eISSN: 2576-4462

Blackberry is a fruit that has high nutritional value, a factor that has expanded its consumption worldwide. However, due to the fragility of the fruits and the high incidence of postharvest diseases, the fruits have a short shelf life. Thus, the objective of this study was to evaluate whether the application of coatings based on micro fibrillated cellulose (NC) and lemongrass essential oil (EO) nanoparticles can prolong the shelf life of blackberry fruits after harvest. EO-coated blackberry fruits at nanocellulose concentrations were analyzed as follows: 0; 0.2; 0.4; 0.6 and 0.8%, in addition to the control treatment of which neither essential oil nor nanocellulose was used, for each treatment five repetitions were used. The fruits were analyzed soon after the application of the cover and at three and six days after storage. Fruit quality was assessed by soluble solids (SS), titratable acidity (TA), pH, fresh weight (FW) and colorimetric parameters such as luminosity, hue angle and fruit peel chroma. Coating on EO (1000 ppm) blackberries combined with NC at concentrations of 0.2, 0.4 and 0.6% is promising in preserving blackberry fruits and reducing the process color reversal, up to six days of storage. The 0.4% NC + 1000 ppm EO conjugated coating showed no SS changes in blackberry fruits during the six days of storage.

Keywords: Morus sp., cellulose, Cymbopogon citratus, post-harvest quality

Blackberry is part of the small fruits group, known for the high amount of antioxidants substances on its composition. It is very explored for the nutraceutical industry for protecting human body cells of the harms caused by free radicals, which are responsible for chronic diseases.1–4

Although blackberry has bioactives that directly attracts the consumer, the fruit has a fragile structure, which reduces its consumption in natura.5 Its lifespan is relatively short after harvesting, because of the high content of water, its metabolism and the occurrence of diseases demanding care with storage.6,7

The use of edible coating is one of the effective technological alternatives in extending the lifespan of fruits and vegetables. This is justified, because the material layer acts with excellent property as an artificial barrier, maintaining its postharvest quality, reducing production costs.8,9According to Veerachandra& Yen-Com,10the use of coatings in food acts in the cross microbial reduction. This fact contributes to the maintenance of the viability of fruits that have a shorter postharvest life, such as blackberry.

Between the new perspectives of the use of coatings, cellulose can be highlighted. It is a natural polymer that, when reduced to nanocellulose, presents a crystalline structure with wide industrial applications.11 Its nanoscale dimension and its capacity of forming a strong nanoporous tangled network, encourage the emergence of new high value applications for the food industry.12

This particle has been widely studied as a component of materials, including food packaging.13 A benefit of the NC is its good water retention capacity, a feature that can be explored when applying coatings on fruits that have a high transpiratory rate.14 Water retention thus contributes to the durability of ready-to-eat foods,15especially due to the properties of the nano fibrillated cellulose, which has high strength and rigidity, low weight and biodegradability. The efficiency of this coat in the conservation of papaya fruits was verified by Trigo et al.16

At the same time, natural products extracted from medicinal plants are been studied as an alternative for the control of diseases and/or reduction of degrading processes in fruits, mainly in postharvest conditions.17Between these products, the OE shows themselves as a promising option.18

In this context, food industry is developing new packaging systems by incorporating EO or its main compounds into films.19This could give them antimicrobial or antioxidant properties, improving shelf life of perishable food products.20

Lemongrass EO is an efficient and sustainable option in postharvest treatment, as it interrupts the development of microorganisms.21,22Associated with other edible coatings, it is explored on guava postharvest.23

Considering the blackberry short postharvest life and the importance this culture represents for the market, the objective of this work was to evaluate if the application of the coatings based on nanoparticles of nano fibrillated cellulose (NC) and lemon grass essential oil (EO) is able of extend the shelf life of blackberry fruits after harvest.

Blackberry fruits of the cultivar Brazos were obtained from a commercial orchard in Ponta Grossa city, Paraná. The harvest was done during the morning and the fruits were immediately conduced to the laboratory, where they were washed in running water, dried with the aid of paper towels and divided into 90 (eighteen) portions of 40 grams (which corresponds to approximately 25 fruits), that were used to compose the treatments, as described in Table 1. At harvest, the selected fruits had the same maturation stage, aiming at uniformity of the experiment.

|

Evaluation times |

|

Nanocellulose (NC) and essential oil (EO) combinations |

|

- After coating (0 days)- 3rd days- 6rd days* |

In each epoch it was tested: |

Control (without NC and EO) |

|

0% (NC)+1000 ppm (EO) |

||

|

0.2% (NC)+1000 ppm (EO) |

||

|

0.4% (NC)+1000 ppm (EO) |

||

|

0.6% (NC)+1000 ppm (EO) |

||

|

0.8% (NC)+1000 ppm (EO) |

Table 1 Description of the treatments used in the research

*Note On the sixth day, no evaluation of fruits belonging to the control treatment was performed, as they deteriorated

To obtain the NC, pinewood residues submitted to acid hydrolysis with sulfuric acid in a cold-water bath to remove lignin were used. Passing through a filtration process, and, finally, dissolving in water to obtain the biofilm according to the methodology described by Ditzelet al.15

In order to obtain nanocellulose concentrations, the standard solution was diluted with 2% concentration in water to obtain the experimental solutions, obtaining 0.2%, 0.4%, 0.6% and 0.8%. After preparing the NC solutions, lemon grass EO was added on each solution, at 1000 ppm concentration, for all the treatments with NC, as the methodology of et al. (2008).

The biofilm application was done by dipping the fruits in the solution with a waiting time of one minute and subsequent drying for complete adhesion to the fruit; the procedure being conducted at laboratoryat 25ºC and 77% RH.Afterwards, the fruits were packed on closed plastic boxes, which allowed ventilation. The set was kept over a bench, in the laboratory, without sunlight exposition. After the fruit coating, the analyses were repeated after a storage period of three and six days.

On this way, a total of three evaluation periods were established, to know: right after harvest (0 days), at three and six days after fruit coverage. FoRozwalkar each evaluation periods, six NC+EO combinations were analyzed: control (without NC and EO), 0% (NC)+1000 ppm (EO), 0.2% (NC)+1000 ppm (EO), 0.4% (NC)+1000 ppm (EO), 0.6% (NC) + 1000 ppm (EO) and 0.8% (NC)+1000 ppm (EO). Still related to the treatments, on the sixth evaluation day for the treatment control, the fruits were discarded, because they were deteriorated and without possibility of been evaluated. The description of the treatments detailed is in Table 1.

Each treatment consisted of five 40gram repetitions (approximately 25 blackberry fruits), each repetition being separately packaged in a previously identified plastic bag.

The fruits were analyzed for the FW, colorimetry, SS, AT and pH

To obtain the FW (g), an analytical bench scale of the Shimadzu brand, model ATX224 was used, where the fruit was identified since the first day and was weighted every three days to evaluate the fresh weight loss. The final values were expressed in grams.

To the quality analysis, SS (ºBrix), AT (% malic acid) and pH were evaluated. The SS were quantified using a Biosystems LTDA bench refractometer (model 103). The AT was quantified by titration with 0,1 N NaOH and further calculated by the formula [ATT= (n. N. Eq)/ V], where n is the volume of sodium hydroxide solution spent on titration in mL, N is the normality of the sodium hydroxide solution, V is the sample volume in mL and Eq is the equivalent gram of malic acid.

The pH values were estimated with a tec5 model TECNAL bench pHgameter.

To the fruit coloration, a Konica Minolta bench colorimeter was used. The L (lightening) parameters reading, a* and b* allowed to calculate the Hue angle and the Chroma or color saturation. The Hue angle is equivalent to the [tangent arc (b*/a*)] and Chroma to [(a*2 + b*2) ½] according to Minolta.24

Statistical analysis

The data were analyzed using a completely randomized design (CRD). In the statistical procedure, the subdivided plots were adopted, with (3x6) scheme, being the first factor evaluation days (immediately after harvest, at three and six days of storage) and the second, fruit coating (0, 0.2, 0.4, 0.6 and 0.8% NC+OE, and the absolute control without NC and OE), with five repetitions. The averages were compared by the Student Newman Keulstest at p ≤0.05. When there was an interaction of the NC OE concentrations in each evaluation period, the regression analysis was performed. All the data were computed and entered in Excel, looking for generate the tables and graphics. The statistical analysis was done using the program RStudio.25

The pH, AT, SS and FW results for blackberry fruits and the comparison of the results obtained between the different evaluation periods, right after coating application, at three and six days of storage are show in Table 2.

|

Evaluation after storage (days) |

Fruit treatment at postharvest |

|||||

|

Control |

EO+NC 0% |

EO+NC 0.2% |

EO+NC 0.4% |

EO+NC 0.6% |

EO+NC 0.8% |

|

|

pH |

||||||

|

0 |

3.05 b |

3.02 c |

2.97 b |

3.06 c |

3.08 c |

2.95 b |

|

3 |

3.37 a |

3.22 b |

3.38 a |

3.52 b |

3.36 b |

3.45 a |

|

6 |

- |

3.52 a |

3.37 a |

3.66 a |

3.56 a |

3.47 a |

|

CV (%) |

2.05 |

|||||

|

|

Titratable acidity (% malic acid) |

|||||

|

0 |

3.07 a |

1.54 a |

2.18 a |

2.30 a |

2.05 a |

1.80 a |

|

3 |

1.18 b |

1.28 b |

1.28 b |

1.28 b |

1.28 b |

1.28 a |

|

6 |

- |

1.28 b |

1.28 b |

1.28 b |

1.28 b |

1.28 a |

|

CV (%) |

24.62 |

|||||

|

|

Soluble solids (°Brix) |

|||||

|

0 |

7.3 a |

6.4 b |

6.5 ab |

6.2 a |

7.0 b |

5.9 b |

|

3 |

7.2 a |

8.2 a |

5.9 b |

7.5 a |

8.8 a |

8.2 a |

|

6 |

- |

6.0 b |

7.8 a |

7.4 a |

6.8 b |

6.0 b |

|

CV (%) |

14.47 |

|||||

|

|

Fresh weight (g) |

|||||

|

0 |

5.15 a |

5.27 a |

5.27 a |

5.50 a |

4.97 a |

5.76 a |

|

3 |

4.63 a |

4.73 b |

4.85 b |

4.91 b |

4.50 b |

5.24 b |

|

6 |

- |

4.10 c |

4.16 c |

4.27 c |

3.94 c |

4.50 c |

|

CV (%) |

5.68 |

|||||

Table 2 Average pH data, titratable acidity (TA), soluble solids (SS) and fresh weight (FW) of blackberry cv. Brazos treated with micro fibrillated nanocellulose coating associated with lemongrass essential oil, in function of the evaluation period. Where: (NC) nanocellulose and (EO) essential oil

Averages followed by the same lowercase letter in the column do not differ from each other by the Student Newman Keuls at p≤0.05. The treatments with “-” means that the evaluations were not performed because of the complete deterioration of the fruit

It is observed that pH values in blackberry fruits varies according to the used coating (Table 2). To the treatments with OE and NC at 0.2% and 0.8% concentrations at three and six days after storage, the highest pH values occurred. Already at six days of evaluation, coating with EO and NC at 0, 0.4 and 0.6% at the sixth day, had the higher pH values (Table 2). High pH values are indicatives of fruit deterioration.6 In this sense, lower pH values indicate fruits that are in less deterioration process. Thus, the best values were found for OE+NC coating at the following values: 0.2% (immediately after coating application), 0.4% at three days of coating and 0.6 and 0.8% NC right after coating.

The process of fruit deterioration occurs due to the greater respiratory activity of the fruit. As cells breathe intensely, there is a higher consumption of sugars and organic acids contained in it.26This fact reduces the fruit lifespan. The fruit coating with biofilms can limit the oxygen diffusion, reducing the respiratory rate and, consequently, the deterioration.

The TA of blackberry fruits (Table 2) coated with NC and lemongrass EO at 0.2, 0.2 and 0.6% concentrations presented the greatest acidity values, been this result obtained right after the coating of the fruits. It is worth noting that high values of titratable acidity are indicatives of the presence of organic acids, which confer flavor to the fruit. According to Hirsch et al.3acidity is one of the important parameters used in classification of pulps for juice production. The pH and TA values coincide with those found by Turmanidze et al.27where the application of edible coatings did not show significant changes during the fruit storage period.The average valued of TA coincide with the ones found by Curiet al.2to the cultivar Brazos, these values are within what is accepted for the fruit’s commercialization.

To the SS of blackberry fruits (Table 2), the highest °Brix values were found to the EO+NC coatings at concentrations of: 0.2% at the sixth day of evaluation, 0.6% and 0.8% at the third day of evaluation. The °Brix is an indicative of the quantity of sugars in the fruits. The values obtained here (Table 2), ranged from 5.9 to 8.8 °Brix and some of these agree with Curi et al.2who obtained 7.4 °Brix for fruits of Brazos cultivar. However, these values can also be influenced by the management and climatic conditions of the plants in the field. According to Kafkas et al.4the accumulation of reducing sugars (glucose and fructose) is very important to the blackberry postharvest physiology, been responsible for the fruits sweet flavor.

With the progress of storage (Table 2), it is observed that the loss of fresh fruits decreases, especially when using the coating of blackberry fruits with nanocellulose and lemon grass essential oil. The smaller fresh fruit loss can be related to the low respiratory rate, because as the fruit tissues cells breathe, there is a sugar consumption contained on it.26 Other factors that interfere in the fresh weight loss reduction is the transpiration process, at storage temperature reduction.28

The use of fruit films alters the gas exchange between the vegetable and the external environment, through a lower respiratory quotient.29This factor explains the variation in fresh mass loss obtained among coated fruits.30

According to Yamamoto et al.31calcium chloride, which may be present in the chemical composition of some biofilms, when associated with the pectin present in the cell wall of the cells lining the fruit, forms covalent bonds rising calcium pectate, component responsible for the external fruit layer rigidity.32This component acts reducing the transpirations and, consequently, the fresh weight loss of the fruit.

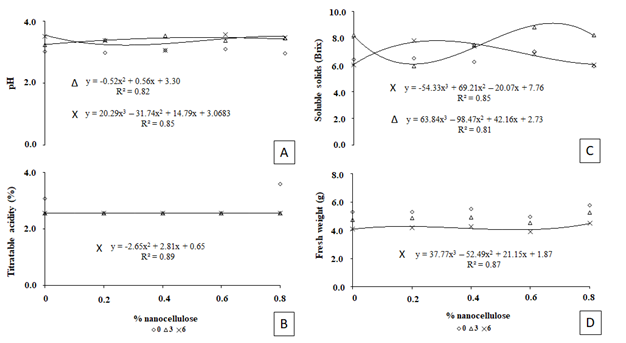

The Figure 1 shows the blackberry behavior as different concentrations of NC were applied. It is worth noting that the periods of evaluation tendency lines (0, 3 and 6 days) that showed significant differences are represented in isolation.

The AT (Figure 1B) and SS (Figure 1C), of blackberry fruits evaluated at six days after storage, presented values reduction tendency as there was an increase in NC concentration. High titratable acidity concentrations may indicate better fruit quality, because it confers flavor to the fruits.

The FW(Figure 1D) of blackberry fruits becomes higher as the NC concentration increased to 0.8%. However, it is noteworthy that when evaluating the individual effect of each NC concentration (Table 2), FW tends to reduce until the sixth day of storage.

Figure 1 pH (A): pH, titratable acidity (B), soluble solids (C) and fresh weight (D) of blackberry cv. Brazos, in function of the different nanocellulose associated with lemongrass essential oil concentrations.

To the blackberry fruits pH (Figure 1A), it was observed that the evaluation performed at three days after storage presented a pH reduction tendency as there were a NC concentration increase. Already to the fruits evaluated at six days, there is a pH stability with the NC concentrations increase (Figure 1A). The pH stability over the storage days and the SS increase do not coincide with the results found by Trigoet al.16where pH increases decreased SS concentration in papaya fruits tested and consequently there was a reduction of the color attributes such as Chroma.

The results of luminosity, Hue angle and Chroma for blackberry fruits are presented in Table 2. The comparison of the obtained results between the different evaluation periods, right after coating application, at three and six days of storage (Table 3), records an oscillation of values between the analyzed treatments.

|

Evaluation after storage (days) |

Fruit treatment at postharvest |

|||||

|

Controle |

EO+NC 0% |

EO+NC 0.2% |

EO+NC 0.4% |

EO+NC 0.6% |

EO+NC 0.8% |

|

|

Luminosity (*L) |

||||||

|

0 |

15.38 a |

19.14 a |

18.58 ab |

18.11 a |

16.94 b |

16.68 a |

|

3 |

14.75 a |

19.55 a |

17.20 b |

15.62 b |

17.66 ab |

16.10 a |

|

6 |

- |

18.26 a |

20.32 a |

19.82 a |

19.69 a |

15.85 a |

|

CV (%) |

9.60 |

|||||

|

|

Hue Angle |

|||||

|

0 |

26.80 a |

17.86 a |

17.74 a |

17.98 b |

20.52 a |

18.98 a |

|

3 |

29.86 a |

16.83 a |

15.95 a |

29.00 a |

14.11 a |

22.04 a |

|

6 |

- |

17.07 a |

15.96 a |

16.43 b |

22.21 a |

29.30 a |

|

CV (%) |

35.04 |

|||||

|

|

Chroma |

|||||

|

0 |

1.10 a |

9.12 a |

10.20 b |

18.11 a |

16.94 b |

16.68 a |

|

3 |

1.78 a |

10.52 a |

9.67 b |

15.62 b |

17.66 ab |

16.10 a |

|

6 |

- |

8.15 a |

13.73 a |

19.82 a |

19.69 a |

15.84 a |

|

CV (%) |

25.29 |

|||||

Table 3.Average luminosity data (*L), Hue angle (hue) and chroma (Chroma) of blackberries cv. Brazos treated with microfibrillated nanocellulose coating associated with lemongrass essential oil, in function of the evaluation period. Where: (NC) nanocellulose and (EO) essential oil

Averages followed by the same lowercase letter in the column do not differ from each other by the Student Newman Keulsat p ≤ 0.05. The treatments with “-” means that the evaluations were not performed because of the complete deterioration of the fruit.

The Hue angle (Table 3) showed no significative differences for EO+NC concentrations at 0, 0.2, 0.6 and 0.8% regardless of the evaluation period. For the control treatments and OE+NC at 0.4% concentration, on the third day of evaluation the fruits already had the highest Hue angle values (Table 3).

When analyzing the average values of Chroma (Table 3), it is observed that the blackberry fruits coating with OE + NC at concentrations of 0.2, 0.4 and 0.6%, determined at six days of storage presented the highest values (Table 3). These results are indicative of better fruit quality (OE + NC 0.2, 0.4 and 0.6%), as it is an indicative of the fruit color intensity, that is, higher values indicate more intense samples which pleases consumers.3

Observing the fruit luminosity results (Table 3), the application of EO+NC coating at 0.2, 0.4 and 0.6% presented high luminosity values at six days of storage. These results are indicative of better fruits quality, because the higher is the luminosity, the better is the visual quality of the blackberry fruits, as it keeps a shine that pleases the final consumer.28

Maintaining the postharvest life and quality of blackberries is a challenge for growers and packers due to several postharvest problems, including fresh weight loss and color reversal.24,33Looking for reducing these losses, the use of techniques as cooling and the use of packaging became viable alternatives.6According to Bischoff et al. (2013), blackberry hue decreases during the storage days due to the fruit water content reduction. It is observed by the luminosity results (Table 3) that even at six days of storage, the blackberry coating with EO+NC at 0.2, 0.4 and 0.6% concentrations are promising in maintaining their quality.

According to Hirsch et al.3the hue angle is a variable that is between 0° and 90°, and the smaller the angle value, the redder the fruit. Such fact is not desirable for blackberry fruits, whose desirable color in the market is purple. Lower Hue values suggest that the fruits began to appear reddish over the days. This reddish appearance of the fruits pericarp (exocarp) is known as the blackberry color reversal process. The color reversal process is undesirable for producers as it impairs the fruits appearance and, consequently, reduces the value of the final product to consumers.34

Chroma values may be associated with the influence of the coating film color, which has a whitish coloration and are also linked to the increase of the fruit’s SS over the storage days due to the starch retrogradation into smaller sugar molecules.16

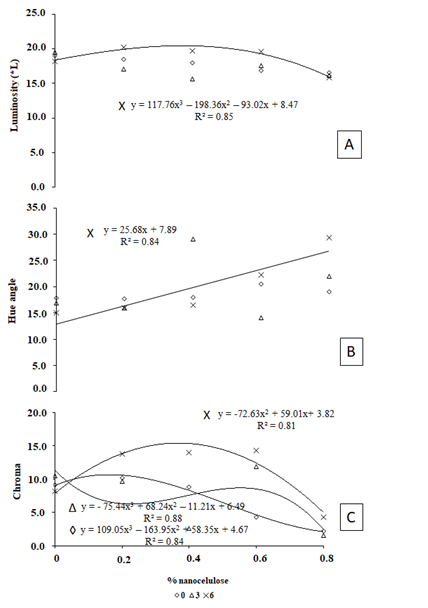

Figure 2 shows the behavior of blackberry fruits as different concentrations of NC are used, as for luminosity (A), Hue angle (B) and Chroma (C). It is noteworthy that the tendency lines of the evaluation periods (0, 3 and 6 days) that presented significative differences are been displayed in isolation.

It is observed that the blackberry fruits luminosity (Figure 2A), for fruits evaluated at six days after storage, the peak value was 0.4% EO + NC. The fruit color changes its luminosity and is an important parameter for producers and consumers as it indicates if the fruit has or not ideal conditions for its commercialization and consumption,3as preferably strong and bright color.

The average Hue angle data (Figure 2B) for blackberry fruits evaluated at six days of storage show an increasing value trend as the concentration of NC increased. Thus, at six days of storage, the increase in the NC + EO concentrations used for coverage keeps the blackberry fruits in their original coloration, not allowing the fruits to change their coloration to a reddish skin coloration.

As for the average values of Chroma, there is a tendency of value reduction, as the NC concentrations increase, both for fruits evaluated right after harvest and for those evaluated at six days after storage (Figure 2C). However, it is noteworthy that the individual evaluation of each NC concentration (Table 3), especially for the EO + NC coatings at concentrations 0.2, 0.4 and 0.6%, gave at six days of evaluation, the highest Chroma values.

Figure 2 Luminosity (*L) (A), Hue angle (B) and Chroma (C) of blackberry cv. Brazos, in function of different nanocellulose associated with lemongrass essential oil concentrations.

The lower luminosity values (Figure 2A), were found in the control treatments, 0% NC = EO, and with the highest concentrations of NC + EO (0.6 and 0.8%) and may result from alteration of some molecular structure of starch, which is responsible for increasing the fruit opacity. The brightness decreases with the ripening of blackberry fruits, indicating that the color becomes more intense or darker. The appearance of the purple color may be related to the appearance of phenolic compounds.34,35

The application of coating associating lemongrass EO (1000ppm) and NC at 0.2, 0.4 and 0.6% concentrations are promising in blackberry fruits conservation until six days of postharvest.The blackberry fruit coating with 0.4% NC+1000 ppm of EO did not present SS changes during the six days of storage.

The visual appearance of the blackberry fruits, postharvest coated with 1000 ppm of lemongrass EO associated with 0.2, 0.4 or 0.6% of NC, maintains characteristics that retard the fruits color reversal process, up to six storage days.

New nanocellulose and EO combinations should be tested to extend potential use of berry biofilms.

The authors declare have no conflict of interest about the publication of this paper.

© . This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.