eISSN: 2576-4462

Research Article Volume 5 Issue 5

1Department of Horticulture, Faculty of Agriculture, Food and Consumer Sciences, University for Development Studies, Tamale, Ghana

2Departmentof Agricultural Mechanization and Irrigation Technology, Faculty of Agriculture, Food and Consumer Sciences, University for Development Studies, Tamale, Ghana

Correspondence: Moomin Abu, Department of Horticulture, Faculty of Agriculture, Food and Consumer Sciences, University for Development Studies, Tamale, Ghana, Tel +233244849469

Received: November 05, 2021 | Published: December 23, 2021

Citation: Abu M, Yuoni EM. A detergent for mango fruit sap-induced injury. Horticult Int J. 2021;5(5):222-227. DOI: 10.15406/hij.2021.05.00232

This study determined the optimum concentration of, and duration of immersion in a local detergent (“awabla”) that protected fruit skin of Kent and Keitt mango varieties from mango fruit sap-induced injury (sap-burn) at harvest.The resultant skin/peel colour, pulp colour, and total soluble solids content was also evaluated for fruit quality. Randomized Complete Block Design and Completely Randomized Design with four replications in each case were used for field and laboratory experiments respectively. For each of the two varieties, ten mango trees were sampled at random in each of the four replications of a mango plantation.On each sample tree, twenty panicles all initiating fruit-set were identified and tagged. The number of days from fruit-set to physiological maturity were monitored and harvested for the experiments. Concentrations of 0.25,0.50, and 0.75% of “awabla” solution for 25,30,and35 minutes immersion period in all combinations were established as appropriate and recommended for management of Kent and Keitt mango fruit sap-induced injury. The detergent (“awabla”) had a proven efficacy in the range of 87-94 % for Kent and 90-93 % for Keitt. The resultant peel colour, pulp colour, and total soluble solids content of Kent and Keitt mango fruit samples were not significantly influenced by the treatments at p>0.05.

Keywords: detergent, efficacy, mango fruit, mango sap, sap-induced injury

Fruits and vegetables are inevitably a necessity since their relevance to mankind is related to their nutritional value as main sources of vitamins and minerals that ensure a balanced diet.1,2 Agricultural Transformation Agency (ATA) demonstrated a universal recognition that fruits and vegetables were important foods and that their production, processing, and marketing were significant contributors to household food security and income.3 This source indicated that fruits and vegetables comprised a large portion of human diet and in most cases the only form of relish for the low-income group. Fruits and vegetables also provide dietary fibre which enhances digestion and improves the health of mankind.3 Fruits and vegetables also contribute substantially to the gross domestic product. Unfortunately, the magnitude of postharvest losses in fresh fruits and vegetables was estimated to be 5 to 25 percent in developed countries and 20 to 50 percent in developing countries depending on the commodity.4,5,6,7

Estimates of loss magnitudes in developing countries for fruits and vegetables indicated very wide ranges for specific crops e.g. losses of tomato fruit varied from 20-50 %; banana, 20-80 %; and papaya, 40-100 %.6,7 For fruits and vegetables produced in Ghana, 5-40 % was lost during the various stages of the marketing process i.e. at every step from harvest to retail and sale.8,9,10 Narrowing down to specific crops in Ghana, it was estimated that e.g. losses of tomato fruits were in the range of 30-70 %; and mango, 50-80 %.11,9 But the aim of postharvest studies is to reduce losses and to do so, the way forward is to understand the biological factors involved in deterioration, the environmental factors that influence deterioration, and use those postharvest technology procedures which will delay senescence and maintain the best possible quality. Abu et al.12 reiterated that reduction in losses resulted in low cost of production, improved trade and distribution, enhanced food security especially in developing countries, lowered the price for consumers and at the same time increased farmers’ income.

During the developmental or growth period of fruits there are many chemical and physical changes taking place that have a bearing on fruit quality ad postharvest behaviour. Fruits are highly perishable products and their quality could be affected by both harvest and postharvest practices such as method and condition of harvest, handling, transportation, storage, and marketing.6,7,9 Losses could also occur in fruits via the natural physiological constitution of the plant species such as the ability or otherwise the inherent characteristic of the species for exuding latex (mango fruit sap) at harvest which is unavoidable in mango production.Yuoni13 reported that when mango fruit sap (latex)came into contact with the mango fruit peel it resulted in sap burn injury. The author however added that the susceptibility of mango fruit to sap-induced injury as well as the severity of the injury variedwith the cultivar.

Porat et al.,6 Yahaya et al.7 and Abu et al.14 reported that latex-flow from harvested mango fruit occurred even after physiological maturity (pre-climacteric stage -the stage of development when most commercial harvests take place) at a decreasing rate. Latex-flow persisted up to packaging.14

Yuoni13 and Abu et al.14 indicated that the sap, which is sticky in nature, caused browning, hardened, and stained the skin of the fruit contacted. The affected skin area sub sequently became site for secondary infection, degraded the aesthetic appeal of the fruit, reduced consumer acceptability, decreased the value and storage life of the fruit, and therefore resulted in quantitative and qualitative losses. These losses were manifested in several ways including weight loss (quantitative), quality loss (qualitative), nutritional loss (food value), seed loss (viability or germination), economic loss (monetary), loss of good will (reputation), and loss of marketing opportunities for the farmer, the seller, and the consumer alike.13,15 Saeed5 earlier on reiterated that these impacted negatively on food security and nutrition. The author added that successful production i.e. production characterized with meagre losses could enhance subsistence, incomegeneration, and even export in the developing world.

Krishnapillai et al.16 reported that the concentration of tannins decreased with maturity as a result of polymerization which is associated with the disappearance of latex. According to Abu et al.14 phenolics such as tannins and perhaps the most important phenolics from the point of view of fruit utilization are polymerized to insoluble compounds resulting in a reduction of astringency during ripening. This seems to be associated with a change in structure of the tannins rather than a reduction in the levels since they form polymers.14 In mango fruit, however, latex-flow does not stop entirely after harvest at physiological maturity stage but reduces in flow rate and quantity along the harvest and pack-house processes with time.14 On-tree ripe mango fruits, however, showed complete disappearance of latex-flow or exudation at harvest. These fruits also developed better quality in flavour and colour, though undesirable in some respects since such fruits were more susceptible to spoilage by birds and other rodents and also did not keep long in storage, and hence in transit.17,18 Parthasarathy19 noted that mango fruits that secreted little to no latex at harvest enhanced fruit acceptability and also allowed for easier fruit handling since the latex was corrosive and damaged the fruit skin and as well caused irritation on human skin when in contact.

Several methods have been used to manage sap burn injury in mangoes19-23 but with the inclusion of chemicals which might have been sophisticated, expensive, and which certainly provided a quick fix but were ultimately self-defeating.18,24 In the same vein Krishnapillai et al.16 indicated that simple, inexpensive, and environmentally friendly methods could be used to reduce sap burn injury in mangoes.

Mango farmers made frantic efforts for any harvest technique(s) worthy of adoption that could aid avert the consequences of mango fruit sap-induced injury.14 Nevertheless, while highly recommended, any precautionary measures may be inadequate and even fruitless if a simple inexpensive de-sapping technique or practice is not known to the mango farming and beneficiary communities. Hence, the need to investigate into and ascertain the efficacy of “awabla” for the purpose.

The objectives were: to determine the appropriate concentration of “awabla” solution for optimum protection of mango fruit from sap burn injury, to determine the appropriated uration for which freshly harvested mango fruits would be immersed in “awabla” solution for optimum protection of mango fruit from sap burn injury, to evaluate the resultant skin/peel colour, pulp colour, and total soluble solids(TSS)content for fruit quality.

Experimental site and plant materials

Field and laboratory studies were conducted at the Integrated Tamale Fruit Company (ITFC) Ltd nucleus Mango Plantation in Dipale and at the Bio-chemistry Laboratory, Spanish Laboratory, University for Development Studies, Tamale, Ghana, respectively. The study investigated and ascertained the efficacy of “awabla” (a local detergent) solution for optimum protection of Kent and Keitt mango fruit from mango sap burn injury consequences. Kent and Keitt are major export mango varieties which are appreciated by importers of mango from Ghana.25,26,15 Dipale is a farming community in the north-western part of Savelugu District in the Northern Region of Ghana.Randomized Complete Block Design (RCBD) and Completely Randomised Design (CRD) were used for the field and laboratory experiments respectively, with four replications in each case.

Field studies

Sampling and harvesting of fruits for experimentation

For each of the two varieties, ten mango trees were sampled at random in each of the four replications. On each sample tree, twenty panicles all initiating fruit-set were identified and tagged i.e. date of fruit-set initiation was noted and recorded for each sample tree. The number of days from fruit-set to physiological maturity (green-hard, outgrown shoulders, pit around the stalk-end, and turning yellow or showing an apparent break of yellow colour in the pulp/flesh characteristic of Kent and Keitt) i.e. at early maturity (pre-climacteric stage) for Kent and Keitt (126 and 140 days respectively) were monitored and harvested for the experiments.15 The authors indicated that the number of days from fruit-set to harvest provide one of the best and reliable indicators of maturity (early, mid or late harvest) and represents the optimum age of the fruit for quality postharvest behaviour.

Composition, different concentrations, and immersion regimes tested

Oyekanmi et.al.20 and Yuoni13 reported that “awabla” was a composition of 10 %moisture, 0.1 %alkaline, 5 % unsaponified neutral fat, 55 %total fatty matter, a bulk density of 2 %,4 % matter insoluble inwater,5 % matter insoluble in ethanol, and a titre value of 58 %. Four different concentration (%) levels {0.00 % (control), 0.25 %,0.50 %, and 0.75 %} of “awabla”solution and three immersion regimes (minutes) (35,30, and 25 minutes) were used, following recommendations of Yuoni.13 Yuoni13 indicated that “awabla” is prepared from Amaranthus spinosus(Spiny Amaranth) which possesses anti-microbial properties.27

Definition of treatments

Concentration one = C1 = 0.25 %

Concentration two = C2 = 0.50 %

Concentration three = C3 = 0.75 %

Control = no “awabla” = C0 = 0.00 %

Immersion period one = T1 = T35 = 35 minutes

Immersion period two = T2 = T30 = 30 minutes

Immersion period three = T3 = T25 = 25 minutes.

Treatments

C1T35 = Concentration of 0.25 % for 35 minutes

C1T30 = Concentration of 0.25 % for 30 minutes

C1T25 = Concentration of 0.25 % for 25 minutes

C2T35 = Concentration of 0.50 % for 35 minutes

C2T30 = Concentration of 0.50 % for 30 minutes

C2T25 = Concentration of 0.50 % for 25 minutes

C3T35 = Concentration of 0.75 % for 35 minutes

C3T30 = Concentration of 0.75 % for 30 minutes

C3T25 = Concentration of 0.75 % for 25 minutes

C0T35 = no “awabla” for 35 minutes

C0T30 = no “awabla” for 30 minutes

C0T25 = no “awabla” for 25 minutes.

Laboratory studies

Application of treatments (de-sapping of mango fruits) and storage of treated fruit samples for sap burn injury determination

Ten fruits were randomly picked for each treatment in each of the four replications in each case of the two varieties. Sample fruits with pedicel length 1 cm9,15,14 were treated as outlined above under subtitle “treatments”. Treated samples were accordingly stored in cardboard boxes under ambient conditions (29-31 oC, 90-95 % RH)9 for seven days15 and assessed for sap burn injury consequences viz. skin/peel colour, pulp colour, and TSS content. Sap burn injuries were highlighted and the area of the injury calculated by multiplying the length by the breadth (L xB) in centimeters (cm) for each fruit.The injury area defined over the seven days storage period was calculated and averaged for each treatment in each of the four replications in each case of the two varieties. The figure obtained represented the injury area defined on the fruit in a particular treatment over the storage period.28

The extent of injury on the fruit in relation to any treatment was scored on the scale 0-4.

0 = no injury,

1= very mild (injury area less than 1cm2),

2 = mild (injury area>1<2cm2),

3= moderate (injury area>2<4 cm2),

4 = severe (injury area>4cm2).

Values were recorded for each of the ten fruits and averaged for each treatment.

NB: Those with least score values were of better quality (with regards to sap burn injury) than those with higher score values.

Physicochemical analyses

Physico-chemical analyses on mango skin/peel colour, consistency of mango pulp, and total soluble solids (TSS, oBrix) content of mango were done on fruits at physiological maturity or at pre-climacteric stage (green-hard, outgrown shoulders, pit around the stalk-end, skins of many fruits develop wax - giving the fruit a shine or bloom, and showing an apparent break of yellow colour in the pulp).29,30,15

Determination of fruit total soluble solids (TSS, oBrix) content was by the AOAC31 procedures whiles that of fruit skin colour and consistency of pulp were by the SAMGA32 procedures. These were done at the early harvest stages obtained by the age control criterion because of its precision in measuring or determining harvest maturity stage.29,30,15

Statistical analyses

All data were analysed using the Analysis of Variance (ANOVA) technique33 with the GENSTAT statistical program. Least Significant Difference (LSD) at 5 % probability level was used to determine treatment differences.

Sap burn injury scores, fruit pulp colour consistency, skin/peel colour mean scores, and total soluble solids (TSS) content in relation to treatments applied to kent fruit samples

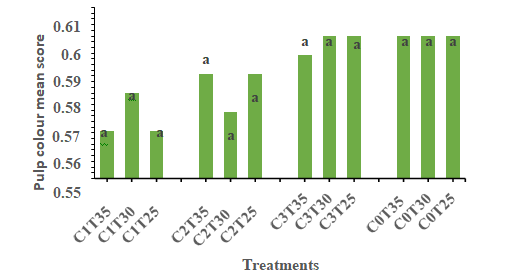

Sap burn injury scores in relation to treatment

Untreated Kent fruit samples (C0T35, C0T30, and C0T25) showed comparatively high sap burn injury (sap burn injury mean scores of 1.87, 1.80, and 1.80 for C0T35, C0T30, and C0T25 respectively) than the other treatments (Figure 1). Treatments C1T30 and C2T30 gave the lowest sap burn injury with a mean score of 0.07 in each case (Figure 1). Fruits treated with C1T30 and C2T30 were therefore of optimum quality in relation to sap burn injury though the different sap burn injury mean scores recorded were not significantly different amongst the treatments at p>0.05 (Figure 1).

Figure 1 Sap burn injury scores in relation to treatment.

Mean bars with similar alphabets are not significantly different. Bar values means ± SEM, n= 3.

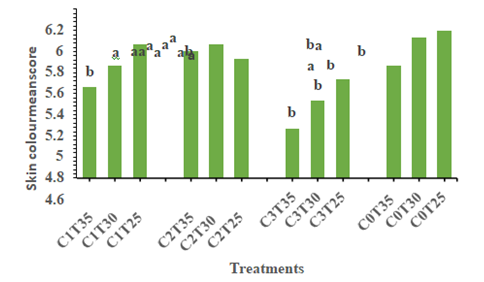

Fruit pulp colour consistency in relation to treatment

Untreated fruits and those treated with C3T30 and C3T25 showed the most developed pulp colour consistency with a common mean score of 0.6,which was the maximum score on the mango pulp colour chart (Figure 2). Treatments C1T35 and C1T25 were least developed in pulp colour consistency with a mean score of 0.57 in each case (Figure 2).

Figure 2 Fruit pulp colour consistency in relation to treatment.

Mean bars with similar alphabets are not significantly different. Bar values means ± SEM, n= 3.

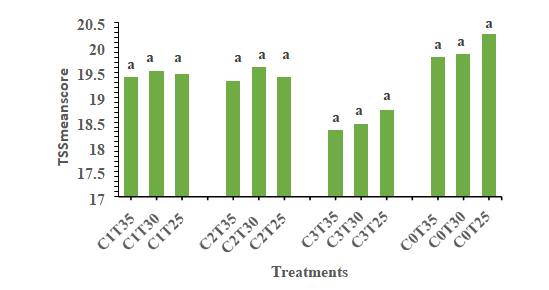

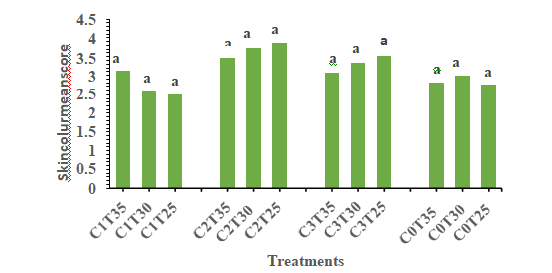

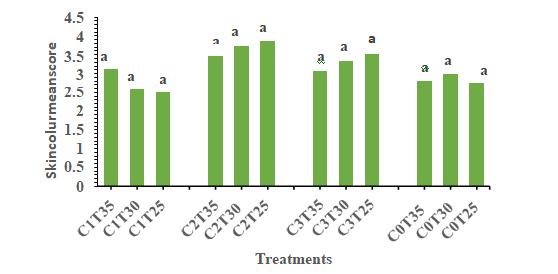

Skin colour mean scores in relation to treatment

Treatment C0T25 showed the most-high mean score of 6.0 for Kent fruit skin colour development over the experimental period while treatment C3T35 recorded 5.08 which was the most-low mean score for peel colour development (Figure 3). Generally, all the treatment recorded fairly high mean scores for skin colour development but there were no significant differences amongst the mat p>0.05 (Figure 3).

Figure 3 Skin colour mean scores in relation to treatment.

Mean bars with similar alphabets are not significantly different. Bar values means ± SEM, n= 3.

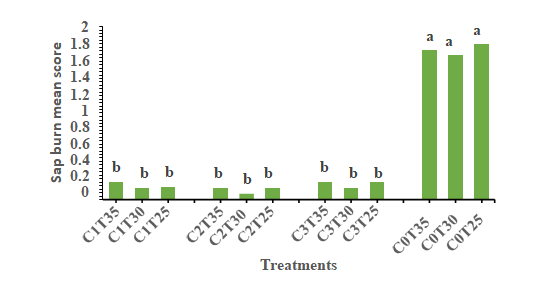

Total soluble solids (TSS) content in relation to treatment

The highest TSS mean score value of 20.27 was recorded for treatment C0T25 over the experimental period whiles a mean score value of 18.33 was recorded for treatment C3T35, and was the least amongst the Kent treatments (Figure 4). There were no significant differences among treatment means at p>0.05 (Figure 4). Sap Burn Injury Scores, Fruit Pulp Colour Consistency, Skin/Peel Colour Mean Scores, and Total Soluble Solids (TSS) Content in relation to Treatments Applied to Keitt Fruit Samples.

Figure 4 Total soluble solids (TSS) content in relation to treatment.

Mean bars with similar alphabets are not significantly different. Bar values means ± SEM, n= 3.

Sap burn injury scores in relation to treatment

Significantly (p < 0.05) high sap burn injury scores of 1.73,1.66, and 1.80 were recorded for treatments C0T35, C0T30, and C0T25 respectively while the most low sap burn injury mean score of 0.07 was recorded for treatment C2T30 of the Keitt fruit samples (Figure 5). There were however no significant (p>0.05) differences in the strength of sap burn injury among treatments C1T35, C1T30, C1T25, C2T35, C2T30, C2T25, C3T35, C3T30, and C3T25 (Figure 5).

Figure 5 Sap burn injury scores in relation to treatment.

Mean bars with similar alphabets are not significantly different. Bar values means ± SEM, n= 3.

Fruit pulp colour consistency in relation to treatment

Treatment C3T25 recorded the most-high pulp colour consistency mean score of 0.58 while treatment C1T25 recorded the least (0.36) (Figure 6). Pulp colour development for all the treatments was generally consistent except for treatments with 0.25 % detergent concentration labels whose mean scores were apparently low as compared to the other treatments (Figure 6). The results also showed that fruit pulp colour consistency increased with increased concentration of the detergent for the Keitt fruit samples (Figure 6).

Figure 6 Fruit pulp colour consistency in relation to treatment.

Mean bars with similar alphabets are not significantly different. Bar values means ± SEM, n= 3.

Peel colour mean scores in relation to treatment

Peel colour development mean score of 3.87 for treatment C2T25 was the most-high over the experimental period while treatment C1T25 recorded the most-low mean score of 2.50 (Figure 7). Peel colour development was fairly uniform amongst the various treatments (Figure 7).

Figure 7 Peel colour mean scores in relation to treatment.

Mean bars with similar alphabets are not significantly different. Bar values means ± SEM, n= 3.

Total soluble solids (TSS) content in relation to treatment

Treatment C3T25 recorded the most-high TSS content mean score of 19.40 whiles treatment C1T25 recorded the least (16.95) (Figure 8).There were however no significant differences among treatment means at p>0.05 (Figure 8).

Sap burn injury scores, fruit pulp colour consistency, skin/peel colour mean scores, and total soluble solids (TSS) content in relation to treatments applied to kent and keitt mango fruit samples

Karunanayake,34 Krishnapillai and Wijeratham,16 and Saby John et al.35 indicated that mango sap is highly acidic in nature with a pH of 4.3and therefore injures/scorches the fruit skin/peel when in contact, thus rendering the fruit unappealing/unsightly. According to Barman et al.,21 the onset and severity of mango sap burn injury increased up to ripening during storage at ambient temperatures.

For Kent mango fruit samples, sap-induced injury levels were managed to an average of 6 % by the 0.25 % concentration of “awabla” solution for the three different durations of immersion, 6 % by the 0.50 % concentration of “awabla” solution for the three different durations of immersion, and 13 % by the 0.75 % concentration of “awabla” solution for the three different durations of immersion; all as a percentage of sap burn injury recorded for the Control in each case. In the case of Keitt mango fruit samples sap-induced injury levels were managed to an average of 9 % by the 0.25 % concentration of “awabla” solution for the three different durations of immersion, 7 % by the 0.50 % concentration of “awabla” solution for the three different durations of immersion, and 10 % by the 0.75 % concentration of “awabla” solution for the three different durations of immersion; again, all as a percentage of sap burn injury recorded for the Control in each case. Therefore, the detergent (“awabla”) had a proven efficacy in the range of 87-94 % for Kent and 90-93 % for Keitt. This meant that out of the samples in the trials, those that received treatment (treated) were at a range of 87-94 % lower risk of developing sap burn injury in the case of Kent and 90-93 % in the case of Keitt. In both cases of Kent and Keitt fruit samples, sap burn injury levels of the untreated samples were significantly higher than those of the treated samples at p<0.05. Thus, both Kent and Keitt fruits that were treated with the local detergent at various concentrations showed significantly (p<0.05) low sap burn injury levels compared to the control (untreated); indicating that the detergent was able to manage sap burn injury up to eat-ripe stage in storage. Abu et al.15 indicated that fruits of Haden, Kent, Palmer, and Keitt mango varieties attained eat-ripe stage maturity from physiological maturity after seven days in storage under ambient conditions.

According to Ikotunetal.23 an African black soap that was prepared from shea butter and cocoa pods was found to be more of an alkaline base with a pH value of 9.56. The application of this local detergent counteracted the effect of the acidity of mango fruit sap and protected the fruits from sap burn injury. For Kent mango fruit samples, treatments C1T30 and C2T30 gave the lowest sap burn injury with a mean score of 0.07 in each case while the most-low sap burn injury mean score of 0.07was recorded for treatment C2T30 of the Keitt mango fruit samples. These suggested that Kent fruits treated with C1T30 and C2T30 and Keitt fruits treated with C2T30 were of preponderance in optimum quality in relation to sap burn injury even though the different sap burn injury mean scores recorded, other than those of the control, were not significantly different from one another at p>0.05. Hence, the statement by Krishnapillai et al.16 that low cost environmentally friendly methods could be used to manage mango fruit sap-induced injury.

Over the experimental period pulp colour of all the Kent and Keitt mango fruit treatments developed to levels that were not significantly different at p>0.05. For Kent fruits, the control treatments and treatments C3T30 and C3T25 recorded a mean score of 0.6 which was the highest though treatments C1T25 and C1T35 recorded the least mean score of 0.57 which was not significantly different from the former at p>0.05. With Keitt fruits, pulp colour development for all the samples was generally consistent except for samples treated with 0.25 % detergent concentration whose mean scores were comparatively low. These suggested that the detergent did not influence the development of pulp colour over the experimental period. According to Parthasarathy,19 Oyekanmi et al.,20 and Krishnapillai and Wijeratham16 mango fruits that were treated with a detergent for sap burn injury management resulted in no significant differences (p>0.05) in pH, TSS, and pulp colour/consistency among treatments in both the non-treated and treated fruits.

Altendorf36 and Tharanathan et al.37 reported that optimum skin/peel colour was an important mango fruit quality parameter that affected consumer acceptance and preference. Generally, all the treatments recorded fairly high mean scores for skin colour development in the present study but there were no significant differences (p>0.05) amongst them; an indication that the detergent did not influence peel colour development over the experimental period.

Amin et al.28 evaluated the performance of lime{Ca (OH)2} at different times of the day in comparison with Australian industry product {“Mango Wash”} for some physico-chemical attributes of mango fruit including fruit peel colour and non-reducing sugar content. Both lime and Mango Wash treatments showed significantly less sap injury when compared to control for all the three times {morning(7a.m.), noon(12 p.m.), and evening(5p.m.) and subjected to lime (0.5%) and Mango Wash at (0.4%) treatments} of treatment application. No sap injury (0 score) was observed in the fruits harvested and de-sapped during morning where as maximum sap injury was observed a noon in both the cases (0.5 score for lime, 0.75 score for Mango Wash). In the same vein significantly high Total Soluble Solids value was recorded for fruit harvested at noon when compared to other times of the day.28

Almost all the physico-chemical attributes were not significantly affected by the de-sapping treatments. Fruit peel colour was slightly suppressed by Mango Wash. Lime was found to give an attractive appearance to the fruits; however, the skin colour was not significantly improved when compared to the control. The time of fruit harvest also indicated non-significant effects on most of the fruit quality attributes.20,23,28

At the end of the storage period, levels of TSS content of all the different treatment samples were not significantly different from one another at p>0.05,suggesting that the detergent did not influence the development of TSS after treatment and storage. Amin et al.,28 Oyekanmi et al.20 and Ikotun et al.23 all attested that the quality of all tested physico-chemical attributes (pH, TSS, and mark etability) were found not to be significantly affected by de-sapping treatments at p>0.05 following their assessment via fruits of different mango (‘Willard’, ‘Chembaddan’, and ‘Ambalavi’ mangoes) varieties.

Concentrations of 0.25, 0.50, and 0.75% of “awabla” solution for 25, 30, and 35minutes immersion period in all combinations were established as appropriate and recommended for management of Kent and Keitt mango fruit sap-induced injury. The detergent (“awabla”) had a proven efficacy in the range of 87-94 % for Kent and 90-93 % for Keitt. The resultant peel colour, pulp colour, and total soluble solids(TSS)content of Kent and Keitt mango fruit samples were not significantly influenced by the treatments at p>0.05.

The management of Integrated Tamale Fruit Company (ITFC) Ltd Nucleus Mango Plantation in Dipale, Tamale, Ghana and the management of the Bio-chemistry Laboratory, Spanish Laboratory, University for Development Studies, Tamale, Ghana, are gratefully acknowledged for their co-operation and moral support.

Authors declare that no conflicts of interest existed.

©2021 Abu, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.