MOJ

eISSN: 2573-2919

Research Article Volume 9 Issue 3

1Coordinator in the areas of agricultural sciences, health sciences and human sciences at UNA Contagem, Brazil

2Veterinary Medicine, UNIBH University Center, Brazil

3Universidade do Sul de Santa Catarina (UNISUL), Tubarão, SC, Brazil

Correspondence: Gabriel Dias Costa, Coordinator in the areas of agricultural sciences, health sciences and human sciences at UNA Contagem, Professor at the UNIBH University Center, Brazil, Tel (31) 992807354

Received: February 26, 2024 | Published: May 13, 2024

Citation: Costa GD, de Souza BM, de Freitas RR. Review of methods for the reuse and recycling of equine bedding waste. MOJ Eco Environ Sci. 2024;9(3):89-94. DOI: 10.15406/mojes.2024.09.00310

The worldwide expansion of the horse industry has changed the role of horses from work animals to competition, companion and recreation animals. Competition and companion horses spend a significant part of their days confined in stalls, on beds made of different materials, such as shavings. Accumulated waste is removed daily or weekly and is often discarded in an uncontrolled manner, becoming a potential pollutant of soil and water. The present work aims to summarize the potential environmental impact of horse litter disposal practices described in the literature in line with the circular economy. The Science Direct database, the website of the United Nations (UN) and the website of the Brazilian Agricultural Research Corporation (EMBRAPA) were used as source material. The results are displayed using the VOSviewer online software. The main horse litter waste disposal practices were burning (to generate heat), pyrolysis (production of biofuels such as bioethanol and biochar) and production of organic fertilizers. The lowest environmental impact was achieved by a combination of these methods.

Keywords: environmental impacts, horse industry, organic fertilizer, biofuels, heating

Graphic summary

The climate crisis has increased the pressure for the sustainable utilization of natural resources and called for a stop in the degradation and loss of natural environments (IRP, 2019; Brodizio, et al., 2019). A circular economy can help avert this crisis. It is based on the reduction in material inputs, keeping products and components in use, cycle materials back in the economy and regenerate natural systems. Becoming more circular is a challenge for the agricultural industry, as waste from agricultural production must become a resource for new uses (Donner, et al., 2021). The horse industry is an example of agribusiness activity that produces solid waste. It has been estimated that the worldwide horse population grew 75% between 1990 and 2014 and reached 58 million animals in 2018 (Faostat, 2018). It is likely that this number will double by 2050. One of the main reasons for this increase is the popularization of horses as companion animals (Lumley, 2017). In Brazil, horse breeding is also popular, with a herd of approximately 6 million animals according to the 2020 Municipal Livestock Research (PPM).1

The increased number of animals led to a reduction in the open space available for each animal. As a result, they often spend most of their days in individual stalls. A horse produces approximately 15 kg of feces per day. Typically, residues in the stalls consist of feces and urine associated with the material used to line the stalls.2 Kusch (2012) estimated a global production of 500 to 800 million tons of manure/horse/year.

The materials used to line the stalls vary across geographic locations and husbandry practices. Horse beddings are usually made of rice husks, wood shavings or dry grasses (Airaksinen, 2006).3 Wood shavings are used due to their great accessibility, low palatability and low value (Airaksinen, 2006). It is estimated that between 9 and 29m³ of material is used to line a horse's stall per month, depending on the climatic characteristics and local hygiene practices care (Pettersson and Lundgren, 2002; Wheeller and Smithzajaczkowski, 2002; Airaksinen, 2006).

The incorrect treatment and disposal of waste generated in horse stalls can affect both the environment, with soil and water contamination, and the horses themselves, due to the transmission of diseases. Among the main pathologies associated with confinement in stalls are pneumonia and habronemosis. Pneumonia is caused by Rhodococcus equi, a saprophytic infectious agent from the intestine of horses that easily multiplies in soils with manure.4 Habronemosis is caused by Habronema muscae, which is a parasite of the intestine of horses. Eggs of H. muscae are eliminated together with the feces of the animals, hatch in the manure and develop into an infective form.5

Horse feces can be considered extremely polluting for the environment if not treated or processed correctly. The potential for soil pollution of bedding residues varies according to husbandry practices, such as the type of feed, amount and type of bedding used, time to clean the stalls, time and type of storage used for waste, and spreading of waste on the ground. According to the characteristics, the waste generated can contribute to greenhouse gas emissions, soil contamination, and water eutrophication (Hooda et al., 2000).6

Horse waste is usually not suitable for use as crop fertilizers due to the digestion process of these animals. Some seeds might pass unharmed through a horse’s digestive system and still be able to germinate and contaminate a crop field (Lundgren and Pettersson, 2009). Despite the lack of scientific evidence (Steineck and Svensson, 2000) the belief that horse manure has a lot of lignin and terpenes and thus inhibits crop growth is another factor that hinders the use of horse waste as fertilizer in agriculture.

Some processes have been applied to horse bedding to make it more sustainable and reduce its polluting potential. Examples of these processes are incineration for heat production (Pettersson and Lundgren, 2002),6 biotransformation to organic fertilizer (Pettersson and Lundgren, 2002)7 and biodigestion for gas production for urban and industrial use (Pettersson and Lundgren, 2002; Böske et al, 2015). However, Pettersson and Lundgren (2002) showed that most of the waste from horse bedding is used as fertilizer, followed by disposal in landfills.

This work summarizes the main methods used to dispose of horse stall waste. The most environmentally friendly destinations were production of biofuels, heat production, and production of organic fertilizers. The best results were obtained by combining heat production and the production of organic fertilizers.

Data collection procedures

Articles were searched for in the Science Direct database, the United Nations (UN) website and the Brazilian Agricultural Research Corporation (EMBRAPA) website. The keywords used in these searches were: “horse manure”, “circular economy”, “ODS”, “horse manure”, “biodigestion”, “manure biodigestion” and “horse manure processing”. The searches used the Boolean operators “AND” and “OR”.

Boolean operators are based on the logic of Boolean algebra following mathematical logic. Operators can be: AND or OR. Its use is necessary to carry out the combination of keywords in electronic databases. Using this strategy can make the search more accurate.8

Data analysis

A total of 118 references were reviewed, being 114 articles and 4 websites. After filtering for content, 66 articles were selected. We used the VOSviewer software to verify the correlation between the selected articles and the theme. Further filters were applied to analyze the co-occurrence of words in the title and abstract of the articles, with a complete count and a minimum of two corresponding keywords.

Articles written by research groups based in a variety of countries and published between the years 2004 and 2021 were used in this work. Based on the analysis of the methods, environmental management actions were suggested to be applied to horse stall waste. Environmental management corresponds to a set of administrative and operational actions that aim at obtaining positive effects on the environment and reduce or eliminate the damage caused by human actions, providing economic return for those who preserve the environment (Kraemer et al., 2002).

Three main methods for disposal of horse bedding waste were aligned with circular economy practices. From the 66 articles analyzed:

One publication (2020) indicated preference for pyrolysis with microwave heating (Table 1).

|

Method |

Authors |

Magazine |

Local |

|

Organic Fertilizer |

Benjamin et al. (2020) |

Journal of Cleaner Production |

USA |

|

Cadena et al. (2009) |

International Journal of Life Cycle |

Spain |

|

|

Castaldi et al.11 |

Waste Management |

USA |

|

|

Das et al. (2017) |

Frontiers in Microbiology |

China |

|

|

Donato et al.7 |

Scientific journal IFRJ |

Brazil |

|

|

Dutra10 |

Brazilian magazine of sustainable |

Brazil |

|

|

Fan H. et al. (2021) |

Resources, Conservation and |

Netherlands |

|

|

Fan S. et al. (2021) |

Resources, Conservation and |

Netherlands |

|

|

Gou et al. (2018) |

Science of the Total Environment |

Australia |

|

|

Hanc et al. (2019) |

Waste Management |

Czech |

|

|

Istrate et al. (2020) |

Resources, Conservation and |

Spain |

|

|

Jeong et al. (2017) |

Bioresource Technology |

Korea |

|

|

Kumar et al. (2005) |

Energy |

India |

|

|

Lundgren et al. (2004) |

Biomass and Bioenergy |

Sweden |

|

|

Moral et al. (2005) |

Bioresource Technology |

Spain |

|

|

Peev et al. (2017) |

Life Science Research |

Bulgaria |

|

|

Pruden et al. (2013) |

Environmental Health Perspectives |

USA |

|

|

Qian et al. (2017) |

Journal of Hazardous Materials |

China |

|

|

Reyes-Torres et al.12 |

Waste Management |

Greece |

|

|

Santos13 |

Institute of Agronomy UFRRJ |

Brazil |

|

|

Weber et al. (2014) |

European Journal of Agronomy |

Poland |

|

|

Wichuk and McCartney (2010) |

Canadian Journal of Civil Engineering |

Canada |

|

|

Zhu et al. (2013) |

Proceedings of the National Academy of Sciences of the United States of America |

USA |

|

|

Incineration and Heat Production |

Eriksson6 |

Energies |

Sweden |

|

Holm-Nielsen et al. (2009) |

Bioresource Technology |

Denmark |

|

|

Lundgren et al. (2009) |

Bioresource Technology |

Sweden |

|

|

Biofuel Production |

Nitsche and Wachendorf (2017) |

Sustainability |

Switzerland |

|

Svanberg et al. (2018) |

Renewable Energy |

Sweden |

|

|

Toka et al. (2016) |

Biomass Supply Chains for Bioenergy and Biorefining |

USA |

|

|

Burga et al. (2018) |

Resources, Conservation and Recycling |

Sweden |

|

|

Cao et al. (2014) |

Bioresource Technology |

China |

|

|

Chong et al. (2019) |

Energy Conversion and |

China |

|

|

Cséfalvay et al. (2018) |

ACS Sustainable Chemistry and Engineering |

Hungary |

|

|

Fawzy (2021) |

Journal of Cleaner Production |

England |

|

|

Kremer et al. (2015) |

Proceedings of the National Academy of Sciences of the United States of America |

USA |

|

|

Kwon et al. (2012) |

Environ Science and Technology |

Korea |

|

|

Lee et al. (2021) |

Chemical Engineering Journal |

Korea |

|

|

Linné et al. (2008) |

Swedish Gas Technology |

Sweden |

|

|

Mönch-Tegeder et al. (2013) |

Agri. Eng Int: CIGR Journal |

Germany |

|

|

Qu et al. (2020) |

Bioresource Technology |

China |

|

|

Woodard et al. (2019) |

Proceedings of the National |

USA |

|

|

Academy of Sciences of the United States of America |

|||

|

Production of Biofuels by Microwave Pyrolysis |

Mong et al. (2020) |

Chemical Engineering Transactions |

Malaysia |

Table 1 Relationship between methodologies for disposal of horse bedding waste, references that indicate them and year of publication. The table was organized alphabetically by author column

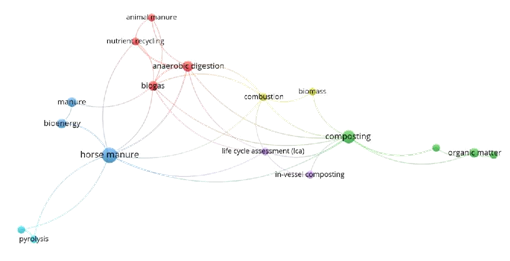

The VOSviewer software generated a map (Figure 1) showing co-occurring words. The colors indicate word clusters, which show different research lines within the same theme. All themes are directly linked to the word “horse manure”, highlighting its size. The size of each sphere was created from the number of repetitions of the word in the articles.

Figure 1 Map of the main co-occurring words found in the 66 selected articles. Different colors represent word cluster of different research lines. All clusters relate to the word “horse manure”.

Source: Prepared by the authors.

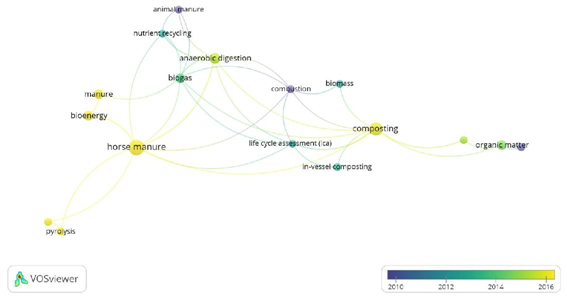

Older publications were highlighted in blue and the more recent ones in yellow (Figure 2). It is possible to observe that the methods composting, bioenergy and pyrolysis (in yellow) appear more in recent works, while the production of biogas and anaerobic digestion appear more often in older works. The size of the spheres corresponds to the number of times the word appeared, highlighting the words “compost” and “horse manure”. The lines in the figure connect co-occurring words.

Figure 2 Map of the main words filtered by the VOSviewer software algorithm, classified by year of publication.

Publications are classified according to the scale present on the map, with the oldest in blue and the most recent in yellow.

Source: Prepared by the authors.

The authors have estimated the financial viability of the methods highlighted in the literature. The cheapest destination was the production of organic fertilizer, with an estimated cost of $14,760 per ton of material produced, followed by incineration for heat production, with an estimated cost of $17,220 per ton of material produced. The values refer to inputs, labor and process costs. Transportation values were not included in the estimates.

Circular economy is characterized as a method of restoring and managing natural systems, to ensure that future generations have access to the same resources that exist today. It is an economic system whose principle is to minimize waste and maximize natural resources.9

Incineration and heat

The search for heat sources with low polluting potential is a recurring issue in countries with severe winters. Waste from animal production is a candidate heat source.6 Lundgren et al. (2009) presented promising data on the combustion potential of horse manure associated with wood shavings. However, data on the use of pure horse manure were not presented. The authors claim that the elimination of carbon dioxide is so low that it can be compared to the combustion of wood; however, more studies are needed to try to reduce NOx emissions.

It has been estimated that a barn can be self-sufficient in heat production if the manure produced in it is burned for heat production. In addition to cost savings, this practice generates ashes that can be used as fertilizer (Lundgren and Pettersson, 2009).

It is extremely important to observe the material that is used as bedding for the animals' stall. Nitsche and Wachendorf (2017) show that horse manure mixed with wood shavings is suitable for combustion, while pure manure associated with straw is not due to the high concentrations of S, K, Cl and N.

The incineration process is a good alternative due to the low concentration of heavy metals present in the ashes. However, the residue will have high concentrations of NOx. If the material is not properly incinerated, it will eliminate nitrogen in the form of ammonia during handling, storage and deposit in the soil (Lundgren and Pettersson, 2009). Examples of incineration processes for heat production are combustion, anaerobic digestion and aerobic digestion. The latter stands out when considering the potential environmental pollution.6

Although the burning residue has a high potential as a pollutant, the entire transport chain from the producing farm to where it will be used is also a source of pollution (Svanberg, et al. al., 2018). Toka et al. (2016) state that the cost-benefit ratio between the transports chains versus energy potential is the main factor that discourages the use of animal manure for energy production. Poultry, cattle and horse manure are examples that can be efficiently used for various energy conversion processes, being transformed into methane by anaerobic digestion (Holm-Nielsen, et al., 2009 Svanberg, et al., 2018).

The production of raw material for heat generation has a high cost and is in high demand by European countries during the winter. Thus, composting has become a sustainable alternative, generating greater interest for researchers who seek to reduce the use of fossil fuels to produce heat and contribute to slowing down global warming (Benjamin, et al., 2020; Istrate, et al., 2020).

The combination of methodologies to optimize the reuse of agricultural waste is efficient (Shiyang, et al., 2021). The temperature of the composting process with the use of horse stall bedding waste, in its thermophilic phase, can be between 65 and 70ºC (Evanylo et al., 2008). The heat released by the compost pile can be used for residential heating, such as water and, in cold places, for heating greenhouses for vegetable production, in addition to its residue serving as an organic fertilizer. However, further studies on economic viability are needed, especially in comparison with technologies already used today, such as solar energy (Shiyang, et al., 2021).

Production of biofuel, biochar and gas

World oil consumption reached a record 14 billion tons in 2018 (Cséfalvay, et al., 2018). Nature is no longer able to sequester the amount of carbon released every day (Woodard, et al., 2019), boosting research for new energy sources.

Following the world trend of reducing pollution and reusing animal production waste, the use of horse manure appears as an option for biofuel production. The bio-oil generated has high phenolic, low ash and high lignin content (Cao, et al., 2014). The process is a better destination for animal manure when compared to traditional destinations such as composting or vermicomposting, as it does not generate methane and carbon dioxide, thus allowing a cleaner conversion, with less harmful effects to the environment (Qu, et al., 2020).

Carbon-neutral energies have an advantage over carbon-free ones because they are compatible with engines that are prepared for traditional energy (Kwon, et al., 2012). Kremer et al. (2015) described a methodology to produce cellulosic ethanol using lignocellulosic biomass from animal manure as a raw material and a substitute for traditional ethanol sources.

The production of bioethanol from horse manure does not generate greenhouse gases. Horse manure meets the necessary concentrations of carbon and nitrogen for fuel production and, unlike other biomass sources, does not require the addition of nitrogen (Lee, et al., 2021).

The thermal conversion of horse bedding, such as combustion or pyrolysis, promotes circular economy in the equestrian industry, reusing waste from its production and reducing greenhouse gas emissions (MONG, et al., 2020). Fawzy (2021) states that the destination of horse manure to produce biochar is an important process for carbon immobilization, preventing it from becoming a pollutant.

Pyrolysis is a thermochemical conversion process that results in solid (biochar), liquid (bio-oil) and gaseous products that vary according to the raw material used (Cao, et al., 2014). The traditional pyrolysis process has the downside of releasing heat and greenhouse gases into the environment (Chong, et al., 2019).

To reduce the production of gaseous products and search for greater efficiency in the production of biochar and bio-oil, Mong and collaborators (2020) used microwaves as an energy source. Although the study was carried out on laboratory scale, the results were promising. In addition to the product having the same characteristics as the product from the traditional pyrolysis process, the process resulted in less damage to the environment as it requires less energy for conversion. Due to the scarcity of studies with the microwave pyrolysis process, studies on an industrial scale are necessary.

In terms of gas production, Sweden stands out in the use of biomass from animal production waste. The Swedish energy potential using horse manure is estimated at 730 GWh per year, which is equivalent to 17% of biogas production from animal waste (Linné, et al., 2008). Horse manure, when used in an anaerobic biodigestion system, can produce from 298 to 259 liters per kg of dry organic matter, the values vary according to the animals' feeding and the material's storage time (Burga, et al., 2018).

The use of horse manure added to wood shavings without processing was not efficient for biodigestion. Mönch-Tegeder and collaborators (2013) state that, this combination is not optimal for biodigestion due to its high fiber content and compaction, decreasing the production of gas and bacterial action. To prevent this problem, the authors suggest crushing the material or mix it with straw to avoid compaction and increase gas production.

Organic fertilizer

Organic fertilizers are obtained from decomposed or fermented manure or plant remains.10 Agricultural production with organic and sustainable characteristics has shown great growth in Brazil in recent years. The demand for sources of organic fertilizers has experimented similar growth. However, economic issues related to the acquisition of this type of fertilizers often make the purchase of the product unfeasible.7

Composting can be divided into three major phases according to the variation in temperature and maturation of the product. The first is the mesophilic phase, which is short (approximately 15 days) and has temperatures lower than 40 ºC. The second phase is called thermophilic and is characterized by being longer than the previous phase (approximately 60 days), with temperatures reaching 65-70 ºC. Such temperatures are deadly to some infectious agents and pests. The third and last phase of the process is the maturation phase, which lasts between one and two months. In this phase, the temperature gradually decreases, following the decrease in microbial activity (Evanylo et al., 2008).11

The temperature produced during the mesophilic and thermophilic phases of composting are kept relatively high for a prolonged period. This is due to the microbial activity degrading organic compounds that are easily broken down and rich in energy, such as sugars, starch and fat, and some more resistant compounds, such as proteins and cellulose. These phases can last from weeks to months, depending on the raw materials used. Residues derived from lignin take the longest to decompose (Fan et al., 2021).

Fresh, unprocessed manure is considered unstable (Moral, et al., 2005). Yet, it is adequate to be used in composting or vermicomposting processes. When manure or immature compost is added to the soil, plant growth can be delayed due to the high concentrations ammoniacal nitrogen and ammonia. Moreover, spaces without oxygenation can form, predisposing the proliferation of anaerobic bacteria that will produce unpleasant smell (Jeong, et al., 2017). On the other hand, when compost is considered stable, it gradually releases nutrients, improving soil structure. In addition to having a long shelf life, without changes in chemical and organoleptic characteristics, the product does not carry viable seeds of weeds (Wichuk and Mccartney, 2010).

The compost or vermicompost can be considered a temporarily or permanently stable product. The temporarily stable product did not complete all the processing stages probably due to sub-optimal conditions for the activity of earthworms or the microbiota. The product is considered permanently stable when the chemical characteristics become stable (Peev et al., 2017). The compost or vermicompost stabilization process, using horse manure, can take 6 to 9 months to reach full maturation (Hanc et al., 2019).

Composting is one of the most traditional processes for reusing animal production waste. It occurs through the controlled decomposition of organic matter by microorganisms such as bacteria and fungi. These microorganisms break down organic molecules, releasing essential nutrients for plant growth and, thus, acting as organic fertilizer.11,12

In this process, aerobic bacteria transform the residues into organic fertilizer. This fertilizer improves the soil structure and can be used for food and feed production13 and plant cultivation in general.12 During the composting process, microorganisms transform ammonia into nitrate, generating a compound with high fertilization capacity (Lundgren, et al., 2004).

Horse manure improves the quality of agricultural soil by improving porosity, aeration, water retention capacity and nutrient availability, which in turn stimulated microbial activity and biomass content (Das, et al., 2017).

Intensive livestock farming routinely uses antibiotics and growth promoters. The metabolites of these products are eliminated via the urinary and digestive routes (Kumar, et al., 2005). When used abusively, these products risk contaminating water and soil. Reversing this contamination would require the implementation of measures to mitigate the effect of antibiotic residues (Pruden, et al., 2013). Animal production waste is a large reservoir of antibiotic-resistant bacteria (Zhu, et al., 2013). The composting process can be a safe way to treat this type of waste, since it deactivates these bacteria and makes the material safe for use as organic correction of agricultural soil (Gou, et al., 2018; Qian, et al., 2017).

Compared to other methods of processing and managing agricultural waste, composting has some advantages. It has a lower technical cost; it is less complex and requires less financial investment (Cadena et al., 2009). In addition, its residue is organic fertilizer (Weber et al., 2014). However, Boldrin et al. (2009) report that the production of heat and greenhouse gases are normally ignored in composting studies.14–16

Horse stall waste is still considered a pollutant by several rural establishments. This view might change with the possibility of reusing stall waste and thus encouraging the circular economy. European countries are more advanced in research on alternative methods for producing heat during winter. Wood shavings proved to be a promising raw material in horse bedding, as burning it is as efficient as burning wood. Also, the ashes can be used as source of organic fertilization.

The demand for replacing the use of fossil fuel encourages the search for neutral or carbon-free energy sources. By pyrolysis it is possible to produce biofuel, biochar and biogas, making the method free of physical by-products, however, with the need for high heat production, apart from microwave pyrolysis.

The production of organic fertilizer is the most common destination of horse stall waste. Due to the low cost and low technology required for implementation, it is accessible for small-scale productions. When composting was associated with heat production, the results were positive, resulting in the heating of homes and water, in addition to the production of organic fertilizer.

All methodologies were effective in preventing horse bedding waste from being inappropriately disposed of in the environment. The best method on a production scale was composting for producing organic fertilizer. The other methods were efficient on a laboratory scale, but additional studies on large scale are needed. In this way, the present work can contribute to the choice of method to be used according to the place where the horse residue is present, thus avoiding improper disposal and adding value to the residue.

None.

None.

The authors declared that there is no conflict of interest.

©2024 Costa, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.