eISSN: 2576-4462

Research Article Volume 7 Issue 4

1Department of Food Science and Technology, Nnamdi Azikiwe University, Nigeria

2Department of Food Science and Technology, Delta State University of Science and Technology, Nigeria

Correspondence: Ernest Eguono Emojorho, Department of Food Science and Technology, Delta State University of Science and Technology, Ozoro, Delta State, Nigeria

Received: December 01, 2023 | Published: December 12, 2023

Citation: Anene MN, Emojorho EE, Chiedu UC, et al. Chemical functional physical and sensory properties of flour and idli produced from blends of rice (Oryza sativa), african yam bean (Sphenostylis sternocarpa) and pigeon pea (Cajanus cajan). Horticult Int J. 2023;7(4):149-157. DOI: 10.15406/hij.2023.07.00289

This study looked at the idli's chemical, functional, physical, and sensory properties when prepared with rice, pigeon peas, and African yam beans. Dhals were made by washing, soaking whole pigeon pea and African yam bean (AYB) seeds in hot water (80°C for 30 minutes), hand-dehulling, and sun-drying them. For the processed dhals, black gram dhals (control), separate water was used to rinse and soak the rice for 5 hours at room temperature (29.2°C). The dhals were wet-milled into a smooth batter separately from the rice, which was crushed to a coarse batter. Rice was combined 2:1 with dhals. The batters were combined, one gram of table salt was added, and the mixture was allowed to sit at room temperature (29.2°C) for 14 hours to ferment. Idli are created by pouring fermenting batter into molds shaped like cups and heating them for 15 minutes. The idli was analyzed for chemical, functional, physical and sensory properties following standard analytical procedure. The flour's protein content spanned the range of 7.88 to 26.27%. the carbohydrate content from 56.00 to 77.39%, and the ash content varied from 0.50 to 2.50% and 1.00 to 3.50%, respectively. Functional properties of the flours include bulk densities between 0.66 and 0.76 g/ml, swelling rates between 149.30 and 219.20%, and foaming rates between 7.69 and 34.62%. The moisture level of the idli samples varied from 63.00 to 68.50%, the protein content was between 4.31 and 6.79%, the fat content was between 0.10 and 2.50%, the ash content was between 0.50 and 2.00%, and the carbohydrate content was between 23.94 and 29.34%. The batter volume was from 109 to 122 ml, the texture was between 9.03 and 10.26 mm, the cooked weight was between 40.31 and 49.91 g, the cooking time was between 7.03 and 14.00 min, and the rise's diameter was between 7.16 and 7.70 cm. The idli samples all received favorable sensory evaluations with improved nutritional value. The idli samples were adjudged acceptable sensory-wise by the panelists.

Keywords: Idli, rice, Africa yam bean, pigeon pea, chemical, functional

Cereal-legume based foods are one of the primary sources of accessible dietary energy and minerals worldwide.1 Rice is one cereal grain that significantly influences human nutrition. Rice has high levels of cysteine and methionine but minimal quantities of several important amino acids, such as lysine.2 Rice cannot supply all the nutrients needed for a balanced diet on its own. Pulses, which are dietary supplements to a rice-based diet and include beans, black gram, pigeon pea, soy bean, African yam bean, groundnuts, and lentils, complete the amino acid profile. To put it another way, rice-based dishes like masa, dosa, dhokla, and idli, among others, are made from a combination of rice and other legumes.3 Idli is one of the cereal-legume based cuisines of India and is consumed three to four times a week for breakfast and dinner. It is a fermented steamed food that is unique to India and Sri Lanka. Idli is typically made with rice (Oryza sativa), a cereal, and black gram (Phaseolus mungo), a legume.4 Idli is a food that naturally ferments; hence it is frequently fermented without the use of inoculum. This is owing to the fact that the required microorganisms, including yeast and lactic acid bacteria, can be found naturally in the materials.5 Leuconostoc mesenteroides, Lactobacillus delbrueckii, Streptococcus faecalis, and Pediococus cerivisiae are a few examples of lactic acid bacteria. African yam beans are a locally underutilized legume,6 despite not being widely consumed in Nigeria. It is widely acknowledged to have an exceptional amount of protein and most of the essential amino acids, including lysine and leucine. Pigeon peas, on the other hand, are a great source of carbohydrates, proteins, and vitamins. However, pulses like African yam bean (Sphenostylis stenocarpa) and Pigeon pea (Cajanus cajan), which are locally available and underutilized grain legumes in Nigeria,7 can replace black gram in the production of idli due to their high nutritional values such as protein, carbohydrates, vitamins, and minerals. From the foregoing, it is imperative to look for high-quality protein sources, like pigeon peas and African yams.

Sources of raw materials: Pigeon pea and African yam bean grains were procured from Ogige market, Nsukka, Enugu State, Rice (Faro 44, Faro 52A and Faro 52B) was purchased from Abakiliki, Nigeria, and black gram (dhals) was purchased from Roban stores Enugu State, Nigeria.

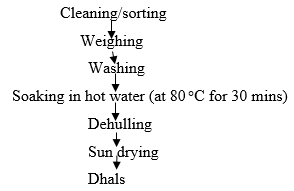

Preparation of pigeon pea and African yam bean (AYB) dhals: A Ohauz Adventurer Corporation Model AR2130 scale was used to weigh African yam bean and pigeon pea grain after been sorted, and cleaned up. The seeds of the pigeon pea and African yam beans were soaked in boiling water at 80°C water for 30 minutes. After which, the hulls were painstakingly removed to make dhals with a motar and pestle. The dhals were airtight-jarred after being sun-dried and stored. The process flow chart for making dhals out of pigeon peas and African yam beans (AYB) is shown in Figure 1.

Figure 1 Processing of pigeon pea and African yam bean seeds into dhals.8

Preparation of idli: Idlis were prepared with rice/black gram (control), rice/African yam bean, and rice/pigeon pea dhals, each having a ratio of 200 g of rice to 100 g of the grain legumes. R1, R2, and R3 were assigned to Faro 44, 52A, and 52B, respectively. The processed dhals and rice were weighed using an Ohauz Adventurer Corporation Model AR2130 after being cleansed to eliminate any adhering debris or dust particles. Rice was then soaked for five hours at ambient temperature (29.1°C) in 300 ml of water, while grain legumes were immersed separately in 150 ml of water. Pigeon pea seeds/African yam bean seeds.

The rice, black gram, African yam bean, and pigeon pea dhals were all ground separately in a hygienic atmosphere using a home blender. During milling, water additions ranging from 1.5 to 2.2 times the rice and dhals' initial dry weight were made. The dhals were pounded into a finely smooth batter while the rice was then ground into a coarse batter. Each grain and legume were mixed with the rice batter. After receiving 1g of table salt, the batters were combined. Then let the batters ferment for 14 hours at 29.1 oC in a bowl that was covered. The pH, titratable acidity, and increase in batter volume were evaluated before and after fermentation. Equal amounts of batter samples were taken, placed in idli moulds stacked one on top of the other, and steamed for 7 to 15 minutes in an idli pot. The idli pans/moulds were then oiled. Figure 2 depicts the production flow chart for idlis. Source9

Description of idli steaming pot: The idli pot was modified and constructed in accordance with the standard idli pot, which consists of a chamber resembling a pot with a perforated cylindrical base and four moulds with cup-shaped depressions placed one on top of the other. Typically, the idli batter is put into the depressions that resemble cups, and they steam for 15 minutes. Figure 3 depicts the steaming pot for idlis. Figures 4-6 show images of the black gram, African yam bean, and pigeon pea, respectively. In Figure 7, matured black gram idlis were displayed.

Analytical methods: The bulk density and foaming capacity were determined.10 The “water absorb capacity” was assessed using a modified version of.11 methodology. Utilizing the techniques outlined,12 the volume of batter was calculated. The swelling power was determined.13 A Venier caliper that had been calibrated was used to measure the diameter of the formed idlis. Ohauz Adventurer Corporation Model AR2130 digital weighing balance was used to measure the cooked weights of the developed idlis. Using a stopwatch Joerex digital timer no-4511-2, the cooking duration of the idli samples was calculated. Using the.14 method, the following values were determined: moisture content, ash, crude protein, fiber, and fat. Carbohydrate content was determined by difference method.

Sensory Evaluation: The created idli samples were coded and given to a 20-person panel from the University of Nigeria, Nsukka's department of Food Science and Technology for sensory evaluation. As illustrated in Figures 8 and 9, the formulated Idli samples were delivered both alone (without accompaniments) and with accompaniments.

Statistical Analysis: It was done using the completely randomized design (CRD). The statistical package for social sciences (SPSS) version 20.0 software was used to analyze the data using a one-way analysis of variance (ANOVA). Mean separation was by Duncan’s New Multiple Range test (DMRT). Significance was accepted at p < 0.05.

Experimental Design: The three different rice varieties Faro 44, 52A, and 52B were mixed with the three different legume dhals (African yam bean, pigeon pea, and black gram). The proportion of cereal to legume was 2:1. The analysis was completed using the experimental design shown below. (Table 1)

|

Cereal (Rice) |

Legumes (dhals) |

Blend ratio (g) |

Sample code |

|

Faro 44(R1) |

African yam bean |

200:100 |

AR1 |

|

Pigeon pea |

200:100 |

PR1 |

|

|

Black gram |

200:100 |

BR1 |

|

|

Faro 52A(R2) |

African yam bean |

200:100 |

AR2 |

|

Pigeon pea |

200:100 |

PR2 |

|

|

Black gram |

200:100 |

BR2 |

|

|

Faro 52B(R3) |

African yam bean |

200:100 |

AR3 |

|

Pigeon pea |

200:100 |

PR3 |

|

|

Black gram |

200:100 |

BR3 |

Table 1 Design of experiment for blends of different rice cultivars, pigeon pea, african yam bean and black gram

Proximate composition of rice, african yam bean, pigeon pea and black gram flours

The approximate proximate content of flours prepared from rice, African yam beans, pigeon peas, and black gram is shown in Table 2. The flours' moisture levels ranged from 10.46 to 12.60%. Faro 44 had the highest at 12.60 %, which was higher than 10.69 % and 11.77% observed for Faro 52A and Faro 52B respectively. There were statistically significant differences between the flours in terms of moisture content (p<0.05). With these moisture values, it is anticipated that the flours will store well and be safe from bacterial action and mold growth.15. These moisture content variations may be the result of varietal differences. The obtained moisture content values are thus low enough for the items, if packaged, to maintain proper shelf stability. All of the sample flours' protein levels varied considerably (p<0.05) and ranged from 7.88 to 26.27%. The protein level of Faro 52B rice (9.85%) was lower than Faro 52A (8.93 %) and 7.88 % of Faro 44. Varietal variances may be the cause of these variations in protein concentration. Faro 52A protein contrasted favorably with the protein value of 8.35% as reported by previous investigator,16 while Faro 44 protein had higher value than (4.60%) as reported by.16 According to Adewale BD, et al.,17 African yam beans were observed to contain between 24 and 28% protein. The samples of flour had a crude fiber level that ranged from 1.49 to 3.00 %. Pigeon peas had the highest crude fiber content (3.00 %) while Faro 52A rice had the lowest (1.49 %). Crude fiber content of Faro 44 (1.86 %) was higher than 1.50 % recorded for Faro 52B. These rice flours' crude fiber contents were within the range (1.50 to 2.00 %) found in.2 results. These differences in crude fiber content could be caused by varietal differences. Additionally, the fat content of black gram flour's was similar to (1.4%) reported.18 While Faris DG, et al.19 findings can be used to compare the fat content of pigeon pea flour. According to Ihekoronye AI,15 the majority of legumes, including pigeon pea, have less than 3% fat content. The range of the ash content of the constituent flours was 1.00 to 3.50%. Black gram flour was discovered to have the greatest value of 3.5%, while Faro 44 and 52A rice flours had the lowest value of ash (1.00 %). Pigeon pea, African yam bean, and Faro 44 and 52A did not vary significantly (p > 0.05). The fat contents found in the rice flours were comparable to.2 findings of 1.00 to 2.00%. The value of 2.2% that was20 reported as the ash content of AYB might be used to compare the two. The fact that black gram has such a high ash level indicates that its mineral richness is higher than other grains'. As a result, the samples' low ash concentration may have resulted from processing steps such drying, dehulling, and grinding.15 The flours' varying carbohydrate levels, which were between 56.00 and 77.39 %. Differences that were significant (p<0.05) were seen. Faro 52A had the highest carbohydrate content (77.39 %) while Faro 44 and Faro 52B had lower value of 76.16% and 74.88 % respectively.

|

Sample flours |

Moisture (%) |

Protein (%) |

Crude fibre (%) |

Fat (%) |

Ash (%) |

Carbohydrate (%) |

|

Faro 44 |

12.60f±0.02 |

7.88a±0.03 |

1.86c±0.04 |

0.50a±0.06 |

1.00a±0.01 |

76.16e±0.06 |

|

Faro52A |

10.69b±0.04 |

8.93b±0.02 |

1.49a±0.02 |

0.50a±0.10 |

1.00a±0.10 |

77.39f±0.03 |

|

Faro52B |

11.77d±0.01 |

9.85c±0.02 |

1.50a±0.02 |

0.50a±0.04 |

1.50b±0.02 |

74.88d±0.03 |

|

Pigeon pea |

11.23c±0.05 |

23.14e±0.05 |

3.00e±0.01 |

1.01b±0.01 |

2.00c±0.05 |

69.63c±0.01 |

|

African yam bean |

10.46a±0.03 |

26.27f±0.01 |

2.77d±0.02 |

2.50c ±0.04 |

2.00 c±0.01 |

56.00a±0.05 |

|

Black gram |

12.00e±0.02 |

19.72d±0.05 |

1.60b±0.05 |

1.00b±0.03 |

3.50d±0.10 |

62.18b±0.01 |

Table 2 Proximate composition of different rice cultivars, pigeon pea, african yam bean and black gram flours

Values are means ± SD (n = 3). Samples with the same superscript in a column are not significantly different (p > 0.05)

Functional properties of rice, pigeon pea, african yam bean and black gram flours

The results of the functional qualities of the flours from different types of rice, pigeon pea, African yam bean, and black gram are shown in Table 3. The flour samples' bulk densities ranged from 0.66 to 0.76 g/ml. Rice flours had the highest bulk density (0.76 g/ml), followed by that of pigeon pea flour (0.74 g/ml), and that of African yam bean flour (0.66 g/ml) was the lowest. The bulk densities for rice flours were similar to.21 results which ranged from 0.511 to 0.878 g/cm3 for defatted and undefatted debittered orange seed flours. When compared to the result (0.67 g/ml) achieved by Ojukwu M, et al.,22 the African yam bean flour performed well. The results of bulk density for pigeon pea flour (0.74g/ml) were better than the results for wheat flour (0.71g/ml) reported by Akubor PI, et al.23

|

Samples |

Bulk density (g/ml) |

Water absorption capacity (%) |

Swelling power (%) |

Foaming capacity (%) |

|

Faro 44 |

0.76c±0.00 |

134.10a±0.15 |

149.30a±1.43 |

7.69a±2.00 |

|

Faro 52A |

0.76c±0.00 |

157.20b±0.12 |

182.00c±0.23 |

9.80b±0.03 |

|

Faro52B |

0.76c±0.00 |

157.90b±1.00 |

164.00b±1.50 |

7.84a±0.20 |

|

Pigeon pea |

0.74c±0.01 |

180.90c±0.05 |

219.20e±2.00 |

30.77d±0.50 |

|

African yam bean |

0.66a±0.01 |

222.20d±2.00 |

197.40d±1.00 |

23.08c±1.00 |

|

Black gram |

0.71b±0.02 |

262.00e±0.20 |

216.90e±1.70 |

34.62e±1.00 |

Table 3 Functional properties of flours from different rice cultivars, pigeon pea, african yam bean and black gram

Values are means ± SD (n = 3). Samples with the same superscript in a column are not significantly different (p > 0.05).

These flours had water absorption capabilities ranging from 134.10 to 260.00%. Faro 44 had the lowest result (134.00%), and the black gram flour sample had the greatest value (262.00%). Differences that were significant (p 0.05) were seen. The differences in water absorption of the samples under consideration is more of genetic make-up of the grains from which the flour was prepared.

Pigeon peas had a water absorption capacity that was comparable to the 188% and 189% values reported for them and cowpeas, respectively, by Arawande JO, et al.24 The range of the flours' foaming capabilities was 7.69 to 34.62%. Differences that were significant (p<0.05) were seen. The greatest amount of foam capacity was recorded in black gram flour (34.62%), followed by pigeon pea flour (30.77%), and Faro 44 rice flour had the lowest observed foam capacity (7.69%).

The proximate composition of idlis from blends of rice, pigeon pea, african yam bean and black gram

Table 4 details the proximate composition of freshly prepared idlis prepared from mixtures of rice, pigeon pea, African yam bean, and black gram. The idlis' moisture content rose from 63.00 to 68.50%. The control idli black gram/Faro 52B (BR3) had the lowest moisture content (63.00%), followed by the African yam bean/Faro 52B idli (AR3) and pigeon pea/Faro 52B idli (PR3). These high moisture contents could be as a result of soaking, the amount of water added to the batter during product formulation and steaming process. These findings are comparable to Ayyappan AA, et al.25 (66.38%) reported for the moisture content of idlis. These outcomes also agree with those for cooked masa obtained by Nkama I, et al.26 As a result of the product's high moisture content, it will therefore encourage bacterial activity and mold growth, which will unquestionably lower its shelf stability.15. Idlis typically contain a lot of moisture and don't keep well for a long time. According to Frazier WC, et al.27 report, a food's moisture content can be used to depict its stability and susceptibility to microbial infection as well as to describe its water activity. These increases in moisture occurred as a result of the idli products' formulation with water. The idlis' protein content increased from 4.31 to 6.70%. The highest value was found in the control idli black gram/Faro 52A (BR1) at 6.79%. This contrasted favorably with the figures.28 reported for conventional idli (7.0%). Pigeon pea/Faro 44 idli (PR1) had the next-highest protein level (5.47%), while pigeon pea/Faro 52B had the least protein value (4.31%).

|

Samples |

Moisture (%) |

Protein (%) |

Crude fibre (%) |

Fat (%) |

Ash (%) |

Carbohydrate (%) |

|

AR1 |

66.50g±0.05 |

4.60b±0.02 |

0.40bc±0.01 |

1.00c±0.04 |

1.00b±0.01 |

26.50e±0.01 |

|

BR1 |

65.00d±0.02 |

5.25d±0.04 |

0.35b±0.04 |

1.00c±0.01 |

2.00d±0.05 |

26.40d±0.03 |

|

PR1 |

64.00b±0.03 |

5.47e±0.03 |

0.52e±0.02 |

2.00d±0.03 |

1.00b±0.05 |

27.01f±0.02 |

|

AR2 |

65.25e±0.01 |

5.25d±0.04 |

0.48de±0.01 |

2.50e±0.03 |

2.00d±0.01 |

24.52b±0.05 |

|

BR2 |

64.50c±0.04 |

6.79f±0.03 |

0.23a±0.03 |

1.00c±0.04 |

1.00b±0.03 |

26.48e±0.05 |

|

PR2 |

65.50f±0.01 |

4.31a±0.01 |

0.66f±0.05 |

1.00c±0.02 |

1.00b±0.01 |

27.53g±0.01 |

|

AR3 |

68.50h±0.03 |

5.25d±0.05 |

0.71f±0.02 |

0.10a±0.03 |

1.50c±0.04 |

23.94a±0.01 |

|

BR3 |

63.00a±0.02 |

4.82c±0.02 |

0.84g±0.05 |

1.00c±0.05 |

1.00b±0.02 |

29.34h±0.03 |

|

PR3 |

68.50h±0.01 |

5.25d±0.04 |

0.43cd±0.02 |

0.50b±0.04 |

0.50a±0.02 |

24.82d±0.01 |

Table 4 Proximate composition of idlis from blends of different rice cultivars, pigeon pea, african yam bean and black gram

Values are means ± SD (n = 3). Samples with the same superscript in a column are not significantly different (p> 0.05). AR1=African yam bean/Faro 44, BR1=black gram/Faro 44, PR1=pigeon pea/Faro 44, AR2= African yam bean/Faro 52A, BR2=black gram/Faro 52A, PR2=pigeon pea/Faro 52A, AR3=African yam bean/Faro 52B, BR3=black gram/Faro 52B, PR3=pigeon pea/Faro 52B.

Therefore, at p > 0.05, there was no difference between the newly developed idlis made from African yam bean/Faro 52A (AR2), African yam bean/Faro 52B (AR3), and pigeon pea/Faro 52B (PR3) and the control idli made from black gram/Faro 44 (BR1).

The high moisture level of the idlis may be the cause of the drop in protein amounts of these samples. Pulses' protein content decreased as a result of dehulling.29 The protein content of the idli samples was significantly reduced (p<0.05) by steaming, which is consistent with observations by EL Hag ME, et al.30 indicated heat treatment may reduce the relative compositions of protein. The protein content of fermented pearl millet decreased, according to EL Hag ME, et al.30 The range of the crude fiber contents in the idli samples was 0.23 to 0.84%, and this difference was significant (p 0.05). The black gram/Faro 52A idli (BR2) had the lowest value (0.23%), followed by the control idli (BR3), which had the greatest value (0.84%). The diluting effect brought on by a substantial amount of moisture content and the dehulling operations may be the cause of the low fiber content. Regarding their crude fiber content, the African yam bean and pigeon pea idli may be compared to the control idli. The crude fiber contents of the other idli samples varied considerably (p<0.05) from one another. The values recorded for crude fibre in this present work is in the range of values (0.50 %) reported by Hotkar D.31 The lowest crude fiber concentration was found in the control idli black gram/Faro 52A (BR2) at 0.23%. According to Chikwendu J.,32 fermentation significantly reduced fibre in fermented flours. However, it might be brought on by an increase in microflora populations and the metabolism's usage of fiber. These findings support the findings of Udedibie AB, et al.,33 who found that boiling Jackbeans reduced the amount of crude fiber. The idlis' fat content varied from 0.10 to 2.50%. African yam bean/Faro 52A idli (AR2) had the highest fat content (2.50%), whereas AR3 idli had the lowest fat content (0.10%). The high moisture level of the idlis and the steaming action, which caused lipids to be depleted, may have diluted the fat levels, while the vegetable oil used to lubricate the idli pans before to steaming may have contributed to the increased fat content. The amount of fat in PR3, BR3, PR2, BR2, AR1, and BR1 (control) was found to be consistent with the findings of Hotkar D, et al.31 for control idli. It was not surprising to find out that all of the idli samples had low fat concentrations because studies have demonstrated that legumes retain energy as carbohydrates rather than fat. All of the idli samples had significantly varying ash concentrations, ranging from 0.50 to 2.00% (p<0.05). The highest value, 2.00%, was found in black gram/Faro 44 (BR1) and African yam bean/Faro 52A (AR2), while PR3 had the lowest value, 0.50%.

These low ash levels may be caused by the leaching of ash-forming minerals into soak water as well as during the dehulling and steaming operations. Idli samples suffered a substantial reduction due to the high moisture content, with reductions ranging from 23.94 to 29.34%. The PR3 idli had the lowest (23.94%) while the control idli (BR3) had the highest (29.34%). Idlis has lower carbohydrate levels than the figure (31.88%) reported by Hotkar D, et al.31

pH, titratable acidity and rise in batter volumes of idlis from blends of different rice cultivars, pigeon pea, african yam bean and black gram before and after 14 hours fermentation

Table 5 displays the pH titratable acidity and increase in batter volumes of idli batters made from mixtures of several rice kinds, pigeon pea, African yam bean, and black gram. A product's level of acidity or alkalinity is determined by its pH. The study's findings indicate that the pH of the idli batters varied from 6.20 to 6.60 at the beginning of fermentation. The greatest value (6.60) was found in the African yam bean/Faro 44 (AR1) and 52B (AR3) idli batters. The control idli black gram/Faro 52A (BR2) had the lowest pH of all the samples at 6.2. The black gram/Faro 44 (BR1) and black gram/Faro 52B (BR3) control idlis had a pH of 6.30, which was in agreement with Sheela S, et al.34 observations that the pH of idli batters varied from 6.2 to 6.5 at the beginning of fermentation. The pH of the control idli batter was 6.32 when Rekha CR, et al.35 first tested it; after 14 hours of fermentation, it had dropped to 4.53.

|

Samples |

pH before fermentation |

pH after fermentation |

TTA before fermentation (%) |

TTA after fermentation (%) |

Rise in volume (ml) |

|

AR1 |

6.60 |

4.50 |

0.12a±0.00 |

0.50bc±0.03 |

120de±1.00 |

|

BR1 |

6.30 |

4.80 |

0.10a±0.04 |

0.62de±0.01 |

122e±1.00 |

|

PR1 |

6.50 |

4.50 |

0.11a±0.02 |

0.40a±0.03 |

109a±1.00 |

|

AR2 |

6.50 |

4.50 |

0.13a±0.03 |

0.56cd±0.03 |

115c±0.57 |

|

BR2 |

6.20 |

4.80 |

0.13a±0.00 |

0.64e±0.00 |

118d±1.00 |

|

PR2 |

6.40 |

4.60 |

0.13a±0.01 |

0.42a±0.08 |

110ab±2.00 |

|

AR3 |

6.60 |

4.50 |

0.14a±0.00 |

0.50bc±0.05 |

114c±2.51 |

|

BR3 |

6.30 |

4.70 |

0.12a±0.02 |

0.68e±0.00 |

118d±2.00 |

|

PR3 |

6.50 |

4.50 |

0.11a±0.02 |

0.46ab±0.05 |

112b±1.00 |

Table 5 pH, titratable acidity and rise in batter volume of idli batters from blends of different rice cultivars, pigeon pea, african yam bean and black gram before and after 14 hours fermentation

Values are means ± SD (n = 3). Samples with the same superscript in a column are not significantly different (p > 0.05). AR1=African yam bean/Faro 44, BR1=black gram/Faro 44, PR1=pigeon pea/Faro 44, AR2= African yam bean/Faro 52A, BR2=black gram/Faro 52A, PR2=pigeon pea/Faro 52A, AR3=African yam bean/Faro 52B, BR3=black gram/Faro 52B, PR3=pigeon pea/Faro 52B.

After 14 hours of spontaneous fermentation, the idli batters' pH values also varied from 4.50 to 4.80. The black gram/Faro 44, 52A, and 52B control idli batters were found to have the highest pH (4.80, 4.80, and 4.70, respectively). The newly developed idli batters (AR1, PR1, AR2, AR3, and PR3) with a pH of 4.50 showed lower values. These pH values were found to be consistent with those reported by Ayyappan AA, et al.25 for control idli and after he added xylooligosaccharide to the batters, which varied from 4.69 to 4.57. According to Ayyappan AA, et al.,25 a reduction in pH (a rise in the amount of acid) would certainly encourage the growth of yeasts and, as a result, increase the creation of carbon dioxide, which leavens the batter. These legumes have a higher content of soluble nutrients to boost the growth of LAB after being soaked in water. According to Soni SK, et al.,36 the purpose of LAB is to bring the batter's pH down to the ideal range (4.4 to 4.7) for yeast activity.

There was no significant (p < 0.05) difference in the titratable acidities of the idli samples before fermentation and ranged from 0.11 to 0.14 %. The control idli batters BR1, BR2, and BR3 were found to have rapid fermentation and maximum values. However, the black gram/Faro 52B (BR3) control idli batter had the highest and lowest values, respectively. It has been suggested that the development of flavor and product stability is caused by acid generation. In the idli samples, an increase in the batter's acid level was seen as the natural fermentation process progressed. So, after 14 hours of fermentation, titratable acidity increased as the pH decreased. The microbial development, particularly of lactic bacteria, which produces lactic acid and reduce the pH and leavens the batter, may be to blame for the shift in pH and acid content.35 Significant (p < 0.05) increase were observed in the batter volumes of the idli samples while there was a noticeable change in the batter volume during natural fermentation. The amount of batter remaining after the 14-hour fermentation process varied between 109 to 122 ml. The pigeon pea idli batters showed the lowest values, with (PR1) having the lowest value of 109 ml. The biggest volume increase was seen in the control idli (BR1, BR2 and BR3). According to Padmashree A, et al.,37 the batter volume increased from 100 ml to 178.4 ml. As a result of the yeast's metabolic activity during natural fermentation, the volume may have increased for this reason.37 It might also be ascribed to microbial development and production of enzymes that catalyze the breakdown of lipids, antinutritional substances, proteins, and carbohydrates.38

Physical parameters of developed idlis from blends of different rice cultivars, pigeon pea, african yam bean and black gram

Table 6 lists the physical characteristics of developed idlis produced from mixtures of several rice kinds, pigeon pea, African yam bean, and black gram. The idli samples' diameters differed significantly from one another. The idli samples had diameters ranging from 7.16 cm to 7.7 cm. The diameter of the control idli (BR1) was 7.70 cm, while that of AR2 was 7.16 cm. Idlis, as reported by Uma MS, et al.,39 are circular in shape and range in diameter from 7 to 10 cm, based on the dimension of the mold. The upper surface bulges, making the product thick in the center and taper toward the edges. This is consistent with the fact that idli often have a diameter of 7 to 10 cm. Due to the dependence on the size of the steaming idli moulds, all of the idlis had a similar diameter. The cooked weights of the idli samples differed significantly (p < 0.05) from each other and varied from 40.31 to 49.91 g. The cooked weights of the African yam bean idlis were higher than those of the control idlis, which had the lowest weights. The cooked weights of the African yam bean and pigeon pea idlis were found to be higher than those of the control idlis. This could be explained by fermentation, which made the black gram idli batter more frothy and spongy than other batters.

|

Samples |

Cooked weights (g) |

Cooking time (min) |

Diameter (cm) |

Texture measurements (mm) |

|

AR1 |

49.91d±0.58 |

12.12b±0.02 |

7.43ab±0.25 |

9.63c±0.32 |

|

BR1 |

41.15ab±0.73 |

7.04a±0.03 |

7.70b±0.20 |

10.10d±0.10 |

|

PR1 |

44.42bc±1.08 |

14.00e±0.01 |

7.46ab±0.28 |

9.16ab±0.15 |

|

AR2 |

48.84d±0.80 |

12.22b±0.24 |

7.16a±0.05 |

9.90cd±0.36 |

|

BR2 |

40.57a±0.56 |

7.03a±0.02 |

7.43ab±0.20 |

10.16d±0.30 |

|

PR2 |

42.33abc±1.89 |

13.02c±0.03 |

7.36ab±0.05 |

9.03a±0.15 |

|

AR3 |

48.97d±0.98 |

12.56b±0.49 |

7.33ab±0.25 |

10.20d±0.20 |

|

BR3 |

40.31a±0.94 |

7.07a±0.03 |

7.66b±0.15 |

10.26d±0.25 |

|

PR3 |

44.12bc±1.68 |

13.50d±0.50 |

7.23a±1.15 |

9.53bc±0.25 |

Table 6 Physical parameters of developed idlis from blends of different rice cultivars, pigeon pea, african yam bean and black gram

Values are means ± SD (n = 3). Samples with the same superscript in a column are not significantly different (p > 0.05). AR1=African yam bean/Faro 44, BR1=black gram/Faro 44, PR1=pigeon pea/Faro 44, AR2= African yam bean/Faro 52A, BR2=black gram/Faro 52A, PR2=pigeon pea/Faro 52A, AR3=African yam bean/Faro 52B, BR3=black gram/Faro 52B, PR3=pigeon pea/Faro 52B.

The weight (50 g) that Nazni P, et al.28 were able to attain for a regular idli can be contrasted to these substantial weights of African yam bean idlis. The newly developed idli samples took between 7.03 and 14.00 minutes to cook. There were significant differences (p < 0.05) between all the samples. The pigeon pea idlis required more cooking time (13.02, 13.50, and 14.00 minutes), but the control idlis required less time (7.03, 7.04, and 7.07 minutes). The idli samples' textures had a range of 9.0 to 10.26 mm, and there were noticeable variances. The PR3 idli had a value of 9.03 mm, while the control idli (BR3) had a value of 10.26 mm. As a result, it is believed that the idlis with the greatest values have soft textures, while those with the lowest values are considered to have harsh textures. As a result, the control idlis were found to have a texture similar to that of the African yam bean/Faro 52B (AR3) and to be more easily pierced. According to Balasubramanian S, et al.,40 the idli produced after 14 hours of fermentation were found to be softer and more porous. The higher the values the softer the texture of the idlis while the lower the values the harder the texture of the idlis.

Sensory quality of developed idlis without accompaniment from blends of different rice cultivars, pigeon pea, african yam bean and black gram

Tables 7 and 8 illustrate the sensory characteristics of idlis with or without accompaniments. The findings demonstrated that when consumed with an accompaniment, the idli samples had appreciable ratings/scores for appearance, color, texture, flavor, taste, aftertaste, mouth feel, and overall acceptability. Comparing the pigeon pea/Faro 44 (PR1) and 52A (PR2) to the control black gram/Faro 44 (BR1) and 52A (BR2), there was no significant difference in appearance (p > 0.05). This indicates that consumers were also satisfied with the color of the freshly prepared/developed idlis. The texture of the freshly prepared idlis compared favourably well with the control idlis. As a result, there was no variation in texture between any of the idli samples that was significant (p > 0.05). The control idli black gram/Faro 52A (BR2) was found to have the highest flavor qualities with a score of 7.30. This flavor reduction could be the result of volatile flavors that were obtained through fermentation but were lost while steaming. Between the newly created samples PR1, AR2 and AR3 and the control idlis BR1, BR3, there was no discernible change (p > 0.05). The taste, aftertaste, mouthfeel, and general acceptability of all the idli samples did not differ significantly (p > 0.05). As a result, the tastes of all the samples were well received by the panelists. Thus, the newly formulated idli products were generally accepted by the consumers and posseses similar physical attributes with their control.

|

Samples |

Appearance |

Colour |

Texture |

Flavour |

Taste |

After taste |

Mouthfeel |

Overall acceptability |

|

AR1 |

7.25a±1.11 |

5.90ab±1.97 |

6.60a±1.87 |

5.85a±1.92 |

6.40a±2.28 |

6.15a±2.03 |

5.50a±2.03 |

6.05a±2.23 |

|

BR1 |

8.40d±0.75 |

6.90bc±1.74 |

6.35a±2.27 |

6.65ab±1.66 |

6.20a±1.90 |

6.45a±1.53 |

6.85b±1.34 |

6.65a±2.00 |

|

PR1 |

7.95cd±0.75 |

6.90bc±1.70 |

6.40a±1.98 |

6.70ab±2.10 |

6.60a±1.95 |

5.80a±2.04 |

6.05ab±1.82 |

6.55a±1.46 |

|

AR2 |

7.35abc±0.74 |

5.90ab±2.17 |

6.45a±1.76 |

6.35ab±2.20 |

6.25a±1.74 |

6.00a±1.58 |

5.60ab±1.75 |

6.40a±1.81 |

|

BR2 |

8.20d±0.83 |

6.75bc±1.91 |

6.65a±2.00 |

7.30b±1.30 |

6.10a±2.02 |

5.85a±1.87 |

6.25ab±2.26 |

6.20a±2.39 |

|

PR2 |

7.45abc±0.94 |

6.70bc±1.89 |

6.45a±1.57 |

5.85a±2.00 |

5.65a±1.56 |

5.45a±1.98 |

6.25ab±1.68 |

6.25a±1.86 |

|

AR3 |

7.90bcd±0.78 |

5.25a±2.51 |

6.30a±1.41 |

6.60ab±2.11 |

6.15a±1.84 |

6.35a±1.63 |

5.50a±2.16 |

6.50a±1.82 |

|

BR3 |

8.30d±0.86 |

7.80c±1.19 |

7.20a±1.73 |

6.90ab±1.55 |

6.50a±1.96 |

6.25a±1.55 |

6.70ab±1.38 |

6.55a±1.57 |

|

PR3 |

7.30ab±1.12 |

6.50abc±1.79 |

6.75a±1.61 |

5.85a±2.05 |

6.00a±1.86 |

5.55a±2.13 |

6.20ab±1.57 |

6.50a±1.27 |

Table 7 Sensory Quality of developed idlis without accompaniment

Values are means ± SD (n = 3). Samples with the same superscript in a column are not significantly different (p> 0.05). AR1=African yam bean/Faro 44, BR1=black gram/Faro 44, PR1=pigeon pea/Faro 44, AR2= African yam bean/Faro 52A, BR2=black gram/Faro 52A, PR2=pigeon pea/Faro 52A, AR3=African yam bean/Faro 52B, BR3=black gram/Faro 52B, PR3=pigeon pea/Faro 52B.

Sensory quality of developed idlis with accompaniment from blends of different rice cultivars, pigeon pea, african yam bean and black gram

Table 8 displays the findings of the sensory assessment and consumer acceptance of idlis manufactured from mixtures of several rice kinds, pigeon pea, African yam bean, and black gram. The results showed that the idli samples all had high scores for appearance, colour, texture, flavour, taste, aftertaste, mouth feel and overall acceptability when consumed with an accompaniment. Overall acceptability scores ranged from 6.25 to 7.35. This demonstrates that the African yam bean/Faro 52A (AR2), black gram/Faro 44 (BR1), 52A (BR2), and pigeon pea/Faro 52B (PR3) idli samples received the highest mean scores of 7.10, 7.10, and 7.00, respectively, followed by the control idli samples. There were no significant variations between samples AR1, BR1, PR1, AR2, BR2, AR3, and BR3 (p > 0.05). This proves that consumers liked idlis more when they were eaten with a side dish.

|

Samples |

Appearance |

Colour |

Texture |

Flavour |

Taste |

Aftertaste |

Mouthfeel |

Overall Acceptability |

|

AR1 |

7.45a±1.35 |

7.10ab±1.68 |

6.55a±1.57 |

7.10a±1.16 |

7.15a±0.98 |

6.80ab±1.36 |

6.55a±1.57 |

7.00ab±1.71 |

|

BR1 |

7.50a±1.05 |

7.35b±1.22 |

6.85a±1.81 |

7.05a±1.46 |

7.35a±1.03 |

7.40b±1.04 |

6.85a±1.81 |

7.10ab±0.91 |

|

PRI |

7.25a±1.48 |

6.95ab±1.57 |

6.90a±1.29 |

6.40a±2.01 |

6.35a±2.05 |

6.15a±1.95 |

6.55a±1.70 |

6.65ab±1.34 |

|

AR2 |

7.65a±0.98 |

6.55ab±1.90 |

6.90a±1.20 |

6.90a±1.41 |

6.85a±1.30 |

6.50ab±1.57 |

6.85a±1.13 |

7.10ab±0.96 |

|

BR2 |

7.80a±1.05 |

7.50b±1.05 |

6.70a±1.97 |

6.75a±1.65 |

7.00a±1.48 |

7.00ab±1.12 |

7.30a±1.41 |

7.10a±1.16 |

|

PR2 |

7.30a±0.97 |

7.15ab±1.26 |

6.85a±1.18 |

6.90a±1.25 |

6.75a±1.29 |

6.85ab±1.26 |

7.10a±1.07 |

6.25a±1.77 |

|

AR3 |

7.65a±1.13 |

6.15a±1.69 |

6.65a±1.34 |

6.65a±1.42 |

6.80a±1.32 |

6.85ab±1.66 |

6.55a±1.43 |

6.75ab±1.25 |

|

BR3 |

7.75a±1.11 |

7.45b±1.53 |

7.05a±1.23 |

6.90a±2.10 |

6.85a±1.75 |

6.65ab±1.56 |

6.70a±1.71 |

6.75ab±1.51 |

|

PR3 |

7.25a±0.91 |

7.30b±1.26 |

6.85a±1.08 |

6.75a±1.80 |

7.05a±1.14 |

7.50b±1.14 |

7.00a±1.41 |

7.35b±1.22 |

Table 8 Sensory quality of developed idlis with accompaniment

This study has shown that mixes of rice, pigeon pea, and African yam bean can be used to make breakfast foods (idli) that are acceptable alternatives to black gram dhals. African yam beans, pigeon peas, and the Faro 44 and 52B rice types all produced idlis with protein level that was comparable to that of the black gram idlis (control). The results also showed that idlis made from blends of African yam beans with Faro 52A and 52B rice cultivars had higher nutritional value. African yam bean idli batters had greater volume to pigeon pea idli batters, in contrast to the control idli batters, according to the physical characteristics of the idlis. Consumers rated these idli food products highly and found them to be acceptable from a sensory and acceptance standpoint. Functional properties outcomes showed that the flours is could be used formulate many food products. The flour's low bulk density makes it possible to formulate foods with less concern for retrogradation and has an impact on package design.

No funding provided for the research

The study's execution was not supported by any funding.

Competing Interests Statement

No conflict of interest or conflicting interests.

Consent for publications

The authors hereby give permission to publish the manuscript and the publisher the license of the copyright which provides the publisher with the exclusive right to publish.

None.

None.

©2023 Anene, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.