International Journal of

eISSN: 2574-8084

Research Article Volume 7 Issue 3

1Atomic energy medical centre, JPMC Karachi, Pakistan

2Institute of space and science technology, University of Karachi, Pakistan

Correspondence: Nasir Ilyas, Institute of space and science technology, University of Karachi, Pakistan

Received: April 07, 2020 | Published: June 30, 2020

Citation: Farrukh S, Ilyas N. Wedge angle confirmation in computer controlled wedge field. Int J Radiol Radiat Ther. 2020;7(3):81-86. DOI: 10.15406/ijrrt.2020.07.00270

Aim: The use of computer controlled wedge system is an important segment of radiotherapy and increases the uniformity of dose in the target volume. The aim of this study is to verify the virtual wedge angles from the machine setup angles in Siemens ONCOR Linear accelerator (Linac) and compare with published data of different linear accelerators as a function of beam energy and field sizes.

Method and material: This experiment was carried out on Siemens ONCOR impression linear accelerator (Linac). The doses at different depth were measured by using CC13 ion chamber. During our work the source to surface distance was kept 100 cm. The square field sizes on which we worked were 10 cm2, 15cm2 and 20 cm2.The selected Virtual wedge angles for our study are 15°, 30°, 45° and 60°.This work is carried out for both photon energies 15 MV and 6 MV, tissue equivalent water phantom IBA blue water phantom inside which all the observations were taken. The LDA 99 detector for virtual wedge profile was used. The wedge angle were calculated for the Siemen’s given formula. The variation in wedge angle from machine setup angle and published data as a function of beam energy and field sizes were analyzed.

Results: The variation increases with field size and wedge angle but decreases with beam energy.

Conclusion: Deviations are under 3% which are acceptable before treatment planning.

Keywords: wedge angle, variation and virtual wedge

In modern radiotherapy techniques the heart toxicity and breast cancer are getting to be concerned issues.1Breast radiotherapy has continuously been challenging in term of size and shape of breast as well as the region of the whole breast volume encompassing critical organs or organs at risk. One of the fundamental encounter when planning whole-breast radiotherapy is the reality that treatment is slightly limited to what is really a different technique in order to avoid these nearby serious organs.2 In most of the patient radiations related cardiac maladies have been commonly establish which were treated for lymphoma, breast cancers, seminoma, peptic ulcer diseases and lung cancer and also in the persons who persisted in nuclear bomb explosion. The risk of cardiac illnesses may be connected to both radiation and exposed volume.3 Quality of a radiation beam is most typically expressed in terms of its penetrating power, which is especially a function of the mean photon energy and it should be fully defined by its depth dose characteristics in water but a increase within the surface dose with the field size is additionally renowned due to the electron scattering from dominant materials.4 In order to attenuate radiation toxicity, the understanding and familiarity of wedge filter handling during treatment planning system is necessary. During the treatment of breast, thoracic and pelvic tumors the use of wedge angle has been common and the steep dose gradient may produce hot spots in lungs, heart, and rectum.3,5,6

Wedge angle is defined as the angle by which an isodose curve at a certain depth (normally 10 cm) is tilted along the central beam is called wedge angle. It can also be defined as the 50% of isodose line and normal to the central axis of beam.7 PWs are available in the range of 15°, 30° , 45° and 60° whereas VWs are available in all possible values of angles lying (10° - 60°). The use of physical wedge (PW) in radiotherapy is easy. However they are limited to angles (15°, 30°, 45° and 60°) and field sizes. PWs are heavy due to high density and atomic number of materials used and creates low energy photons and electrons scatters .Treatment time for PW increased because of diminished primary beam intensity and time required for installation and removal. With the development of computer controlled method collimator jaws can be moved which produce the virtual replacement of PW.8 Siemens has presented a virtual wedge (VW) that generates dose distribution comparable as created by wedge through the motion of one of the collimator jaws across the field during irradiation. For a definite VW field, the speed of the jaw motion is constant but the dose rate varies. VW was designed to produce dosimetric properties same as of physical wedges (PWs).9 In virtual treatment we do not require handling of PW and attain accurate and faster treatment. After this concept of dynamic wedges (DW) and Virtual wedges were purposed. DW and VW both are computer-controlled wedges that generate wedge shaped profiles. VW differs from DW in two ways. First, in VW the moving jaws close and then fully open during treatment. Second, the jaws move with the constant speed while the dose rate is varied as a function of time.

Intrafractional organ motion (tumor motion) is a noticeable problem in radiotherapy.10 Tumor movement can be produced by the skeletal muscular, respiratory, cardiac, and gastrointestinal systems. Respiratory motion in particular affects all tumor sites in the thorax and abdomen; the disease of most significant in this case is lung cancer as shown in Figure 1.Respiratory motion is just one potential source of error in radiotherapy.11 Intrafractional organ motion can result in two types of effect. The first is the “dose-blurring effect” which results in the under/over dose to the irradiated tumor one of the major cause of dose blurring is the wedge angle variation from actual one. Second is called the “interplay effect,” which is only an obstacle in the case of vibrant delivery of intensity-modulated radiation therapy or dynamic treatments with computer controlled wedges. This influence is the result of interaction between the moving tumor and the motion of the radiation beam as defined by the computer control wedges and can result in dose deviation.12,13 In this study we will go through the variation in the wedge angle from the prescribed formula and how much it will effect during treatment planning system.

All the measurements were taken on Siemen’s ONCOR linear accelerator having 82 Leaves MLC as Y-collimator, while PW produces by collimator jaws in X- direction. In the commissioning of TPS, the beam data for wedge field needs to be more precise because minor instability can cause greater impact in clinical setting due to dose gradient profile. Because of altered techniques use to generate wedged dose distribution and their positions with respect to the target of linear accelerator The linear accelerator is fixed at Atomic energy medical center (AEMC), Karachi for both 6 MV and 15 MV X-ray beams using 3D water phantom (Blue phantom, IBA Germany). The measurement of water tank is 480 mm × 480 mm × 400 mm and walls are made of acrylic. The point accuracy of water phantom in 0.1 mm has 500 mm/s scanning speed. We align the water phantom with the laser such that the vertical axis (y-axis/in-plane direction) is the up down position. The scanning the orientation in gun target and up-down direction can compromise the treatment planning system of wedged field but in open field orientation does matter. For accurate scanning process, the phantom must be positioned so that it is adjusted with in-plane direction. This can be done by line up probe holders with the field’s edge. Standard relative dosimetry setup was arranged for measurement, using CC13 ion chambers, (IBA, Germany), portable IBA electrometer/control unit, CU-500E and dosimetry computer having Omnipro-accept software. CC13 Ion chamber was kept at beam’s central axis, with chamber center at water surface, such that the distance from source to surface (SSD) was 100cm.In plane beam profiles were measured only for 10 cm depth for various field sizes (10 × 10 cm2, 15 × 15 cm2, 20 × 20 cm2) for nonphysical wedged field. Then all the profiles converted into tabular form using option in the Omnipro accept software. We confirmed the wedge angles of 15°, 30°, 45° and 60° from the Siemens given formula. All the deviations were finally analyzed as a function of field size and energy .These variations were compared with published data.

The dose is varied according to the following equations.14

MU(x) = MU(0)e(−µxtanθ)MU(x) = MU(0)e(−µxtanθ) (1)

δμνdt =v MUµtanq (0)e(−µxtanθ) δμνdt =v MUµtanq (0)e(−µxtanθ) (2)

Where

MU(x) = Number of monitor units that is given while a point at position x is irradiated.

MU (0) = Number of monitor units at x=0 that is also the number of monitor unit enters to machine console.

q = Desired wedge angle.

µ= Effective attenuation coefficient of the beam. V = Speed of moving jaws.

Attenuation coefficient (µ) in equation (1) and (2) varies as a function of energy. When implementing on VW a default effective attenuation coefficient (µdef) is needed. A calibration coefficient (c) is used to adjust effective attenuation coefficient. In case of VW.

µ= C x µdef (3)

By adjusting the c factor VW angle was modified to achieve calibration.

The wedge angle according to Siemens acceptance procedure, we need only four points for the measurements of wedge angle. Two central axis points taken along a beam profile at 9 and 11 cm depths.

The definition of virtual wedge angle according to the Siemens manual is given by the formula1.15

Wedge angle =θ=tan−1[(dp−dq)/Δd (d9−d11)/2] Wedge angle =θ=tan−1[(dp−dq)/Δd (d9−d11)/2] (4)

According to the Instruction by Siemens D9 and D11 are the doses at 9 cm and 11 cm depths on the central axis respectively. At 10 cm depth with lateral coordinates (Dp and Dq) ± field width /4 (for 15° and 30° wedges angles) or ± field width/6 (for 45° and 60° wedges angles). A Pair of wedge can also be use in treatment planning system, angling of wedge is useful in compensating slopping surface such as in nasopharyngeal treatment in which wedges are used to balance for decreases thickness anteriorly. Another application of pair of wedge in treating relatively low lying lesions ,in this case two beams are placed at an angle of less than 180° normally called hinge angle, in this case normal wedge angle can be calculated by 90° - ½ (hinge angle(7). To determine the wedge angle for selected field sizes (10 x 10 cm2, 15 x 15 cm2 and 20 x 20 cm2) of 6 MV x-ray photon from equation (4) ,profile will be measured for 15°,30°,45° and 60° wedge angle. The same work will be repeated for 15 MV energy. The calculated wedge angle will be compared with machine setup angles. The deviation of calculated angles from machine angles will be calculated by subtracting the calculated values from real values for all selected field sizes. According to Siemens this formula is only valid for virtual wedge. By calculating the deviation we can prove the formula according to our data. Virtual wedge profiles were obtained using linear detector array (LDA-99) at 10 cm in 3D water phantom (Blue phantom, IBA Germany) and above said field sizes and energies.

In Table 1 the wedge angles were calculated for 6 MV energy for all concerned field sizes. In case of 10° 10 cm2 field size according to Siemens instruction for 15° and 30° the values of Dp and Dq are 2.5 cm and – 2.5 cm respectively and for 45° and 60° the values of Dp and Dq are 1.67 cm and – 1.67 cm respectively. In case of 15 x 15 cm2 field size Siemens instructed for 15° and 30° the values of Dp and Dq are 3.75 cm and – 3.75 cm respectively and for 45° and 60° the values of Dp and Dq are 2.5 cm and – 2.5 cm respectively. In case of 20 x 20 cm2 field size Siemens instructed for 15° and 30° the values of Dp and Dq are 5 cm and – 5 cm respectively and for 45° and 60° the values of Dp and Dq are 3.33 cm and – 3.33 cm respectively.

|

Field sizes (cm2) |

Machine setup wedge angles (°) |

Calculated wedge angles (°) |

Deviation (°) |

Percent deviation (%) |

|

10´10 |

15 |

14.69 |

0.31 |

2.067 |

|

30 |

29.16 |

0.84 |

2.8 |

|

|

45 |

44.75 |

0.25 |

0.556 |

|

|

60 |

58.42 |

1.58 |

2.633 |

|

|

15´15 |

15 |

15.15 |

-0.15 |

1 |

|

30 |

30.33 |

-0.33 |

1.1 |

|

|

45 |

46.35 |

-1.35 |

3 |

|

|

60 |

61.97 |

-1.97 |

3.283 |

|

|

20´20 |

15 |

15.35 |

-0.35 |

2.333 |

|

30 |

30.64 |

-0.64 |

2.133 |

|

|

45 |

45.85 |

-0.85 |

1.889 |

|

|

60 |

59.9 |

0.1 |

0.167 |

Table 1 Percent deviations in the virtual wedge angle from machine set-up angles at 10 x 10 cm2, 15 x 15 cm2 and 20 x 20 cm2 for 6 MV

|

Field sizes (cm2) |

Machine setup wedge angles (°) |

Calculated Wedge angles |

Deviation (°) |

Percent deviation (%) |

|

(°) |

||||

|

10´10 |

15 |

14.69 |

15.03 |

0.03 |

|

30 |

29.16 |

29.93 |

0.07 |

|

|

45 |

44.75 |

44.73 |

0.27 |

|

|

60 |

58.42 |

60.77 |

0.77 |

|

|

15´15 |

15 |

15.15 |

14.92 |

0.08 |

|

30 |

30.33 |

29.6 |

0.4 |

|

|

45 |

46.35 |

45.41 |

0.41 |

|

|

60 |

61.97 |

59.9 |

0.1 |

|

|

20´20 |

15 |

15.35 |

15.11 |

0.11 |

|

30 |

30.64 |

30.82 |

0.82 |

|

|

45 |

45.85 |

44.39 |

0.61 |

|

|

60 |

59.9 |

60.48 |

0.48 |

Table 2 Percent deviations in the virtual wedge angle from machine set-up angles at 10 x 10 cm2, 15 x 15 cm2 and 20 x 20 cm2 for 15 MV

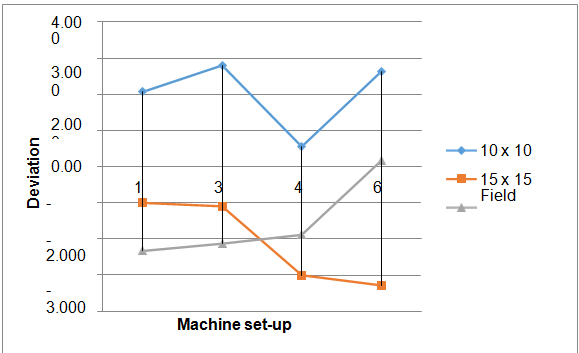

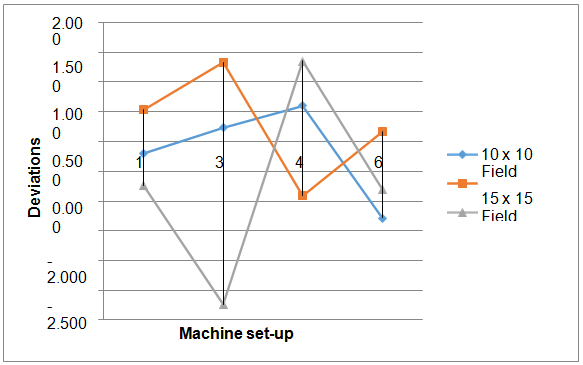

After calculating wedge angles we determine the deviations between calculated angles and machine set-up angles by subtracting calculated angles from machine set-up angles in degrees then finally calculated the percent deviation. The Figure 2 shows the percent deviation between machine set-up angles and calculated angles for 6 MV energy. This shows that the deviation is independent of machine set-up angles and field sizes the deviation in this case within 4 %. The Figure 3 shows the percent deviation between machine set-up angles and calculated angles for 15 MV energy. This shows that the deviation is independent of machine set-up angles and field sizes, the deviation in this case within 3 %. The variation or deviation in 15 MV is lesser than 6 MV it is may be due to beam hardening effect in 6 MV, beam hardening is the effect when radiations passes through from metal low energy captured in metal. The previously study was done on PRIMUS3008 linear accelerator Siemens and the deviation between calculated and machine set-up angle is found to be within 1%.16 The recent study regarding the wedge angle confirmation for Elekta for 15° 15 cm2 field size is given in Table 3.17 Our study shows the deviations from original value within 3 % ,which is acceptable this variation increases in higher fields due to the electron contamination with x-rays beam ,deviation also increases with wedge angle as thickness increases energy decreases. As far as the effect of energy beam is concerned ,in low energy deviation increases due to the beam hardening effect.

Figure 2 Deviation between calculated and machine set-up angles at various field sizes for 6 MV energy.

Figure 3 Deviation between calculated and machine set-up angles at various field sizes for 15 MV energy.

|

Machine setup wedge angle (°) |

Calculated effective wedge angles(°) |

Percent deviation (%) |

|

15 |

12.35 |

2.65 |

|

30 |

26.29 |

3.71 |

|

45 |

41.12 |

3.88 |

|

60 |

57.1 |

2.9 |

Table 3 Effective wedge angles and Percent deviations in Elekta monitored wedge angle from machine setup virtual wedge angle for 15 x 15 cm2 square field size

This study verified the treatment of using virtual wedge angle in SIEMENS ONCOR linear accelerator. The effective wedge angles were calculated for various field sizes and energies that were required for TPS. The beam hardening and scatter of the wedge effect caused the difference between effective wedge angle and planned wedge angle.18 Scattering of the wedge increased with field size and could be reduced by modification of the wedge shape and material. The influence field size on effective wedge angle was not higher than proposed uncertainly 3%.19 So this outcome in treatment planning system should not be considered. The required dosimetric characteristic of TPS for all field sizes could not be measured in the present study. This paper shows the variation in the effective wedge angles from machine setup angles as a function of the field size and beam energy. This algorithm was validated with measuring data successfully. The method was proved to calculate wedge angle based on factors of field method can be used as an alternative method for TPS by minimum required measurement.

This work is the part of M.Phil. research job of Mr. Nasir Ilyas which was accomplished at the Atomic Energy Medical Centre (AEMC), Karachi. I would like to express my sincere gratefulness to the oncologists, medical physicists, dosimetrists, radiographers, engineers, and other members of the treatment squad and all staff of AEMC.

None.

This work has no conflict of interest.

©2020 Farrukh, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.