MOJ

eISSN: 2576-4519

Mini Review Volume 9 Issue 1

1Instituto Politécnico Nacional, México

2Universidad Tecnológica de Durango, México

Correspondence: Guillermo Urriolagoitia Sosa, Instituto Politécnico Nacional, Escuela Superior de Ingeniería Mecánica y Eléctrica, Sección de Estudios de Posgrado e Investigación, Zacatenco, C.P. 07320, México

Received: August 30, 2025 | Published: September 15, 2025

Citation: Suarez-Hernandez ML, Urriolagoitia-Sosa G, Romero-Ángeles B, et al. Biomechanical analysis in FEM of the shoulder abduction-based 3D biomodelling. MOJ App Bio Biomech. 2025;9(1):90-92. DOI: 10.15406/mojabb.2025.09.00230

The development of biomodels for analyzing human body joints has become a primary tool for visualizing stress, elongation, and contraction along the anatomical structures that conform to the human body. This paper explains how to develop a virtual model of the human shoulder joint using computerized axial tomography. The development of a three-dimensional model of the structures that comprise the shoulder joint of the human body is a tool that helps to understand the functioning of the soft tissues of the joint during abduction movement at 30°. The results indicate elongation and contraction values of 0.79005 mm in the superior glenohumeral ligament, while the inferior glenohumeral ligament shows values of -0.22257 mm. Furthermore, the superior glenohumeral ligament shoes stress values of -0.1108, indicating compression. The inferior glenohumeral ligament shows stress values of 0.39811 MPa. The ability to analyze the results obtained from numerical analyses is particularly valuable for understanding ligament function, capturing in detail the regions with potential injury in ligaments for patient-specific conditions, which cannot be identified with precision with experimental analysis.

Keywords: biomodel, anatomical structures, shoulder joint, abduction

The human shoulder is one of the most complex structures of the human body. Dynamic stabilizers (muscles) and static stabilizers (ligaments) work together during movement to keep bones in position and prevent excessive motion.1 The irregularity of the bones and biological tissues facilities the wide range of movements for daily activities.

Over time, the interest in having a better understanding of anatomical structures like the human joints and the behavior of soft tissues under different circumstances has gained relevance, so the development of technologies and medical equipment has been used to improve the ability to obtain three-dimensional biomodels that have a sufficiently accurate characterization of the anatomical structures.2,3 One of the main problems with biomodels is that the results presented are unique and exclusive to that specific human body, because it does not consider the biological variations that may occur among the population. Tissue interactions are often idealized to simplify the analysis. However, do not always represent the complexity of real physiological interaction.

With the biomodel and finite element tools provide a realistic representation of elongation, contractions and stress distribution, providing significant advantages helping to understand the complexity of the biological tissue interaction that are difficult to evaluate by experimental methods.

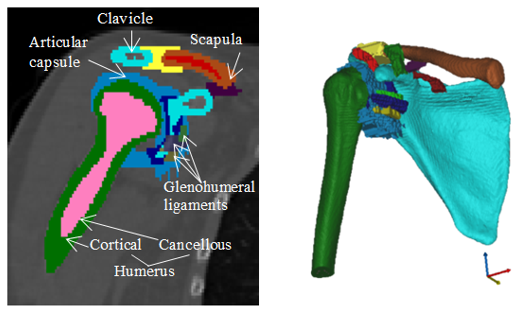

The methodology used for the development of the biomodel is the one that has been previously reported,4,5 that begin obtaining images across human body sections, generated by computerized axial tomography saved in a DICOM file. The process continues with the import of the DICOM file into CAD-type software. For this research were used Mimics Medical®, where were filled or delimited the area of each structure that are going to be part of the biomodel, generating a cloud of points that represent the model (Figure 1).

Figure 1 Manual segmentation of the biomodel´s structures and the cloud points that represent the model.

The bones (cortical and cancellous) were delineated using the cavity foll tool in the software. The soft tissues (ligaments and joint capsule) were delimited based on the data reported in the literature.6

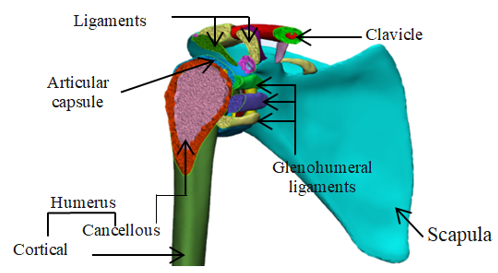

The next step in this process is the surface correction in Materialise 3 matic® software. Geometry mistakes such as overlapping surfaces and cavities are corrected for each structure that is part of the model. Next, each element surface is smoothed, obtaining a cleaner model (Figure 2).

Figure 2 Final biomodel with their structures that represent the different types of biological tissue.

Subsequently, the model volume is developed, generating tetrahedral elements from the surface elements. Having a model conform by 3 bones (cancellous and cortical bones), ligaments and the articular capsule, as shous in Figure 2.

Each biomodelo structure is saved individually with STL extension for later import, resulting in a 3D model shoulder joint model with morphological characteristics like a real human shoulder. In the finite element software, like Ansys Workbench®, environmental conditions are replicated.

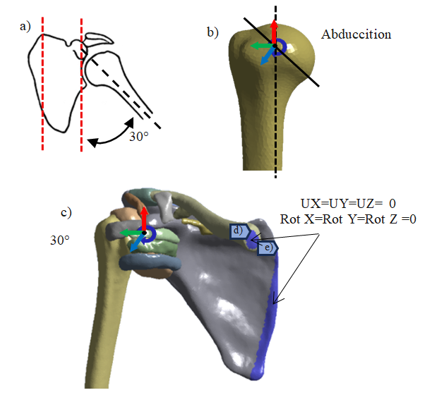

A local coordinate system was established at the humeral head to establish a revolute joint in the Z axis, to simulate the arm raising in abduction to 30°. Clavicle movement was restricted, where the sternoclavicular joint takes place, and the distal edge of the scapula, where the muscles are attached, as are illustrated in Figure 3.

Figure 3 Boundary conditions: a) Schematic diagram of humeral rotation in posterior view, b) Local coordinates of the humerus, c) Restriction of movement in the clavicle and scapula, 30° rotation of the humerus in the Z axis, d) Sternoclavicular joint location, e) Location of muscle attachment in the scapula.

The research focuses on learning about the effects of sudden abduction at 30° movements on the static stabilizers of the shoulder. The shoulder joint numerical simulation data represents the abduction movement on the ligaments of the shoulder. These allow for the evaluation of the Stress, elongation, and contraction of the biological tissues (Figure 4 & 5).

Elongation and contraction values of 0.79005 mm in the superior glenohumeral ligament, and the inferior glenohumeral ligament shows values of -0.22257 mm. Coracohumeral ligaments that contracts the most with a value of 1.3427 mm in numerical evaluation. For stress values, the superior glenohumeral ligament shows values of -0.1108, indicating compression. The inferior glenohumeral ligament shows stress values of 0.39811 MPa. While the coracohumeral ligament presents values of -0.50747 MPa.

This work varies from others research7 because it preserves and replicates the complexity of the geometries of the joint. Integrating most of the biological structures that are part of the joint, which allows us to identify the ligament that contracts the most, which is the coracohumeral ligament with values of 1.3427 mm. On the other hand, the ligament with most elongation is the superior glenohumeral ligament with value of 0.79005 mm.

The integration of different areas (such as medicine and technology) has improved the development of biomodels that have a morphology as close to reality, which facilitates the simulation planting different circumstances, which helps the understanding of biological tissues contributing to the diagnosis of various pathologies that affect the human body, such as wear and tears, dislocations or fractures affecting the upper joint. It is possible to generate new knowledge without having to experiment tests with patients, saving time and resources, allowing better treatment of patients for their specific cases.

The authors gratefully acknowledge the support from the Mexican government by la Secretaría de Ciencia, Humanidades, Tecnología e Inovación and the Instituto Politécnico Nacional.

None.

The authors declare that there is no conflict of interest.

©2025 Suarez-Hernandez, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.