eISSN: 2576-4500

Research Article Volume 2 Issue 2

Space Propulsion Department, Rafael-Advanced Defense Systems, Israel

Correspondence: Dan R Lev, Rafael-Advanced Defense Systems, Acre. Rd., Haifa, Israel , Tel 972-52-429-1745

Received: December 29, 2017 | Published: March 28, 2018

Citation: Franco DK, Lev DR, Appel L. Performance Validation and Plume Divergence of the CAM200 Low Power Hall Thruster. Aeron Aero Open Access J. 2018;2(2):75–78. DOI: 10.15406/aaoaj.2018.02.00033

CAM200 is a low power Hall thruster operating in the 100-250 W power range. We present two recent activities in the development of the CAM200 Hall thruster-performance validation in an independent facility and measurement of the ion flux in the thruster plume. We show that the thruster performance, measured throughout six different operation points, is in line with the performance recorded at the Technion in past experiments (At 250W: Thrust of 13.9±0.6 mN, Isp of 1570±73 sec and efficiency of 43±3.7%). We also present ion flux curves for each operation point and show that the beam divergence angle is less than 40° for discharge power of 160W and higher.

Keywords: space propulsion, hall thruster, plasma propulsion, low power thruster, plume divergence

Due to their small size micro-satellites (10-100kg) are power limited and normally utilize chemical propulsion to meet their propulsion requirements. However, the use of high efficiency low power (<300W) electric propulsion with Hall Effect Thrusters (HET) can greaty improve satellite capability and allow for the execution of a veriety of missions, particularly in Low Earth Orbits (LEO). Additionally, thanks to the associated high specific impulse the use of low power HETs allows for propellant mass savings; therefore reducing the overall satellite mass and increasing payload mass. Although HET technology carries these advantages, at power levels below about 500W HETs suffer from low efficiency and short operating lifetime relative to their higher power cousins.1,2 The Coaxial Anode Magneto-Isolated Longitudinal Anode (CAMILA) HET confronts these low power HET weaknesses. The CAMILA HET has been developed and patented by Kapulkin et al.3 from the Asher Space Research Institute (ASRI) at the Technion. The CAMILA HET consists of an electrically floating gas distributer and a co-axial anode, where a longitudinal magnetic field is induced by dedicated anode coils and a radial magnetic field configuration at the thruster exit plane, which is induced by a conventional HET magnetic circuit4. This unique configuration enables close to full ionization of the propellant in the anode cavity even at low mass flow rates.4,5

During the past few years CAM200, was designed and tested by Rafael in cooperation with the Asher Space Research Institute (ASRI)6 implementing the gained knowledge of previous ASRI work on Hall Thrusters. During development tests CAM200 Hall thruster exhibited outstanding performance at the low power operating range, from 100 to 300 W. Following the preliminary laboratory model tests phase CAM200 thruster entered the next development phase in which an Engineering Model (EM) was designed, manufactured and tested at Rafael, Israel (Table 1). During the past year the CAM200 EM model was tested in order to validate the MEPS project vibration requirements,7 ECSS requirements and manufacturability requirements and proceed to the next project phases. CAM200 takes part in the joint European-Israeli Micro-satellite Electric Propulsion System (MEPS) project.8,9 The goal of the MEPS project, which is funded by European Space Agency (ESA) and the Israeli Space Agency (ISA), is to design, manufacture and qualify an electric propulsion system for micro-satellites. MEPS, which is planned to be qualified for space in coming years, is collaboration between Rafael and the Italian electric propulsion company, Sitael. In this paper we present two recent activities carried out as part of the CAM200 Hall thruster development plan–(1) performance characterization at a new facility in Sitael, Italy and (2) ion flux measurements in the thruster plume. Lastly, we draw conclusions for future activities both for general thruster development and for within the scope of the MEPS project.

CAM200 hall thruster

Rafael’s CAM200 Engineering Model (EM) (Shown in Table 1) was designed, manufactured, integrated and initiated its testing campaign during 2014 and 2015. Lessons learned and further improvements from CAM200 Development Model (DM) were implemented in the CAM200-EM with the purpose of producing a lighter-weight, electrically and mechanically robust thruster capable of operating in the expected environment of space.10 In addition, an effort was made to simplify some of the manufacture procedures of the thruster; therefore making it quicker to produce and cost effective.

Test facility

The performance characterization was conducted at two independent test facilities, the Asher Space Research Institute (ASRI) electric propulsion laboratory at the Technion, Haifa-Israel and at Sitael, Pisa-Italy.

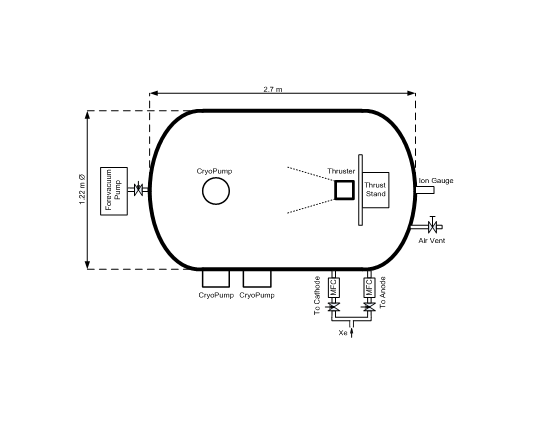

ASRI, Technion Haifa, Israel test facility: The test facility (Figure 1) includes a1.22mØ×2.7m stainless steel vacuum chamber with inner volume of approximately 3.2m3. The chamber is equipped with a 'RUTA WAU 501/D65B/A' fore vacuum pump with pumping speed of 230 liter/s of air. Three 'Sumitomo' CP-22 cryopumps are located on the vacuum chamber's opposite end from the thruster. The combined measured pumping speed achieved is approximately 9,000 liter/s on xenon. The residual pressure of the vacuum chamber is lower than 9×10-8 torr. During thruster operation at a total flow rate of 1.2 mg/s of xenon, chamber pressure was lower than 2×10-5 torr.

IV4 vacuum facility (Sitael spa. Pisa, Italy): Sitael’s IV4 facility (Figure 2) consists of a main vessel (Auxiliary Chamber–AC), 2m in diameter and 2.5m in length connected through a 1m gate valve to a service chamber (Small Chamber-SC), 1m in diameter and 1m in length. The two vessels are both built out of stainless steel AISI 316 L with low magnetic relative permeability (μr<1.06). The main chamber provides the volume for expansion of the beam and contains the main pumping system, the beam target and the beam diagnostic devices. The SC is usually dedicated to the installation of the thruster, the thrust stand and all the connections (propellant, power lines, diagnostics etc.) required for thruster operation. To improve the accuracy of the beam diagnostics, a thrust stand can be placed in the AC and aligned with the Faraday cup rake’s axis. At the far end of the AC, on the opposite side with respect to the thruster, a bi-conical, water cooled, Grafoil lined target is placed in order to dump the beam energy. The IV4 facility is equipped with two independent completely oil-free pumping systems: one connected to the AC and one connected to the SC for redundancy and emergency operations. The main pumping system includes, in addition to a 25mc/hr rotary pump and a 2000l/s turbo molecular pump used for evacuation, a cryogenic high vacuum stage based on 1x3,000 l/s cryo pump plus 6x12,000 l/s custom cold plates. The total pumping speed is therefore in the order of 70,000 l/s which ensures ultimate vacuum pressure <10-7 torr and chamber pressure in the order of <2×10-5 torr (Xe) during the test campaign.

Diagnostics

ASRI, Technion Haifa, Israel test facility: Pressure is measured using an 'Ionivac' sensor, model ITR90 from 'Leybold', located behind the thruster. The 'Ionivac' pressure gauge is calibrated by the manufacturer and has a declared precision of 15%. A commercial 0÷1.96 mg/s flow controller, model M100b from MKS, controls xenon flow rate to the thruster’s gas distributor. Similarly, a 0÷0.98 mg/s flow controller controls flow rate to the cathode. The mass flow controllers are calibrated by the manufacturer, with a declared precession of 1% of full scale. The thrust stand used is a feedback-controlled inverted pendulum type, manufactured for ASRI by PLATAR LTD, Moscow, Russia. It is capable of thrust measurements in the range 1÷200mN. Measurement accuracies, as declared and verified by the manufacturer, are ±3.5% between 5÷10mN and ±3% between 10÷20mN. During tests the thrust stand is calibrated using weights once in every two hours.

IV4 vacuum facility (Sitael spa. Pisa, Italy): The pressure level within the chamber is continuously monitored by three Leybold-Inficon ITR90 Pirani/Bayard-Alpert sensors, two placed within the SC (i.e. behind the thruster) and one in the AC (nearly at the exit plane of the thruster). A SRS QMG-220 is placed in the SC to monitor the composition of the residual background gas. Usually all the partial pressures of gases (except Xe) are <10-7mbar during thruster operations. The IV4 is equipped with a thrust balance capable of measuring 1-200mN with 0.1mN resolution and 0.5mN declared accuracy. In order to get the plume divergence angle a mobile Faraday Cup is mounted and mechanically controlled, permitting a 162° of transversal current flux measurements at a 1.8° step.

Experimental method

The experiment consists of gathering performance parameters at both independent facilities and compares them in order to depurate any facility coupling effects on the test results. Prior to taking thrust measurements the thruster was operated for 4 hours to outgas the various gas impurities captured in the thruster and cathode surfaces. During this process thruster operation is closely monitored and thruster re-ignited in case of spontaneous shut downs. In addition, before taking any thrust measurement the thruster is operated continuously for at least two hours to assure thermal stability and verify correct measured performance values. Every thrust measurement was obtained by turning the thruster off, to measure the "zero thrust" position of the thrust stand, and subtract the value from the value measured during operation.11 After performing the measurement the thruster is re-ignited and operated continuously for at least 10 minutes, to assure thermal stability, before taking the subsequent thrust measurement. The thruster operating points are as required by the MEPS project specifications for a low power electric propulsion system regarding the anodic discharge power range: 100–250 W. In particular, the Thruster Unit (TU) operates at the following six operational points: 100±8W, 130±8W, 160±8W, 190±8W, 220±8W and 250±8W.

Error analysis

For the thrust measurement error estimation several factors were taken into consideration such as the test stand thrust measuring systems declared accuracies, estimated human data recording accuracy, manufacturer’s mass flow meters and controller accuracies, thruster manufacturing tolerances etc. In addition, estimated errors were mathematically propagated to error estimations of the specific impulse and thrust efficiency.

Figure 1 Schematic of the Asher Space Research Institute (ASRI) electric propulsion laboratory experimental facility (not to scale).

| # |

Property |

Value |

1 |

Discharge Power |

100-300 W |

2 |

Discharge Voltage |

150-400 V |

3 |

Xenon Mass Flow Rate |

0.5-1.4 mg/s |

4 |

Thrust |

6 mN @ 100 W |

5 |

Isp |

900sec @100W |

6 |

Lifetime |

>60 kNsec |

Table 1 Key features of the CAM200 low power hall thruster

Thruster performance

The performance results of CAM200-EM, in terms of, thrust, specific impulse and anode efficiency, at ASRI and Sitael facilities are presented in (Figure 3A)(Figure 3B)(Figure 3C). It can be observed from the figures that both tests presented performance results within the estimated error bars. In particular, the thrust measured at 100 W is at least 4.88±0.35mN with specific impulse of 900±66sec corresponding to thrust efficiency of 21±2.8%. This very low power performance, although lower than with higher power HETs, is higher than the performance measured with other similar low power Hall thrusters. Additionally, at the maximum power examined (250W) the measured thrust is at least 13.9±0.6mN with specific impulse of 1570±73sec corresponding to thrust efficiency of 43±3.7%. The specific impulse and the corresponding thrust efficiency values are in accord with high power Hall thrusters that generate thrust-to-power ratio of 60mN/kW (55.6mN/kW for the CAM200-EM at Pd=250W). The similarity between thruster performances measured in both facilities validates CAM200 thruster performance as was recorded and published in past years.

Divergence angle measurements

This is the first time ion flux measurements in the plume of the CAM200 thruster are measured. This experiment was performed using the Sitael Faraday probe diagnostics system. The facility creates a close-to semi-spherical picture of the ejected ion current density around the thruster. To measure the distribution of the ion current density around the thruster CAM200 was operated in its six operational points, also described above. At each point the array of Faraday probes rotated around the thruster in the -90° to +90° angle range. Measured values of current density are presented in Figure 4. It can be seen from the figure that the measured values of current density are in line with similar measurements conducted with other thrusters.12‒14 Also, as expected, the lower the discharge power the lower the current density, due to lower mass flow rate and reduced concentration of charged particles. With the acquired data it is possible to compute the half beam divergence angle and correlate it with the performance parameters obtained from the test. The corresponding half beam divergence angle for the CAM200, containing 95% of the ejected ion flux, is lower than 40° for discharge power 160W and higher, also presented in the Figure 4. This measured result strengthens the postulation and numerical analysis that indicate on a focused ion beam ejected from the thruster, helped by its anode co-axial design, and assuring good performance at low discharge power.

We presented two recent activities in the development of the CAM200 Hall thruster. The first involves performance validation in an independent facility, while the second involves the measurement of the ion flux inside the thruster plume. The latter was also used to calculate the thruster's divergence angles in all pre-determined operational points. We showed that the performance parameters measured multiple times at the Asher Space Research Institute (ASRI) are in line, and within error bars, with the performance parameters measured at Sitael. This validates CAM200’s outstanding thruster performance. In particular we validated that at the maximum power examined (250 W) the measured thrust is at least 13.9±0.6mN with specific impulse of 1570±73sec corresponding to thrust efficiency of 43±3.7%. We showed that the divergence angle of CAM200 Hall thruster is lower than 40° for discharge power of 160W or higher. This value is in accord with higher power Hall thrusters and with a more focused beam than that typical for similar low power Hall thrusters. We also pointed out that the highly focused beam may explain the relatively high performance of the CAM200 Hall thruster.

None.

None.

©2018 Franco, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.