MOJ

eISSN: 2576-4519

Review Article Volume 2 Issue 1

Zhejiang University of Technology, China

Correspondence: Yun Qing Gu, College of Mechanical Engineering, Zhejiang University of Technology, Hangzhou 310014, China

Received: February 21, 2018 | Published: February 27, 2018

Citation: Qing YGU, Zhang W, Mou J et al. Bionics technology on resistance and noise reduction of centrifugal pump. MOJ App Bio Biomech. 2018;2(1):00048. DOI: 10.15406/mojabb.2018.02.00048

During the actual operation, the centrifugal pump will suffer a great energy loss due to the friction resistance between the fluid and the over-current components, and create great noise due to the hydraulic pulsation caused by the complex distribution of flow field. In order to reduce resistance and noise, it is significant to apply the bionics technology. Through the observation and study of the natural biological characteristics, some available bionic structure has been designed to improve the properties of centrifugal pumps. Combined with the traditional resistance and noise reduction technology, the bionics technology, such as super hydrophobic pump, non-smooth impeller, ladder tongue and bionic volute show efficient and simple functions of resistance and noise reduction. In current studies, bionics technology had abilities of reducing the friction resistance between the fluid and over-current components, improving distribution of pressure and reducing radial force. It can be seen that bionics technology will be widely used in resistance and noise reduction of fluid machinery.

Keywords: bionics, centrifugal pump, resistance reduction, noise reduction

As one of important fluid machinery, pumps play a significant role in modern industry, so as to the high requirement of property and stability. During the actual working condition of centrifugal pumps, the flow fields in the centrifugal pump become more complicated due to the fluid separation, the cavitation and other hydraulic vibrations, which can significantly raise the resistance and reduce the working stability.1,2 In addition, due to the geometric asymmetry of the impeller and the interaction between the impeller and the volute, the pressure and the velocity will be different along the radial direction, so that lead to strong pulsation and noise near the tongue of volute. The induced vibration in the centrifugal pump can bring a series of the relevant breakdown in the machines, even to result in disaster in the chemical plant so it can not only reduce the energy conservation, but also enhance the safety and stability to adapt new technology to reduce the resistance and noise of centrifugal pumps. Some traditional technology, which was firstly applied in the special field, such as the fire fighting system, the urban pollution discharge system, the ships and the underwater weapons etc,3‒6 has been applied to the resistance and noise reduction for the fluid machinery, but it is nowhere near enough.

The trend of bionics technology applied in industry has arisen since the middle of twentieth Century. It has provided an effective method for the modification and innovation of industrial equipment, and become the source of more and more design and creation, such as shark, the lizard and the dung beetle, the micro structure on their surfaces has the function of the anti-adhesion, the anti-wear and could effectively reduce the resistance and noise.7 By modifying the interface between the fluid and the wall by processing the fringe, pits or bulges on the surface of the fluid machinery, the ordered structure of the turbulent boundary layer can be reshaped to achieve efficient, convenient and low consumption resistance reduction.8 At present, there are many bionic engineering models and instances based on the biological principle and structure, which can realize many excellent properties. Han et al.9 adapted bionics technology to hydraulic design to reduce the resistance and noise. Liu et al.10 confirmed the effect of bionic design to reduce resistance compared with traditional design. Chen et al.11 got the idea from eagle owl feathers, applied the structure and saw tooth shape of the feathers to axial fan blades, revealed the significant effect of non-smooth surface on the reduction of resistance, noise and pressure pulsation. Their works provide a new kind of method, which is bionics technology, to reduce the resistance and noise of centrifugal pump from the design of structure. If bionics technology of resistance and noise reduction can be applied in the pump design and manufacturing, it will accelerate the development of this technology and broaden the research field of pump, which has the important engineering value and theoretical significance.

As centrifugal pump transferring mechanical energy from the motor to the fluid, no doubt that there are mechanical loss and hydraulic loss causing by vibration, flow separation and sharp direction change of fluid velocity, which would lead to the instability of flow and waste of energy. The viscosity of fluid is an important reason of fluid flow resistance and energy loss in centrifugal pump and how to reduce the friction resistance between over-current components and fluid is significant. In recent years, centrifugal pumps are designed and produced to meet the targets of energy saving, environment protection and high efficiency, more and more resistance reduction technology is applied to centrifugal pumps. Besides the factor of pump design, in the process of pump manufacture, the coarse unmachined surfaces, air holes and different smoothness in the casting of the inlet channel would increase the hydraulic loss.12 The hydraulic loss in the pump is mainly consumed in the vortex and friction. And the friction is mainly related to the friction coefficient of over-current components. So In order to reduce the surface roughness of the over-current components, the resistance reduction of coating is applied to the centrifugal pump. The experiments prove that the over-current components coating of water pumps can improve the hydraulic efficiency about the 2%~7% by smooth coating. In addition, by adding the polymer into the fluid, the flow resistance of the centrifugal pump can be effectively reduced. On the one hand, the polymer can hinder the vortex formation on the other hand the polymer can reduce the rotation rate of whirlpool. Together these two effects lead to turbulent resistance reduction effect.

Besides the traditional methods of resistance reduction, with the development of science and technology, bionic resistance reduction technology is becoming more and more mature and bionic non-smooth surface resistance reduction is also used in the centrifugal pump. The idea of bionics is to imitate biological systems, or based on biological system characteristics, to bring about design optimization and transform products into a new bionic ones through the modification of the function, shape, structure and materials etc. At present, more and more scholars apply bionics principle to fluid machinery. Based on the earthworm rough surface, Ru et al.13 optimized the sealing performance of wear of slurry pump piston to reduce resistance. Chen14 invented a new type of peristaltic pump, the worm pump by imitating the movements of caterpillar crawling. Liu et al.15 invented a film type micro fluidic liquid drive pump, the minipump is based on the bionics principle of plant gas transpiration. According to the surface structure of carabid beetles and other organisms whose non-smooth surface showed excellent properties of resistance reduction, antifriction, ant adhesion and antiwear, Ren et al.16 adapted the bionic non-smooth surface technology into the impeller blade to reduce resistance and noise. The key Laboratory of bionic engineering in Jilin University researched the centrifugal water pump with imitation shark skin using single factor bionic technology and found that the resistance reduction effect was significant in some flow segments.17,18

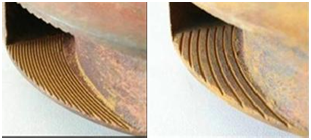

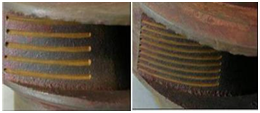

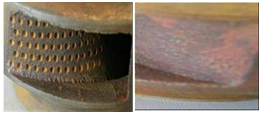

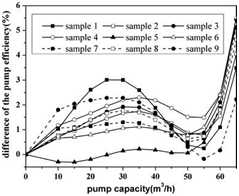

Researchers use scanning electron microscope to observe the lotus leaf surface and found the submicron papillae structure. Because of the existence of such microstructures, the lotus leaf has the effect of super hydrophobic and a good self-cleaning property.19 Barthlott et al.20 called this behavior “lotus effect”. Cottin-Bizonne et al.21 found that this super hydrophobic surface of the lotus leaf surface could significantly reduce the flow resistance. For the resistance reduction mechanism of super hydrophobic surface is generally considered that the contact mode between fluid and solid is changed to rolling from sliding due to the microstructures. So that the velocity gradient of boundary layer is decreased, the shear force is reduced. Because of the hydrophobic properties, the application of super-hydrophobic materials on the over-current components of pump is in promotion. With super hydrophobic coating, the probability of forming sharp peaks and valleys was greatly reduced, effectively control the roughness of the pump inner surface, the original and with coating samples of impeller and over-current sample were shown in Figures 1&2. Thus it reduced the fluid friction on the outer edge of the impeller. Also it reduced energy loss caused by the vortex flow between the pump shells. Super hydrophobic coating showed effective properties in preventing the formation of crystals on the surface of cast iron, preventing small solid particle deposited on the internal surface and reducing the viscosity of the fluid, as shown in Figure 3. The application of non-smooth resistance reduction technology based on biological surface is more and more widely in engineering. Typical representatives of non-smooth surface resistance reduction are golf. In order to make golf fly farther, people have made its surface into non-smooth surface with pit type, compared to smooth surface golf it’s only about half the resistance.22 Ren use the bionic non-smooth surface resistance reduction technology in agricultural machinery-bionic plough. Research results show that compared with the ordinary plough, the plough with bionic non-smooth surface can reduce the oil consumption 5.6%~12.6%. And the plowing resistance can be reduced 15% to 18%, also has good wear resistance and soil removal.23‒25 As the fastest aquatic animal in the sea, shark not only benefit from its streamline body to reduce the resistance, but also due to non-smooth surface structure on the body which can reduce the friction resistance. Observation of sharks showed that shark's surface is not smooth. It composed with a lot of groove shaped scales. It orderly arrangement and compact with the type of dentate.26 The key Laboratory of bionic engineering in Jilin University, based on bionic non-smooth technology, change the structure of liquid flow in centrifugal pump through the imitation of the non-smooth structure of shark skin. Previously non-smooth surface manufacture with method of metal corrosion. Experimental results show that in some flooding Regions, pump efficiency up to 3.45% 27,28 and increase efficiency up to 6.81%. However, this method has significant limitations, now the casting method is used for processing. After optimization, the pump efficiency can be increased to more than 5%.27‒29 In the study of blade with non-smooth surface, the non-smooth surface can be designed into different shapes like oval groove; serrated groove; rectangular groove; Semi-circular pits and V-shaped groove. The structures were shown in Figure 4, and efficiency of different samples were shown in Figure 5.27

When the fluid flow in impeller, Tangential resistance generated when the fluid is sliding relative to the impeller, internal friction formed due to the viscous of fluid, fluid adhesion on the wall generated shear stress and friction. Researchers found that shear stress of blade arrangement with non-smooth surface was lower than the corresponding smooth surface. Further studies conclusively showed, the fluid velocity gradient was significantly reduced in non-smooth surface of blade compared to smooth surface; the distribution of velocity in normal direction is relatively uniform. That was because that the non-smooth surface of the blade changed the structure of turbulent boundary layer near the wall. Due to the effect of non-smooth surface structure on the blade, low velocity fluid was kept in non-smooth unit groove, high velocity flow of fluid near the wall was blocked, reducing the velocity gradient on boundary layer, which resulted in reducing the shear force on the solid wall, so that reduced the wall surface viscous resistance. At the same time, non-smooth surface transformed from laminar boundry layer to turbulent boundary layer, reduced the turbulent energy dissipation rate, so flow layer near the wall was more stable. Resistance reduction mechanism can be concluded as the reverse vortex with low velocity flow inside the groove of non-smooth surface, the sliding friction between the fluid and the wall is changed into the rolling friction, forming “micro-rolling bearing”. The direct contact area between the fluid and the solid is reduced, so the friction loss and energy consumption between the fluid and the wall is reduced.

Figure 4 Various forms of non-smooth surface of blade surface.27

Figure 5 Pump efficiency of different sample.27

Bionic single factor resistance reduction technology showed obvious effect only in a certain flow range.27 Because the realization of biological functions relies on the influence of a variety factors, which is called biological coupling.30,31 For example, dolphin can swim so fast with its special skin structure.32,33 Dolphin skin can be divided into three layers, the outermost cuticle is smooth; there are many papillae exist in the dermis; innermost is staggered gum and elastic fibers. This is a very excellent biological coupling, can effectively reduce the resistance during swimming.34‒36 Based on the effect of biological coupling, bionic coupling pumps have been designed. Bionic coupling pumps make the impeller and pump housing’s surface bionic coupling treatment without changing the original water pump hydraulic model and installation. The impeller and the pump have three combinations: First, a combination of bionic coupling impeller and normal pump; Second, a combination of bionic coupling the pump casing and normal impeller; Third, a combination of bionic coupling impeller and bionic coupling the pump casing. Bionic coupling impeller make various forms of bionic structure on conventional impellers surface and coupled with the thermoplastic polyurethane elastomer material whose surface is coated a certain thickness. Bionic coupling the pump casing is formed with various forms of bionic structure based on the traditional pump housing, the structure is also coated with a bionic thermoplastic polyurethane elastomer material, as shown in Figure 6. Bionic coupling centrifugal pumps can effectively reduce the probability of occurrence of cavitation and improve the performance of the pump.37 From the viewpoint of energy saving when using bionic coupled centrifugal pump, due to the elastic deformation of bionic coupling surface, which can store part of the energy in the form of elastic energy, but not dissipated into heat. In the recovery process of deformation, the elastic potential energy converted into the kinetic energy of the fluid, to avoid excessively losing of energy, so as to achieve the purpose of resistance reduction and synergism.

Figure 6 Bionic coupling pumps (A) bionic groove (B) bionic coupling impeller.37

As a centrifugal rotary fluid machine, centrifugal pump produce noise and vibration due to both mechanical and hydrodynamic reasons. Noise of centrifugal pump comes from two aspects, one is the fluid induced vibration noise caused by fluid hydrodynamic. Another is pump noise and vibration caused by partial pressure which comes from pump flow field distribution uneven caused by poor coaxial of rotary member by unreasonable design of internal structure and low manufacturing quality or improper installation and.38 For solution of centrifugal pump noise, in addition to improving design factor, it is also feasible to control cavitation erosion.39 For example, place minor gas to control cavitation before centrifugal pump cavitation to suppressing the generation of noise; optimize the noise generated by centrifugal pump cavitation-induced vibration by adjusting the number of leaves.40 And with the development of industrial technology and manufacturing technology, mechanical vibration and noise caused by the dynamic and static rotor unbalance has been effectively controlled. Thus, the noise caused by flow-induced vibration become the decisive factor to evaluate a centrifugal pump noise level, it is an urging problem.41 The characteristics and strength of flow-induced noise is closely related to internal fluid pressure pulsation. Generally because of unsymmetrical geometry of spiral volute, there is a big difference in the distribution of internal flow field along the radial due to the interaction of impeller and static volute, as shown in Figure 7. Because of the strong pressure and velocity pulsation near the tongue, flow-induced noise generates. Up to now, many scholars have made a detailed study of centrifugal pump pressure pulsation. As early as 1995, Chu et al.42,43 found that the interaction of tongue and blade and non-uniform flow of impeller outlet were main factors in the formation of the internal flow field pressure pulsation to generate noise. The strength of the noise was also closely related to the gap between the tongue and impeller, by studying the impact of impeller and volute geometry changes to noise, Dong et al.44 found that the noise significantly reduced when the gap between impeller and the tongue clearance gradually increased. When the gap was very narrow, the noise was caused by impingement of tongue and blade. As the gap gradually increased to 20%, only the jet and the tongue had a weak interaction, an appropriate increase of the clearance of impeller and tongue could significantly change the flow and reduce the noise. By summing up the various factors relating to the impact of vibration and noise, Timouchev et al.45 found that when the gap between impeller and tongue kept unchanged, the pressure pulsation was related to the thickness of the tongue. Dong et al.46 through experiment found that while keeping the impeller parameters unchanged, the change of tongue angle would significantly change the state of the fluid flow within the volute. By studying the distribution of multi-stage pump internal pressure pulsation, Cao et al.47 found that the radial force acting on the impeller was cyclically pulsatile. The formation of noise internal the pump is very complex, the fluid inside the pump rotates with the rotation of the impeller and then flow into the volute, while the volute keeps stationary, due to the change of the flow pattern and pressure distribution of the flow field, acoustic waves generate and pass in the flow field, which means the formation of noise. At the same time due to the complexity of the hydraulic impeller and volute, the influence of fluid viscosity and centrifugal force, and the complex flow phenomena internal centrifugal pump, such as flow separation, reflux, secondary flow and cavitation, it will produce radiation noise structure, the structure of the original noise and radiated noise caused by moving parts are superimposed to form a new flow-induced noise. By summarizing the results and mechanism of noise generation,48‒51 in order to improve the flow field inside the pump pressure pulsation, currently feasible way is changing the impeller diameter or the tongue placed corner.52,53

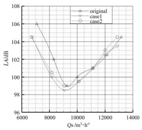

With the gradual development of bionics technology, bionics technology of noise reduction has been widely promoted in fluid machinery. Based on the noise reduction properties of owl, goshawk and birds, morphological characteristics bionics has been used in fan machinery products. Combination of bionics, the fan noise reduction research mainly concentrated in the radius, angle, shape and gap of the tongue. Based on the long-eared owl skin, Sun et al.54‒56 designed the axial flow fan blade into non-smooth surface to introduce coupled acoustic noise reduction technology, found that compared with the original of the centrifugal fan, the bionic centrifugal fan showed a significant noise reduction function, as shown in Figure 8. According to the long-eared owl wings organizations, Huang et al.57 designed coupled acoustic structure across the tongue, the study found that the structure not only had the noise reduction effect, but also enhanced the performance of the centrifugal fan. Similar with the working principle of fan, due to the vibration mechanism of flow field in the centrifugal pump and the unsteady flow dynamic phenomenon, the gap between centrifugal pump impeller and tongue plays a vital role on the distribution of internal flow field.58 Bionics has been mainly used in the design of tongue to carry out the research of internal flow state, pressure pulsation and radial force ripple characteristics. The noise interference of flow field in the centrifugal pump may caused by pressure pulsation, reflux, eddy current and external response.59 Compared with single tongue, the bionic ladder tongue under different conditions could reduce the pressure pulsation amplitude, as shown in Figure 9. In both small and large flow condition the ladder tongue could eliminate the pressure pulsation amplitude mutation due to deviate from the design condition. That is because ladder tongue restrains the cyclotron, and therefore could weaken its impact pulse. Asymmetry volute is the main reason for the radial force, under off design conditions, especially in small flow condition, the ladder tongue all could improve the radial force on the impeller. The special airfoils of long-eared owl have significant noise reduction effect, it is mainly used in the noise reduction of centrifugal pump volute fan control of air flow noise, 54‒57 the long-eared owl non-smooth morphology has been adapted in the hydraulic design of volute centrifugal pump, to achieve the bionic volute vibration noise reduction function. Analysis showed that the bionic volute could reduce the pressure pulsation amplitude, significantly reduced the max value of pressure pulsation amplitude in tongue, and maintained stability of the pulse in each frequency. This is because of the fluid elastic area in the bionic volute convex structure, the area can absorb liquid flow impact energy, greatly reduce the influence of vortex area of impeller. Further study found that the bionic volute could improve the distribution of internal pressure, reduce the pressure gradient, so that it would be hard to form vortex and secondary flow in the diffuser, significantly improved the state of the flow of the fluid in the volute, the flow field distribution would be more homogeneous symmetric.

Figure 8 (A) Morphology of long-eared owl skin (B) noise of original and bionic centrifugal fan.56

Figure 7 Frequency-domain diagram near tongue for different volutes (A) prototype volute (B) bionic volute.59

With the principle of bionics, through the research on the mechanism of resistance and noise of centrifugal pump, coupled with the traditional technique, super hydrophobic pump, bionic non-smooth blade, ladder tongue and bionic volute tongue have been designed. Compared with the smooth blade, the velocity gradient of bionic non-smooth surface and super hydrophobic pump decreased greatly, the distribution of velocity became more uniform, the structure of the near wall turbulent boundary layer was improved, thus reduced the surface viscosity resistance; and non-smooth surface postponed the laminar boundary layer transition to turbulence, reduced the turbulent kinetic energy dissipation rate, the flow became more stable. Follow the bionics technology applied in fan machinery, ladder tongue and bionic volute in centrifugal pump has been designed. Due to the special structure of the ladder tongue, it could effectively restrain the cyclotron, and weakened pressure pulsation. With bionic volute, the max pressure pulsation amplitude was significantly reduced, and the pulse maintained stability in each frequency. Convex structure bionic volute formed fluid elastic region to reduce the vortex area of impeller, improved the distribution of the pressure in the volute, significantly improved the flow state in the volute. With the application of bionics technology in the centrifugal pump, the resistance and noise has been effectively reduced, and the high efficiency and energy-saving centrifugal pump based on bionics technology will play a significance role in the long-term development.

The work was supported by the Zhejiang Provincial Natural Science Foundation of China (LQ15E050005), the National Natural Science Foundation of China (51476144, 51609212, 51606167); the China Postdoctoral Science Foundation (2016M601736), the Public Welfare Technology Application Projects of Zhejiang Province(2017C31025).

The authors declare that there is no conflict of interests regarding the publication of this paper.

©2018 Qing, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.