MOJ

eISSN: 2573-2919

Research Article Volume 5 Issue 6

1Physiology and Sugar Chemistry Division, Bangladesh Sugar crop Research Institute, Bangladesh

2Department of Agricultural Chemistry, Faculty of Agriculture, Bangladesh Agricultural University, Bangladesh

3Department of Food Technology and Rural Industries, Faculty of Agricultural Engineering, Agricultural University, Bangladesh

4On-Farm Research Division, Bangladesh Agricultural Research Institute, Bangladesh

Correspondence: Md Shamsul Arefin, Physiology and Sugar Chemistry Division, Bangladesh Sugar crop Research Institute, Ishurdi, Pabna, Bangladesh

Received: November 18, 2020 | Published: December 21, 2020

Citation: Arefin MS, Rahman MM, Alim MA, et al. Physico-chemical properties of goor and quality of sugarcane (Saccharum officinarum) as influenced by integrated nutrient management in Bangladesh. MOJ Eco Environ Sci. 2020;5(6):271-278. DOI: 10.15406/mojes.2020.05.00204

Sugarcane is the only sugar yielding and economically important crop in Bangladesh. Although, it is a good source of sucrose, alcohol and organic matter waste, soil fertility is declining in sugarcane growing areas. Considering the facts, a field study was carried out during 2014-2015 cropping season to evaluate the impacts of integrated use of different organic and chemical nutrients on the quality of sugarcane. Seven treatments were comprised in this experiment (T1 = Control, T2 = 165:55:120:30:10:2.5:4 kg NPKSMgZnB ha-1, T3 = Poultry Litter (PL) @ 5 t ha-1 + 95:51:87:9:10:2.5:4 kg NPKSMgZnB ha-1, T4 = Cow Dung (CD) @ 15 t ha-1 + 36:52:60:17:10:2.5:4 kg NPKSMgZnB ha-1, T5 = Press Mud (PM) @ 15 t ha-1 + 10:50:43:0:10:2.5:4 kg NPKSMgZnB ha-1, T6 = Mustard Oil Cake (MOC) @ 0.5 t ha-1 + 140:54:115:25:10:2.5:4 kg NPKSMgZnB ha-1 and T7 = GM (Green Manure) @ 5 t ha-1 + 140:53:100:28:10:2.5:4 kg NPKSMgZnB ha-1). The experiment was carried out in a Randomized Complete Block Design (RCBD) with three replications. Results of cane quality parameters, the treatment T3 (PL @ 5 t ha-1 + 95:51:87:9:10:2.5:4 kg NPKSMgZnB ha-1) recorded the highest brix (20.9 %), pol in cane (14. 9%) and sugar yield (15 t ha-1). The goor quality parameters likes sucrose (80.1 %), colour transmittance (57.80%) and goor recovery (11.21%) were noticed highest in T3 treatment, which was similar to T4 treatment (CD @ 15 t ha-1 + 36:52:60:17:10:2.5:4 kg NPKSMgZnB ha-1). On the other hand the lowest reducing sugars (6.56%) and ash content (2.96%) were also observed in T3 treatment. The results from this experiment revealed that the treatment - PL @ 5 t ha-1 + 95:51:87:9:10:2.5:4 kg NPKSMgZnB ha-1 followed by CD @ 15 t ha-1 + 36:52:60:17:10:2.5:4 kg NPKSMgZnB ha-1 provided a scope to supply raw material with juice and goor quality of sugarcane grown in High Ganges River Floodplain soils to sugar industry and goor makers.

Keywords: juice quality, organic fertilizer, poultry litter, colour transmittance, sucrose

Sugarcane is a tropical and subtropical giant grass crop belonging to the grass family, Gramineae. Sugarcane shares 0.91% of total GDP in the national economy sector and 9.11% of the total value of agricultural output. It occupies only 1.39% of Bangladesh gross cropped area.1 Sugarcane is used for making white sugar and goor in our country. The minimum per capita consumption of sugar is 13.0 kg or its equivalent quantity of goor 17.0 kg.2 Total sugar need is 1.95 million tons or 2.55 million tons of goor based on 142 million people in our country for the 21st century. Therefore, there is a huge gap of 1.35 million tons of sugar or goor in the country. Sugar production in Bangladesh is much less than that of other sugar-producing countries due to low cane yield and sugar recovery. Due to the fluctuation of the area under sugarcane cultivation, the production of sugarcane fluctuated from year to year. Sugarcane, long duration and large biomass accumulating crop remove substantial quantities of plant nutrients from the soil. Increasing land-use intensity has to result in massive exhaustion of nutrients from the soil. Depletion of soil fertility is a major constraint for sustainable crop production in Bangladesh. Farmers generally use inorganic fertilizers for crop production due to easy access and scarcity of organic fertilizers. Improper and imbalanced use of fertilizers along with cultivation of exhaustive crops like sugarcane causes a detrimental effect on soil properties. Further use of excess nitrogenous fertilizer may cause nitrate contamination in surface and ground water).3 As a result soil productivity has come down and concerns like physical, chemical and biological degradation and declining organic matter content are also becoming increasingly relevant. From this aspect, it is urgently needed to increase the yield of sugarcane and sugar recovery. Hence, the combined application of organic and chemical sources of plant nutrients may be done in such a way that the soil fertility is maintained without compromising yield loss. Integrated nutrient management involves the integrated use of chemical fertilizers along with organic fertilizers to increase production and improve soil health without environmental hazards. The concept of integrated nutrient management (INM) included appropriate crop rotations, cover crops, manures, crop residues, fertilizers and conservation tillage.4 In Bangladesh, soil fertility status is decreasing day by day due to intensive cultivation of the high yielding crop, little use of organic materials, improper soil and crop management practices as well as the use of higher doses of chemical fertilizers.5 Soomro et al.6 stated that quality parameters such as Brix, pol, purity, commercial cane sugar and its accumulation in sugarcane were higher with the application of three-fourth of the recommended rate of NPK fertilizer (169-84-1261) + 20 tons press mud ha-1. Incorporating press mud into the soil increased sugar yield and cane juice quality.7 This study investigated the effects of INM strategy on the quality of sugarcane as compared to traditional nutrient management to know the effect of either alone or in a combination of organic and chemical fertilizers. To achieve the research goal, the present study was designed to investigate the impact of integrated nutrient management on the quality of juice and goor in sugarcane.

Description of the experimental site

The field experiment was carried out at the research field of Bangladesh Sugarcrop Research Institute (BSRI), Ishwardi, Pabna, Bangladesh. The station is situated between 24°06'56.6"N latitude and 89°05'17.0"E longitude and situated about 15.5m above the mean sea level. The rainfall is heavy during the month of April to September and moderately low rainfall during the month of October to March. The total rainfall occurs within eight months with mean monthly values in the range of 1.13-12.93 mm. Generally, the temperature is moderately high during the month of April to September and moderately low with scant rainfall during October to March. The mean temperature ranges from 13.0 to 27.2oC. The average sunshine hour of the experiment site varied from 0.16 to 5.11 hours. The site of the experiment belongs to the Sara soil series under the High Ganges River Flood Plain Tract belonging to Agro-Ecological Zone 11 (AEZ 11). The soil of the experimental site was calcareous alluvial soil with low organic carbon (0.72%). The soil type of the site was silty loam. The experimental field was a medium high land soil with the well internal drained condition.

Experimental materials

As a sugarcane variety is a test crop, Isd 39 is largely cultivated by farmers and responds very well to organic sources of nutrients. This variety was selected in addition to the recently released high sugar content. As a high tillering variety, it is tolerant of water logging, flood and drought situations and is the most ideal for sugar production and goor making.

Treatments and experimental design

The experiment comprised of the combinations with seven treatments was used in this study. The field experiment was laid out in Randomized Complete Block Design (RCBD) with three replications (Table 1).

|

Treatment abbreviation |

Treatment description |

|

T1 |

Control |

|

T2 |

165:55:120:30:10:2.5:4 kg NPKSMgZnB ha-1 |

|

T3 |

PL @ 5 t ha-1 + 95:51:87:9:10:2.5:4 kg NPKSMgZnB ha-1 |

|

T4 |

CD @ 15 t ha-1 + 36:52:60:17:10:2.5:4 kg NPKSMgZnB ha-1 |

|

T5 |

PM @ 15 t ha-1 + 10:50:43:0:10:2.5:4 kg NPKSMgZnB ha-1 |

|

T6 |

MOC @ 0.5 t ha-1 + 140:54:115:25:10:2.5:4 kg NPKSMgZnB ha-1 |

|

T7 |

GM @ 5 t ha-1 + 140:53:100:28:10:2.5:4 kg NPKSMgZnB ha-1 |

Table 1 Treatment details included in the experiment

PL – Poultry litter (moisture – 22 %, pH – 7.1, organic carbon – 29.2 %, N – 1.69 %, P – 0.08 %, K – 0.8 %,S – 0.51 %); CD – Cowdung (moisture – 33 %, pH – 8.2, organic carbon – 17.0 %, N – 1.17 %, P – 0.03 %, K – 0.55 %, S – 0.12 %); PM – Press Mud (moisture – 51 %, pH – 7.27, organic carbon – 12 %, N – 1.3 %, P – 0.04 %, K – 0.64 %, S – 0.32 %); MOC – Mustard Oil Cake (moisture – 3 %, pH – 7.21, organic carbon – 30.6 %, N – 5.1 %, P – 0.05 %, K – 1.0 %, S – 0.88 %); GM – Green manure (moisture – 81 %, organic carbon – 41.3 %, N – 2.5 %, P – 0.16 %, K – 1.9 %, S – 0.14 %)

Agronomic management

The experimental plot was set as per treatments and design. The settlings of poly bag were planted following spaced transplanting (STP) method. The raised poly bag settlings were transplanted in trenches at 45 cm distance. The rates of chemical fertilizers for different treatments were calculated on the basis of recommended fertilizer dose (RFD) for high yield goal (HYG) and integrated plant nutrition system (IPNS) based on the composition of each organic waste material and its major nutrient contents. Chemical fertilizers were used at the rates of 165 kg N, 55 kg P, 120 kg K, 30 kg S, 10 kg Mg, 2.5 kg Zn and 4 kg B ha-1 in the form of urea, TSP, MoP, gypsum, magnesium sulfate, zinc sulfate and borax, respectively as recommended dose of sugarcane. Cow dung (CD), poultry litter (PL), press mud (PM), mustard oil cake (MOC) and green manure (dhaincha) were applied as per treatments. All the sources of organics and a full dose of P, S, Mg, Zn and B fertilizers were applied in trenches and mixed with soil prior to transplanting of settlings. The basal dose of N fertilizer (1/3rd) was applied as side-dressing at 30 days after transplanting (DAT). The rest amounts of N and K fertilizers were applied as a top dressing in two equal splits at 120 and 180 DAT. In case of green manuring treatments, dhaincha seeds were sown in between two rows of sugarcane at the rate of 25 kg ha-1 in the month of April. After 45 days, dhaincha was cut into small pieces and mixed into the soil. Irrigation was applied in trenches just after transplanting of the settlings in the plots under STP method to ensure quick and maximum establishment. Supplementary irrigation was also applied after 15, 60, 90 and 120 DAT when the moisture reached 60% depletion of the field capacity. The soil in trenches was loosened twice at 30 and 60 days after transplanting to prevent the settlings from suffering from soil compaction. All the plots were kept weed-free up to 140 DAT, as the period is considered to be the critical period for crop-weed competition in the sugarcane field. The cultural, mechanical and chemical control measures were done for insect-pests and disease management as and when required. Earthing-up was done three times on 120, 150 and 180 DAT. This operation has converted the ridges into furrow and furrow into ridges. Tying was done two times, first in July and then September to keep the clump straight to protect the cane stalks from lodging against the possibility of strong wind. The dried leaves were removed from plants and green leaves on plants were tied together by taking all the canes in one bundle. Cross tying was done by binding two clumps of adjacent rows together. Regarding the planting date and method, the crop was harvested manually at its physiological maturity stage.

Data collection and measurements

Sugarcane quality parameters: Cane samples were randomly taken from different parts of the plot and made the total number of stalks to 20. Cane samples were crushed by BSRI developed modern cane crusher. Juice samples extracted by means of a power driven sugarcane crusher from 10 canes were selected at random from the net plot area at harvest. Sugarcane juice was chemically analyzed for the following quality parameters:

Brix (%) : Percentage of total soluble solids present in cane juice

Pol (%) in juice: Percentage of pure sucrose content in cane juice

Purity (%): Percentage of pure sucrose in dry matter =

Pol (%) in cane: Percentage of pure sucrose content in whole cane

Total Soluble Solids (TSS) or Brix: Brix readings of the filtered juice samples were recorded with the help of brix hydrometer standardized for 20oC. Juice temperatures were also recorded for necessary temperature corrections.8

Pol in juice: Juice samples were clarified as per Horne’s dry basic lead acetate method with the help of digital polarimeter (Model: ATAGO AP 300, Japan). Pol readings so recorded were correlated with observed degrees brix with the help of Schmitz's table to obtain the values of pol in juice, which was synonymously used for sucrose content in juice.9

The purity of juice: Purity of juice values was computed as per the following formulae.

Pol in cane: Pol in cane was estimated by Horne’s dry basic lead acetate method using polarimeter (Model: ATAGO AP 300, Japan). The corrected pol reading was obtained by comparing the pol reading measured with the corresponding corrected Brix reading referring to Schmitz table and the values were computed as per the following formulae.9

Where, F = Fibre in cane (%); 5 = constant

Reducing sugars: Lane and Eynon (original) method was used to determine reducing sugars as described by Varma.10 Reducing sugar was calculated by the usual formulae:

Where, TV = Titre value; FF = Fehling factor and DF = Dilution factor

Phosphate: Phosphate content of the cane juice was determined by ammonium molybdate method (Varma, 1988).10

Fiber: Fibre content of the cane was calculated by using the following formula:

Sugar yield: Sugar yield was calculated with cane yield and recoverable sucrose using the following formula.9

Analysis of goor quality parameters: Goor samples prepared in the laboratory of Physiology and Sugar Chemistry Division at harvest as per the method standardized at Bangladesh Sugarcrop Research Institute (BSRI), Ishurdi, Pabna were analyzed and graded according to quality parameters. The chemical analysis was carried out for certain characteristics to determine the quality and grading according to net rendament values.

Sucrose: Sucrose content was determined by digital polarimeter (Model: ATAGO AP 300, Japan) as done for sucrose of sugarcane juice.

Reducing sugars: Reducing sugars were estimated by titrating goor solution dissolved in 100 mL water and clarified with dry basic lead acetate with 10 mL of Fehling’s A + B solution according to Lane and Eynon volumetric method. 10

Where, TV = Titre value; FF = Fehling factor and DF = Dilution factor

Colour transmittance: For colour transmittance in 0.25 N solutions of goor samples, 6.5 g goor was dissolved in 100 mL of water. 11

Ash: Sulphated ash content in goor was calculated. Carbonated ash content was usually determined by making a deduction of 10% of sulphated ash. Ash content was expressed as per cent goor basis as indicated below 11:

pH: Thirteen grams of goor were dissolved in water and made up to 100 mL volume. pH solution was determined by pH meter (Model: Hanna, China).

Goor recovery: Goor recovery was calculated by using the following formulae9:

Grading based on net rendament (NR) value: Net rendament values were calculated by substituting the values in the formula given below:

Net rendament (NR) value = Sucrose (%) – [RS (%) + (3.5 × Ash (%)]

Based on NR values, goor samples were classified and graded according to the scale proposed by Jabber.11

Statistical analysis

The experimental data were statistically analyzed through “Statistics 10” computer software. The least significant difference (LSD) at p = 0.05 was used to compare treatment means12.

Total soluble solids or Brix, Pol in juice and Purity

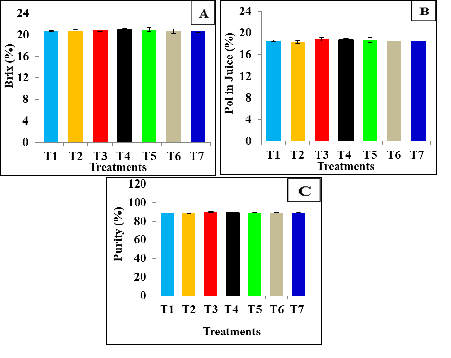

Integrated use of organic and inorganic fertilizers application had no significant effect on total soluble solid (TSS) or brix of sugarcane juice (Figure 1). The treatment T3 (PL @ 5 t ha-1 + 95:51:87:9:10:2.5:4 kg NPKSMgZnB ha-1) recorded the highest brix (20.93%), while the treatment T6 produced the lowest TSS or brix (20.63%). However, the use of higher chemical nitrogen decreased in total soluble solids. This might be due to dilution caused by higher dose of chemical nitrogen or due to increase in ash in cane juice. Similar findings were claimed by Bangar et al.13 and Bokhtiar and Sakurai,14 who proved that increasing press mud increased juice brix.

Figure 1 Effects of integrated nutrient management practices on brix (A), pol in juice (B) and purity (C) of sugarcane. Bars indicate SE (n=3).

T1 – Control, T2 – 165:55:120:30:10:2.5:4kg NPKSMgZnBha-1, T3 – Poultry litter @ 5t ha-1 + 95:51:87:9:10:2.5:4kg NPKSMgZnB ha-1, T4 – Cowdung @ 15t ha-1 + 36:52:60:17:10:2.5:4kg NPKSMgZnBha-1, T5– Press Mud @ 15t ha-1 + 10:50:43:0:10:2.5:4kg NPKSMgZnB ha-1, T6 – Mustard Oil Cake @ 0.5t ha-1 + 140:54:115:25:10:2.5:4kg NPKSMgZnB ha-1, T7 – Green manure @ 5t ha-1 + 140:53:100:28:10:2.5:4kg NPKSMgZnB ha-1

Application of different doses of organic and inorganic fertilizers did not significant influence in pol in juice (Figure 1). Among the treatments, the highest pol in juice (18.84%) was noted in treatment T3. Higher results, although not significant, were obtained in the treatments that received poultry litter (PL) with chemical fertilizers (PL @ 5 t ha-1 + 95:51:87:9:10:2.5:4 kg NPKSMgZnB ha-1). Pol in the juice was decreased in the plots where green manure (GM) was applied. The results were in line with the findings mentioned by Arefin et al.1 Bokhtiar and Sakurai15 also reported similar results, those who found that pol in juice occurred decline due to more N from (C. juncea) incorporated as green manure so that increased the concentration of N made plant succulent, which in turn diluted the sucrose.

Sugarcane juice purity did not significant influence by different doses of integrated fertilizer application (Figure 1). Results observed that maximum purity (90.02%) produced in treatment T3 among all the treatments. While the minimum purity (88.46%) was recorded in T2 treatment. Similar trend was recorded as in total soluble solids and sucrose as indicated by Mohammad16 and Bokhtiar et al.17 They found that reduction in purity was dependent upon sucrose and brix values. A similar conclusion was drawn by Bangar et al.13 while comparing with press mud as organic nitrogen fertilizer.

Cane quality parameters

Application of different integrated fertilizer did not affect on sugarcane juice quality as indicated pol in cane (Table 1). Pol in cane varied from 14.49 to 14.89%. The results found that the treatment T3 contained the highest pol in cane (14.89%) and it was statistically similar to all other treatments. However, the lowest pol in cane (14.49%) was found in the treatment T1. Higher results were obtained in the treatments that received chemical fertilizers in combination with poultry litter (PL @ 5 t ha-1 + 95:51:87:9:10:2.5:4 kg NPKSMgZnB ha-1). Application of green manure (GM) plots decreased the values of pol in cane than organic treated plots. The same results were cited by Arefin et al.1 and Bokhtiar and Sakurai,17 who found that the pol in cane occurred decline due to more N from incorporated C. juncea as green manure so that increased concentration of N made plant succulent, which in turn diluted the sucrose.

Phosphate content of sugarcane juice significantly varied among the treatments (Table 2). Maximum phosphate content (327.00 mg L-1) produced in treatment T4 followed by T3 (326.85 mg L-1), which was statistically similar. While, treatment T1 (control) produced the lowest phosphate content (319.67 mg L-1) in sugarcane juice. The treatments T6 and T7 with the values of 325.26 and 324.97 mg L-1, respectively were found similar effect on phosphate content of sugarcane juice. Arefin et al.1 noticed the same results who explained that the lower dose of chemical nitrogen in combination with organic fertilizer increased phosphate content in sugarcane juice.

|

Treatments |

Pol in cane (%) |

Phosphate (mg L-1) |

Reducing sugars (%) |

|

T1 |

14.49 |

319.67 d |

0.26 a |

|

T2 |

14.63 |

322.67 c |

0.25 a |

|

T3 |

14.89 |

326.85 a |

0.19 c |

|

T4 |

14.77 |

327.00 a |

0.20 bc |

|

T5 |

14.75 |

323.00 c |

0.24 ab |

|

T6 |

14.64 |

325.26 b |

0.20 bc |

|

T7 |

14.61 |

324.97 b |

0.24 ab |

|

LSD at 0.05 |

NS |

0.88 |

0.04 |

Table 2 Effects of integrated nutrient management (INM) on cane quality parameters

Figure(s) having common letter(s) in a column did not differ significantly at 5% level of significance T1 – Control, T2 – 165:55:120:30:10:2.5:4 kg NPKSMgZnBha-1, T3 – Poultry litter @ 5 t ha-1 + 95:51:87:9:10:2.5:4 kg NPKSMgZnB ha-1, T4 – Cowdung @ 15 t ha-1 + 36:52:60:17:10:2.5:4 kg NPKSMgZnBha-1, T5 – Press Mud @ 15 t ha-1 + 10:50:43:0:10:2.5:4 kg NPKSMgZnB ha-1, T6 – Mustard Oil Cake @ 0.5 t ha-1 + 140:54:115:25:10:2.5:4 kg NPKSMgZnB ha-1, T7 – Green manure @ 5 t ha-1 + 140:53:100:28:10:2.5:4 kg NPKSMgZnB ha-1

Reducing sugars exhibited significant differences among the fertilizer treatments (Table 2).It was seen that the content of reducing sugars in sugarcane juice ranged from 0.19 to 0.26%. The T3 treatment gave the lowest reducing sugars (0.19%) content and it was statistically similar to the treatments T4 (0.20%) and T6 (0.20%). The highest reducing sugars (0.26%) content was recorded significantly in T1 treatment. The T1 treatment produced the highest reducing sugars content due to unripened cane as well as low recovery, while the content of reducing sugars (0.19%) was lowest due to higher purity and sugar recovery. Similar findings were reported by Hussain et al.,18 who found that the higher reducing sugars in the juice also increased its concentration in goor.

Fibre and sugar yield

The fiber content of sugarcane was differed significantly due to application of different organic and inorganic nutrient management treatments (Table 2). Among the treatments, T1 (control) gave the highest fibre content (16.84%) and the lowest fibre value (15.51%) was produced in T7 treatment, which was statistically as par with T3 (15.66%) and T4 (15.76%) treatments. Furthermore, the lowest fibre content (16.84%) was recorded by the treatment T1 treatment. The softness and juiciness of sugarcane mainly depends on its fibre content. Higher is the fibre content; lower is the juice extraction and cane quality. Higher fibre content leads to higher bagasse production and lower juice extraction resulting higher loss of pol in bagasse.20 These were agreement with the findings of Bokhtiar et al.,17 who stated that the integrated use of organic and inorganic fertilizers decreased fiber content in cane. Arefin et al.1 also mentioned the same results.

Sugar yield was significantly influenced by the application of integrated nutrient management treatments (Table 3). Higher sugar yield was produced by fertilizer treated plots than control plot (T1). The highest sugar yield (14.95 t ha-1) was recorded in the treatment T3 and was not significant difference over T4 treatment. Sugar yield in T3 and T4 treatments with values of 14.95 and 13.22 t ha-1, respectively were statistically as par. The treatments T4, T6 and T7 were also similar on sugar yield with the values of 13.22, 10.79 and 10.52 t ha-1, respectively. Sugar yield (6.21 t ha-1) was recorded in the treatment T1 (control), which was significantly lower as compared to the fertilizer treatments. The results were in agreement with the findings of Arefin et al.,1 who mentioned that poultry litter application with inorganic fertilizer increased sugar yield. Bangar et al.13 reported the increase in sugar yield with varying levels of organic fertilizer application along with chemical fertilizer. It was also found that the integrated use of press mud with inorganic fertilizers increased sugar yield.17

|

Treatment1 |

Fibre (%) |

Sugar yield (t ha-1) |

|

T1 |

16.84 a |

6.21 d |

|

T2 |

16.52 b |

8.79 cd |

|

T3 |

15.66 d |

14.95 a |

|

T4 |

15.76 d |

13.22 ab |

|

T5 |

16.36 bc |

10.45 c |

|

T6 |

16.16 c |

10.79 bc |

|

T7 |

15.51 d |

10.52 bc |

|

LSD at 0.05 |

0.26 |

2.71 |

Table 3 Effects of integrated nutrient management (INM) on fibre and sugar yield of sugarcane

Figure(s) having common letter(s) in a column did not differ significantly at 5% level of significance

Physical properties of goor

The application of integrated use of organic and chemical fertilizer was significantly influenced by physical properties of goor (Table 4). Treatments T2, T3, T4, T5, T6 and T7 showed hard and T1 showed moderately soft texture in goor. In respect of crystalline in nature of goor, treatments T2, T3, T4, T5 and T6 produced good crystalline nature. While treatments T1 and T7 recorded non-crystal and moderately crystal in nature. Furthermore, the golden colour observed in T2, T3, T4, T5, T6 and T7 treatments and T1 showed brown colour of goor in solid state. On the other hand, sweetest of goor produced by the treatments T2, T3, T4, T5, T6 and T7 but T1 treatment slightly salty taste was found.

|

Treatments1 |

Texture |

Crystalline in nature |

Colour in solid state |

Taste |

|

T1 |

Moderately Soft |

Non-crystal |

Brown |

Slightly salty |

|

T2 |

Hard |

Good crystal |

Golden |

Sweety |

|

T3 |

Hard |

Good crystal |

Golden |

Sweety |

|

T4 |

Hard |

Good crystal |

Golden |

Sweety |

|

T5 |

Hard |

Good crystal |

Golden |

Sweety |

|

T6 |

Hard |

Good crystal |

Golden |

Sweety |

|

T7 |

Hard |

Moderately Crystal |

Golden |

Sweety |

Table 4 Effects of integrated nutrient management (INM) on physical properties of goor

Chemical properties of goor

The sucrose content of goor significantly influenced by different integrated nutrient management treatments (Table 5). Treatment T3 had the highest sucrose content of goor (80.14%) and it was statistically similar to the treatment T4 (79.67%). However, the treatment T1 (control) showed the lowest sucrose content (75.80%). It may be maintained that sucrose per cent being the main sweetening factor of goor and good quality goor should have high sucrose content. These results cited that minimum sucrose content of goor produced in chemical fertilizers alone treatment and maximum sucrose content produced in integrated fertilizer use treatment. Similar findings were reported by Keshaviah.19

|

Treatments1 |

Sucrose (%) |

Reducing sugars (%) |

Colour transmittance (0.25 N) |

|

T1 |

75.80 d |

6.77 ab |

45.83 b |

|

T2 |

78.02 c |

6.80 a |

51.58 ab |

|

T3 |

80.14 a |

6.56 c |

57.80 a |

|

T4 |

79.67 ab |

6.58 bc |

56.54 a |

|

T5 |

77.77 c |

6.74 abc |

52.20 ab |

|

T6 |

79.41 b |

6.73 abc |

54.70 a |

|

T7 |

78.17 c |

6.69 abc |

53.98 a |

|

LSD at 0.05 |

0.6944 |

0.1951 |

6.82 |

Table 5 Effects of integrated nutrient management (INM) on chemical properties of goor

Reducing sugars of goor were significantly influenced by the application of different integrated fertilizers treatments (Table 5). Treatment T3 indicated minimum reducing sugars (6.56%) in goor and it was at par the treatments T4, T5, T6 and T7. On the contrary, the treatment (T2) mentioned maximum reducing sugars (6.80%) in goor, which was not identical to the treatments T1, T5, T6 and T7. Goor containing higher reducing sugars percent generally discourage because it is hygroscopic, poor quality and low shelf-life. The reducing sugars in T2 treatment were found highest due to unripened and lower purity of cane, while, the lowest reducing sugars were observed in T3 treatment due to higher purity. Hussain et al.18 cited the same findings who observed that the highest reducing sugars in sugarcane juice increased its concentration in goor. Organic sources of nutrients have brought about reduced content of reduced sugars owing to their steady and continuous supply of nutrients particularly nitrogen, which was responsible for reducing sugar content. The inorganic nitrogen at sugar accumulation stage resulted in accumulation of reducing sugars at higher concentration. Arefin et. al.1 described the same results.

Application of different integrated fertilizers treatments significantly differed on colour transmittance of goor (Table 5). The treatment T3 showed the maximum colour transmittance (57.80%) of goor. The treatments T3, T4, T6, T7, T5, and T2 with the respective values of 57.80, 56.54, 54.70, 53.98, 52.20 and 51.58% were observed statistically similar. The lowest color transmittance of goor (45.83%) was found in the treatment T1 (control). Light-coloured goor is always preferred by consumers for eating purposes, and good quality goor is characterized by light colour. The use of organic fertilizer with chemical fertilizers increased sucrose content and decreased reducing sugars level in goor. This might be due to concentration caused by higher dose of organic nitrogen or due to increase in colour transmittance in goor. These results were agreed with the findings of Arefin et. al.1

pH, ash and goor recovery

The pH was significantly influenced by the practice of integrated nutrient management treatments (Table 6). The highest pH value (5.75) of goor was found in the treatment T6, which was at par to all other treatments except the control treatment T1. Similarly, the lowest pH value (5.58) of goor was obtained from the treatment T1 (control) but it was similar to T2, T3, T4, T5 and T7 treatments. Lower pH indicates acidic. Table 5 showed that pH value of goor prepared from the treatments (Except T1) which was equivalent to neutral pH, and this type of goor was suitable for consumption. Results agree with findings obtained by Arefin et. al.1

|

Treatments1 |

pH |

Ash (%) |

Goor recovery (%) |

|

T1 |

5.58 b |

3.57 a |

10.13 b |

|

T2 |

5.67 ab |

3.36 ab |

10.27 b |

|

T3 |

5.72 ab |

2.96 b |

11.21 a |

|

T4 |

5.71 ab |

3.21 ab |

10.78 ab |

|

T5 |

5.67 ab |

3.45 ab |

10.42 b |

|

T6 |

5.75 a |

3.25 ab |

10.50 ab |

|

T7 |

5.65 ab |

3.30 ab |

10.46 ab |

|

LSD at 0.05 |

0.16 |

0.54 |

0.76 |

Table 6 Effects of integrated nutrient management (INM) on pH, ash and goor recovery

The ash content in goor was significantly influenced by the practice of integrated nutrient management treatments (Table 6) and its range varied from 2.96 to 3.57%. The treatment T1 recorded significantly the highest ash content (3.57%) and was statistically similar to all other treatments except T3 treatment and the lowest ash content (2.96%) was observed in treatment T3, which was statistically similar to all other treatments except T1 treatment. The increasing dose of organic fertilizers decreased ash content in juice. A similar but significant trend was recorded for ash content of goor. This showed that a higher concentration of ash in juice also increased ash in goor and a higher concentration of ash in the juice was directly proportional to higher doses of mineral fertilizers. These results of ash content in the juice were contrary to Bangar et al.,13 who concluded an increase in ash with increasing press mud. But these results were analogous to Hussain et al.,18 who proved that higher concentration of ash in goor was due to its higher concentration in juice.

The goor recovery (%) was significantly influenced by the practice of integrated nutrient management treatments (Table 6). The treatment T3 significantly produced the highest goor recovery (11.21%) among all the treatments, which was statistically similar to the treatment T4 (10.78%), T6 (10.50%) and T7 (10.46%). While the control treatment T1 gave significantly the lowest goor recovery (10.13%). These results confirmed with the findings of Hussain et al.18

Net rendement values

The effects of integrated nutrient management treatments on net rendement (NR) values were significant (Table 7). Based on NRV, goor was classified into different classes such as A2 to B. Among the treatments, the T3 treatment gave significantly the highest NR value of goor (61.08). The second and third highest NR values were observed in T4 (61.0) and T6 (60.92) treatments. Again, the treatment T1 (control) produced the lowest value (58.67) of NR. Goor quality was higher with more of A1 quality goor with organic nutrient management practices. Similar results were reported by Keshaviah.19

|

Treatments1 |

NR values |

Grading |

|

T1 |

58.67 g |

B (Medium) |

|

T2 |

59.98 d |

B (Medium) |

|

T3 |

61.08 a |

A2 (Good) |

|

T4 |

61.01 b |

A2 (Good) |

|

T5 |

59.65 f |

B (Medium) |

|

T6 |

60.92 c |

A2 (Good) |

|

T7 |

59.93 e |

B (Medium) |

|

LSD at 0.05 |

0.029 |

|

Table 7 AmplitudeNet rendement values (NRV) of goor under different INM treatments

Figure(s) having common letter(s) in a column did not differ significantly at 5% level of significance.

High yielding sugarcane production using integrated nutrient management practices is the most important strategy to nourish the rapidly growing population. From the above discussion, it is concluded that juice quality parameters such as brix, pol and purity did not vary significantly but goor quality parameters like sucrose, reducing sugars, colour transmittance, pH and ash varied significantly with different integrated nutrient managements. Among seven fertilizer treatments, the use of PL @ 5 t ha-1 + 95:51:87:9:10:2.5:4 kg NPKSMgZnB ha-1 was superior on yield and quality parameters than other nutrient management treatments. It was also found that the treatment - PL @ 5 t ha-1 + 95:51:87:9:10:2.5:4 kg NPKSMgZnB ha-1 followed by CD @ 15 t ha-1 + 36:52:60:17:10:2.5:4 kg NPKSMgZnB ha-1 provided an opportunity to supply raw material with better juice and goor quality of sugarcane grown in High Ganges River Floodplain soils to sugar industry and goor makers in Bangladesh.

The authors are thankful to Bangladesh Agricultural University for their financial support to conduct this study. Also grateful to Bangladesh Sugarcrop Research Institute (BSRI) for providing necessary facilities to carry out the field. We sincerely thanks to the staff of BSRI for their technical support during the implementation of the field work.

Bangladesh Agricultural University.

The authors declare that there are no conflicts of interest.

©2020 Arefin, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.