electrochemical catalysis have been employed.16 These techniques are vital, especially when dealing with high concentrations of contaminants, including heavy metals.

It is essential to highlight that heavy metals present in wastewater, such as cadmium, lead, nickel and vanadium, come from organometallic complexes and represent a significant risk to the environment and human health.16 In addition, wastewater from other sectors, such as rare earth metallurgy, also contains radioactive metals, highlighting the need for effective treatments.14

Removal of these heavy metals has been shown to be effective using biocatalysts, such as hydrophobic sawdust co-immobilized with Rhodococcus cultures, which resulted in up to 96% removal of certain heavy metals.14

Type of research

The type of research is explanatory with a correlational research level at a longitudinal research level since its purpose is to evaluate the relationships that exist between the coagulants elaborated from cassava starch and Opuntia ficus indica.

Study population

The population corresponds to a mass load of wastewater, extracted from the mud used in the drilling of hydrocarbon wells, which were supplied by a company in the sector, legally constituted and authorized by the National Hydrocarbon Agency to explore and exploit oil and gas deposits in Colombia, and conducts work in different sedimentary basins in Colombia.

Population sample

Corresponding to the wastewater from the drill cuttings, which will be evaluated for the following parameters: BOD, COD, turbidity, pH, metals such as Hg, Fe and Pb.

Experimental design

The experiment was carried out in three replicates and three treatments corresponding to wastewater from oil and gas drilling, with different pH; since this variable was not controlled, three treatments were carried out and the last one was the one with three replicates. From the data obtained, a study of means and standard deviation was carried out, and from these, an analysis of variance was performed with support in the Dunnett test, since this test is used to make planned comparisons, where each of the groups (in this case each jar studied in each of the treatments) is compared with respect to a control group, through this procedure the treatments that present effective conditions with respect to the control are detected (Cardoso, 2008). This made it possible to have a reference for a total of 40 trials.

Methodological development

Step 1: Characterize physicochemically (before the application of the natural coagulant) by alkalinity test, heavy metal test, hardness, and pH the concentration of metals present in a sample of wastewater from oil and gas drilling wells.

These activities will be carried out based on the water monitoring protocol and IDEAM guidelines on alkalinity, hardness and heavy metals.

Activity 1.1. Sample collection

Description

Using the simple manual sampling method, the amount of water required for alkalinity, hardness and heavy metals analysis will be taken. To determine heavy metals, plastic bottles with a hermetic seal of 1 L capacity will be used, open the container, rinse 3 times and submerge it about 20 cm below the surface and then preserve it (IDEAM, 2019).

Activity 1.2. Identify the physicochemical properties of the wastewater sample by testing pH, TURBIDITY, BOD, COD of heavy metals (Hg, Zn, Ni, Fe, Ba).

Description

Stage 2: Determine the optimum dosage when adding the natural coagulants based on starch extracted from cassava and Opuntia ficus indica in the coagulation-flocculation process by means of the jar test trial Table 1

|

Analytical parameters |

Unit of measurement |

Analytical method |

|

Turbidity |

NTU |

SM 2130 B |

|

pH |

|

pH-meter |

|

COD |

mg O2/L |

SM 5220 C |

|

BOD5 |

mg O2/L |

SM 5210 B 360.3 |

|

Temperature |

°C |

In situ thermometry SM 2550, Electrometric. |

|

Mercury |

Mg/L |

EPA7470.Zeeman.PLTX-045. |

|

Iron |

Mg/L |

SM3030G,SM3111-B |

|

Chrome |

Mg/L |

SM3030G,SM3111-B |

|

Nickel |

Mg/L |

SM3030G,SM3111-B |

|

Copper |

Mg/L |

SM3030G,SM3111-B |

|

Lead |

Mg/L |

SM3030G,SM3111-B |

|

Arsenic |

Mg/L |

EPA3015-SM311-GFAASPLTX-012 |

|

Manganese |

Mg/L |

SM3030G,SM3111-B |

Table 1 Parameters and analytical methods to be identified

Source: Resolution 0631 2015, Adapted by author, 2022.

Activity 2.1 Collection of yucca and Opuntia ficus indica

Description

The necessary quantities of yucca and Opuntia ficus indica will be collected for later processing.

Activity 2.2 Opuntia ficus indica spraying

Description

To extract the coagulant powder, a procedure similar to that suggested by Almendárez, (2004) will be applied. The general methodology involves five stages, which will consist of initial size reduction, drying, grinding and sieving, chlorophyll extraction, and solvent removal.

Activity 2.3 Process for obtaining cassava starch

Description

To obtain cassava starch, a process similar to that of Jiménez and Martínez (2016) in their thesis entitled "Obtaining and physical and chemical characterization of cassava starch (Manihot esculentum) Guayape variety" will be applied. And to that of Alcocer et. Al.,2 in their thesis entitled "Cassava starch (Manihot esculentum Crantz) as an adjuvant in the coagulation flocculation of domestic wastewater."

Activity 2.4 Coagulation process for optimal dose determination

Description

For the determination of the optimum dosage with both natural components, the jar test will be carried out.

Step 3 Evaluate the effectiveness, efficiency and impact of the coagulant (after application of the optimum dosage) in terms of removal and/or control of heavy metals by testing alkalinity, hardness, pH and metal concentration in a sample of wastewater from oil and gas drilling wells.

Activity 3.1 Coagulant efficiency (coagulant activity)

The efficiency of the process will be determined by the percentage of turbidity removal according to the following formula:

𝒕𝒐= initial turbidity.

𝒕𝒇 = final turbidity.

Activity 3.2 Comparison of the percentage of removal in accordance with current environmental standards

These activities will be carried out based on the water monitoring protocol and IDEAM guidelines on alkalinity, pH and heavy metals.

Physicochemical characteristics of wastewater from oil and gas drilling wells

The results obtained after analyzing wastewater effluent from oil and gas drilling wells are shown in Table 2.

|

Parameters |

Value obtained |

Value limits - Res. 0631 DE 2015 |

|

pH |

11,48 |

6.00 - 9.00 |

|

Turbidity |

15825 |

NR |

|

BOD5 |

3168,75 |

200.00 mg O2/L |

|

COD |

5216,14 |

400.00 mg O2/L |

|

Iron |

1971 |

3.00 mg/L |

|

Copper |

1,94 |

1.00 mg/L |

|

Lead |

<LC (0.10) |

0.20 mg/L |

|

Chrome |

2,66 |

0.50 mg/L |

|

Nickel |

0,51 |

0.50 mg/L |

|

Arsenic |

18,03 |

0.10 mg/L |

|

Mercury |

0,74 |

0.01 mg/L |

Table 2 Characterization results of wastewater from oil and gas drilling wells

Source: University of Cordoba Laboratory, 2022.

In general terms, it can be observed that the parameters pH, COD, BOD, Iron, Copper, Chromium, Nickel, Arsenic and Mercury do not comply with the maximum permissible limits according to the Colombian legislation Resolution 0631 of 2015, so it is evident that the water from the extractive activity presents a huge concentration of pollutants as observed in the initial characterization performed. Thanks to the results obtained, three metals (Lead, Mercury, Iron) were chosen in order to evaluate the percentage of removal of these through the application of natural coagulant solution.

Obtaining and characterization of coagulant from cactus opuntia ficus indica and cassava starch

Characterization of the coagulants summarized in the following tables. These properties are very important because they will be part of the identity profile of the material and to compare it with the other coagulant used to evaluate the removal efficiency of heavy metals present in drilling wastewater (Table 3, 4).

|

Property |

Value |

Method |

Team |

|

pH |

4,42 |

Potentiometer |

pH meter |

|

Physical condition |

solid |

Ground |

Manual |

|

Texture |

Soft powder |

Sieving |

Manual |

|

Color |

Beige |

Not applicable |

Colorimeter |

|

Density |

0,72 |

Gravimetry |

pycnometer |

Table 3 Characterization of the coagulant Opuntia ficus indica

Source: Authors, 2023.

|

Property |

Value |

Method |

Team |

|

pH |

5,8 |

Potentiometer |

pH meter |

|

Physical condition |

Solid |

Extraction |

Manual |

|

Texture |

Fine powder |

Filtration |

Manual |

|

Apparent color |

White |

Not applicable |

Colorimeter |

|

Density |

0,98 |

Gravimetry |

Pycnometer |

Table 4 Characterization of cassava starch coagulant

Source: Authors, 2022.

Determination of turbidity and pH changes

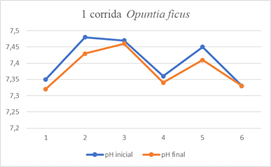

The pH changes using both natural coagulants remained close to natural, as they were at the beginning in the waters associated with oil and gas extraction. Graph 1-3

Graph 1 pH change with the coagulant Opuntia ficus indica - First evaluation.

Source: Authors, 2022.

Graph 2 pH change with the coagulant Opuntia ficus indica - Second evaluation.

Source: Authors, 2022.

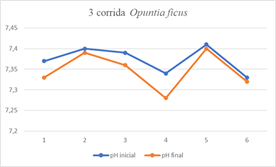

Graph 3 pH change with the coagulant Opuntia ficus indica - Third evaluation.

Source: Authors, 2022.

In graphs 1, 2 and 3 the blue color represents the pH value before adding the coagulant, while the orange color is after it has been added, as can be seen in the peaks and valleys of the curves, the tendency is that when the initial pH is high, the final pH tends to decrease, thus inferring that the reduction in pH tends to seek neutrality in the sample. Graph 4-6

In graphs 4, 5 and 6 the blue color represents the pH value before adding the coagulant, while the orange color is after it has been added, as can be seen in the peaks and valleys of the curves, the tendency is that when the initial pH is high, the final pH tends to decrease, thus inferring that the reduction in pH tends to seek neutrality in the sample.

In the study by Bravo,4 background information is presented where it is evident that Opuntia ficus indica presents a better performance for turbidity, heavy metals, BOD5 and COD removal at low pH, managing intervals between 3 - 8.

In the study by Espinoza, et al (2021), it is shown that cassava starch has a better performance for turbidity, BOD5 and COD removal in pH ranges of 6 - 7.

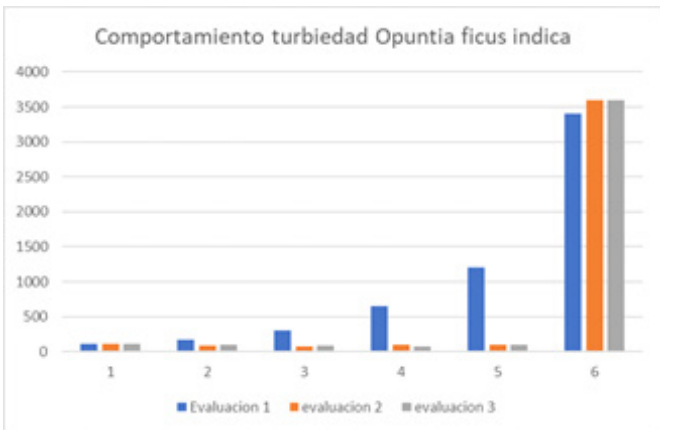

Turbidity behavior

The bars show the behavior of turbidity with respect to the evaluations made in each run, where it is observed that the optimal dose with respect to turbidity is found in the third run in jar 4 with 71.6 NTU and 99.5% removal this when we talk about the coagulant Opuntia ficus indica, showing a slightly higher percentage compared to the data provided in the monograph of Bravo (2017) since in this one percentages of 80%, 85% and 91% are shown. Graph 7, 8

Graph 7 Behavior of turbidity due to the action of the natural coagulant Opuntia ficus indica in the three evaluations.

Source: Authors, 2022.

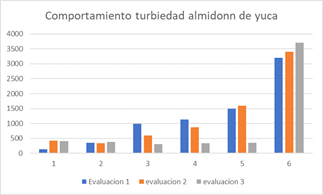

Graph 8 Behavior of turbidity due to the action of the cassava starch coagulant in the three evaluations.

Source: Authors, 2022.

The bars show the behavior of turbidity with respect to the evaluations made in each run, where it is observed that the optimal dose with respect to turbidity is found in the third run in jar 3 with 311 NTU and 96% removal rate for the cassava starch-based coagulant.

Now, at first sight, a high removal value can be observed, but it must be taken into account that due to the type of water used, this contains a high amount of suspended solids that, when the flocculation process is carried out, a change in turbidity can already be observed, and it is under this concept that we can affirm that the removal percentage gave such a high value in comparison with other investigations such as Calle and Adolfo (2021), where it is stated and studied that the percentage of removal in terms of turbidity with cassava starch is 68.5%.

According to the expected results of the project and the results obtained, we can affirm that Opuntia ficus indica is an effective coagulant that efficiently removes parameters such as COD, BOD5, turbidity and metals such as iron, where removal of up to 90% was obtained.

At the time of characterizing the water, it is observed that it does not comply with the permissible values of resolution 0631 except for pH; however, after finding the optimum dose with Opuntia ficus indica, it was possible to comply with the permissible values in the parameters of COD and BOD5.

It can be concluded that in comparison of both coagulants, the most effective was Opuntia ficus indica with a turbidity removal percentage of 99.5%, COD presented 92.79% removal, BOD5 with 93.47% removal and Iron 87.83%.

The pH range in which the cassava starch performed best was pH 7.12, showing that at low pH its performance and effectiveness is much more noticeable, being able to eliminate a BOD5 removal percentage of 78.69, COD whose removal percentage was 77.47 and iron with a percentage of 65.50; however, none of these values complies with the provisions of resolution 0631.

In the last characterization of metals carried out before the application of the coagulant, mercury and lead were not present. Due to the formation environment, they are subject to changes and deformations depending on the deposit environment found at that time, or on external and internal environmental factors in the basin, which can generate a variability in the pollutant load.

None.

There is no conflict of interest.

©2023 Solís, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.