eISSN: 2641-936X

Conceptual Paper Volume 2 Issue 4

Electrical Engineering Department, Shahid Sattari Aeronautical University of Science and Technology, Tehran, Iran

Correspondence: Hamid Radmanesh, Electrical Engineering Department, Shahid Sattari Aeronautical University of Science and Technology, Tehran, Iran

Received: March 14, 2018 | Published: November 27, 2018

Citation: Radmanesh H, Samkan M, Kazemi M. Quasi-Z-Source DC-DC converter for fuel cell-battery power generation system. Electric Electron Tech Open Acc J. 2018;2(4):296-300. DOI: 10.15406/eetoaj.2018.02.00031

Due to optimization, economical issues and the current sharing in the fuel cell (FC) system, a battery or a super capacitor is also used along it which would require an additional adapter to connect the battery to the DC link; This paper presents a new topology and control method for fuel cell- battery system using the quasi-Z-source converter (qZSC). Additional adapter is omitted in proposed system. Also The battery State of charge, fuel cell power and the output voltage of the converter are controlled independently. This new method is evaluated by simulation using MATLAB/SIMULINK software.

Keywords: quasi-Z-source converter, fuel cell, battery, DC/DC

Green energy and distributed generation play a key role against global warming and our main reachable sources are solar energy, fuel cell system and wind energy, and they are developing rapidly due to cost and availability.1 FCs are fascinating electrical sources that could be considered as the cleanest and most efficient energy sources.2 This system of energy production is largely used in electric vehicles3,4 and distributed generation (DG)5,6 despite of its benefits, due to its inherent features, special specification should be considered in design procedure. For example, for increasing efficiency and extending the lifetime, FC should be used in almost fixed and smooth situations and could not be used with the highly variable loads, so a power supply that has low time constant such as the battery or super capacitor is required, and also the current drawn from the FC should be continuous to avoid any damage to the FC stack. Figure 1 shows a typical FC-battery system.

Another important feature is the low voltage of FC stacks and this is one of the most challenging points in designing FC system, because a DC-DC converter is required for increasing the voltage level, whereas the input current of the converter is very high. There are usually two methods for increasing the voltage level, one is two-stage voltage rising which consists of a boost converter and an isolated converter, and the other way is using an isolated converter with a transformer with large turns ratio. Each of these ways has its specific benefits and disadvantages. In two-stage one, the complexity of control and large number of components and in one-stage method, high rate of leakage inductance and losses are undesirable.

An interesting solution for this application is voltage fed quasi-z-source dc-dc converter7 that its schematic view is shown in Figure 2. Z-source (ZSC) and quasi-z-source (qZSC)8,9 have found many applications in several fields, particularly for DC-AC, DC-DC and matrix conversion in last few years.10 qZSCs have some unique features such as: voltage buck and boost functions in a single-stage power conversion, inherent input filter, immunity against dc-link capacitor short circuit and dead time consideration for switching and continuous input current that is necessary for FCs. Also battery can be added to the system with no need for an extra interface adapter and it will increase the efficiency of the system.11 is an excellent example of discussed application.

The qZSC operates in two states:

Proposed system and configuration

System configuration: Configuration of the proposed system is shown in Figure 2 and it includes fuel cell (Vin), voltage-fed quasi-z-source impedance network, the battery, isolated booster full bridge, and the output filter. If characteristics of the high frequency isolated transformer are near ideal transformer, for simplicity of modeling and calculation, an equivalent circuit can be assumed like Figure 3.

As it mentioned, there is two switching state, which would be explained as following:

1) shoot-through state occurs when all switches are on and dc-link gets short circuit; also the battery current (Ib) is outward and according to the equivalent circuit (Figure 3a), one can write:

(1)

2) non-shoot-through state occurs when just one switch in each leg from upper and lower switches are on, also Ipn represents the input current to the bridge and according to the equivalent circuit (Figure 3b), one can write:

(2)

At the steady state, the average voltage of inductors in a period and also the average current of capacitors in a period will be zero, and considering these relationships one can write:

(3)

and also

(4)

FC and battery characteristics

The voltage of the FC is a function of its current and the injected hydrogen and oxygen to it. Although this function is non-linear and complex, it can be approximated and considered as a voltage source (Ve) and an internal resistance (Rin), in which the terminal voltage is called Vin. For the efficient performance FC should be used just in a limited zone of voltage-current characteristic curve. Also the battery voltage is related to its current and the value of the state of charge. Also in many applications SOC level should be maintained in the certain area (e.g. 50% to 90%) and its current is limited to a maximum value, to avoid damaging the battery. In this project the typical model of the battery is used in MATLAB/SIMULINK software.

Description of the proposed system modes

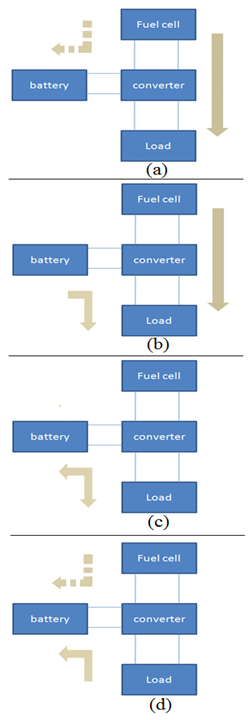

To explore the control system, operating modes are studied first, which proposed system should be able to work properly in all of these modes and provide essential energy management strategies. These modes are as following:

Figure 4 Operation modes of a FC-battery system, (a) medium power. (b) high-power. (c) low-power. (d) returning energy.

Implementation of proposed control system

Figure 5 shows the control principle and switching pattern of the proposed system, that7 studied a similar method with block diagrams in details completely. In this method control of Da (active state) and Ds (ST state), is done separately in a way that control signal and its negative are compared with a triangle wave to determine the pulse width of each one. Triangular signals are with 90 degree phase difference. In addition, for increasing efficiency and reducing the losses which are due to high current ripple of L1 and L2, its limited the Ds value to at most 30%. In Figure 5, signals illustrate the method of creating Da, Ds, pulse width of Da and the transformer primary voltage, respectively.

As it mentioned previously, relation between Vfc and Vb is:

(5)

When n is the transformer turns ratio, output voltage is

(6)

In addition to control the output voltage with Da, the FC voltage terminal (Vin) is controlled by Ds that its current will be controlled consequently. So the battery provides excess or shortage of the load current and the fuel cell remains in the most efficient and safe range.12,13 Figure 6 shows a schematic of the two parallel controllers.

Simulation is provided to evaluate the proposed system and Parameters in Table 1 are used in it. Also according to similar other papers, to have visible changes in SOC, the battery capacity is selected a low quantity; But it would not make any stain at the accuracy of the employed methods and the results are valid with all batteries.

Parameter |

Description |

Value |

L1,L2 |

inductance |

500µH |

C1,C2 |

capacitance |

470µF |

Cout |

capacitance |

40µF |

L3 |

Filter |

150µH |

Vin |

Input voltage |

70V |

Ve |

Internal voltage |

75V |

Rin |

Internal resistance |

0.4ῼ |

q |

Battery capacity |

0.01Ah |

Vb |

Battery nominal voltage |

90V |

vo |

Output voltage |

600V |

n |

Transformer turns ratio |

10 |

R |

Nominal Load |

2800w |

f |

Frequency |

10kHz |

Table 1 The system parameters

Two scenarios is performed for checking the system as

Case 1: In this case the initial SOC of the battery is near 0.5, the input voltage is constant and only the load varies. According to Figure 7, the output power is fixed on 2800watts and at the two intervals that are indicated, it varies to 3800 and 800watts and then switches back to the 2800watts. The impact of these changes and results are depicted in Figure 7.

Figure 7 (a) Output power. (b) output voltage. (c) battery current. (d) SOC of the battery. (e) FC current.

Simulation results shows that the output voltage remains fixed and the load power is apportioned between FC and the battery, that in lack of the battery, tolerance of the delivered power by the FC would increase greatly, but in this system and control method FC power is smoothed. Also The SOC value of the battery is reduced while the load is increased, and it is increased while the load is decreased. So this control method operates quite desirable.

Case 2: The fuel cell also has a separate controller to adjust the hydrogen and oxygen flows to it that varies its voltage (Ve), in fact the current-voltage characteristic is changed. With this variable, the delivered power of the fuel cell could be changed and thereby the battery could be charged or discharged, which is essential, especially when the SOC value gets close to its boundary values (50-90%) that should be restrained to prevent any damages to the battery.

In this case the load power is constant on 3200 watts and only the internal voltage (Ve) is changing according to Figure 8a. The results are depicted in Figure 8. According to results, it is determined that the control system could well charge and discharge the battery when it is necessary.

This paper presented a FC-battery system based on the qZSC and a control strategy has implemented for both power management and adjusting output voltage. Also the battery was connected to the qZSC with no extra converter. The battery shaves the output power changing effectively. Also charging and discharging the battery is possible in this system. The simulations proved the performance of this method eventually.

None.

The author declares there is no conflicts of interest.

©2018 Radmanesh, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.