eISSN: 2574-9927

Mini Review Volume 4 Issue 3

1Department of Chemical Engineering, Texas Tech University, USA

2Department of Metallurgical & Materials Engineering, Federal University of Technology, Nigeria

Correspondence: Oladayo Olaniran, Department of Metallurgical & Materials Engineering, Federal University of Technology, Akure, Nigeria

Received: June 23, 2020 | Published: June 29, 2020

Citation: Olaniran O. Efficacy of surface modification by layer-by-layer loading for drug delivery. Material Sci & Eng. 2020;4(2):64-67. DOI: 10.15406/mseij.2020.04.00128

Controlled drug release can improve efficacy and decrease toxicity by keeping drug concentration at the optimal level. It can also limit the required number of drugs to be administered, thereby improving the compliance of the patient. Layer by layer (LbL) drug delivery systems, for its features; bendability, functionalizability, cost and case of development/production has dominated research in controlled release systems. Some drugs cause serious side effect to other parts of the body. The use of such drugs is encouraged if it can only get to a target area by distribution control. This distribution control can be achieved by either implant at the target site or polymeric surface modification (LbL) that is capable of releasing drug to the site of action. Beside controlling of drug release, it also increases efficacy by preserving the active form of the drug within its protective microenvironment. This work presents the efficacy of LbL as controlled drug delivery.

Keywords: controlled drug delivery, degradation, LbL, deposition, nanocomposites, polyelectrolyte

Research on drug delivery systems (DDS) has been recognized as one of the most significant challenges in biomedical science.1,2 New approaches which allow self-controlled drug release, such that a minimum concentration of drugs in the blood and minimizing drug toxicity in vivo is required. One of the various approaches is the application of thin film to drug delivery. This is novel in that, variety of materials can be incorporated in developing the film. Thin film, therefore, allows incorporation and controlled drug release.3 Various methods have emerged for the development of ultrathin film devices. These methods include Langmuir-blodgett,1,4 self-assembled monolayer method5,6 and Layer-by-layer (LbL) assembly.7–11 LbL assembly has been adjudged most suited for the development of films used for drug delivery system since it has no limitations on shape of the substrate and still does not involve high temperature or pressure. In the development of LbL assembly, multilayer films are deposited onto the surface of the substrate by alternative adsorption of the participating materials. These materials interact with each other by driving forces such as electrostatic interactions, hydrogen bonds, covalent bonds, and bio-specific interactions. Electrostatic interactions between the nanoparticles (NPs) and the polyelectrolytes (PEs) are the core driving force for adsorption. Meanwhile, for NPs that are neutral in charges, other interactions such as hydrophobic interactions12–15 and physical interactions such as entanglements16–18 between the PEs and the NPs are the main considerations. These interactions should be strong enough to hold tight the adsorbed layers else, the layer would peel off at the adsorption of the next layer of NPs. In a similar manner, it must not be too strong to be able to allow drug release. In LbL coating buildup, polycation and polyanion are used as oppositely charged polyelectrolytes. The coating with these polyelectrolytes forms the foundation on which other drug nanoparticles will be incorporated via electrostatic interactions. LbL method of thin film production can be considered as the most appropriate method for preparing nano-multilayer films incorporated with therapeutic molecules.1,18–20 Another advantage of LbL coating is its ability to coat both flat and colloidal surfaces.

Factors to be considered for LbL loading

In the development of thin films for effective drug release, it must be ensured that appropriate materials were selected for the film buildup and, must also be present in the right concentration of the drug that is to be delivered.19–21 Another consideration is the stability of the thin film to be loaded with the drug. This is to be physically and chemically stable.10,22 Stimuli-responsive polymers relating to environment of the target areas are most often used as thin film materials to achieve precise drug targeting.1,23 This can be achieved by certain coatings to effect surface modification. The number of layers of coating is the determinant for the thickness of the coatings. However, to get an estimation on the thickness of the LbL coating, scanning electron microscopy (SEM) and atomic force microscopy (AFM) can be performed on both the coated and uncoated specimen. According to the work by De Geest and coworker, poly (styrene sulfonate) (PSS)/poly(allylamine hydrochloride) (PAH) multilayer was deposited on planar substrates at high salt concentrations. The difference between uncoated and PSS/PAH coated dex-HEMA-DMAEMA microgels was confirmed by AFM measurements. Uncoated microgel show lower irregularities of between 2 to 5nm while PSS/PAH coated microgels show higher irregularities ranging between 40 to 100 nm. This irregularities of morphology of the coated are mostly due to the differential drying between the template and the LbL coating. This forms the basis for the coating difference estimation for the LbL coating. Lastly is the period of release and the release rate of the drug.24 Drug is meant to be released in the target site without suffering losses in the event of delivery.

Drug loading onto the film

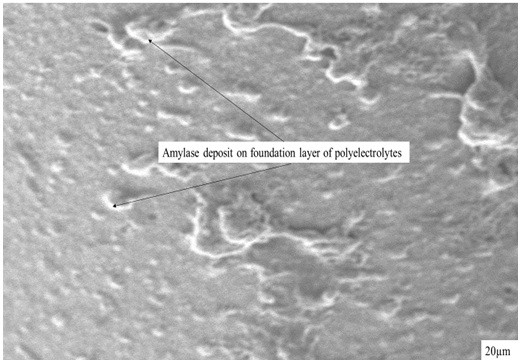

There are different methods for drug loading onto the film surface. this is referred to as surface modification. During this process of loading, immobilization occur by simple adsorption or via different driving forces such as electrostatic interactions, hydrogen bonds, hydrophobic interactions, and van der Waals interactions.10,25,26 Layer-by-layer (LbL) nanoparticle (NP) preparation uses the electrostatic interaction between oppositely charge polyelectrolytes such as chitosan, with dexran. The bioactive agents used as the core for growing the vesicular structure is the solid form. The process includes first adsorption of a polymer layer onto the template by incubation in the polymer solution, washed and transferred to the oppositely charged polymer solution. Repetition of this cycle forms a multi-layed coating that can control the release mechanism. This type of process can be used for encapsulation of various bioactive agents such as vitamins, insulin, proteins, antigenic peptides, and nucleic acid.27–30 LbL DDS has been found to be very effective in delivery of drugs and suppression of inflammation. In this approach, the coating thickness is the controlling factor for particle size and drug release rate.27 Figure 1 showed the SEM image of a commercial nylon coated with assembly of polycatanion/polyanion; chitosan (CHI) /carboxymethyl cellulose (CMC) by alternate adsorption as a foundation layers before further deposits of nanocomposite (Amylase) was made. This has been reported elsewhere as a previous work by the author. The adsorption of the polyelectrolytes and amylase nanoparticles was a great pointer that the process is laudable and can accommodate deposition of many drugs within the layers of the composites. Figure 2 shows the QCM-D analyses that allows the probing frequency (f) of the electrolytes and energy dissipation (D) values at different harmonics of resonant frequency in succession on the millisecond time scale. This showed the changes in the mass adsorbed. Invariably, this was the continuous increase in mass and thickness of adsorbed polyelectrolytes and amylase with the time. This further confirmed that amylase nanoparticles was adsorbed to the surface of the foundation layer. The advancement in nanofabrication enables precise control over size and shape of particulate DDS. More so, the use of microfluidics in preparation of DDS allows the possibility for automation and scaling up.

Figure 1 SEM image of commercial nylon bandage coated with amylase after the foundation layers of CHI/CMC via layer-by-layer technique.

Drug delivery

Research on drug delivery is important to medicine and healthcare. Controlled drug delivery has been found to improve bioavailability by preventing premature degradation and enhancing uptake, maintains drug release rate, and reduces side effects by targeting to disease site and target cells.27 Drug delivery system (DDS) has helped to prolong life and changed the economics of drug development. Design and synthesis of various biocompatible materials has driven the progress of DDS in the past decades.27,31,32 Drug release rate from Nanoparticles (NPs) could be controlled by varying the molecular weight of the participating components, such as poly (lactic acid) (PLA). This control the degradation rate of the vesicle. The drug releasing ability of LbL coating is influenced by the swelling pressure of the degrading NPs. For enough pressure to be exerted, it is necessary that the degradation products of the NPs do not diffuse through the coating during the degradation of the NPs. However, it has been reported that the permeability of the membrane cover is pH dependent. This is an important factor, especially in self rupture or controlled drug delivery system (DDS).27,33,34 LbL assembly, using microparticles such as polystyrene latex beads and metal particles has led to the creation of high surface-area thin films, electromagnetically active films, and 3D structures, eliminating the labour and expense of photolithography. LbL can be fabricated on traditional synthetic polymers. It can also be fabricated using biopolymers i.e. Proteins, nucleic acid and even charged bioparticles such as lipids vesicles and viruses. This has opened countless biological applications such as arterial wall repair, bioactive coatings, biosensors, and drug delivery.34,35

In this report, layer-by-layer (LbL) assembled multilayer thin films has been reported to be a surface modification and, an effective design for drug loading intended for controlled drug release. Multifunctional drug capable of delivery to a target site can easily be loaded by adsorption process. This process is being controlled by simple adsorption or via different driving forces such as electrostatic interactions, hydrogen bonds, hydrophobic interactions, and van der Waals interactions. A better drug delivery system is possible by LbL technique when appropriate materials were selected for the LbL system.

None.

The author declares that there is no conflict of interest.

©2020 Olaniran. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.