International Journal of

eISSN: 2574-9862

Research Article Volume 2 Issue 3

Livestock Research Center, National agriculture and forestry research institute, Colombia

Correspondence: Toum Keopaseuth, Livestock Research Center, National agriculture and forestry research institute, Ministry of Agriculture and Forestry, PO Box 6644 Vientiane, Lao PDR, Colombia

Received: May 16, 2017 | Published: July 21, 2017

Citation: Keopaseuth T, Preston TR. Cassava (manihot esculenta cranz) foliage replacing brewer’s grains as protein supplement for yellow cattle fed a basal diet of cassava pulp-urea and rice straw. Int J Avian & Wildlife Biol. 2017;2(3):65-68. DOI: 10.15406/ijawb.2017.02.00018

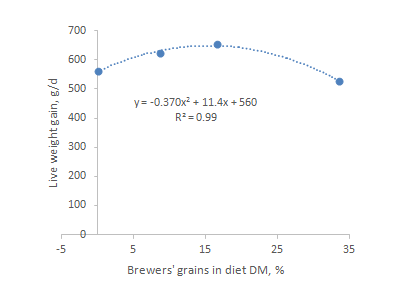

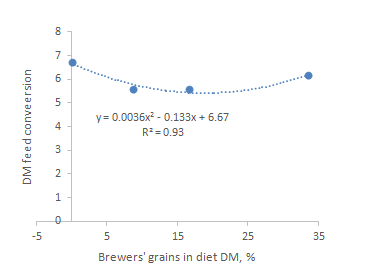

Twelve local “Yellow” cattle with initial weight from 114 to 117kg and 1.8 to 2 years of age were allocated in a completely randomized block design to 4 treatments and 3 replicates. The treatments (as supplements to ad libitum cassava pulp plus 3% urea on DM basis and rice straw 1% of LW) were: cassava foliage and brewers’ grains in the ratio 4:0, 3:1, 2:2 and 0:4 as % of live weight, fresh basis. The experiment was carried out for 120 days from February to July 2016. At the end of the trial, concentrations of methane and carbon dioxide were determined in eructed gas mixed with air in a closed chamber in which the animals were kept for 20 minutes prior to measurement of the gases. There was a quadratic relationship between the rate of live weight and the proportion of brewers’ grains in the diet DM, with the maximum growth rate being recorded when the brewers’ grains provided 15% of the diet DM. There was a similar relationship between level of brewers’ grains and DM feed conversion with the optimum value at about 17% of brewers’ grains in the diet DM. The ratio of methane to carbon dioxide in mixed eructed gas and air declined with a curvilinear trend as the fresh cassava foliage replaced brewers’ grains in the diet.

Keywords: cassava foliage, brewers grains, urea, rice straw, cassava pulp, yellow cattle

A recent development in Lao PDR is the industrial production of starch for export using cassava roots as the feedstock. There are presently 5 factories in operation with a yearly demand of 200,000 tones of cassava roots. The extracted starch accounts for some 60% of the root DM, the remainder being a byproduct known as cassava pulp. Recent research has demonstrated that the pulp has nutritive values only slightly less than that of the original cassava root1 and can be used as the basis of an intensive system of cattle fattening. The first demonstration of this system2 was based on the use of urea, brewers’ grains and rice straw as sources of the fermentable nitrogen, bypass protein and fiber needed to complement the cassava pulp which contains negligible quantities of protein (<3% in DM) and crude fiber (<10% in DM). However, farmer access to brewers’ grains is limited to the immediate area in which beer factories are found. Cassava production is rich in three part of Lao PDR, it can make many kind of foods for people and animal in fresh and dry, the cassava leaves is source of protein content according to many reports Cassava contains high protein (20–27% crude protein), 25% DM depend on age, residue of cassava factory we call cassava pulp were abandon cause pollution. Cassava pulp is source of carbohydrate feed of animals. Another source of bypass protein is cassava foliage.3‒6 Cassava foliage is available as a byproduct of root production or can be grown as a semi-perennial forage (Preston 2005). It has been fed successfully to improve performance of sheep,7 goats (Ho Quang Do et al 20018 and cattle5,9 in fresh, wilted or dried form. Cassava leaves are known to contain variable levels of condensed tannins; about 3% in DM according to10 and Bui Phan Thu Hang and Ledin (2005). Cassava also contains cyanogenic glucosides, mainly linamarin, which release hydrogen cyanide after hydrolysis in the rumen by an endogenous linamarase (Butler et al 1965). Methane production was inhibited in anaerobic biodigesters charged with cassava root waste because of the high sensitivity of methanogenic bacteria to cyanide (Eikmanns and Thauer 1984.11,12 Reduced production of methane was observed when cassava foliage was the protein source in an in vitro rumen fermentation of molasses-urea.13 The purpose of the present study was to determine the effect of cassava foliage as protein source replacing brewers’ grains in diets for growing cattle fed cassava pulp-urea and rice straw as the basal diet.

Location and duration

The experiment was conducted in the Livestock Research Center, 44 km from Vientiane city Lao PDR from December 2015 to May, 2016.

Treatments and experimental design

A completely randomized block design was used with 4 treatments and 3 replicates. The treatments as supplements to ad libitum cassava pulp (plus 3% urea on DM basis), rice straw at 1% of LW (fresh basis) and minerals were:

Animals and housing

Twelve male “Yellow” cattle, average age 1.5 years and initial weight 114-117 kg were purchased from farmers and housed in individual pens (Photo 1). They were treated for internal and external parasites with Ivomex-F and vaccinated against Foot and Mouth Disease.

Feeding management

Cassava foliage (sweet variety) was planted on an area of 2000 m2 in the Livestock Research Center. The foliage (leaves, petioles and stems) were harvested at 55 day intervals. With an expected yield of 2 kg fresh foliage/m2, an area of 15m2 was harvested daily increasing to 30m2/day by the end of the experiment. Brewers’ grains were purchased (about 3000 kg fresh basis) from the brewery and ensiled in polyethylene bags enclosed inside sacks of polypropylene (Photo 2). Cassava root pulp (about 5000 kg) was collected from the Indochina Tapioca factory and ensiled in the same way as the brewers’ grains. The cattle were adapted gradually to the experimental feeds beginning with ad libitum rice straw which was reduced gradually to 1 kg/head per day after 14 days with other components of the diet being increased gradually over the same period. A solution of urea (1 part urea; 3 parts water) was mixed with the cassava pulp at the rate of 6 g urea per 1 kg of ensiled pulp. The urea-supplemented pulp was fed ad libitum (expected intake was about 10 kg per 100 kg LW). The rice straw was given in two equal feeds (am and pm). Total requirements were 1500 kg which was procured at the beginning of the experiment.

Data collection and measurements

The cattle were weighed before feeding in the morning at the beginning of the experiment and at 14 day intervals. Feed offered and residues were recorded daily to determine feed intake. Chemical composition of feeds (DM, N, NDF, ash) was determined on representative samples of feed and feed refusals at 14 day intervals. The pH of the ensiled cassava pulp and ensiled brewers’ grains was recorded at weekly intervals.

Methane in eructed gases

After 90 days the cattle were confined individually in a gas-proof chamber (a bamboo frame covered with polyethylene) for sampling of eructed gases and residual air in the chamber. Measurements of the concentrations of methane and carbon dioxide were taken continuously over a 10 minute period, using a Gasmet infra-red meter (GASMET 4030; Gasmet Technologies Oy, Pulttitie 8A, FI-00880 Helsinki, Finland), following the procedure outlined by.14

Mean values for effects of supplementation on weight gain, feed intake and feed conversion were compared using the general linear model (GLM) option of the analysis of variance software in Minitab (2016). Sources of variation in the model were: treatments, replicates and error. Quadratic equations were fitted to the data to demonstrate trends in responses (y) for live-weight gain and feed conversion against dietary levels of brewers’ grains (x) and between methane: carbon dioxide ratio (y) and percent cassava foliage in the diet (x).

Growth and feed conversion

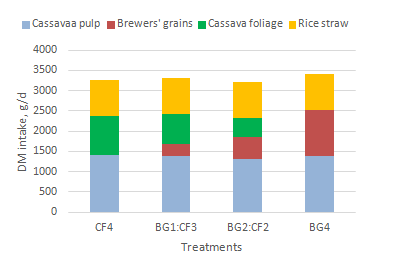

The 16.4% crude protein in the DM of the harvested cassava foliage (Table 1) was similar to the value of 17.3% reported by13 for cassava foliage fed to goats in Vietnam, and reflected the presence of petioles and young stems, along with the leaves, in the harvested foliage. Due to the lower content of crude protein in the cassava foliage (16.4% in DM) compared with the brewers’ grains (24.8% in DM), the overall level of crude protein in the diet DM increased from 9.90 to 13.0% as the level of brewers’ grains was increased (Table 2). However, despite these differences the overall DM intake was not affected by the changing ratio of cassava foliage to brewers’ grains (Table 3 & Figure 1). There was a quadratic relationship between the rate of live weight and the proportion of brewers’ grains in the diet DM, with the maximum growth rate being recorded when the brewers’ grains provided 15% of the diet DM, thereafter declining (Figure 2). There was a similar relationship between level of brewers’ grains and DM feed conversion with the optimum value at about 17% of brewers’ grains in the diet DM (Figure 3).

Figure 1 Effect of varying the offer levels of cassava foliage (CF) and brewers’ grains (BG) on the components of the diet DM consumed.

Cassava pulp |

Brewers' grains |

Cassava foliage |

Rice straw |

|

DM, % |

23.6 |

24.3 |

26.6 |

90.1 |

As % in DM |

- |

- |

- |

- |

Crude protein |

2.6 |

24.8 |

16.4 |

3.1 |

NDF |

34.8 |

32.8 |

42.8 |

67.8 |

ADF |

28.7 |

22.6 |

33.4 |

43.1 |

Ash |

4.48 |

6.3 |

9.7 |

13.6 |

Table 1 Chemical composition of diet ingredients.

Figure 2 Growth rates of “Yellow” cattle fed cassava pulp/urea and increasing amounts of brewers’ grains replacing fresh cassava foliage.

CF4 |

BG1:CF3 |

BG2:CF2 |

BG4 |

SEM |

p |

|

DM intake, g/d |

||||||

Cassava pulp |

1399 |

1393 |

1323 |

1379 |

52 |

0.99 |

Brewers’ grains |

0 |

287 |

534 |

1140 |

76 |

|

Cassava foliage |

987 |

748 |

467 |

0 |

37 |

|

Rice straw |

889 |

889 |

889 |

889 |

||

Total |

3275 |

3317 |

3213 |

3408 |

132 |

0.77 |

% in diet DM |

||||||

Crude protein |

9.94 |

10.8 |

11.4 |

13 |

||

Brewers’ grains |

0 |

8.7 |

16.6 |

33.5 |

||

Table 2 Mean values for feed intake, crude protein in the diet and relative proportions of brewers’ grains (BG) and cassava foliage (CF) in the diet of “Yellow” cattle fed ad libitum ensiled cassava pulp-urea with cassava foliage replacing ensiled brewers’ grains (1 kg/d of rice straw fed on all treatments).

Figure 3 DM feed conversion of “Yellow” cattle fed cassava pulp/urea and increasing amounts of brewers’ grains replacing fresh cassava foliage.

CF4 |

BG1:CF3 |

BG2:CF2 |

BG4 |

SEM |

p |

|

DM intake, g/d |

3275 |

3317 |

3213 |

3408 |

132 |

0.77 |

Live weight, kg |

||||||

Initial |

115 |

116 |

114 |

117 |

10.9 |

0.99 |

Final |

166 |

177 |

173 |

170 |

11.4 |

0.92 |

ADG, g/d |

528 |

654 |

625 |

563 |

105 |

0.83 |

DM conversion# |

6.74 |

5.59 |

5.58 |

6.16 |

1.06 |

0.84 |

Table 3 Mean values for feed intake, change in live weight and DM feed conversion for “Yellow” cattle fed ad libitum ensiled cassava pulp-urea with cassava foliage (CF) replacing ensiled brewers’ grains (BG) (1 kg/d of rice straw fed on all treatments).

# kg feed DM/kg live weight gain.

Methane: carbon dioxide ratio in eructed breath of the cattle

The ratio of methane to carbon dioxide (in the mixture of eructed gas and air in the plastic-enclosed chambers in which the cattle were confined individually over 10 minute periods) declined with a curvilinear trend as the fresh cassava foliage replaced brewers’ grains in the diet (Table 4 & Figure 4).

Cassava foliage, % in diet DM |

||||||

0 |

15 |

23 |

30 |

SEM |

P |

|

CH4:CO2 |

0.018a |

0.0049b |

0.003b |

0.002b |

0.001 |

<0.001 |

Table 4 Mean values for the ratio methane: carbon dioxide in mixed eructed gases: air from “Yellow” cattle fed cassava pulp/urea and increasing amounts of fresh cassava foliage replacing brewers’ grains.

ab Means without common letter in the same row differ at p<0.05.

The benefits from brewers’ grains, added to a cattle fattening diet based on cassava pulp-urea-cassava foliage, were first demonstrated by,16 when replacing 50% of the cassava foliage by brewers’ grains (DM basis) led to almost doubling of the growth rate. In terms of diet composition this represented concentrations in the diet DM of brewers’ grains of 20% and cassava foliage 20%. In the present experiment the optimum combination appeared to be of the order of 9% brewers’ grains and 23% of cassava foliage (in diet DM). The two experiments cannot be directly compared as in the research of 17 the cassava was a “bitter” variety whereas in our study the cassava was a ”sweet” variety. Phuong et al (2016, personal communication) reported major benefits in growth of cattle (from zero to 600 g/day) when brewers’ grains (at only 4% of the diet DM) were added to a similar diet of cassava pulp-urea-cassava foliage. In this case the cassava was a bitter variety. It was also observed that urinary excretion of thiocyanate was substantially reduced by supplementation with the brewers’ grains. These authors concluded that the benefits from the small amounts of brewers’ grains (4% of diet DM) possibly were due to a “prebiotic” effect of this supplement in reducing the sub-clinical toxicity caused by the cyanogenic glucosides in the cassava foliage .

Discussion as to the nature of the chemical entities in brewers’ grains that could be responsible for the apparent “prebiotic” action of this supplement is:

There was a quadratic relationship between the rate of live weight and the proportion of brewers’ grains in the diet DM, with the maximum growth rate being recorded when the brewers’ grains provided 15% of the diet DM, thereafter declining. There was a similar relationship between level of brewers’ grains and DM feed conversion with the optimum value at about 17% of brewers’ grains in the diet DM. The ratio of methane to carbon dioxide in mixed eructed gas and air declined with a curvilinear trend as the fresh cassava foliage replaced brewers’ grains in the diet.

This research was done by the senior author as part of the requirements for the MSc degree in Animal sciences "Improving Livelihood and Food Security of the people in Lower Mekong Basin through Climate Change Mitigation" The authors are grateful to the MEKARN II project, financed by Sida, Sweden for the support for this research. Livestock Research Center (NAFRI) was acknowledged for provision of research facilities. . I am very grateful to my supervisor Assoc. Prof. Dr. Preston, for his endless assistance, discussing and providing comments and suggestions to accomplish this thesis.

The author declares no conflict of interest.

©2017 Keopaseuth, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.