MOJ

eISSN: 2576-4519

Review Article Volume 1 Issue 4

Energy Research Institute (ERI), United Kingdom

Correspondence: bdeen Omer, Energy Research Institute (ERI), Nottingham, NG7 4EU, United Kingdom

Received: July 20, 2017 | Published: November 20, 2017

Citation: Omer A. Biogas technology for sustainable energy generation: development and perspectives. MOJ App Bio Biomech. 2017;1(4):137–148. DOI: 10.15406/mojabb.2017.01.00022

Biogas from biomass appears to have potential as an alternative energy source, which is potentially rich in biomass resources. This is an overview of some salient points and perspectives of biogas technology. The current literature is reviewed regarding the ecological, social, cultural and economic impacts of biogas technology. This article gives an overview of present and future use of biomass as an industrial feedstock for production of fuels, chemicals and other materials. However, to be truly competitive in an open market situation, higher value products are required. Results suggest that biogas technology must be encouraged, promoted, invested, implemented, and demonstrated, but especially in remote rural areas.

Keywords: biomass resources, biogas application, sustainable development, environment

Energy is an essential factor in development since it stimulates, and supports economic growth, and development. Fossil fuels, especially oil and natural gas, are finite in extent, and should be regards as depleting assets, and efforts are oriented to search for new sources of energy. The clamour all over the world for the need to conserve energy and the environment has intensified as traditional energy resources continue to dwindle whilst the environment becomes increasingly degraded. The basic form of biomass comes mainly from firewood, charcoal and crop residues. Out of the total fuel wood and charcoal supplies 92% was consumed in the household sector with most of firewood consumption in rural areas. The term biomass is generally applied to plant materials grown for non-food use, including that grown as a source of fuel. However, the economics of production are such that purpose-grown crops are not competitive with fossil-fuel alternatives under many circumstances in industrial countries, unless subsidies and/or tax concessions are applied. For this reason, much of the plant materials used as a source of energy at present are in the form of crop and forest residues, animal manure, and the organic fraction of municipal solid waste and agro-industrial processing by-products, such as bagasse, oil-palm residues, sawdust and wood off-cuts. The economics of use of such materials are improved since they are collected in one place and often have associated disposal costs. Combustion remains the method of choice for heat and power generation (using steam turbines) for dryer raw materials, while biogas production through anaerobic digestion or in landfills, is widely used for valorisation of wet residues and liquid effluents for heat and power generation (using gas engines or gas turbines). In addition, some liquid fuel is produced from purpose grown crops (ethanol from sugarcane, sugar beet, maize, sorghum and wheat or vegetable oil esters from rapeseed, sunflower, and palm trees). The use of wastes and residues has established these basic conversion technologies, although research, development and demonstration continues to try and improve the efficiency of thermal processing through gasification and pyrolysis, linked to combined cycle generation. At the same time considerable effort is being made to increase the range of plant-derived non-food materials. To achieve this several approaches are being taken. The first is to provide lower cost raw materials for production of bulk chemicals and ingredients that can be used in detergents, plastics, inks, paints and other surface coatings. To a large extent these are based on vegetable oils or starch hydrolysates used in fermentation to produced lactic acid (for polylactides) or polyhydroxbutyrate, as well as modified starches, cellulose and hemicellulose. The advantages are biodegradability, compatibility with biological systems (hence, less allergic reaction in use) and sparing of fossil carbon dioxide emissions (linked to climate change). Associating an economic value to these environmental benefits, linked to consumer preferences has contributed to increased production in this area.

The second expanding activity is the use of plant fibres, not only for non-tree paper, but also as a substitute for petroleum based plastic packing and components such as car parts. These may be derived from non-woven fibres, or be based on bio-composite materials (lingo-cellulose chips in a suitable plastic matrix). At the other end of the scale, new methods of gluing, strengthening, preserving and shaping wood have increased the building of large structures with predicted long-lifetimes. These include a wide range of natural products such as flavours, fragrances, hydrocolloids and biological control agents. In spite of decades of research and development, engineering (recombinant DNA technology) is being widely investigated to achieve this, as well as to introduce new routes to unusual fatty acids and other organic compounds. In addition such techniques are being used to construct plants that produce novel proteins and metabolites that may be used as vaccines or for other therapeutic use. Processing of the crops for all these non-food uses will again generate residues and by-products that can serve as a source of energy, for internal use in processing, or export to other users, suggesting the future possibility of large multi-product biomass-based industrial complexes.

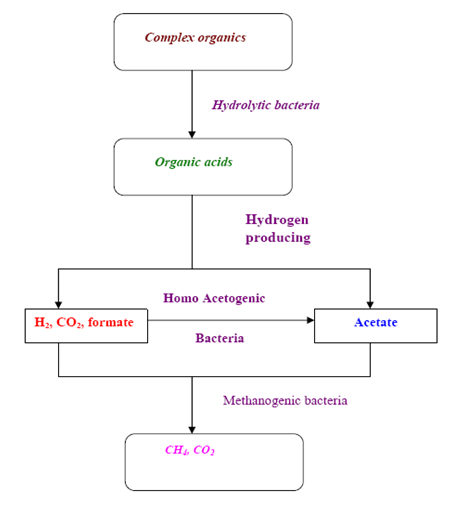

Bacteria form biogas during anaerobic fermentation of organic matters. The degradation is very complex process and requires certain environmental conditions as well as different bacteria populations. The complete anaerobic fermentation process is briefly described below as shown in Table 1, and Figure 1. Biogas is a relatively high-value fuel that is formed during anaerobic degradation of organic matter. The process has been known, and put to work in a number of different applications during the past 30 years, for rural needs such as in.1 Food security, water supply, health cares, education and communications. During the last decades thousands of biogas units were built all over the world, producing methane CH4 for cooking, water pumping and electricity generation. In order not to repeat successes in depth on local conditions and conscientious planning urged.2 The goals should be achieved through:

|

Level |

Substance |

Molecule |

Bacteria |

|

Initial |

Manure, vegetable, wastes |

Cellulose, proteins |

Cellulolytic, proteolytic |

|

Intermediate |

Acids, gases, oxidized, inorganic salts |

CH3COOH, CHOOH, SO4, CO2, H2, NO3 |

Acidogenic, hydrogenic, sulfate reducing |

|

Final |

Biogas, reduced inorganic compounds |

CH4, CO2, H2S, NH3, NH4 |

Methane formers |

Table 1 Anaerobic degradation of organic matter3

Figure 1 Biogas production process.3

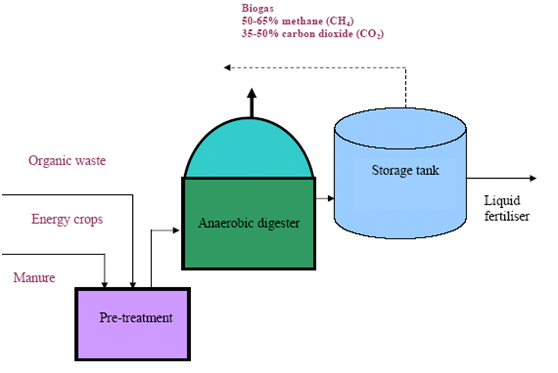

Biogas technology cannot only provide fuel, but is also important for comprehensive utilisation of biomass forestry, animal husbandry, fishery, agricultural economy, protecting the environment, realising agricultural recycling, as well as improving the sanitary conditions, in rural areas. The introduction of biogas technology on wide scale has implications for macro planning such as the allocation of government investment and effects on the balance of payments. Factors that determine the rate of acceptance of biogas plants, such as credit facilities and technical backup services, are likely to have to be planned as part of general macro-policy, as do the allocation of research and development funds.3,4 Biogas is a generic term for gases generated from the decomposition of organic material. As the material breaks down, methane (CH4) is produced as shown in Figure 2. Sources that generate biogas are numerous and varied. These include landfill sites, wastewater treatment plants and anaerobic digesters. Landfills and wastewater treatment plants emit biogas from decaying waste. To date, the waste industry has focused on controlling these emissions to our environment and in some cases, tapping this potential source of fuel to power gas turbines, thus generating electricity. The primary components of landfill gas are methane (CH4), carbon dioxide (CO2), and nitrogen (N2). The average concentration of methane is ~45%, CO2 is ~36% and nitrogen is ~18%. Other components in the gas are oxygen (O2), water vapour and trace amounts of a wide range of non-methane organic compounds (NMOCs).4 For hot water and heating, renewables contributions come from biomass power and heat, geothermal direct heat, ground source heat pumps, and rooftop solar hot water and space heating systems. Solar assisted cooling makes a very small but growing contribution. When it comes to the installation of large amounts of PV, the cities have several important factors in common.

Figure 2 General schematic of an agricultural biogas plant.3

These factors include:

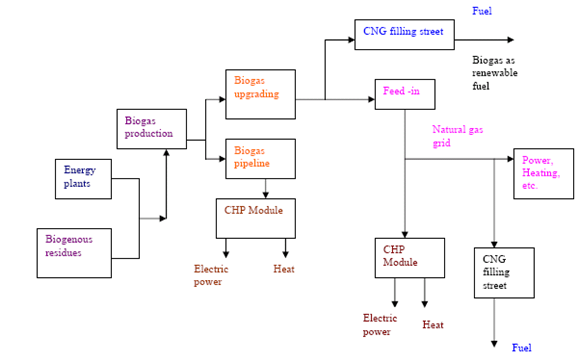

The importance and role of biogases in energy production is growing. Nowadays, a lot of countries in Europe promote utilisation of renewable energies by guaranteed refund prices or emission trading systems. A general schematic of an agricultural biogas plant, with the anaerobic digester at the ‘heart’ of it as shown in Figure 2. Pre-treatment steps (e.g., chopping, grinding, mixing or hygienisation) depend on the origination of the raw materials. In the past two decades the world has become increasingly aware of the depletion of fossil fuel reserves and the indications of climatic changes based on carbon dioxide emissions. Therefore extending the use of renewable resources, efficient energy production and the reduction of energy consumption are the main goals to reach a sustainable energy supply. Renewable energy sources include water and wind power, solar and geothermal energy, as well as energy from biomass. The technical achievability and the actual usage of these energy sources are different around Europe, but biomass is seen to have a great potential in many of them. An efficient method for the conversion of biomass to energy is the production of biogas by microbial degradation of organic matter under the absence of oxygen (anaerobic digestion). It is now possible to produce biogas at rural installation, upgrade it to bio-methane, feed it into the gas grid, use it in a heat demand-controlled CHP and to receive revenues. Biogas is a mixture containing predominantly methane (50-65% by volume) and carbon dioxide and in a natural setting it is formed in swamps and anaerobic sediments, etc., due to its high methane concentration, biogas is a valuable fuel. Wet (40-95%) organic materials with low lignin and cellulose content are generally suitable for anaerobic digestion (Figure 3).

Figure 3 Overview of biogas utilisation pathways.17

A key concern is that treatment of sludge tends to concentrate heavy metals, poorly biodegradable trace organic compounds and potentially pathogenic organisms (viruses, bacteria and the like) present in wastewaters. These materials can pose a serious threat to the environment. When deposited in soils, heavy metals are passed through the food chain, first entering crops, and then animals that feed on the crops and eventually human beings, to whom they appear to be highly toxic. In addition they also leach from soils, getting into groundwater and further spreading contamination in an uncontrolled manner. European and American markets aiming to transform various organic wastes (animal farm wastes, industrial and municipal wastes) into two main by-products:

An easier situation can be found when looking at the ecological effects of different biogas utilisation pathways. The key assumptions for the comparison of different biogas utilisation processes are:

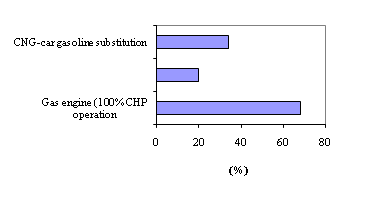

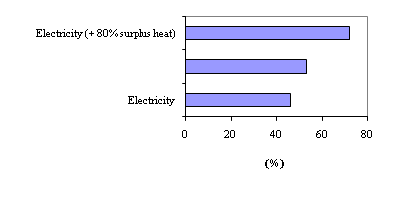

Figure 4 presents the results of the greenhouse gas (GHG) savings from the different biogas utilisation options, in comparison to the fossil fuel-based standard energy production processes. Biogas can be converted to energy in several ways. The predominant utilisation is combined heat and power (CHP) generation in a gas engine installed at the place of biogas production. There are mainly two reasons for this. First, biogas production is an almost continuous process; it is rather difficult or, in the short-term, even impossible, to control the operation of anaerobic digesters according to any given demand profile. Secondly, promotion of renewable energies is focused on electricity production. Because of that, biogas plant operators receive the predominant fraction of revenues from the guaranteed feed-in tariffs for electricity. Summarising the results of the eco-balances it becomes obvious that - not only by using fossil fuels but also by using renewable fuels like biogas – combined heat and power cogeneration is the optimal way for fighting climate change. From a technical point of view it can be concluded that biogas production, i.e., the conversion of renewable resources and biowaste to energy, can be seen as state-of-the-art technology. In an economic analysis, many factors have to be considered as outlined in Table 2. Due to the lack of knowledge and awareness, villagers cannot be expected to understand the benefits of solar stills, nutrient conservation, or health improvement.5 A poor rural peasant is very hesitant to enter a new venture. The negative attitude towards the use of stills water varies from place to place, but when it occurs, it is a major obstacle to the implementation of solar still technology. In designing the solar still, the following points were considered: the unit has to cost as little as possible and materials should be readily available in rural areas.

Biogas upgrading

Local gas engine

Figure 4 Greenhouse gas emissions savings for different biogas utilisation pathways in comparison to fossil energy production.17

|

Economic Factors |

Social Factors |

Technical Factors |

Ecological/Health Factors |

|

Interest on loan |

Employment created |

Construction, maintenance and repairs of biogas plants |

Improved health |

|

Current/future cost of alternative fuels |

Less time consumed for fetching clean water |

Availability of materials and land required |

Environment pollution abatement |

|

Current/future cost of construction materials |

Improved facilities in villages; thus less migration to cities |

Suitability of local materials |

Improvement in yields of agriculture products |

|

Saving of foreign currency |

Less expense for buying alternative fuels |

||

|

Current/future labour cost |

More time for additional income earning activities |

||

|

Inflation rate |

Table 2 Factors to be considered in economic analysis17

Technology should be simple, within the reach of a common village man. The unit should be usable in situations of emergency, e.g., during floods and after cyclones, etc. Energy efficiency brings health, productivity, safety, comfort and savings to the homeowner, as well as local and global environmental benefits. The use of renewable energy resources could play an important role in this context, especially with regard to responsible and sustainable development. It represents an excellent opportunity to offer a higher standard of living to the local people, and will save local and regional resources. Implementation of renewable energy technologies offers a chance for economic improvement by creating a market for producing companies, maintenance and repair services. Production of bio-fuels such as ethanol from sugar cane, takes advantages of year-round cultivation potential in a tropical countries. Benefits extend from local, national and international levels. Local rural economies benefit through new economic opportunities and employment in the agricultural sector. Urban regions benefit through cleaner air and health improvements. The nation benefits through substituting domestic resources for costly imported gasoline. The world benefits from reduced CO2 emissions.

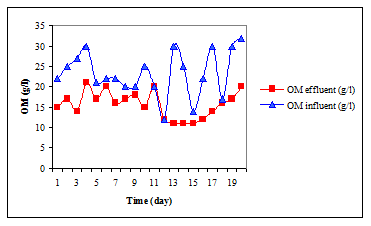

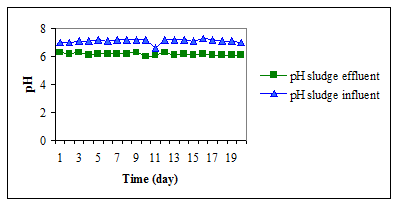

Bacteria form biogas during anaerobic fermentation of organic materials. The degradation is very complex process and requires certain environmental conditions as well as different bacteria population. The organic materials were biodegradable to produce biogas and the variation show a normal methanogene bacteria activity and good biological process shown in Figures 5 & 6. Gasification is based on the formation of a fuel gas (mostly CO and H2) by partially oxidising raw solid fuel at high temperatures in the presence of steam or air.6,7 The technology can use wood chips, groundnut shells, sugarcane bagasse, and other similar fuels to generate capacities from 3kW to 100kW.8,9 Three types of gasifier designs have been developed to make use of the diversity of fuel inputs and to meet the requirements of the product gas output (degree of cleanliness, composition, heating value, etc.). The requirements of gas for various purposes, and a comparison between biogas; and various commercial fuels in terms of calorific value, and thermal efficiency are presented in Table 3.

Figure 5 Organic matters before and after treatment in digester.24

Figure 6 pH sludge before and after treatment in the digester.24

|

Fuel |

Calorific Value (kcal) |

Burning Mode |

Thermal Efficiency (%) |

|

Electricity, kWh |

880 |

Hot plate |

70 |

|

Coal gas, kg |

4004 |

Standard burner |

60 |

|

Biogas, m3 |

5373 |

Standard burner |

60 |

|

Kerosene, l |

9122 |

Pressure stove |

50 |

|

Charcoal, kg |

6930 |

Open stove |

28 |

|

Soft coke, kg |

6292 |

Open stove |

28 |

|

Firewood, kg |

3821 |

Open stove |

17 |

|

Cow dung, kg |

2092 |

Open stove |

11 |

Table 3 Comparison of various fuels8

Growth, modernisation and urbanisation in many states of Sudan have created both energy supply shortages and a growing source of free fuel: biogas. The use of biogas has been proven and is ready to be deployed in Sudan. The technology is available, it is economically feasible and it is reliable. An additional benefit of using these gases as a fuel source is minimization of the environmental impacts that result from gas venting or flaring. The burning of such gases will release air-borne pollutants, which can also enter groundwater sources and pollute farmlands. The optimum range in Table 4 is for ambient temperatures during hot seasons of Sudan tropical climates. The potential gas volumes produced from wastes vary depending on many factors (the amount of material fed, the type of material, the carbon/nitrogen ratio and digestion time and temperature).

|

Parameter |

Optimum Value |

|

Temperature °C |

30-35 |

|

pH |

6.8-7.5 |

|

Carbon/Nitrogen ratio |

20-30 |

|

Solid content (%) |

9-Jul |

|

Retention time (days) |

20-40 |

Table 4 Optimum conditions for biogas production9

There is an unmistakable link between energy and sustainable human development. Energy is not an end in itself, but an essential tool to facilitate social and economic activities. Thus, the lack of available energy services correlates closely with many challenges of sustainable development, such as poverty alleviation, the advancement of women, protection of the environment, and jobs creation. Emphasis on institution-building and enhanced policy dialogue is necessary to create the social, economic, and politically enabling conditions for a transition to a more sustainable future. On the other hand, biomass energy technologies are a promising option, with a potentially large impact for Sudan as with other developing countries, where the current levels of energy services are low. Biomass accounts for about one third of all energy in developing countries as a whole, and nearly 96% in some of least developed countries.10-12

Climate change is a growing concern around the world, and stakeholders are aggressively seeking energy sources and technologies that can mitigate the impact of global warming. This global concern is manifest in the 1997 Kyoto Protocol, which imposes an imperative on developed nations to identify feasible options by the next Conference of the Parties to the Convention (COP) meeting later in 2001. Possible actions range from basic increases in energy efficiency and conservation, to sophisticated methods of carbon sequestration to capture the most common greenhouse gases (GHGs) emission (CO2). On the other hand, renewable energies have always been identified as a prime source of clean energies that emit little or no net GHGs into the atmosphere. Forest ecosystems cause effects on the balance of carbon mainly by the assimilation of CO2 by the aboveground biomass of the forest vegetation. The annual emissions of greenhouse gases from fossil fuel combustion and land use change are approximately 33x 105 and 38 x 105 tonnes respectively. Vegetation and in particular forests, can be managed to sequester carbon. Management options have been identified to conserve and sequester up to 90Pg C in the forest sector in the next century, through global afforestation.13,14 This option may become a necessity (as recommended at the Framework Convention on Climate Change meeting held in Kyoto), but a preventative approach could be taken, reducing total GHGs emissions by substituting biomass for fossil fuels in electricity production. Simply sequestering carbon in new forests is problematic because trees cease sequestering once they reach maturity, and as available land is used up the cost of further afforestation will grow.

Indeed the cost of reducing the build-up of GHGs in the atmosphere is already lower for fossil fuel substitution than for sequestration, since fast growing energy crops are more efficient at carbon removal, and because revenue is generated by the scale of electricity. Some biomass fuel cycles can also provide the additional benefits of enhanced carbon storage. The relative merits of sequestration versus fossil fuel substitution are still debated. The flow of carbon during the life cycle of the biomass should determine whether it is better left standing, used as fuel or used as long-lived timber products. Where there are existing forests in good condition there is general agreement that they should not be cut for fuel and replanted. This principle also concurs with the guidelines for nature protection, i.e., energy crops should never displace land uses of high ecological value. Where afforestation is undertaken, however, fossil fuel substitution, both by using wood fuel and using timber as a renewable raw material, should be more sustainable and less costly approach than sequestration could also be used to displace the harvest of more ecologically valuable forests. For efficient use of bioenergy resources, it is essential to take account of the intrinsic energy potential. Despite the availability of basic statistics, many differences have been observed between the previous assessments of bioenergy potential.15,16 These were probably due to different assumptions or incomplete estimations of the availability, accessibility and use of by products. The biomass sources have been used through:

Wood is very important raw material used by a number of industries. Its excessive utilisation as a fuel results in soil erosion, degradation of the land, reduced agricultural productivity and potentially serious ecological damage. Hence, minimization of fuelwood demand at the national level and increase the efficiency of fuelwood use seems to be essential. Utilisation of more efficient stoves and improvement of insulation using locally available materials in buildings are also effective measures to increase efficiency. Biogas or commercial fuels may be thought of as possible substitutes for fuelwood. In rural areas of Sudan, liquefied petroleum gases (LPGs) are strong candidate to replace firewood. Indeed, increased, LPG utilisation over the last decade has been one of the main reasons has lead to the deceleration of the diffusion of biogas technology into rural areas.

The main advantages related to energy, agriculture and environment problems are foreseeable both regionally and globally and can be summarised as follows:

A study16 individuated on the basis of botanical, genetical, physiological, biochemical, agronomical and technological knowledge reported in literature some 150 species potentially exploitable divided as reported in Table 5. Turning to chemical engineering and the experience of the chemical process industry represents a wakening up but does not lead to an immediate solution to the problems. The traditional techniques are not very kind to biological products, which are controlled by difficulty and unique physico-chemical properties such as low mechanical, thermal and chemical stabilities. There is the question of selectivity. The fermentation broths resulting from microbial growth contain a bewildering mixture of many compounds closely related to the product of interests. By the standards of the process streams in chemical industry, fermenter is highly impure and extremely dilutes aqueous systems. The disadvantages of the fermentation media are as the following: mechanically fragile, temperature sensitive, rapidly deteriorating quality, harmful if escaping into the environment, corrosive (acids, chlorides, etc.), and troublesome (solids, theological, etc.), and expensive. Thus, pilot plants for scale-up work must be flexible. In general, they should contain suitably interconnected equipment for: fermentation, primary separation, cell disruption fractionalises and clarifications, purification by means of high-resolution techniques and concentration and dry. The effects of the chlorofluorocarbons (CFCs) molecule can last for over a century.

Groups of Plants |

Number of Species |

Plants cultivated for food purposes that can be reconverted to new uses |

9 |

Plants cultivated in the past, but not in culture any more |

46 |

Plants cultivated in other world areas |

46 |

Wild species, both indigenous and exotic |

47 |

Total |

148 |

Plant product |

Number of species |

Biomass |

8 |

Sugars and polysaccharides |

38 |

Cellulose |

17 |

Hydrocarbons |

3 |

Polymeric hydrocarbons |

5 |

Gums and resins |

12 |

Tannins and phenolic compounds |

3 |

Waxes |

7 |

Vegetable oils |

38 |

Total |

131 |

Table 5 Plant species potentially exploitable for production of agricultural biomass for energy or industrial utilisations16

There are in practice two main types of biogas plant that have been developed; the fixed-dome digester, which is commonly called the Chinese digester, and the type with a floating gas holder known as Indian digester. The potential gas volumes produced from wastes vary depending on many factors, and can be expressed based in head count as shown in Table 6, or on a fixed weight as shown in Table 7. A list of the potential gas production from a number of materials is presented in Table 8. The requirements of gas for various purposes, and a comparison between biogas; and various commercial fuels in terms of calorific value, and thermal efficiency are presented successively in Table 9. The amount of biogas actually produced from a specific digester depends on the following factors: (1) Amount of material fed (2) Type of material (3) The carbon/nitrogen ratio and (4) Digestion time and temperature. Combined heat and power (CHP) installations are quite common in greenhouses, which grow high-energy, input crops (e.g., salad vegetables, pot plants, etc.).

Source of Waste |

Waste Production (kg d-1) |

Gas Production (m3 d-1) |

1 cow |

10 |

0.25-0.40 |

10 chicken |

- |

0.02-0.04 |

1 latrine user |

1 |

0.02-0.03 |

1 sheep/goat |

- |

0.02-0.04 |

Table 6 Average daily gas production based on head count25

Source of Waste |

Gas Production m3/103 kg Animal |

Gas production m3/103 kg waste |

Dairy cattle |

2.53 |

- |

Beef cattle |

2.47 |

- |

Poultry |

6.92 |

65.5-115 |

Pretreated crop waste |

- |

30-40 |

Water hyacinth |

- |

40-50 |

Table 7 Average gas production based on waste amount27

Materials |

Yield (m3/kg day solids) |

Manure |

|

Cow |

0.34 |

Poultry |

0.48 |

Human |

0.4 |

Vegetable matter |

|

Straw |

0.17 |

Grass |

0.43 |

Leaves |

0.3 |

Water hyacinth |

0.4 |

Table 8 Ultimate gas yields for some different materials27

Purpose |

Specifications |

Gas Required (m3/day) |

Cooking |

per person |

0.425 |

stove 10 cm dia. |

0.47 |

|

Lighting |

200-candle power |

0.1 |

40-watt bulb |

0.13 |

|

2-mantle |

0.14 |

|

Gasoline engine |

Per HP |

0.43 |

Diesel engine |

Per HP |

0.45 |

Refrigerator |

Per m3 |

1.2 |

Incubator |

Per m3 |

0.6 |

Table fan (indirectly) |

30 cm diameter |

0.17 |

Space heater |

30 cm diameter |

0.16 |

Table 9 Biogas requirements for various purposes27

Scientific assumptions for a short-term energy strategy suggest that the most economically efficient way to replace the thermal plants is to modernise existing power plants to increase their energy efficiency and to improve their environmental performance. However, utilisation of wind power and the conversion of gas-fired CHP plants to biomass would significantly reduce the dependence on imported fossil fuels. Although a lack of generating capacity is forecast in the long-term, utilisation of the existing renewable energy potential and the huge possibilities for increasing energy efficiency are sufficient to meet future energy demands in Sudan in the short-term. A total shift towards a sustainable energy system is a complex and long process, but is one that can be achieved within a period of about 20 years. Implementation will require initial investment, long-term national strategies and action plans. However, the changes will have a number of benefits including: a more stable energy supply than at present and major improvement in the environmental performance of the energy sector, and certain social benefits. A vision used a methodology and calculations based on computer modelling that utilised:

In addition to realising the economic potential identified by the National Energy Savings Programme, a long-term effort leading to a 3% reduction in specific electricity demand per year after 2020 is proposed. This will require: further improvements in building codes, and continued information on energy efficiency.

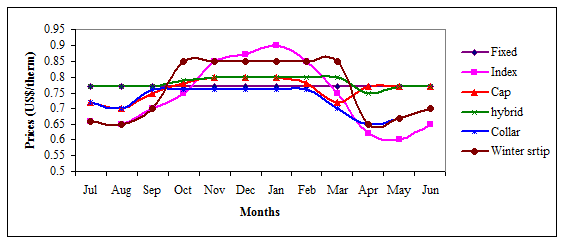

Financial hedges (such as futures and options) are contractual vehicles that convey rights and obligations to buy or sell a commodity at a specified price. Possible purchasing strategies using hedges are summarised in Table 10. These financial derivations are a method of reducing price risk with a relatively modest transaction price. Over the past 10 years the use of financial hedges has grown dramatically. Figure 7 illustrates various hypothetical reduction strategies and the resulting average fuel price. The basic concept is to utilise existing financial tools to guard against conditions that will negatively affect the operating budget. Basic hedges include:

Strategy |

Description |

Index

Collar Hybrid Winter strip |

Fuel is purchased month-by-month at a first of the month index price |

Table 10 Purchasing strategies using hedges27

Figure 7 Purchasing strategies using hedges.28

Politicians at the local and national level have evaluated sustainability as an important issue facing the communities. The future will have leaders who develop sustainable solid waste programmes that further improve the community to achieve the following:

In compiling energy consumption data one can categorise usage according to a number of different schemes:

Table 11 lists the energy sources available. Table 12 presented some renewable applications.

Energy Source |

Energy Carrier |

Energy End-Use |

Vegetation |

Fuel-wood |

Cooking |

Water heating |

||

Building materials |

||

Animal fodder preparation |

||

Oil |

Kerosene |

Lighting |

Ignition fires |

||

Dry cells |

Dry cell batteries |

Lighting, Small appliances |

Muscle power |

Animal power |

Transport |

Land preparation for farming |

||

Food preparation (threshing) |

||

Muscle power |

Human power |

Transport |

Land preparation for farming |

||

Food preparation (threshing) |

Table 11 Sources of energy17

Systems |

Applications |

Water supply |

Rain collection, purification, storage and recycling |

Wastes disposal |

Anaerobic digestion (CH4) |

Cooking |

Methane |

Food |

Cultivate the 1 hectare plot and greenhouse for four people |

Electrical demands |

Wind generator |

Space heating |

Solar collectors |

Water heating |

Solar collectors and excess wind energy |

Control system |

Ultimately hardware |

Table 12 Renewable applications17

Considerations when selecting power plant include the following:

Table 13 lists the most important of energy needs. Table 14 listed methods of energy conversion. A great amount of renewable energy potential, environmental interest, as well as economic consideration of fossil fuel consumption and high emphasis of sustainable development for the future will be needed. Explanations for the use of inefficient agricultural-environmental polices include: the high cost of information required to measure benefits on a site-specific basis, information asymmetries between government agencies and farm decision makers that result in high implementation costs, distribution effects and political considerations.18-20 Achieving the aim of agric-environment schemes through:

Transport, e.g., small vehicles and boats |

Agricultural machinery, e.g., two-wheeled tractors |

Crop processing, e.g., milling |

Water pumping |

Small industries, e.g., workshop equipment |

Electricity generation, e.g., hospitals and schools |

Domestic, e.g., cooking, heating, and lighting |

Table 13 Energy needs in rural areas17

Muscle power |

Man, animals |

Internal combustion engines |

|

Reciprocating |

Petrol- spark ignition |

Diesel- compression ignition |

|

Humphrey water piston |

|

Rotating |

Gas turbines |

Heat engines |

|

Vapour (Rankine) |

|

Reciprocating |

Steam engine |

Rotating |

Steam turbine |

Gas Stirling (Reciprocating) |

Steam engine |

Gas Brayton (Rotating) |

Steam turbine |

Electron gas |

Thermionic, thermoelectric |

Electromagnetic radiation |

Photo devices |

Hydraulic engines |

Wheels, screws, buckets, turbines |

Wind engines (wind machines) |

Vertical axis, horizontal axis |

Electrical/mechanical |

Dynamo/alternator, motor |

Table 14 Methods of energy conversion17

In some countries, a wide range of economic incentives and other measures are already helping to protect the environment. These include:

District Heating (DH), also known as community heating can be a key factor to achieve energy savings, reduce CO2 emissions and at the same time provide consumers with a high quality heat supply at a competitive price. DH should generally only be considered for areas where the heat density is sufficiently high to make DH economical. In countries like Denmark DH may today be economical even to new developments with lower density areas due to the high level of taxation on oil and gas fuels combined with the efficient production of DH.21-30 To improve the opportunity for DH local councils can adapt the following plan:

Renewable energy policy model based biomass industry for rural electrification involving small and medium enterprises are very dependent on funding from non-banking agency is to make a feasibility study as a condition of the issuance of the power purchase agreement by state own electricity company. Based on the six elements studied then obtained the factors that influence energy policy based on renewable biomass from social forestry are: (1) the determination of the energy tariff, (2) competent human resources, (3) coordination between the related local government offices, (4) a system of incentives, (5) community participation, (6) funds and investment banking business, (7) microfinance, (8) the need for local governments to design spatial and territories. These factors should involve financial institutions, NGOs and Professional Association. Biomass is a renewable energy source that is important and will continue to be developed in the world. The development is now seen one of them in China that the development of biomass is very high, i.e., 3,511 MTCE (million tons of coal equivalent). Biomass highly distributed in China depends on the geography and climate in various provinces where development is still very necessary policies, and Feed -in Tariff incentives and subsidies for capital goods and research and development expenses also include tax incentives and pricing. Geographical distribution of biomass in China is unbalanced depending on the provinces of Sichuan, Yunnan and Tibet which is 33.3 % of the total distribution in China.31-35

Renewable energy policy for the industrial private forest-based biomass has an input controlled or not controlled. Uncontrolled inputs include land use, land use rights, the exchange rate, the price of the product and the market demand. Controlled inputs include appropriate technology, human resources quality, supporting infrastructure, access to finance, supply chain systems and socialization. Input controlled and uncontrolled inputs along with the input environment (legislation, government regulation, public culture and agro-climate) produce the desired output in the form of job creation, the utilisation of forest products that are environmentally friendly, green growth, availability of renewable energy, and empowerment people and viable biomass energy rates. In addition to produce the desired output, the output is also obtained in the form of unwanted output: serviceability degradation, deforestation, high production costs and low public participation. These undesirable outputs into a feedback to management control and then the controlled input and renewable energy policy for the social forestry-based biomass industry will produce output that controllable.36 Utilisation of biomass, directly as firewood and charcoal for locals cooking purposes not included in the utilization of renewable energy. As for which is included in the utilisation of renewable energy is for electricity generation through biomass gasification process. Under these circumstances the research aims are: (1) identifying factors that influence development of renewable biomass energy policy, based on forest biomass managed by people (2) designing bio-pellet industry supply chain system with sustainable empowerment of community forests, and (3) developing renewable energy policy of biomass based industry, for rural electrification. The development of biomass-based renewable energy needs continuity of feedstock. It is strongly associated with land use and social conditions, related to community empowerment. Raw materials continuity can be supplied from forest harvest, both public forests and forest plantations. In this context, the development is directed to areas that have potency for widespread cultivated forest.

The introduction of biogas technology on wide scale has implications for macro planning such as the allocation of government investment and effects on the balance of payments. Factors that determine the rate of acceptance of biogas plants, such as credit facilities and technical backup services, are likely to have to be planned as part of general macro-policy, as do the allocation of research and development funds.

None.

Author declares that there is no conflict of interest.

©2017 Omer. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.