Research Article Volume 1 Issue 2

On the analytical tuning of controllers for grid-coupled voltage source converter: frequency analysis

Cajethan M Nwosu,

Regret for the inconvenience: we are taking measures to prevent fraudulent form submissions by extractors and page crawlers. Please type the correct Captcha word to see email ID.

Cosmas U Ogbuka, Stephen E Oti

Department of Electrical Engineering, University of Nigeria, Nigeria

Correspondence: Cajethan M Nwosu, Department of Electrical Engineering, University of Nigeria, Nigeria

Received: July 22, 2017 | Published: November 8, 2017

Citation: Nwosu CM, Ogbuka CU, Oti SE. On the analytical tuning of controllers for grid-coupled voltage source converter: frequency analysis. Electric Electron Tech Open Acc J. 2017;1(1):33-41.

DOI: 10.15406/eetoaj.2017.01.00007

Download PDF

Abstract

This article presents frequency analysis of controllers parameters tuning methods for grid-coupled voltage source converter. In distributed power systems, the grid-coupled voltage source converter exists in pairs linked back-to-back through a DC-link capacitor. The grid-side converter is coupled to the grid through L, LC, or LCL filter. Each of the three analytical methods of pole-zero placement, Butterworth polynomial and Internal Model Control is analyzed and tested through simulation studies in a MATLAB Simulink environment for the three filter conditions. The results so obtained shows that even as any of the three methods can be adopted for efficient control performance, the IMC method presents the best option with the addition of minor loop in the DC-link voltage control loop. In this method, the usual problem of trial and error tuning of PI controller parameters is reduced to only selecting an appropriate bandwidth frequency for the closed loop control.

Keywords: back-to-back converter, filter, controllers parameters, grid-connection, filter current, dc-link voltage

Introduction

The grid conditions determine what the output voltage of a grid connected power converters should be. Control of the output voltage of these power converters is by this condition not possible. The power converters are however, not directly connected to the grid. The conventional method to interface these converters to the grid is through filters.1,2 The duty of the filter is to reduce the current harmonics around the switching frequency of the converter. The current harmonics is capable of polluting the grid with the effect of disturbing any connected equipment.2,3 In some practical applications, the converter is not just a single three-phase converter but two back-to-back converters usually interfacing two AC systems. The two converters are linked to each other through a DC-link. The converter adjacent to the grid is in this work referred to as grid-side converter (GSC). The scope of this paper is limited to the analysis of control of the filter current and the influence of the filter on the grid and the grid-side converter with the DC-link. The filter can be a simple L, LC or LCL filter. The choice of any scheme may depend on cost, size, or dynamic performance. The filter current injected into the grid becomes the control variable since the grid voltage can’t be controlled. The filter input current is usually sensed and given back as feedback to close the control loop. Hence, the transfer function which decides the closed loop performance of the filter is the transfer function between output current and input voltage of the filter for zero grid voltage.1 Usually the current control is implemented in a dq-rotating frame in order to obtain a control with rapid dynamic response. The dq components of converter output currents are controlled using state-of-art synchronous frame PI control.4 Generally the current control is designed on per phase basis and the decoupling terms are added to allow such design. This decreases the order of system and hence simplifies controller design.5

In the past decades, PI controller has found wide applications in industrial process controls. This is majorly due to simplicity of its control law and the few tuning parameters. However, research is still on going on methods of obtaining the appropriate parameters. The researched tuning processes include but not limited to trial and error methods, feature based methods, analytical methods, optimization based methods, loop shaping methods, and auto-tuning methods.6 Among others, the analytical methods are the preferred parameter tuning process in the control of grid-connected power converters. In this paper, three kinds of analytical methods: pole-zero placement method, Butterworth polynomial method and Internal Model Control (IMC) method are each adopted for the tuning of controllers parameters for L, LC, and LCL filter interfaced grid-connected power converters. In effect pole-zero placement method and Butterworth polynomial method are similar in the sense that the primary objective of both methods is to place the closed-loop poles at the desired location in the left-half of the frequency domain. These methods, their controllers’ parameters results and the effects of the application of the parameters on the dynamic responses of the system are compared. The filter interface constitutes the PI controller process plant for the control of filter current injected into the grid.

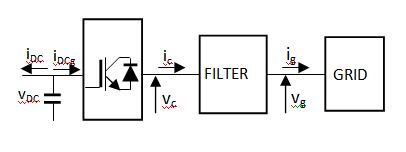

System modeling

Models for the L, LC, and LCL filters shall be developed with a view to generating the respective transfer function for the grid current control. The transfer function which decides the closed loop performance of the filter is the transfer function between output current and input voltage of the filter for zero grid voltage.1 (Figure 1) shows a one-line diagram of the converter connected to the grid through per-phase filter inductance. vDC is the DC-link voltage; vc and ic are converter voltage and current respectively while vg and ig are grid voltage and current respectively.

Figure 1 Per-phase simple filter as an interface between power converter and grid.

L Filter

The voltage balance across the three inductors can be written as:

(1)

where va, vb, and vc are the three phase grid voltages, va1, vb1, and vc1 are the front-end converter voltages, and ia, ib, and ic are the line currents. L and R are the filter inductance and resistance, and

. Applying phase and rotation transformations to Eq. (1) results in:

(2)

(3)

vd and vq, id and iq, and vd1 and vq1 are the d- and q-axis components of the grid voltages, line currents, and front-end converter voltages respectively. The terms ωeLid and ωeLiq cause a cross-coupling of the d- and q-axis, while the last terms are the d- and q-axis converter terminal voltages. The system is said to be coupled because the inductance matrix is not diagonal. This means that any changes in voltage component in d- or q-axis results in changes in both current components. The third and the last terms are treated as disturbances on the output. The PI controller tracks the id and iq errors to give vd and vq respectively. To ensure good tracking of these currents, the cross-related flux terms are added to vd and vq to obtain the reference voltages. The dynamics of the d-q reference frame are:

(4)

(5)

The transfer function from

as input to

as output yields:

(6)

LC Filter

The filter capacitor in an LC filter provides a low-impedance path for the high frequency PWM ripple current and, thus, attenuates the content of current ripple in the utility current.7 For a balanced three-phase system, the d-q dynamic equations for the grid current control are same as Eqns. (4) and (5). On the assumption that the parasitic grid impedances are neglected, the transfer function of grid current to inverter voltage is same for L and LC filters. Therefore, the size of inductor does not change from L to LC filter.

LCL Filter

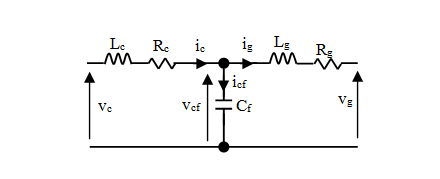

In order to obtain the transfer function of the LCL filter, the one phase electrical diagram in (Figure 2) is considered. The subscripts ‘c’ and ‘g’ denote converter-side and grid-side components respectively. The components of the filter on each phase are considered to be identical, so the circuit below is suitable for the other two phases. Using Kirchoff’s laws, the filter model in s-plane can be written with the following equations:8

(7)

(8)

(9)

(10)

In the mathematical analysis of the transfer function, the grid voltage is assumed to be an ideal voltage source and it represents a short circuit for harmonic frequencies, it is therefore set to zero: vg = 0.

Figure 2 One phase electrical circuit of an LCL filter.

From equations (9) and (10), the following relation can be written:

(11)

from which we obtain:

(12)

Equation (8) can be re-written as:

(13)

By introducing (9), (7) and then (12) into (13), the converter voltage can be written as:

(14)

(15)

The transfer function of the filter can be obtained as:

(16)

The transfer function of equation (16) is particularly useful for stability and harmonic analysis of LCL filter. For the design of the controller, the filter capacitor is neglected to obtain the d-q reference frame dynamic equations similar to (4) and (5) as:

(17)

(18)

where LT = Lc + Lg, and RT = Rc + Rg.

The system plant is obtained as:

(19)

Controller’s design

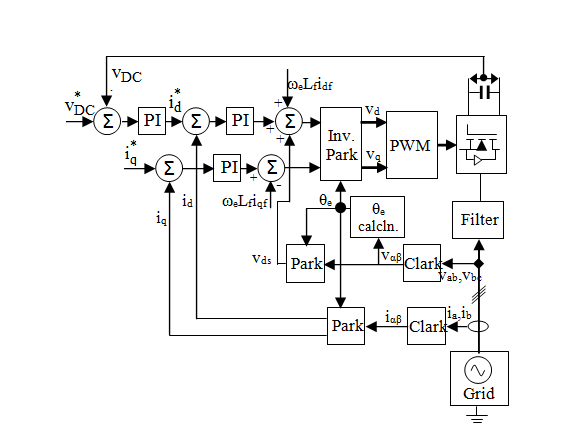

The control of the grid-side converter consists of a fast inner current control loop, which controls the current through the line inductance, and an outer slower control loops that regulate the DC-link voltage and the reactive power exchanged between the GSC and the grid. The structure of the d-q current-control, DC-link voltage control and the reactive power exchange control loops is shown in Figure 3. For unity power factor, the reactive power reference current

is set to zero.

Figure 3 Current-control loop of grid-side converter.

Current controller

The term ωeLidq in Figure 3 is the d-q rotational emfs which appear as cross-coupling terms due to the transformation. The transfer function of the PI controller is given by:

(20)

where kpdq is the d and q components proportional gain, kidq is the integral gain of the d and q components controllers, and Ti is the integration time obtained as the ratio of the proportional gain to the integral gain. The representations of d-q in the gains mean that the d and q axis currents are controlled via independent regulators.

The PI current controller in each axis generates the control signals

and

in a way to regulate the currents id and iq, respectively. These signals are then synthesized by the converter and, so, injected in the electrical grid. In,9 it is assumed that there are no delays and so the converter transfer function Gconv also known as converter constant kc may be considered ideal because

and

. In this paper however, the influence of kc is taken into consideration in all the three methods under analysis. For the grid-side converter, kc may be modeled as:10

(21)

where m1 is the grid-side converter modulation depth, vDC is the DC-link voltage, and Vtri is the amplitude of the triangular carrier which is usually compared with the reference signal to generate the converter switching pulses. Tuning of PI controllers entails obtaining the appropriate parameters, proportional gain and the integration time in order to obtain a control with rapid dynamic response. This paper focuses on generating the PI controllers’ parameters through the three analytical methods.

DC-link voltage controller

The dynamics of the DC-link may be rewritten as:

(22)

Applying Laplace Transform to (22) yields:

(23)

The transfer function from

as input to

as output yields:

(24)

where

. The component iDCg represent the grid-side DC-link current. The other component iDC, may bear any designation based on the second AC system which the filter interfaces with the grid. The iDC component is regarded as a disturbance in the control and may be neglected.

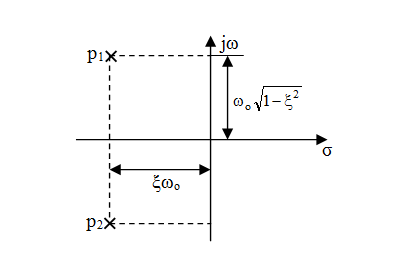

Pole-zero placement method

The objective of pole-zero placement technique is to place the closed loop poles at desired locations. Here, complete knowledge of the transfer function is needed to calculate the appropriate controller parameters. Desired closed loop poles are specified, and the controller parameters that move the poles to these positions are analytically calculated. The filter plant in each case is of first order so that a direct pole placement technique is used all through. The parameters of the controller are calculated, such that the closed-loop poles which are a pair of complex conjugates are located at desired pole locations, specified by their undamped natural frequency ω0 and damping ratio ξ as:

(25)

(26)

The complex conjugate poles lie in the left-half s-plane as shown in Figure 4.

Figure 4 Complex conjugate poles.

Current controller

In order to apply the three analytical methods in the determination of the current controller parameters, a design example is taken into consideration. The LCL filter-based active rectifier has the following components: Lc=L=17.7mH, Lg=5.7mH, and Cf=3.45μF with a resonance frequency around 1.30kHz. In addition, Rc=Rg=0.1Ω is assumed in this paper. The filter has been designed to reduce the switching current ripple to less than 1% of the rated current. The system parameters considered for calculating the components for the filter are shown in (Table 1).11

Grid Voltage (V) |

230 |

Output Power of the Converter (kVA) |

1.5 |

DC-link Voltage (V) |

550 |

DC-link capacitor (mF) |

2.4 |

Grid Frequency (Hz) |

50 |

Table 1 Parameters for calculating the filter components

The d and q control loops have the same dynamics, so the same tuning of the PI parameters is adopted for the two current control axes. The voltage feed forward and the decoupling between the d and q axes in the current control loop of Figure 3 are neglected in the analysis for the generation of the controller parameters as they are considered as disturbances. Employing a more general PI controller transfer function as:

(27)

and the plant model in (19), the open loop Goc(p) and closed loop Gclc(p) transfer functions are as follows:

(28)

(29)

Calculation of the closed-loop poles involves solving characteristic equation of the control system:

(30)

Knowing that a 2nd order system is characterized by the characteristic equation:

(31)

where ξ and ωo correspond to the damping ratio and the natural frequency of the system oscillation, respectively. The gains kpc and kic can be obtained by equating (30) and (31), so that:

(32)

and

(33)

The grid-side converter constant is obtained by assuming a unit value for the Vtri, 0.75 for m1, and substituting the DC-link voltage value in Table 1. The natural frequency of the system oscillation and the damping ratio may be established by selecting the settling time ts and maximum overshoot Mp. In this paper, ts≤5ms and Mp≤4.6% are selected.

corresponds to ξ=0.7. From

ωo is obtained as 1142.86 rad/s. Substituting ωo into (32) and ωo and ξ into (33), the controller parameters are obtained.

DC-link voltage controller

The PI controller transfer function for the DC-link voltage control is given as:

(34)

The open loop Gov(p) and closed loop Gclv(p) transfer functions are as follows:

(35)

(36)

Comparing the denominator of (36) with (31) yields:

(37)

(38)

Substituting ωo and ωo and ξ obtained previously into (37) and into (38) respectively, the controller parameters are obtained.

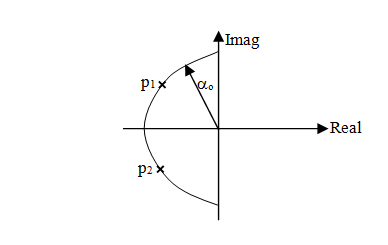

Butterworth polynomial method

The Butterworth polynomial method of controller parameter tuning like the pole-zero placement method aims at optimizing the closed-loop eigenvalue locations. In this case the eigenvalues are located uniformly in the left-half s-plane on a circle with bandwidth frequency of the controller denoted in this paper by αo as radius, with its center at the origin,13 as shown in Figure 5. The PI parameters are determined through comparing the coefficients of the Butterworth polynomial with the denominators of the corresponding transfer functions as in pole-zero placement method. The Butterworth polynomial for a transfer function with a second order denominator is given as:

(39)

Unlike in the pole-zero placement method, where the settling time ts, and the maximum overshoot Mp must first be specified in order to calculate the natural frequency of the system oscillation and the damping ratio prior to obtaining the controller parameters, the Butterworth polynomial method and the IMC method are both concerned with selection of only the bandwidth frequency of the control loop. The method of selecting the bandwidth frequency is explained in the next section.

Figure 5 Poles location for 2nd order Butterworth polynomial.

Current controller

To design the inner-loop current controllers, the relation between the d-q components of voltages and currents is first established from (17) and (18) as:

(40)

(41)

Equations (40) and (41) are coupled and nonlinear. In order to apply the linear PI controller, the nonlinear equations are linearized by moving the nonlinear parts of the two equations to one side to have:

(42)

(43)

From (42) and (43), the current control loop equations are obtained as:

(44)

(45)

where

is the current controller. Again, the d and q control loops have the same dynamics, so the same tuning of the PI parameters is adopted for the two current control axes. Thus (44) and (45) may be expanded in one to have:

(46)

from which we obtain:

(47)

Comparing the denominator of (47) with the Butterworth second order polynomial of (39) yields:

(48)

(49)

where αo is the bandwidth frequency of the current controller.

DC-link voltage controller

The DC-link voltage dynamics may be given by:

(50)

where mdg and mqg are the d and q-axis modulation indexes of the GSC and md and mq are the d and q-axis modulation indexes of the second converter not shown, respectively. In order to generate the d-component of the reference current

for the inner loop, (50) may be re-written as [13]:

(51)

Equation (50) may also be re-written as:

(52)

where kV is the PI controller for DC-voltage control given as:

(53)

In an expanded form, (52) will be:

(54)

from which:

(55)

Comparing the denominator of (55) with Butterworth second order polynomial, the PI controller gains are obtained as:

(56)

(57)

where αo is the bandwidth frequency of the DC-link voltage controller.

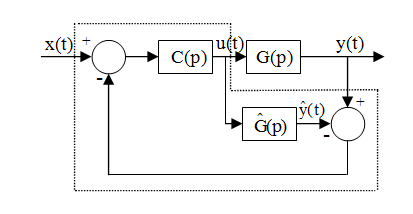

Internal model control method

The internal model control (IMC) structure has been a very popular one in process control application, especially as applied to AC machine current and speed controls.14-16 The prime benefit of this structure is the deployment of the model of the plant and the desired closed-loop bandwidth in the determination of the controller parameters (gain and integration time). In this case, the tuning problem, which for a PI controller involves adjustment of two parameters, is reduced to the selection of one parameter only, the desired closed-loop bandwidth α. The idea behind IMC is to augment the error between the process, G(p) and a process model,

by a transfer function C(p); see (Figure 6).

Figure 6 Principle of IMC.

Current controller

The IMC structure uses an internal model

in parallel with the controlled system plant G(p). For an AC machine, u and y could be the stator voltage and current vectors, respectively, while

is the current set point (reference) vector. The control loop is augmented by a block C(p), the so called IMC controller.

are all transfer function matrices. It should be noted that, if the internal model is perfect, i.e.

there is no internal feedback loop in Figure 6 and the closed-loop system has the transfer function matrix:

(58)

Controller design is a matter of choosing the “right” transfer function C(s). One common way is:17

(58)

where n is chosen so that C(p) become proper, i.e., the order of the denominator is equal to or greater than that of the numerator. The parameter α is a design parameter, which for n=1, is set to the desired bandwidth of the closed-loop system. For a first-order system, n=1 is sufficient. For the inner-current control, the controller then typically becomes an ordinary PI controller:

(59)

With GC(p) comprising the product of the grid-side converter constant and the system plant as:

(60)

the PI controller gains are:

;

(61)

DC-link voltage controller

For the DC-link voltage control, the PI controller is:

(62)

With GV(p) comprising the product of the DC-link voltage control constant and the system plant as:

(63)

from which the controller gains are obtained as:

;

(64)

The closed-loop bandwidth frequency α is selected in relation to the converter switching frequency. In order to mitigate the degrading of the system performance, it is recommended that the angular switching frequency ωsw should at least be five times the closed-loop bandwidth:18

(65)

A chosen converter angular switching frequency of 12252 rad/s (or1950Hz) corresponds to a bandwidth of 2450 rad/s. The current control closed-loop bandwidth is thus selected to be 2000 rad/s while the DC-link voltage control bandwidth is 200 rad/s.

Simulation studies

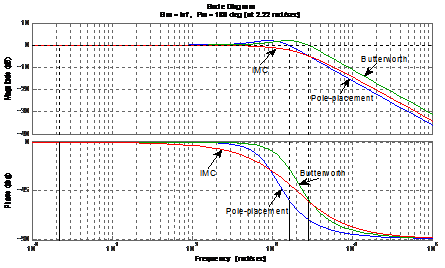

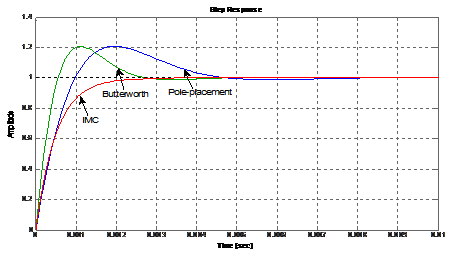

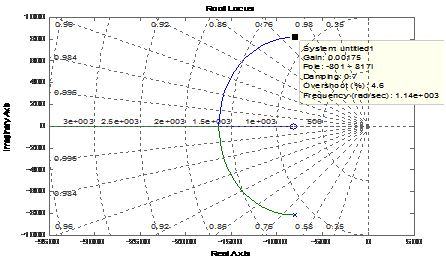

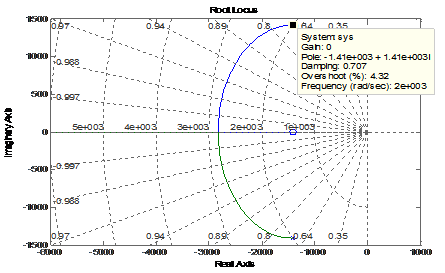

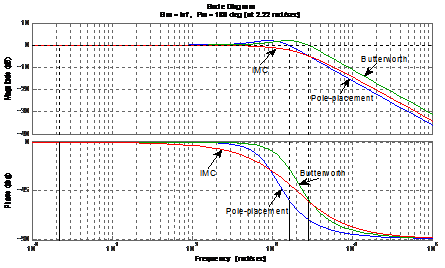

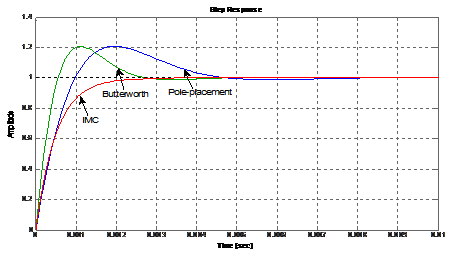

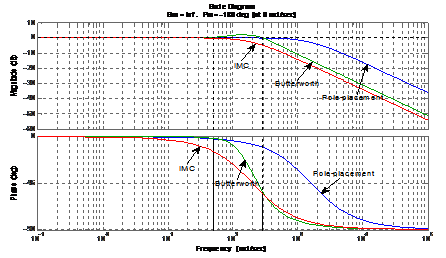

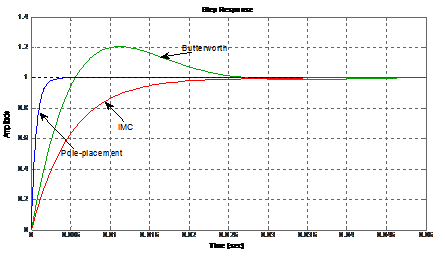

The controllers’ parameters for the current control and DC-link control for the three methods under study are generated for L, LC, and LCL filters. These parameters which are used in the simulation studies are shown in Table 2. Figure 7 is the root-locus map showing the pole-zero locations for the closed loop current control. The dominant poles have a damping of 0.7 at a frequency of 1140 rad/s. The percentage maximum overshoot of 4.6 corresponds with the calculated value. The root-locus map for the closed loop current control resulting from the Butterworth polynomial method of tuning controller parameters is shown in (Figure 8-10) show the Bode plots and step response plots for the three controller parameters tuning methods for the inner current control. (Figures 11 &12) show the Bode plots and step response plots for the three controller parameters tuning methods for the DC-link voltage control.

Method |

L or LC filter |

LCL filter |

Pole-placement |

KPC=0.137 |

KPC=0.181 |

|

KIC=112.090 |

KIC=148.186 |

|

KPV=4.827 |

KPV=4.827 |

|

KIV=3.941 |

KIV=3.941 |

Butterworth polynomial |

KPC=49.963 |

KPC=65.985 |

|

KIC=70800 |

KIC=93600 |

|

KPV=0.679 |

KPV=0.679 |

|

KIV=96.000 |

KIV=96.000 |

IMC method |

KPC=0.172 |

KPC=0.227 |

|

KIC=0.970 |

KIC=0.970 |

|

KPV=0.603 |

KPV=0.603 |

|

KIV=0.000 |

KIV=0.000 |

Table 2 Gain parameters for the three analytical methods

Figure 7 Root-locus map of the closed loop current control using pole-placement method.

Figure 8 Root-locus map of the closed loop current control using Butterworth polynomial method.

Figure 9 Bode plots for the three controllers’ parameters tuning methods for the inner current control.

Figure 10 Step response plots for the three controllers’ parameters tuning methods for the inner current control.

Figure 11 Bode plots for the three controllers’ parameters tuning methods for DC-link voltage control.

Figure 12 Step response plots for the three controllers’ parameters tuning methods for DC-link voltage control.

Discussion of results

Each of the three analytical tuning techniques for the controllers’ proportional gains, integral gains, and integration times can effectively be adopted to maintain stable system operation. The root-locus map of (Figure 7) confirms the assumed data for overshoot and damping ratio and calculated natural frequency of operation of the system for the pole-placement method. For same value of closed loop control bandwidth frequency chosen for the Butterworth polynomial and IMC methods, the Butterworth polynomial root-locus map of (Figure 8) share similar characteristics with that of (Figure 7). These similarities can easily be observed in Bode plots of Figure 9 and step response plots of (Figure 10). Considering the current control and the DC-link voltage control, it is observed however, that while the IMC method gives better performance for the current control, the pole-placement method gives better performance for the DC-link voltage control. The settling times (a measure of the dynamic response of system to transients) for the current control are 3x10-3s, 4.6x10-3s, and 8x10-3s for IMC, Butterworth polynomial, and pole-placement methods respectively. In the same order, their phase margins (a measure of the stability of feedback systems) are 180o, 127o, and 126o. Unlike the other two methods, the IMC method simulates a critical damping criterion as evidenced in Figure 10 with closed loop control negative real poles. For the DC-link voltage control, the pole-placement and IMC methods share some similarities. However, while the phase margin for the pole-placement method is 178o, the phase margin for IMC method is -180o. The negative phase margin is an indication that the use of IMC method for the DC-link voltage controller parameters results in instability of the controller system. This instability emanated from the existence of pole at the origin of the DC-link system plant. One solution for the instability is to add an inner feedback loop for active damping in the voltage control loop. The critical damping criterion of the IMC method exhibited in the current control is also extended in the DC-link voltage control. Of the three analytical tuning methods, the Butterworth polynomial method exhibits consistency in the phase margin, overshoot, and damping ratio for the current control and DC-link voltage control.

Conclusion

Detailed study of analytical tuning of controllers for grid-coupled voltage source converter has been carried out. It is concluded that any of the three methods under study can effectively be adopted for good performance operation for the control system. However, with the addition of minor loop in the DC-link voltage control loop, the IMC method presents the best option owing to its capability to simulate a critical damping criterion both for current control and voltage control. Here, the problem of controller parameter tuning is reduced to only the selection of appropriate bandwidth frequency of the closed loop control. The additional inner loop in the DC-link voltage control has been established to have the capacity to damp the DC-link current component disturbance iDC, with the same bandwidth as the DC-link voltage control loop. Due to the consistency in the phase margin, overshoot, and damping ratio for the current control and DC-link voltage control exhibited in the Butterworth polynomial analytical method, it becomes the second choice after the IMC method. Like the IMC approach, it only requires proper selection of bandwidth frequency of the closed loop control as against the initial specification of settling time and percentage overshoot prior to obtaining the damping ratio and natural frequency of system oscillation.

Acknowledgements

Conflict of interest

The author declares no conflict of interest.

References

- Nazareno AG, Laurance WF. Brazil's drought: beware deforestation. Science. 2015;347(6229):1427.

- Escobar H. Water security. Drought triggers alarms in Brazil's biggest metropolis. Science. 2015;347(6224):812.

- Bellard C, Bertelsmeier C, Leadley P, et al. Impacts of climate change on the future of biodiversity. Ecology Letters. 2012;15(4):365−377.

- Keppel G, Van N, Kimberly P, et al. Refugia: identifying and understanding safe havens for biodiversity under climate change. Global Ecology and Biogeography. 2012;21(4):393−404.

- Franco AC, Davi RR, Lucas de CRS, et al. Cerrado vegetation and global change: the role of functional types, resource availability and disturbance in regulating plant community responses to rising CO2 levels and climate warming. Theor Exp Plant Physiol. 2014;26(1):19−38.

- Jung M, Markus R, Philippe C, et al. Recent decline in the global land evapotranspiration trend due to limited moisture supply. Nature. 2010;467:951−954.

- Gedney N, Cox PM, Betts RA, et al. Detection of a direct carbon dioxide effect in continental river runoff records. Nature. 2006;439(7078):835−838.

- Lammertsma EL, Friederike WC, David LD, et al. Climate forcing due to optimization of maximal leaf conductance in subtropical vegetation under rising CO2. PNAS. 2011;108(10):4041−4046.

- Arraut JM, Carlos N, Henrique, et al. Aerial Rivers and Lakes: Looking at Large-Scale Moisture Transport and Its Relation to Amazonia and to Subtropical Rainfall in South America. J Climate. 2012;25:1−14.

- Pan S, Hanqin T, Jia Y, et al. Responses of global terrestrial evapotranspiration to climate change and increasing atmospheric CO2 in the 21st century. Earth’s Future. 2015;3(1):15−35.

- Dai A. Increasing drought under global warming in observations and models. Nature Climate Change. 2013;3:52−58.

- Horta, Pablo R, Gilberto M, et al. Rhodoliths in Brazil: Current knowledge and potential impacts of climate change. Brazilian Journal of Oceanography. 2016;64:117.

- IPCC. Fifth Assessment Report of the Intergovernmental Panel on Climate Change. Cambridge Univ Press, UK; 2013. p. 1−20.

©2017 Nwosu, et al. This is an open access article distributed under the terms of the,

which

permits unrestricted use, distribution, and build upon your work non-commercially.