eISSN: 2576-4462

Short Communication Volume 5 Issue 4

1Campo Experimental Rosario Izapa, Instituto Nacional de Investigaciones Forestales, Agrícolas y Pecuarias, México

2Estudiante de Doctorado en Genética y Biología Molecular, Instituto de Biología, Universidad de Campiñas, Brasil

Correspondence: Víctor Hugo Díaz Fuentes, Campo Experimental Rosario Izapa, Instituto Nacional de Investigaciones Forestales, Agrícolas y Pecuarias. México. Kilómetro 18 carretera Tapachula-Cacahoatán, Tuxtla Chico, Chiapas, México, Tel 8000882222 ext. 86410

Received: December 16, 2020 | Published: November 4, 2021

Citation: Fuentes VHD, Hernández BGD. “Maravillas” agroforestry system: an alternative for sustainable soil management in tropical steeplands. Hort Int J. 2021;5(4):165-166. DOI: 10.15406/hij.2021.05.00224

Sprouting is one of the major problems in potatoes during storage. Many consumers refuse to eat potato with sprouts. For this reason, treatment with sprout suppressants is vital. Spearmint oil and Ethylene can be used to suppress sprouts. However, spearmint oil is expensive and Ethylene changes potato colour. CIPC is the best chemical in the market that can suppress sprouting effectively at a low cost. CIPC is toxic and dangerous for the environment. However, by wearing protective equipment and displaying relevant signs, the risk to ourselves and other people can be minimised. The risk to the environment can also be minimised by disposing the containers legally to a licensed disposal contractor and avoiding spillage. The case presented is that of a 2000 tonne store of potato in Hereford in the United Kingdom. A CIPC application has been carried out. The result is 99% control.

Keywords: sprout suppressants, CIPC, potato storage, ethylene, spearmint oil

FAOSTAT, the food and agriculture organization corporate statistical database; CIPC, chlorpropham

Potato is a very vital crop in the UK. Around 5,911,000 tonnes of potato have been produced in the country in 2014. The total area harvested of potato amounted for 141,000 ha in 2014.1 There are many problems that potatoes encounter as a result of storage. One of them is potato sprouting. After harvest and during storage, potato tuber starts initiating. Sprouting has many disadvantages as it decreases the marketability of potato and reduces its value and quality. Potatoes also lose weight and acrylamide level is higher in potatoes that have sprouted. Sugar content also will be reduced.2 This will have a tragic impact on farmers after all their hard work. Many factors affect tuber initiation. One of these is temperature as sprouting increases by increasing temperature. Humidity is another important factor that has a similar effect. Other factors include light, darkness decreases sprouting. Moreover, the period of storage has a major impact as sprouting increases with a longer storage period.3 At 3.3 Co, potato stays without sprouting for a long period. At 4.4 Degrees Celsius, eyes will start immerging but with no sprouts. At 5.5 Co, sprouts will be seen but only after a few months. Thus, when temperature is higher, tuber initiation increases.4

These reductions in weight loss have been a result of a combination of improvements in the stores used and improvements in chemical and non-chemical control measures. Sprouting is one of the main problems in potato storage and can contribute to the majority of weight losses. Refrigeration is widely considered as the main form of cultural control; however, this process has drawbacks. By reducing temperatures within the store, sugar level rises.7 Burton (1969) stated that refrigerating potato between 4 and 5 Co has many benefits, such as reducing sprouting. There are disadvantages to refrigerating such as the high cost.6 Furthermore, storing potato in cold temperature increases sweeting. Sweeting causes an increase in acrylamide content and, as a result, potato colour will turn to brown during frying and have a bad taste.8

CIPCCOMPLIANT9 argues that in order for the quality of potato not to be reduced during frying, potato should be stored at between 6 and 13°C. For this reason, there should be a chemical that should be used to stop tuber initiation.

One of the major chemicals that is used in the United Kingdom to suppress tuber initiation is CIPC (Chlorpropham). CIPC is a carbamate chemical that was first introduced as an herbicide.9 The mode of action of a CIPC formulated product is that the active ingredient stops cells from dividing. By doing so, sprouting is reduced significantly.9 By taking CIPC off the pesticide market, farmers will be left with little options to select, as CIPC is used in 1/2 of potato storage in the UK.9 One of the problems in chlorpropham use is that it leaves a residue on potatoes.

Another product that could be used to stop sprouting is spearmint oil, which is an organic product.10 Spearmint oil organic status depends on the solvents used with it as well as the inert materials. If it is extracted by physical means then it is organic. Spearmint oil use is very limited due to its high cost.10 That is why it is needed to produce spearmint oil in more efficient ways, such as by the use of cell farming technology, which will reduce the production cost of this material.

Another substance that could be used is ethylene gas. Ethylene gas is found to be effective in stopping tuber initiation. Ethylene gas leaves no residue on the potato, which give it an advantage over CIPC. However, ethylene darkens potatoes’ colour, making them less desirable to consumers.11 The mode of action of ethylene is that it replaces O2 in the store atmosphere and as a result, the potato breathing decline.12 Ethylene has low toxicity to people and animals.12 Ethylene is also highly flammable.13

It can be concluded from this discussion that using several methods at the same time could have a better result. However,11 argues against this theory as when they applied both ethylene and CIPC together the ethylene caused potato colour changing in all applications.

There are other tuber initiation suppressants that are used in other counties that have lower residual effects compared to CIPC such as 1.4-Dimethylnapthalene and 3-decen-2-one. They have both been registered in the US and used to suppress sprouting. However, the active ingredient 3-decen-2-one has not been approved in the European Union yet.14 Overall, there is no one magic solution to suppress sprouting. A combination of using cultural and chemical control measures with different active could be beneficial.

This project aims at analysing the most suitable sprouting suppressants that could be used to protect potatoes from initiation during storage. Both the advantages and disadvantages of using a particular treatment were looked at, taken into consideration many factors such as the toxicity and eco-toxicity profile for each method, as well as residues in potatoes. The case presented is that of a 2000 tonne store of potato in Hereford in the United Kingdom. A CIPC application has been carried out. The potatoes lost quality during storage after harvest, water and nutrients supply are stopped from the potato plant. The advancement in refrigerated storage has improved the quality of potato stored as respiration is reduced.15,16 estimates that the use of CIPC reduces costing as a result of tuber initiation inhibition.16,17 suggested that S-carvone that has been extracted from caraway seeds has a great impact of reducing tuber initiation.

Cultural (non-chemical control measures)

Refrigeration

In the UK, using joint ambient cooling devices and refrigeration in potato storage is common.18 Storing potato at a low degree reduces sprouting.6 There are many disadvantages of using air cooling systems during storage as the sugar content will increase and potato will have sweeter taste due to the high level of fructose and glucose.19 People do not prefer eating such potatoes, which is why it is best to store potatoes between 8 and 12 °C.19

When potatoes are kept between 2 and 4 °C, they turn brown. This colour change is less desirable for consumers.20 states that potato stored at low temperature are unacceptable for the shoppers.

Variety choice

Choosing the right potato variety is one of the cultural (non-chemical) controls for sprouting. Varieties vary in their dormancy period. Some varieties have a very short dormancy period and some have a longer dormancy period. Both of these categories are not suitable for sprouting control. There are varieties that have a medium dormancy period and are thus suitable for a medium period of storage. Farmers can select varieties that have long and very long dormancy period to avoid sprouting during storage. Varieties that have a very long dormancy period are Eurostar, Gourmandine and Leonata.4 Eurostar and Leonata are suitable for French fry and Gourmandine is suitable for salad.4 However, there are other important factors that farmer’s need to take into account before choosing the right varieties, such as resistance to pests like potato cyst nematode, or resistance to diseases such as late blights and common scab as well as resistance to physical damage such as splitting.4 Some farmers also choose potatoes based on the contract with the distributor. In this study, the store manager chose half of his supply as potato Royal as he supplies McCain, who want this potato variety. The other half is Desiree; therefore, chemical control is needed to stop spurting.

The advantages of current non-chemical control measures

Non-chemical control measures have many advantages. One of them is there will be no impact on human or animal health. Non-chemical control measures also have zero impact on the environment and they leave no residues on crops or the environment.

The disadvantages of current non-chemical control measures

In case of refrigeration, sugar content will increase and potato will have a brown colour.19 Refrigeration can be expensive. Therefore, choosing the right variety that has long dormancy is not an easy step, as the choice is subject to several other factors.

Chemical control

Synonyms

CIPC

Chemical name: Isopropyl (3-chlorophenyl) carbamate

Structural formula

CAS no: 101-21-3

Physical state of the formulated product: liquid

CIPC is a tuber initiation inhibitor. It is a liquid formulation that is applied into potato during storage by hot fogging machines.9 The mode of action of CIPC is it causes the cells to stop multiplying.9 CIPC was first registered as a herbicide.21 CIPC efficacy increases by increasing the temperature above 15 Co.22

CIPC rate of use

PRO-LONG is a UK approved tuber initiation inhibitor. It is a liquid formulation that is used in thermal fogging machines. It contains 500 g/l of the active ingredient CIPC. The application rate of CIPC is 12g of CIPC active ingredient / tonne for each application. The total amount needed for all applications is 36 g CIPC active ingredient / tonne.9 The product is toxic to humans, and it is dangerous for the environment in case of spillage and it is also highly flammable. For this reason, special safety equipment should be worn during handling and application. The maximum residue level for CIPC is 10 parts per million, that is why it is important to allow 14 days for the residue to be cleared after the last application.9 When applying the product, it is vital to wear a respiratory mask type (EN 140) with a filter to avoid inhaling the product.23 It is also vita to wear overalls, pesticide special safety boots as well as gloves, hood and goggles.23 Normally full-face masks can provide better protection and there is no need to wear goggles as a face shield is provided with the full-face mask.23

Applying CIPC requires air circulation. Using fans would be ideal to circulate the fog generated. When applying in highly equipped storage, it is required to switch on the air ventilation system. Ventilation should be turned on from the beginning of fogging until the fog disappears from the store.

Instruction

When building new potato stores, it is necessary to include built-in positive ventilation.9Any agrochemical application to potatoes during storage is the responsibility of the owner of the potato. No random person is allowed to apply CIPC. CIPC operator should have NPTC PA1 and PA9 qualification and must be an NAAC member. The person who recommends using CIPC should be a BASIS qualified agronomist.9 Before any CIPC application, the store must be inspected. The inspection is to make sure that the store is suitable for CIPC. The inspection is done under the Red Tractor Farm Assurance Scheme. It is to make sure that fogging can be circulated without any problems in the store. All CIPC equipment needs to be inspected each year. The inspection is done by the NSTS and it is required to make sure that there is no leakage or any fault in the machines used, as any fault could have a detrimental impact on the efficacy of the chemical as well as human health.7 The label must be read carefully before use and the Material Safety Data Sheet must be looked at to have a wider picture about the use implication. If the MSDS for Fog 300 is being looked at, it is apparent that it is an irritant to the skin. Special gloves should be worn to avoid skin contact. It is also harmful if swallowed, and children must be kept away from it. As the application is through thermal fogging, fog will be generated and that is why respiratory mask should be worn. Fog 300 is also toxic to the environment so fogging operators should be careful and avoid spillage. In case of spillage, the spillage kit must be used. It contains the absorbent that absorbs the chemical. It is also necessary to avoid throwing the container away irresponsibly or throwing the remains of the chemical in the field. After finishing the job, containers should not be thrown away or recycled with normally household wastes. They must be recycled according to local regulation with an approved pesticide licensed recycling contractor.29

Advantages of CIPC

Disadvantages of CIPC

One of the problems that could happen during fogging is flames, especially if there is leakage or fault. Some chemicals tend to be more flammable than others. Flames can reach 1 to 2 meters. It is important to have a fire extinguisher during fogging to avoid a fire risk. Figure 1 below shows how flame can happen during CIPC application.

Spearmint oil

Spearmint oil can be used as a sprout suppressant. Spearmint oil was first introduced in the UK in 2012 when BIOX–M received approval from the HSE.34 The approval is valid until 2022. BIOX–M is a liquid formulation and contains 100% spearmint oil. It is formulated for use in fogging machines. The rate of use is 90 ml per tonne per application. Total allowed amount is 360 ml per tonne.34

Advantages of spearmint oil

Disadvantages of spearmint oil

Only trained operators can apply ethylene.30 To apply ethylene, special devices must be installed. This is done by the supplier of Ethylene (Bio-fresh)31 or Restrain.32 A respiratory mask must be used by operators during application. The type of mask is EN137, EN139, and EN270. Operators must wear gloves and eye protection googles.

As can be seen in Figure 2A Ethylene can be provided in cylinders. Ethylene cylinders must be installed outside the store. These should then be connected to the Ethylene management device. Then it should be linked to the circulation fan and the store to release ethylene. After the device has been installed, it should be turned on and an accurate amount of ethylene will be released. Figure 2B shows Restrain ethylene generator, which uses ethylene fuel and must be filled with a faunal to ensure it releases ethylene at a steady rate.

Advantages of ethylene

Ethylene has low toxicity to people and animals.12

Disadvantages of ethylene

The advantages of current chemical control measures

An effective sprout inhibition can be achieved by using the current chemical control procedures.

The disadvantages of current chemical control measures

Chemical control measures have many disadvantages including that some of them have an impact on human’s health and animals. Some also have a negative impact on the environment. Moreover, some are toxic to birds, aquatic fauna, plants and beneficial insects and leave residues on crops and the environment.

This study was conducted at Flag Station Farm at 8:30 am on the 17th of November2017.Flag station farm is located in Yazor, Herefordshire. Post code HR4 7HN.A GIS map was created in DIVA GIS to illustrate the study area (Figure 3).

As can be seen in Figure 4, the location of the study area is in the countryside and away from people, so applying CIPC is safe.

As can be seen in Figure 5, the location of the study area has a sign, which indicates there is a potential hazard in case of spraying pesticide.

Figure 6 confirms the potato store is away from houses and there are no people living in the area. This is important in case there is pesticide fogging so that the fog will not enter people houses and cause health problems.

The store capacity is 2000 tonnes of potato. It is a modern and well-designed store. When fogging, the store was ¾ full so it contains 1500 tonnes of potato.

Figure 7 a picture of the store from outside showing the CIPC thermal fogger in operation (Author's own work, 2017).

Figure 7 A picture of the store from outside showing the CIPC thermal fogger in operation (Author's own work, 2017).

Before starting fogging, there are important steps that need be taken to avoid any risk to people and the environment. A warning sign must be placed in the entrance of the farm to warn people that fogging is in operation so they will be alerted not to come closer due to the health risk they could have. The sign should be made from steel or other metals. It should be heavy so it will not move by the wind. The words should be clear with no mud on the sign (Figure 8).

During fogging, it is important to wear the recommended safety equipment before application. Safety equipment list are found in section 8 of the Material Safety Data Sheet of a pesticide. One of the most important safety equipment that must be put on is the safety mask during pesticide application. In the case of CIPC, it is important to wear a full-face mask. The researchers tried many types and think the Moldex full-face mask is among the best available (Figure 9). It is comfortable while wearing. Some of poor quality masks when wearing may blocks the blood vessels, as they are very tight on the head and the materials are harsh on the face. Therefore, Moldex was our choice.

Figure 9 A full-face mask that is suitable for CIPC thermal fogging during operation (Author's own work, 2017).

It is important to choose the right filter to go with the full-face mask, and to replace the filters according to manufactures recommendations. There is an expiry date on the filters, which depends on the time length it was used. It is recommended to change them regularly. The most suitable filters for CIPC is type ABEK1P3 in the case of Moldex (Figure 10).

Figure 10 A mask filter suitable for CIPC thermal fogging during operation (Author's own work, 2017).

Another important protective item that should be worn during CIPC application is Nitrile gloves. It is important to make sure the gloves are chemical-resistant. It is important to check there are no holes or any wear in the gloves and they are the right size. In case you need to itch your eyes during application, it is important not to do so and to wait until the application is completed. Then you should take the gloves off and wash your hand before touching your face. Itchy face and eyes is common when wearing masks for a long time as sweeting is increased (Figure 11).

Safety boots should also be worn during application. It can be noted that wellington boots are suitable for such application as they are easy to clean after and reduce pesticide exposer. It is also important to have them with metal caps to protect your toes in case some heavy equipment fall on them. Figure 12 shows safety boots recommended for CIPC thermal fogging.

Equally, suitable overalls should be worn to avoid skin contact. It is important to have clean overall and wash them after each application. There are disposable overall on the market for one single use, however, it is better to buy a normal one and wash them (Figure 13).

It is also important to wear a High Visibility Vest above the overall so other people could see you from a distance and pay attention (Figure 14).

It should be noted that not everything on the CIPC label says everything about the safety equipment. Risks should be examined by the operator to decide the best way to protect other people, the environment, and ourselves. For example, it is important to wear ear protection during thermal fogging (Figure 15). Ear protection was not mentioned on the CIPC label. However, the fogger is very noisy.

After donning all safety equipment, then installing the fogger could be started and then fogging can be started. In the side of the store there is a little hole for fogging, which needed opening (Figure 16).

Once the hole is opened, it is needed to attach the fogging pipe to the machine to the store’s fogging hole (Figure 17).

The make of the thermal fogging machine used in this study was the SAM Unifog thermal fogger (Figure 18).

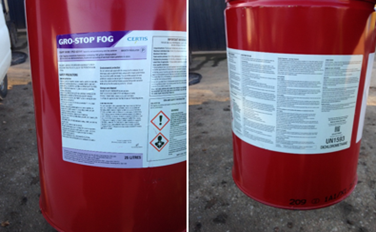

The pesticide active ingredient used in this case is Chlorpropham or CIPC. The trade name is GRO-Stop fog and it is supplied by Certis (Figure 19). The container contains 25L of concentrated CIPC in a liquid format. It is common in pesticides to mix them before use. However, CIPC is used without mixing or dilution.

The chose fogging machine works by petrol. The machine produces fog by introducing petrol to the hot surface of the internal fogging. The chemical is introduced to the same surface but closer to the exit of the fogging pipe and that is how the fog carries the active ingredient. It is also advisable to use a fogging enhancer to enhance producing fog. Before starting fogging, it is important to look at the MAPP number on the HSE pesticide database (https://secure.pesticides.gov.uk/pestreg/ProdList.asp). The MAPP can be found on the pesticide label (Figure 20). It is 14183 in this case. The MAPP number was checked and the registration is still valid. Product expiry date is 31/07/2019, after which, if the product is withdrawn, the industry might struggle as spearmint oil is expensive.

Figure 16 Fogging hole in the store from outside for CIPC thermal fogging (Author's own work, 2017).

Figure 18 Sam thermal fogging machine used for CIPC thermal fogging in potato (Author's own work, 2017).

Figure 19 CIPC container for thermal fogging in potato used in this study (Author's own work, 2017).

The next stage is to read the label carefully and apply the right dose. In this application, 12 g of active ingredient /tonne was used. It is a single application and compliant with the cipccompliant regulations.9 For 12 g active ingredient /tonne, the rate is 40 ml CIPC /tonne. For 1500 tonnes, 60 litres are needed, which equates to around 2x 25 containers plus 10L. The time of application is 45 min to 1 hour. After making sure the pipes are connected, it is needed to open the pesticide container and place it in the area provided in the thermal fogger. It is important to insert the pesticide pipes inside the container to allow CIPC to run through the machine (Figure 21).

Figure 21 Connecting the 25L CIPC container for potato thermal fogging to the thermal fogger (Author's own work, 2017).

The next step was to make sure the machine had enough petrol, and then it was turned on. The machine will start producing fog immediately so it is just needed to wait and monitor the machine until it was completed and to replace the pesticide container once finished. It is necessary not to enter the store during fogging and after fogging for a period of 24 hours. The potatoes have to wait 14days before they could be taken to the market. This period is called the post-harvest interval. The reason for this is that the CIPC needs 14 days to be cleared from potato to ensure it does not exceed the Maximum Residue Levels (MRLs). This PHI period is published by CIPCCOMPLIANT (2017). The MRLs for CIPC is 10mg/kg.7 It is also very important to keep the ventilation on after application to recycle the fog, as the fog will stay in the higher part of the store and it is important to circulate it. Ventilation after CIPC application can take several hours. The result is 99% control.

It is vital to keep potatoes 14 days before marketing them to avoid having residue of CIPC in the potatoes. MRL must not exceed 10mg of CIPC /kg of potatoes. However, it seems CIPC is being taken off the market in a few years. 3-Decen-2-One could be an alternative, although it is still under evaluation for approval. It is not easy to change, but the future of potato storage may need help via genetics and plant breeding.

None.

The authors declare that they have no conflict of interest.

©2021 Fuentes, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.