MOJ

eISSN: 2573-2919

Research Article Volume 8 Issue 6

1Departamento de Cartografia, Universidade Federal de Minas Gerais, Brasil

2Departamento de Engenharia Agrícola, Universidade Federal de Viçosa, Brasil

3Departamento de Engenharia de Minas, Faculdade Adjetivo – CETEP, Brasil

Correspondence: Marcelo Antonio Nero, Departamento de Cartografia, Universidade Federal de Minas Gerais, Av. Antônio Carlos, 6627, Belo Horizonte, Minas Gerais, Brasil, Tel +55 (31) 3409.5000

Received: December 08, 2023 | Published: December 19, 2023

Citation: Junior EJA, Alves ISL, Tavares JR, et al. Evaluation of environmental damage in clandestine mining. MOJ Eco Environ Sci. 2023;8(6):240-244. DOI: 10.15406/mojes.2023.08.00298

Remotely piloted aircraft (RPAs) are remote sensing platforms with capabilities for taking images at various altitudes, proving to be an alternative with great potential for acquiring geospatial data remotely. In addition to the imaging capacity, RPAs serve as transport for other sensors for geo-ecological applications such as Light Detection and Ranging (LIDAR). If associated with the photogrammetric technique, obtaining geometrically corrected planimetry and altimetry data, the results and products derived from RPAs gain satisfactory quality for precise environmental analyzes that can be useful in estimating mining volumes. Therefore, the objective of this work is to evaluate the environmental damage and losses caused by the irregular mining of ore carried out at Fazenda Mina do Vigia. The temporal photogrammetric data available on the Google Earth platform, as well as those obtained by LIDAR, show a large removal of excavated material over the years. Based on the LIDAR altimetry, it was possible to calculate the volume of excavation carried out in 2009, as well as the comparison with the data obtained from RPAs allowed an accurate estimate of irregularly mined mining. The study concluded that more than 17 tons of materials were extracted, financially valued at 5.6 million reais.

Keywords: RPAs, LIDAR, photogrammetry, clandestine mining

RPA, remotely piloted aircraft; LIDAR, light detection and ranging; UAV, unmanned aerial vehicle; GIS, geographic information system; DEM, digital elevation model; GNSS, global navigation satellite system; GPS, global positioning system; GLONASS, Russian global navigation satellite system

The potential of remotely piloted aircraft (RPAs) has been highlighted in several application areas due to its ease of operation, high data acquisition rate, and independence for users.

Digital aerial photogrammetry and remote sensing techniques, have now gained wide operational application, driven by the combination of RPAs and low-cost sensors.1 Additionally, it is very important to relate recent searches with RPA, DRONE, LIDAR, UAV and GIS applied in the several themes as such as in2–10, for example.

However, images obtained by satellites have coarser spatial and temporal resolution when compared to images captured by RPAs, which makes it difficult to monitor accidents and environmental occurrences, especially for applications in small areas of land. This worse spatial resolution results in a limited representation of the observed area, reducing redundancy in observations of variables on the ground. To overcome these limitations, multispectral and multifunctional sensors can be installed on unmanned aerial vehicles (RPAs), or geoprocessing techniques are combined with the data, aiming to improve temporal and spatial resolutions.11

In addition to applications in remote sensing, advances in the mining exploration industry have been driven by scientific studies such as that of12, who developed a methodology for exploration by using of programming ore piles using simulators linked to the Solver tool, which is integrated with Microsoft Excel. This innovative approach demonstrates how the integration of simulation technologies and software use can optimize processes in the mining industry, improving efficiency and operations planning.

Associated with these innovations, scientific research such as that of13 have sought to identify the best processing route for iron ore tailings and demonstrate the technical feasibility of reusing fractions. This study, contextualized in the scenario of the mining industry in constant search for more sustainable and efficient practices, highlights the crucial importance of strategies that aim not only to optimize processes, but also to reduce environmental impact.

The Light Detection and Ranging (LIDAR), which is a multifunctional sensor that was traditionally used to generate digital terrain elevation models (DEM), is now being used in other applications as well, such as monitoring surface changes. The LIDAR generates a dense cloud of georeferenced points, which makes it possible to extract information, such as the topography of the terrain through contour lines, estimation of the height of vegetation that covers the ground, density, diameter of objects on the surface and their spatial distribution, among others.14 A good example of such studies was recently applied in15, where researchers used LIDAR data to identify and determine the height of eucalyptus trees.

The extraction of natural resources is becoming more and more increasingly evident challenges in the environmental context.16 On the other side, research on the use of multispectral cameras and LIDAR to estimate ore usurped in clandestine mines aligns with the need for innovative solutions in mining extraction industry. The remotely piloted aircraft (RPAs) obtain accurate data in real time, thus facilitating the calculation of the volume of minerals efficiently and contributing to the sustainable management of mineral resources.17–19

Furthermore, RPA technology offers significant advantages, such as the ability to cover large areas in a short space of time, obtaining images with better spatial and temporal resolution, as well as generating detailed 3D models, essential for monitoring and estimating volumes, as demonstrated by.20 By combining multispectral cameras to identify variations in soil properties and LIDAR to accurately map the terrain, these studies promote not only the detection of illegal mining, but also the assessment of opportunities for using mining waste, thus contributing to environmental and economic improvements in the mining industry. This innovative approach represents an important step towards efficiency, sustainability, and responsibility in the management of mineral resources. Knowledge of estimates of excavation volumes and variables related to changes in natural landscapes also adds value to the preparation of environmental reports, allowing the precise quantification of volumes of ore removed from the natural environment and the validation of environmental thefts. With this objective this job traits of the use of multispectral camera and LIDAR system to estimate irregularly extracted ore in clandestine mining in a region of the one of the richer miner potentials of the World as such as the Minas Gerais State, Brazil.

Study area

The images and field data were collected at Fazenda Mina do Vigia, located near the district of Pires and the community of Motas, Minas Gerais State, Brazil, a place where there were signs of ore theft. On September 18, 2021, a visit was carried out to verify the location of the clandestine mining and demarcate the limit of the usurped area. This limit of the affected area combined with the rich historical coverage of satellite images in Google Earth for this location made it possible to estimate that the first mining activities at the site were carried out in 2015, being reported and stopped later.

As can be seen in Figure 1 and Figure 2, mining activities began between the months of June and July 2015, with small progress being made until the existing final configuration.

Figure 1 Image of the mining site. Source: Google Earth Pro, image dated 06/2015. Location in latitude and longitude (20°25'59.07"S; 43°49'26.66"W).

Figure 2 Image of the mining site. Source: Google Earth Pro, image dated 07/2015. Location in latitude and longitude (20°25'59.07"S; 43°49'26.66"W).

The methodology used to estimate the volume of excavated ore was developed based on field surveys, technological tests and studies carried out by the company Vórtice Consultoria Mineral Ltda in 2007 and the difference between local topographic surfaces, aiming to define whether the volume of material extracted irregularly within the limits of the polygonal.

A topographic survey was carried out in the experimental area using GNSS signal receivers. To this end, a GNSS receiver configured as a base using the static relative positioning method was installed. The occupation time of base receiver was two hours using a dual-frequency L1/L2 Topmap Hiper V GNSS geodetic receiver. The data collection rate was set at 5 Hz, with an elevation mask of 10º. The base receiver data was processed using the post-processing method, with the support of an IBGE base station, part of the Continuous Monitoring Brazilian Network.

Cartographic bases and previous studies

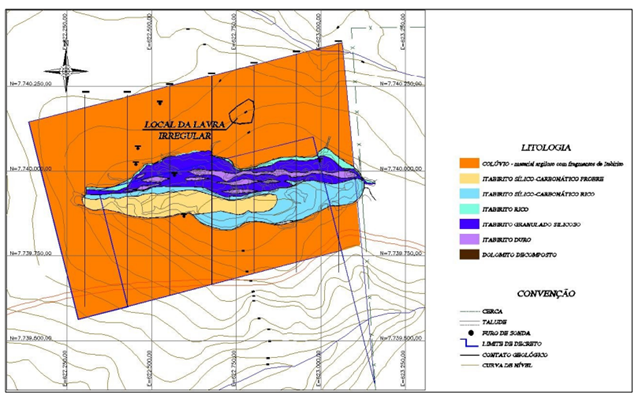

In the practical statements was carried out a miner extraction potential evaluation, referring to the year 2007, which generated a report, which contains the reserves for these areas, and a cartographic product composed of plans and geological profiles. Based on surveys carried out by the company in charge of the geological study, it was verified that the mining in question was carried out in the colluvium that covers a large part of the area. The local colluvium is composed of clay with fragments of itabirite, making it suitable for use.

Based on the technical report generated, it was possible to identify the various geological features and local lithologies. All information regarding the chemical and physical characteristics of the usurped material was extracted from the report, as shown in Figure 3. The report was also useful for obtaining density data and possible calculation of the volume extracted in tons.

Figure 3 Topographic-geological original map in Portuguese of the area. Source: Company Vórtice Consultoria Mineral Ltda.

Volume estimation from LIDAR data

To confirm the removal of ore from the study area, it was necessary to calculate the volume on different dates, that is, to estimate the volume before and after the theft. The comparison was performed using two methods: the previous volume was estimated using Lidar altimetry data and the current volume using RPA images. To obtain the original topography of the site, altimetry data obtained through LIDAR in 2009 was used.

The contour lines of the study area were extracted and exported in an AutoCAD format file (dwg). The contour lines made it possible to create 5 cross sections within the polygon with a spacing of 15 meters between them. Section areas were calculated, and volume estimated based on section spacing.

Volume estimation from georeferenced RPA images

To obtain better accuracy of estimates in the deposit areas, an aerial survey was chosen using RPA, popularly known as drones, capable of electronically generating stereoscopic pairs. The data obtained through the flights were georeferenced from terrain control points collected using GNSS (Global Navigation Satellite System) technology. The control points collected with the GNSS were downloaded, calculated, and drawn following the assumptions indicated by the relevant topographic design standards in specific software for each collection and processing modality.

The RPA used in this study was the DJI Phantom 4. Its flight autonomy is around 30 min. The equipment weighs approximately 1368 grams and has an integrated positioning system with information acquisition from the GPS and GLONASS systems. Furthermore, it is equipped with a 20-megapixel RGB camera that helped in collecting images. The flight was carried out after planning and defining parameters, such as flight height, percentage of lateral and longitudinal overlap, as well as the limit of the study area. In this case, height of 60 meters, 70% lateral overlap and 80% longitudinal overlap. The images were processed with the help of Pix4D software. Figure 4 shows the study region, where the white polygon represents the demarcated area that showed characteristics of ore theft over the years.

The purpose of this work was to compare the volume of ore excavated between two dates and estimate the damage caused by removing the material. The analysis and calculations of numerical values were carried out based on LIDAR data, RPA images and positioning measurements using the static method carried out with GNSS technology.

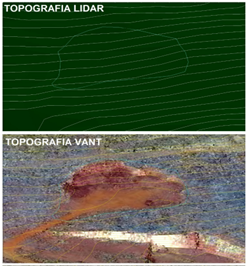

The objective of applying LIDAR and RPA together was to extract the contour lines of the study area in the two different periods of interest. The result of the contour lines from 2009 shows the original topography of the land, before the extraction of the ore. Topography based on RPA made it possible to extract contour lines after the mineral theft violation in 2021. Figures 5, top and bottom, present an overview of the results obtained with LIDAR and RPA within the study region, respectively. The change in the contour lines, in terms of terrain slopes, within the polygon is noticeable. This change characterizes that the place has undergone topographical changes over the years.

Figure 5 Comparative data of the original topography (LIDAR), above, without intervention, and current topography (RPA), below, after excavations. Location in latitude and longitude (20°25'59.07"S; 43°49'26.66"W).

Within the polygon defined in Figure 4, five cross sections were created. The division into sections made it possible to calculate their areas and subsequently estimate the excavation volume since the spacing between sections was defined at 15 meters. Figure 6 shows the version, direction of sections and contour lines for 2009 and 2021.

Figure 6 Cross sections in Portuguese. Location in latitude and longitude (20°25'59.07"S; 43°49'26.66"W).

After defining the sections (Figure 6), the transversal profiles of the two periods of interest were drawn in AutoCAD software. It is worth mentioning that the cross sections were calculated according to each contour scheme extracted on the different dates. In Figure 7, it is possible to compare the differences in the sections of the sections according to the contour lines and topography of the years under study (2009 and 2021).

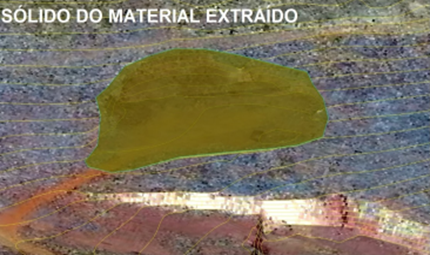

In addition to estimating the volume by sections, the software generated a 3D model of the extracted solid, through the comparison of the two topographies, defining the volume extracted from a digital terrain model (DEM) of the two topographies. This estimate served to compare the values. The solid presented in Figure 8 was obtained through specific mathematical models and its volume was estimated at 6,332.73 m³ by the software.

Figure 8 3D model of the extracted solid. Location in latitude and longitude (20°25'59.07"S; 43°49'26.66"W).

In estimating the volume, the topographic method of parallel cross sections was used. The volume of material in the block is calculated by multiplying the average material area of two adjacent sections by the distance between the sections. In Table 1 the area and volume of each section are presented.

|

Section |

Area (m²) |

Distance (m) |

Volume (m³) |

|

S01 |

59 |

15 |

1,230.00 |

|

S02 |

105 |

15 |

1,725.00 |

|

S03 |

125 |

15 |

1,680.00 |

|

S04 |

99 |

15 |

960 |

|

S05 |

29 |

15 |

217.5 |

|

Total volume |

|

|

5,812.50 |

Table 1 Area of cross sections, distance and excavated volume between sections and total excavated volume

The volume can also be estimated in tons if multiplied by the density of the material. The density of the material is 2.7 t/m, obtaining the result in tons, 15,693.75 t. Also multiplying the volume found in the 3D model, the theft was estimated at 17,098.34 tons.

Discussion

As shown, the usurped volume in the area in question totals 6,332.72 m³ or 17,098.34 tons. Considering a reserve utilization rate of approximately 52%, the sales reserve reaches approximately 8,891.14 tons. With the current price of iron ore at around US$ 120.00 per ton and an exchange rate of 5.25 reais per dollar, the total value extracted reaches R$ 5,601,417.49. Therefore, it is evident that in the polygon studied, 17,098.34 tons of ore were extracted, resulting in an approximate value of R$ 5,601,417.49.

It is important to highlight that the use of advanced technologies, such as remotely piloted aircraft (RPA) and aerial laser systems, has demonstrated its effectiveness in terms of inspection and expertise. With the increasing popularization and use of the equipment and technologies presented in this study, there is a tendency towards more effective use and greater dissemination of these methodologies. This represents a promising scenario to improve the management and monitoring of mining areas, contributing to sustainability and responsibility in the mineral industry. It should also be noted that the use of technologies that employ RPA are increasingly being disseminated and applied in the monitoring of mineral exploration, with new and increasingly productive sensors being used with the aim of providing better productivity. It should also highlight the advantages of a better integration with GNSS real-time correction systems and the use of onboard multispectral sensors, as well as LIDAR. Such technological advances have provided better prevention and the possibility of decision-making with greater agility, in order to prevent the occurrence of environmental disasters, such as the one that occurred in 2019, at the Córrego do Feijão Dam, in the municipality of Brumadinho, state of Minas Gerais, Brazil. Therefore, the results of this research is expected to contribute to the prevention of environmental accidents, as well as better subsidize the inspection and exploration processes in open mines both in Brazil and around the World.

None.

None.

The authors declare that there is no conflicts of interest.

©2023 Junior, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.