eISSN: 2577-8242

Research Article Volume 2 Issue 5

Hindustan Construction Company, India

Correspondence: Rajeev Prasad, Chief Geologist, Tehri Pump Storage with Hindustan Construction Company, Kandkhala, Tehri Garhwal, India, Tel (+)918192899283

Received: September 24, 2018 | Published: December 31, 2018

Citation: Sharma N, Prasad R. Geological and Geotechnical Evaluation for the Stabilization of Tail Race Tunnel Outfall Slope – A case study of Tehri Pump Storage Plant (1000 MW), Tehri Garhwal (Uttarakhand). Fluid Mech Res Int J. 2018;2(5):234-241. DOI: 10.15406/fmrij.2018.02.00043

Tehri project, a prestigious hydropower project is the first major attempt to harness vast hydro potential of bhagirathi river which is fed by gangotri glacier. The storage project in the bhagirathi valley in uttarakhand himalaya, envisages impounding of surplus monsoon water of the river for utilizing it in regulated manner for hydropower generation. The 2400mw tehri hydro power complex comprises of tehri hydropower project(hpp)) (1000mw) stage-1,koteshwar hydroelectric project(400mw) and tehri pumped storage plant (psp) (1000mw).tehri pumped storage plant(psp) is being under construction and aligned parallel in the same hill as the tehri hpp underground complex. Major project components under construction are machine hall, upstream surge shafts, butterfly valve chamber, penstock assemble chamber, downstream surge shafts, pair of tail race tunnel and outlet structure. The two tail race tunnel namely trt-3 (1081m long) & trt-4(1174 m long) are connected to outfall/intake structure with sluice gate and trash rack. This outfall structure is an integral part of the tehri pump storage plant and is of utmost importance. To accommodate the hydro mechanical and electro mechanical components at outlet structure, safe cut slope is require based on rock type and geotechnical parameters to ensure safety of the outfall structure. Detailed geological/geotechnical investigations were carried out and suitable methodology for the slope stabilization adopted in different variant of phyllitic rock and patch of rbm/dumped material, which is emerged as a geological surprise. This paper briefly describes the construction methodology for trt outfall structure giving excavation sequence, slope stabilization and strengthening of slope based on geological and geotechnical data obtained from the investigation and monitoring instruments installed at the structure.

Keywords geological/geotechnical investigation, excavation sequence, slope stabilization, strengthening of slope, rock mass, recycling the water, penstock assemble chamber, geological mapping, core drilling, chandpur phyllites, lithological variants, outfall area, rock stratigraphy, lithological variants

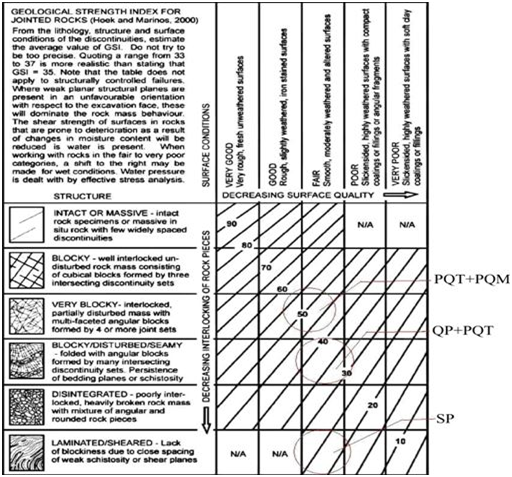

Tehri pump storage plant is located in the left bank of river bhagirathi in the state of uttarakhand falling between78°30´ and 79°00´ e longitudes and corresponding 30° 30´ and 33°30´ n latitudes (Figure 1). the nearest rail head is rishikesh which is located approximately 82 km from project site.1 It will be a peaking power plant located between the tehri and koteshwar dam, which is also the part of tehri hydro power complex. Tehri pump storage plant is being developed by thdc india limited (a joint venture of central government of india and government of uttar pradesh).2 Tehri dam forms as an upper reservoir while koteshwar dam will serve as a lower reservoir to the tehri pump storage plant. Power will be generated by recycling the water discharge between two reservoirs. Tehri pump storage plant which is under construction and being executed by m/s Hindustan Construction Company under epc mode. The major project components are machine hall, upstream and downstream shafts, butterfly valve chamber, penstock assemble chamber, a pair of tail race tunnel and outlet structure. Tail race tunnel outfall structure is not like a usual outfall structures, but a very critical one as this structure also has to work as an intake. Design and construction of this structure involves some key issues, such as stability of outfall slope, geotechnical parameters of the rock mass and support estimation. In view of these issues detailed surface geological mapping, core drilling at various locations suggested by designers as well as exploratory cross cut drifts(ea-08)3 has been excavated to explore the subsurface geological conditions behind the slope. Based on all above information geological model of slope has been developed. To support the findings a geological plant and sections have been developed using geological information of ea-08 and core logs drilled at various locations in trt outfall area.4 In addition to this geotechnical parameters such as ucs and gsi have also been taken using schmidt hammer readings and geological strength index chart5 after carried out detailed geological/geotechnical investigations, a methodology was chalk out to strengthened the outfall slope with detail excavation sequence using geological/geotechnical data obtained from monitoring instruments installed at site described briefly in this paper. The typical excavation plan of trt outfall /intake and natural slope are shown in (Figures 2-3).

Tehri project area lies within the main himalayan block (mhb) , in the midlands of lesser himalayas bounded to north and south by regional tectonic lineaments – the main central thrust (mct) and main boundary fault (mbf) respectively. The former, to the north separates the meta-sedimentary sequence of lesser himalayas from the crystalline rocks of higher himalayas and the latter marks boundary between lesser himalaya and tertiary sequence of frontal foothill belt (ffb), in the south. The rock stratigraphy of lesser himalaya exposed around the tehri project area are broadly classified in to garhwal, shimla, jaunsar, karol and tal groups,2 the folded metasedimentary rocks exposed around the project site form an uninterrupted sequence of chandpur phyllites having variable propotion of argillaceous and arenaceous constituents. Considering the rythmicity of intercalated bands and varied degree of tectonic effects in them, the phyllites has been classified in to mainly four lithological variants. Rock mass in this area are mainly variants of phyllites and classified as below:

Pqm and pqt are more quartzitic (arenaceous) and rarely micaceous in composition with coarser grain size. These rocks are grey, dark grey, greenish and grayish grey in colour. It is mainly comprises of quartz, feldspar and oriented leths of micaceous minerals.qp is more arenoargillaceous in composition. Sp comprises of argillaceous and deformed variants of pqm and pqt rock formed in shear zone area which has weak rock mass characteristics.7

Trt outfall slope is characterized by the presence of pqm+pqt, qp with bands of pqt and sp. Pqm and pqt are the massive varieties with different bed thickness while sp occupies very weak and sheared phyllite zone. In general thickness varies from few cm. To 1.50m as observed in exploratory drift. Surface geological mapping indicates that the rocks of pqt+pqm are well exposed in the rocky cliff just upstream of trt-3 portal i.e. Near the upstream of coffer dam and extended up to exploratory drift(ea-08) portal.in general the strata is uniformly dipping with kinking particularly in sp occupied stretches and dips at n195°/45°-55°(j1 set of joint) and are dissected by joint set j2:n150°/35°-45°,j3:n20°/60°-65° and j4:n295°/60°-70°other than the foliation joint j1.this foliation joint is represented by smooth and slightly undulating surfaces. Very closely to closely spaced and have persistence and have persistence along strike of 3-10m.joint sets j2 and j3 are slightly rough, planar to slightly undulating, closely to widely spaced and have a persistence of generally <10m.joint set j4 is rough, planar and discontinuous with persistence of < 3 to 4 m.details of discontinuity data observed in trt outfall area mentioned in (Table 1). On the nw side of the cutting several shear bands within the phyllites are exposed and these can be traced 20-30m along the slope, but appear to not extend as far as the ea-08 portal area. These shear zones are the major cause of planar/polygonal failure as they are dipping along the direction of cut slope. Some kink bands have been observed in the upstream part of slope which can also the cause of failure along with other joints as shown in (Figure 4). Overburden observed just downstream of trt-4 portal and also towards upstream of trt-3 portal comprises the colluviums limit of rock exposure. The thickness of overburden increases at higher reaches, however in general it has been expected less then 3.0meters in both directions. The present slope is moderately inclined; dipping towards sw direction i.e. N225°. Overall this slope is concave in disposition and the slope is sub-parallel to strike of foliation towards upstream (near ridge i.e. 30-40m upstream of ea-08 portal) and is oblique at an angle of 40°-45° towards downstream (Figure 5).

Joint Set |

Avg. Dip Amount |

Average Dip Direction |

Spacing (Cm) |

Filling |

Roughness |

J1 |

N180° - 210° |

45°-55° |

Oct-40 |

Clay & Crushed Rock |

Undulation , Slightly Rough |

J2 |

N140°- 165° |

35°-45° |

25-60 |

Crushed Rock with Quartz |

Planner, Slightly Rough |

Table 1 Discontinuity data of the TRT Outfall Slope

Sl. No. |

Name of Hole |

RD/Location |

Size of Hole (mm) |

Length of Hole |

Angle with Horiz. |

Start Date of Bore hole |

Finish Date of Boring |

Remarks |

1 |

CH 57 |

TRT-3 Outlet |

76(Nx) |

34 |

90 |

13-Oct-11 |

18-Oct-11 |

|

2 |

CH 58 |

TRT-4 Outlet |

76(Nx) |

34 |

90 |

19-Oct-11 |

25-Oct-11 |

|

3 |

CH P1 |

76(Nx) |

37.2 |

90 |

20-Apr-15 |

30-Apr-15 |

||

4 |

CH P2 |

TRT Outlet |

76(Nx) |

30.2 |

65 |

18-May-15 |

2-Jun-15 |

|

5 |

CH P3 |

76(Nx) |

55 |

0 |

9-Jun-15 |

27-Jun-15 |

||

6 |

CH P3’ |

|

76(Nx) |

20 |

90 |

12-Apr-15 |

18-Apr-15 |

|

Table 2 Showing the details of Core Hole executed at different locations of TRT outfall

Rock Type |

Average UCS Value(MPA) |

Assigned UCS Value(MPA) |

SP |

23 |

23 |

PQT+PQM |

53 |

53 |

QP+PQT |

45 |

45 |

Table 3 Assigned UCS Values for different Litho-units

Rock Type |

GSI Range |

GSI Assigned |

SP |

20-30 |

25 |

PQT+PQM |

40-50 |

45 |

QP+PQT |

30-40 |

35 |

Table 4 Assigned UCS Values for different Litho- units

Figure 9 Geological Strength Index for different litho-units along EA-08(After Marinos & Hoek 2000).

Detail design analysis has been carried out to finalize the support system on trt outfall slope using global and local stability in dry, wet and saturated ground water conditions (Table 5) summarized the support recommendations for outfall slope.9-10 It has also been recommended that all the activities for stabilization of slope to be carried out from top to bottom elevation with proper monitoring.

Sl. No. |

Activity |

Support Details |

1 |

Slope Excavation |

The cut slope above El:-616.0m to be excavated in 1(H):2(H) slope while below that 1(H):5(H) in slope |

2 |

Rock bolts and Cable anchors at main cut slope face |

8 rows of 120 Ton cable anchors @ 2.0 X 2.0m c/c spacing (staggered) above El:-608.0m to be provided(Figure:-11) |

Apart from this pre tensioned fully grouted rock bolts of 310 KN, 12.0m in length@1.5 X1.5m c/c shall be provided |

||

3 |

Rock bolts at Upstream and Downstream cut slope faces |

Pre tensioned fully grouted rock bolts of 310 KN,12m in length @ 1.5 X 1.5m c/c spacing shall be provided |

4 |

Shotcrete at all slope faces |

100 mm thick layer of shotcrete with one layer |

of wire mesh shall be provided |

||

5 |

Drainage System |

Drainage holes of 76 mm diameter , 10.0m long @ 3.0m c/c (staggered) shall be provided in upward 20° direction to avoid the saturation of rock mass |

6 |

Monitoring of Slope |

Proper monitoring of slope is required during and after construction |

Table 5 Summarized the support recommendations

Keeping view of support recommendations after conducting detailed analysis, a methodology with sequence wise excavation and support details prepared to stabilize the out fall slope. As stated above all the excavation and stabilization work carried out from top elevation. Top bench elevation varying from el:-670.0 to 660.0m.the support system for this bench is reinforced cladding wall with berm at el:-660.0m along with rock anchors of 25mm diameter, 6.0m long cement grouted @ spacing of 2.0m c/c. Drainage holes of 76 mm diameter, 6.0m long @ 4.0m c/c spacing with perforated pvc pipe. To ensure that rock anchors and cladding wall work as a composite system, the bearing plate on rock anchors are placed over cladding wall.10 The cladding wall is provided to strengthen the existing road level @ el:-670.0m. After completion of cladding wall, excavation and support installation work below el:-660.0m will be started. The bench wise sequence and support system is mentioned in tabular form (Table 6-7).

Slope Support at Face |

|

|

|

|

|

|

|

Elevation |

Shotcrete |

Wire Mesh |

Rock Bolts |

Drainage Holes |

Cable Anchors |

||

From |

To |

|

|

Type |

Length |

|

|

660 |

644 |

100 mm |

1 layer |

350 KN,32 Ø Pretensioned grouted rock bolts |

12.0m |

76Ø, 10.0m long, inclination 20° upward |

El:-624.0 to 610.0m ,20.0m long , 10° downward with 120 Ton capacity |

644 |

632 |

||||||

632 |

616 |

||||||

616 |

608 |

||||||

608 |

598 |

||||||

Table 6 Slope supports at face corresponding to Bench Elevation

Slope Supports at End Walls |

||||||

Elevation |

Shotcrete |

Wire Mesh |

Rock Bolts |

Drainage Holes |

||

From |

To |

|

|

Type |

Length |

|

660 |

644 |

100 mm |

1 layer |

350 KN,32 Ø Pretensioned grouted rock bolts |

8.0m |

76Ø, 10.0m long, inclination20° upward |

644 |

632 |

|||||

632 |

616 |

|||||

616 |

608 |

|||||

608 |

598 |

|||||

Table 7 Slope supports at End wall corresponding to Bench Elevation

The geotechnical instrumentation plays a vital role in evaluating the structural performance of an underground structure. The natural ground or rock mass tends to deform and de-stress when subjected to excavations, foundation and other loadings etc. Activities like squeezing, swelling and creeping depending upon the mechanical characteristics of the material are also responsible for the disturbances inside the rock mass. The long term performance of any structure is monitored by installing the structural instruments to predict and evaluate the safety of excavated openings. However, the question on number, type of instruments can only be addressed by fortuitous combination of understanding the structural behavior.11 Various type of instruments are recommended like multiple type bore hole extensometer (mpbx), optical targets and stand pipe piezometer at various level as mentioned below

Proper geotechnical monitoring with prescribed instruments carried out regularly and it has been observed that the deformation are beyond warning limit.

Excavation sequence and support system provided as per approved methodology with proper monitoring. Benches are properly monitored and geologically mapped to know the structural behavior of rock mass. Details of support system installed till date is shown in (Figure 11). A geological surprise was encountered during excavation in the downstream area from el:-660.0 to 641.0m where rbm (rive borne material) and talus/filled muck were observed. The thickness of this band is± 60.0 m. It was decided to protect this zone by single layer of wire fixed with soil nails along with 100 mm thick dry shotcrete (m25 a10).self drill anchors (25ø),3.0m in length with a spacing 1.5m c/c has been provided. Till date support system provided up to el:-±652.0m in rbm and el:-± 634.0m in rocky strata (Figure 12). On the basis of surface geological map two numbers of sections were developed to know the accuracy of rbm and talus deposit thickness (Figure 13). Designed methodology reviewed and support system recommended for this area is slightly changed .high tensile rolled cable with secondary mesh along 32ø self drill anchor, 12.0 m in length to be provided. Instead of shotcrete, non woven geogreen erosion control blanket for plantation will be used in such type of exposure.12-13 The typical tensile strength is more than 7.5 kn/m in machine direction and 1.5 kn/m in cross direction the specified nominal weight of blanket is 600 gm/sqm and thickness is 6 mm. Installation of self drill anchors was not smooth in rbm due to encounter of boulders and pebbles. Further excavation in rbm at el:-646.00m gabions were provided to support the toe. The high tensile cable net will also be anchored through the bottom of gabion walls. Slope is being cut in bench depth of 1:5 with application of simultaneously support system. The soil nails will also be used in excavation to hold the rbm behind the treated area while excavating below the treated portion of rbm for each bench. Excavation is in progress and support system shall be provided based on geological features and geotechnical monitoring.

Selection of excavation methodology for the geological surprise area and design of support system is always a challenging. Following are the conclusions from the analysis for the recommendation during construction:

Authors are thankful to the management of thdc india ltd. & m/s. Hindustan construction co. Ltd. For providing necessary support to carry out the work.

There is no conflict of interest between the authors.

©2018 Sharma, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.