eISSN: 2576-4500

Review Article Volume 6 Issue 2

1Université de Bordeaux, France

2Institut Supérieur des Arts et Métiers de Sfax (ISAMS), Tunisie

3Arts et Métiers ParisTech, France

Correspondence: Yann Ledoux, Université de Bordeaux, I2M–UMR 5295, F-33400 Talence, France

Received: June 08, 2022 | Published: June 22, 2022

Citation: Ledoux Y, Kallel WS, Nadeau JP. Parsimonious analysis for eco-innovation of products. Aeron Aero Open Access J. 2022;6(2):38-45. DOI: 10.15406/aaoaj.2022.06.00140

The integration of the environmental dimension is crucial in industrial activity. Designers should integrate the new environmental constraints to adapt their approaches and methodologies in the framework of eco-innovation of industrial products and consumer goods. This paper proposes a new method integrating ecological aspects into the innovation process. We analyze different tools proposed in the literature to determine the relevant parameters to consider for assuring an efficient methodology. Relevant parameters are related to different phases in the lifecycle of the product and it is proposed to link them to different impacts on the environment. Actions are set up to guide engineers in the early phase of concept generation for eco-innovation. The methodology is essentially based on functional analysis, energy analysis and physical analysis of products and problem solving tools stemming from Triz theory.

Keywords: triz theory, sustainable development, actions for eco-innovation, functional and energy analysis, physical model

According to the Afnor association, industrial activity affects the environment by quantities of energy, volumes of consumed raw materials and more generally by its environmental impacts generated in upstream and downstream production.1 The true ecological performance of a product can only be determined by considering impacts arising from its entire lifecycle, and by including all known damage categories in the ecological assessment. The classical approach to assessing environmental impacts is the Lifecycle Assessment (LCA) defined by ISO 14040 and 14044.2,3 This approach involves analyzing the product through four main topics: the goal and scope definition, the inventory lifecycle, the lifecycle assessment and finally the interpretation.

In4 Berliner argues that at the end of preliminary design, only 8% of the total product budget has been spent but more than 70% of lifecycle costs are committed by decisions. Andersen estimates that the concept or architecture product determines 60% of the costs.5 The challenge is to propose and implement strategies to take into account these new environmental constraints from the early product design phases. This framework corresponds to the eco-innovation of products.

Eco-innovation has to be regarded as a global approach to innovation with new types of heterogeneous constraints related to different external elements. These may derive from societal aspects (i.e. suitability to user needs and future needs), economic aspects (i.e. suitability to market, including constraints of sustainable development) and technological aspects (i.e. suitability with a view to reuse, recycling and effluent control). As eco-innovation concerns the early design stage of products, to assess the environmental impact of the future product and then support the choice of design alternatives, it seems to be difficult to apply a standard approach (e.g. from ISO standards) since the product is only partially defined (i.e. few elements of the system have been defined and some of the data are imprecise). The different technical choices made during this phase will then determine, in the next phases of the product development, the material types, properties and associated quantities, the weight and shapes of products, the resulting energy efficiency, etc.

To guide and orient designers during innovation research under these new environmental constraints a new methodology needs to be developed. The originality of our approach is to rely on the definition of specific actions to eco-innovate based on relevant situations in the product lifecycle. We combine environmental impacts with a selection of lifecycle situations and develop as full a vision as possible of the environmental analysis of the product. The challenge is to translate the different environmental constraints, which are difficult to consider in the early phase of the design, into opportunities to design a new eco-product. This set of actions to be followed during product innovation integrates the environmental aspect, the necessary functions and the expected performances of the product.

To achieve this, it has been necessary to find, adapt and develop effective methods and tools to guide engineers as they generate and then qualify various alternative solutions with imprecise and incomplete product knowledge. In the literature, many tools or methods are available,6 such as eco-compass,7 the PIT diagram8 or other tools based on MindMap9 and Triz.10,11 These tools are analyzed and adapted to make them more effective in the framework of innovative design integrating ecological constraints.9,12–14 Other works integrate eco-innovation constraints into the early design stages.15 They intend to change approaches to analyzing needs and defining problems, to develop tools which support innovation and develop eco-efficiency indicators to be used in concept choice. According to this selected literature review, major key parameters are chosen with the aim of reflecting business strategies or product improvement methods by integrating the environmental perspective.

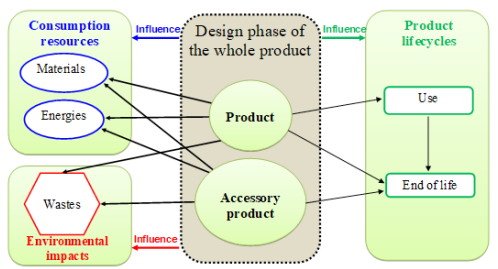

Based on this analysis, we propose a particular point of view, centered on the product, inspired by the concept of eco-efficiency developed by the World Business Council for Sustainable Development.16 The definition of new actions for eco-innovation is explained and finally product opportunity is based on the identification of resources available in the product for sustainable development. The general synoptic of the proposed method is given in Figure 1.

To illustrate this approach to eco-innovate, the evolution of an iron waffle is studied.

The framework of eco-innovation

Proposing an eco-innovation definition is not an easy task since various proposals have been made in the literature. A general definition is proposed by the Organization for Economic Co-operation and Development (OECD). First, innovation consists of developing a new or significantly improved product (good or service), or process, a new marketing method, or a new organizational method in business practices, workplace organization or external relations.17 Eco-innovation generally follows the same definition with two major distinctions: i) eco-innovation should represent innovation that results from a reduction of environmental impact; ii) the scope of eco-innovation may go beyond the conventional organizational boundaries of the innovating organization and involve broader social arrangements that trigger changes in existing socio-cultural norms and institutional structures.18,19 Bleischwitz, in20 distinguishes three different types of eco-innovation through three general categories: process, product and system innovations.

The whole product, product and accessory product

Products are not limited to a product delivered to the customer or end user. Related products exist in other lifecycle situations, particularly during the distribution or use situations, which are necessary to protect or assure a proper functioning of the system. These are called "accessory products". The product is not defined only as a stand-alone entity, but is considered as a whole product formed by the product itself and its accessory products.

First, the product is made up of a set of components, components of interaction and external components. It is possible to list:

Elements of the whole product can be considered as edible components even if they have a shorter lifespan than the required duration of the product. They may be components or components of interaction related to the safety engineering of the product (cartridges, filters, batteries, etc.) or external components (fluids, energy, signal, etc.). These consumables are sold with the product or separately. They could be standard or adaptable, single use or reusable.

Accessory products are related to packaging for marketing, transportation, sale, information (…), user manuals, regulatory documents, promotional materials, shipping documents, software support, etc. They exist in the lifecycle “distribution” (i.e. packaging) and “use” (i.e. cartridge) and must perform one or more constraint functions. These specific functions are due to the evolution of the product through its lifecycle. The use of such products may be temporary. Different accessory products are related to these three constraint functions:

Like a product, an accessory product is also made up of components, components of interaction and external elements. An overview of the whole product and its structural decomposition is proposed in Figure 2.

The evolution of the whole product through its lifecycle generates waste. This waste may be material or energy flows which could have hazardous properties. It is the result of a total or partial fragmentation of the different components that make up the whole product. It could correspond to edible or inedible components, operating fluids, effluents, noise or the whole product. This waste results from an evolution of a fluid state, an alteration of a component, a loss of effluent, etc. It comes from interactions between components, components of interaction and external elements. Accessory products are considered as waste from the whole product when they have fulfilled their functions.

When the particular point of view is centered into the whole product this helps reduce the complexity of taking into account the environmental impact of the product throughout its lifecycle. As innovation sessions consist mainly of brainstorming activities, it is necessary to limit the complexity of the integration of all environmental impacts which could limit the efficiency of the creativity group. It is assumed that this approach does not consider all phases of product lifecycle. For instance, it would be difficult to explicitly consider:

In this paper, we target evolutions in product design related to the 'use' and 'end of life' lifecycle phases.

The next step is to research in the literature for relevant tools providing both qualitative and quantitative information to set up an effective and parsimonious integration of the different environmental constraints in the innovation phase and then propose actions to redesign products.

Overview of tools proposed in literature

Considered as qualifiers of environmental impacts, assessment tools enable the designer to manage different data in the analysis of a product. This is the case for "energy content" a quantitative tool which makes the energy evaluation of a product possible throughout its lifecycle. It is well adapted for products which have a major energetic criterion.21 This tool enables us to identify and then limit energy consumption and associated costs. In this same context of quantitative assessment tools, many other tools like waste assessment,22 air or water pollution indicators23,24 the consumption indicator of raw material like Material Intensity Per unit of Service – MIPS,25 may be used as a vector for a quantitative assessment of environmental impacts generated by the product.

Qualitative assessment tools enable us to evaluate a product through its environmental impacts according to multi-environmental criteria. The Eco-compass, shown in Figure 3,26 is a graphical model considering six design criteria. It ranges existing products from 0 to 5. Among the tools for quality assessment, we have selected the "Lifecycle Design Strategy"(Figure 4).27

The analytical tools of environmental impacts are proposed and used both in the definition of need phase and in the phases of selection and ranking concepts. Most of these tools are in the form of a matrix, which makes it possible to vary environmental criteria in the product analysis phase. Their main significance is that they analyze qualitatively or quantitatively different categories of environmental impact (resource depletion, waste, radiation, noise pollution, greenhouse, etc.). The simplified quantitative evaluation matrix (ESQCV,1 shown in Table 1) is an example of such a matrix. It is a tool for product quality assessment for different categories of environmental impacts through particular stages of its lifecycle. The classification range starts from unfavorable (value of 2), median (1), positive (0) or no data (×). Using this tool, subjective nuisances can be considered, which are usually difficult to quantify.

|

Extraction of raw |

Production |

Distribution |

Use |

Recycling |

Production and waste (quantity, toxicity) |

× |

2 |

0 |

0 |

× |

Resource depletion (use quantity, renewable |

2 |

1 |

1 |

0 |

× |

Noise, odor, non-aesthetic |

2 |

× |

1 |

0 |

× |

Table 1 Illustration of the ESQCV utilization

In addition to these matrix analyses, the matrix of hierarchical analysis is proposed, such as the Analytic Hierarchy Process – AHP – (Table 2). Data from this type of matrix are used to guide and refine the analysis through the weights and cross elements of eco-efficiency, evaluation alternatives based on pair-wise comparison and thus, directions of product evolutions can be deduced.28

|

Material reduction |

Energy reduction |

Toxicity reduction |

Material retrieval |

Resource sustainable |

Product durability |

Product Service |

|

|||

Material reduction |

- |

|

|

Relative importance determined by the designer |

|

||||||

Energy reduction |

|

- |

|

|

|||||||

Toxicity reduction |

|

|

- |

|

|||||||

Material retrieval |

|

|

|

|

|

|

|

|

|||

Resource sustainable |

Inverse importance defined by the designer |

|

|

|

|||||||

Product durability |

|

|

|

||||||||

Product service |

|

|

|

||||||||

Table 2 Analytic hierarchy process

Other kinds of tools are proposed in the literature based on environmental assessment check-lists to identify and quantify the impacts of products through criteria. These check-lists are usually lists of questions or recommendations.

Among these tools, we should mention the golden rules,29 the checklists from the eco-design pilot software,30,31 or Information/Inspiration developed by Loughborough University and Electrolux.32,33 This last tool is composed of two blocks of particular checklists (Information and Inspiration) adapted to industrial designers.34 The "Inspiration" block provides examples of eco-design by international companies and identifies six criteria to study: ‘general’, ‘materials’, ‘recycling’, ‘production’, ‘use’ and ‘packaging’. The "Information" block recapitulates all the proposed check-lists through six different design goals: ‘materials’, ‘form’, ‘energy’, ‘function’, ‘parts’, and ‘packaging’.

The main importance of these checklists is that they guide the designer in his approach to environmental design. Check-lists are also easy to adapt and may be regarded as a tool to improve the product at different stages of the design process. However, check-lists are typed according to fields of activities and do not generally analyze the environmental impacts of a product.35 These approaches are not structured and combine both environmental impacts and lifecycle situations (materials, recycling, and production). For all these reasons, checklists do not seem to be suitable tools for structuring a general methodology for eco-innovation. Qualitative tools like Eco-compass or LiDS seem to be relevant in case of environmental assessment of the product and identifying the strategy required. In the framework of innovation and creativity, these tools are not well adapted and could be time consuming, and results could be biased due to the lack of knowledge about the product and associated process. Thus, it is interesting to use a matrix like ESQCV which leads to cross impacts with different lifecycle stages of the product. This particular structure is interesting because it is possible to consider different strategies to improve the product and then act either on impact or on particular lifecycle situation of the product.

Eco-efficiency principle

Eco-efficiency of a product can be described as a continuous process of change in order to decrease its environmental impacts while increasing its values and services. It is defined as the ratio between the value of the product and its environmental impacts throughout its lifecycle,16,36 see equation 1.

Eq (1)

The World Business Council for Sustainable Development (WBCSD16) provides design guidelines for a better eco-efficiency and has laid out seven elements:

All elements of eco-efficiency refer to environmental effects. The main categories of impacts are present (e.g. materials, energy and toxicity). For the first three points of eco-efficiency, we find an explicit definition of impacts linked to direct consumption or action to limit material dispersion. The last four points define a positive action and design approach, and in this way indirectly avoid some environmental impacts. This macroscopic environmental overview has a direct or indirect impact on the optimization of environmental resources and provides a comprehensive and exhaustive view of all existing environmental impacts. We propose to sum up eco-efficiency in terms of the eco-efficiency elements, introducing two minor changes to points F and G (in bold in Table 3).

Eco-efficiency axes (WBCSD) |

Eco-efficiency elements |

A. Reducing material requirements; |

A. Material reduction |

B. Reducing energy intensity; |

B. Energy reduction |

C. Reducing toxic dispersion; |

C. Toxicity reduction |

D. Enhancing material recyclability; |

D. Increase recyclability and reuse |

E. Sustainable use of renewable resources; |

E. Increase resource sustainable |

F. Extending product durability; |

F. Increase durability and desirability of product |

G. Increasing the service intensity of goods |

G. Increase functionality and service of product |

Table 3 Eco-efficiency axes and eco-efficiency elements

It seems to be interesting to associate the concept of desirability of the product with the durability aspect in axis F. The increase in esteem functions will act on the user’s affectivity for the product and increase the duration of ownership. Increased functionality is juxtaposed to the increase in services. The last point of the matrix, point G, corresponds to the natural evolution of a product "the increase in product functionalities". According to,10 this evolution is the step before the conversion of goods to services (dematerialization phase).

Association of the 7 elements to lifecycle phases

For every eco-efficiency element, we will define particular actions in the eco-innovation phase. These actions will modify some product lifecycle situations. An association between these 7 elements and the lifecycle phases is proposed (Table 4). This defines a strategy like a directive or environmental design objectives and provides a structured and oriented view in preliminary design. Environmental problems related to the production appear through weight reduction and toxicity. Reductions in energy generation cannot be taken into account in the search for concepts.

Product and accessory product |

Extraction of raw material |

Production |

Distribution |

Use |

End of life |

A. Material reduction |

× |

× |

× |

× |

× |

B. Energy reduction |

|

|

|

× |

× |

C. Toxicity reduction |

|

× |

× |

× |

× |

D. Increase recyclability and reuse |

|

|

|

× |

× |

E. Increase resource sustainability |

|

|

|

× |

× |

F. Increase durability and desirability of product |

|

|

|

× |

|

G. Increase functionality and service of product |

|

|

× |

× |

|

Table 4 Relation between the selected lifecycle phases and the eco-efficiency elements

In this paper, we will restrict the study and it is only considered the final stages: use and end-of-life of the product lifecycle.

Figure 5 shows, in the centre, the whole product composed of the product and accessory product. The left hand side shows the consumption resources (materials and energies) and beyond the environmental rejects corresponding to waste. The right hand side lists the two selected lifecycles, use and end-of-life of the product. The different links (black arrows) from the whole product to lifecycle situations, the consumption resources and the waste indicate the direct influence that design choices on the whole product have on its environment.

Figure 5 Representation of the whole product and the different influences on materials, energies, waste and the associated impacts through lifecycle phases use and end of life.

Increasing the recyclability and the reuse of whole products is related to two product lifecycle situations, use and end of life. If the reuse of the whole product is improved, we can optimize the use or end of life phases by allowing the reuse of part of the whole product. If the recyclability of components is improved, the end phase of life is directly impacted.

Increasing the resource sustainability is a point related to specific resources of the product or those available in the environment. This action concerns the last two lifecycle situations since we are only focusing on the internal and external resources of the product.

Increasing the durability and the desirability of the whole product can limit the renewal phase of the product and thus increase the use phase. Thus, the design has to take this new life duration into account. Increased functionality and service of the whole product are going to influence the “use” phase. This action increases the esteem of the user towards the product by making it more attractive.

Analysis and actions to be carried out

To be efficient in the eco-innovation process, an analysis phase for the whole product has to be included. The objective is to propose actions and define a strategy to implement for product eco-innovation. It should be as short as possible during the research into concepts through creativity sequences. These sequences are usually carried out by a creativity group and the time available for this research has to be as short as possible, yet effective without causing “psychological barriers” (e.g. presentation of too specific examples). We define actions to be implemented on the studied system from the organic decomposition developed in section 3. In this work, we list actions dedicated to the eco-efficiency axes: increasing recyclability and reuse.

For this point, which elements have to be considered during the design stage to ensure that components are reusable or that its substances will be recyclable? Reuse requires that the reusable property of every component is considered from the initial design stage and must therefore subsequently be protected and conserved throughout the “use” phase of the product (Table 5, action #1). The consumable substances of the system must be storable and retrievable during the lifecycle of the product. These two actions impact the "use" lifecycle situation. Other actions will affect the evolution of the product to improve the “end of life lifecycle situation”. We will list the possible changes to the components or the interaction of one component with another and the material used.

Lifecycle situation |

Action in design phase |

Opportunity for the product |

Use |

1. Protect, make components or component of interactions reusable |

1-a) Information |

1-b) Space |

||

1-c) Self-service |

||

1-d) Interaction resources |

||

1-e) Organizational resources |

||

2. Promote recovery or storage of consumable product |

2-a) Space |

|

2-b) Self-service |

||

2-c) Interaction resources |

||

2-d) Organizational resources |

||

2-e) Differential resource |

||

End of life |

3. Act on the geometry of components and component of interactions of product and accessory products to reduce the quantity and volume to be recycled (handling, transport, storage, etc.) |

3-a) Self-service |

3-b) Space |

||

3-c) Functional resources |

||

3-d) Interaction resources |

||

3-e) Organizational resources |

||

3-f) Differential resource |

||

4. Promote the use of reusable components and components of interaction or made with recyclable materials |

4-a) Substances |

|

4-b) Self-service |

||

4-c) Information |

||

5. Suppress the component of interactions and the poly-material component. |

5-a) Substances |

|

5-b) Self-service |

||

5-c) Interactive resources |

||

5-d) Organizational resources |

||

6. Design for disassembly, simplify and standardize the component of interaction |

6-a) Information |

|

6-b) Interaction resources |

||

6-c) Organizational resources |

||

6-d) Differential resources |

Table 5 Actions, opportunities, function of the use and end of life lifecycle phases

We must encourage the use of reusable components and recyclable materials to increase the overall recyclability of the product (Table 5, action #2). To reduce the volume of components, it is important to act on the component’s geometry to facilitate storage and waste transportation at the end of life of the product (Table 5, action #3).

Reuse also requires collecting the different components (Table 5, action #4). Product design should include the constraint to facilitate the disassembling phase (Table 5, action #6). A classical technique consists of carrying out modular design, standardizing component interactions or suppressing them. One way to achieve modularity is to separate or segment these functions; every component or group of components should then correspond to a single function or can contribute to its realization. In the framework of modularity, the components identified cannot be assembled by permanent links. In the same way, components made from poly-material must be separated or eliminated; this means that poly-material can become several mono-materials after particular modifications (Table 5, action #5). This analysis also concerns the accessory product. Information about the material used in every component has to be identified and labeled.

We have listed different possibilities for influencing the recyclability and reuse phases, using semantic forms. These sentences in the second column of Table 5 will be proposed to the creativity group in the analysis phase to be interpreted according to the case being studied.

Identification of product opportunities

To guide engineers during the brainstorming phase and the search for product evolutions, we propose to use a specific tool called a “resource list” developed in the MAL'IN software.13 These particular resources give a comprehensive overview of the available opportunities. This list is based on previous work by Savransky10

Aiming at developing a problem-solving methodology, so called, Triz theory. Its main goal is to stimulate and generate innovative ideas and solutions in a structured and systematic way through a set of tools and methodologies. From this, it is proposed to improve it and to express the 12 points for setting up a systematic analysis more precisely (Annex 1).

The concept of substance (Item 1) is based on the Triz theory11 and includes the component and its environment. Energy (Item 2) and the differential resources (Item 10) specify the available energy in the system and its environment. The functional resources (item 6 and 11), self-service (item 7) underline the additional capabilities of the product to those observed during operation. Finally, we find the resource interaction (item 8), which concerns the evolution or the suppression of such components. Many product developments are the result of layout changes envisaged in items 2 (space) and 9 (organizational resources), which may change through the operating time (item 3). Waste (item 12) is directly explicit in terms of sustainable development.

We use this list to identify opportunities already present in the system, and every opportunity has been linked to an action. Annex 2 presents an analytical framework for every resource in terms of sustainable development. The following paragraphs cite some of the points listed in Table 5 in the third column.

The substances considered in the resource list are components which can be loseable, with no particular functionality, redundant, disposable, toxic, splittable or non-reusable. It is then possible to suppress them or to make them reusable by modifying them.

Similarly, external substances which are consumables will provide opportunities to make changes for the reuse and recycling phases. The self-service property allows for the discovery of physical, chemical or geometrical properties like buoyancy for selecting or recycling phases or the retention of fluid property for later retrieval or conditional retrieval. For example, in the case of using porous media, a depression could separate fluid from media.

According to the authors, the use of interaction resources is a major source of opportunity for product evolution. In this case we consider simultaneously standardization for recycling, changing interactions to eliminate them completely or increasing the degrees of freedom of products (dynamic modification) to make the system controllable and increase energy efficiency. Organizational resources can change layouts and thus lead to increased compactness, containment of effluent and reduced energy losses. The third column of Table 5 lists the resources for checking or finding eco-innovation opportunities according to selected actions.

Description and formal decomposition

To illustrate the method, proposed to study an evolution of a classical waffle iron. The device shown in Figure 6, is composed of two heating units connected by a hinge. Each heating unit includes a unit cover, a massive aluminum plate for baking with a non-stick coating. Each plate is heated by an electrical resistance. The white external cover isolates the plates from the outside.

In the approach used here, we first produced an organic decomposition of the whole product by identifying the different components and component interaction, external elements and accessory product (Figure 7). In this figure, the main components and external elements are represented. To make this decomposition more readable, we have identified some components of interaction without systematically linking them to other components with which they interact.

Evolution of the waffle iron

Table 5 lists different general opportunities for the product. We propose to select actions #2: Promote recovery or storage of consumable product and 5: Suppress the component of interactions and the poly-material component and then make a few changes to the waffle iron.

Promote recovery or storage of consumable product

Concerning the action “promote recovery or storage of consumable product”, it is necessary to identify the consumable product of the waffle iron. The main elements are the waffle batter and the oil introduced between the batter and the heater units. The batter corresponds to an external element and the oil is a component of interaction. One problem that the user can encounter is that the batter or oil can flow inside the waffle iron. This drawback was noticed when we disassembled the product after it had been used. We consider the various opportunities in Table 5:

Suppress the component of interactions and the poly-material component

By considering the action, "Suppress the component of interaction and the poly-material component for the end of life", it is possible to act on removing components of interaction such as oil. If we observe the waffle iron, components such as heater plates with a non-stick coating or the painted white plastic cover, these could be considered all together as poly-material. The opportunities identified propose to act on substances, to use the self-service property, to work on the interactions or organizational resources.

Acting on substances (5-a) suggests analyzing all components of interaction to envisage their evolution or their elimination. Thus, the pivot joint between the two plates, made up of 3 components (hollow shaft, tongue and screw) as shown in Figure 6, could be studied and improved.

Acting on substances also leads us to consider the materials that make up the components. In this case, it is possible to research a particular material with non-stick properties, thus suppressing the non-stick coating of the plate.

Removing the poly-materials that make up the plate can lead the group to study the interaction between the plate and the batter to prevent the adhesion of the batter during cooking.

The self-service opportunity allows us to use particular phenomena like elastic strains or adhesion property between parts in order to remove components of interaction. This opportunity could be exploited to modify the joint between the 2 plates; the designer could replace the three parts (tongue, hollow shaft and screw) with only one deformable hollow shaft.

Using resources of interaction can standardize the components of interaction, reduce them or even eliminate them. Organizational resources are the last opportunity for the selected action. This directly concerns the arrangement of components, the aim being to remove components of interaction and poly-material components. It may lead to a simplification and reduction in the number of components.

We have proposed an original method for integrating constraints for sustainable development during research into innovative concepts. This method is based on functional analysis, on energy analysis of physical behavior and solving tools derived from Triz theory. We rely on the simplified evaluation matrix of lifecycle assessment (ESQCV) and the seven elements of eco-efficiency defined by WBCSD. The eco-efficiency elements have been used with the aim of adapting them to the framework of eco-innovation. We chose to restrict the possible intersections between lifecycle phases (use and end of life) and efficiency axes, preferring to focus only on defining actions directly applicable and quantifiable during the innovation phase. The goal is to propose a parsimonious tool for eco-innovation and to lead the creativity group to take into account new environmental constraints as a source of potential development while assuring the minimal required time to carry out such a study. An analysis phase makes it possible to consider eco-innovation strategy quickly, or it could be used to select eco-efficiency elements to improve the product. The decision to use a set of actions coupled with classical innovation tools means that potential problems (e.g. technical and environmental) can be identified and provides tools for structuring the study based on a substance-field graph. Finally, combining action and sustainable resource datasheets (Annex 2) simplifies the resolution of eco-innovation problems. The global overview of the proposed approach is shown in Figure 8.

Different developments have to be applied to complete the method:

The quantification and hierarchy of the different design alternatives in the earlier design is not an easy task since only a few elements are available and these are usually not sufficient to select the process needed to manufacture the product, identify clearly the volume of material, etc. This is an important research point and a few interesting elements have been proposed in the literature, such as LCA, LiteLCA, FactorX...

The extension of the action into the other phases of the lifecycle of the product. It seems to be difficult to propose relevant actions for every phase, for the same reasons cited previously (lack of knowledge concerning the material, the process, etc.).

Finally, to make the method easier to use, it is necessary to implement it in an eco-innovation software. It could then be possible to study a wider variety of examples with the aim of validating not only all systematic actions to be carried out, but also the resource list developed in the general industrial framework.

Our aim is first to produce an organic decomposition of the product to be eco-innovated in order to identify the components, the components of interaction and the external element. A classification of every component is then possible. Depending on the company's view of product evolution (i.e. strategic vision, returns to experience or technical analysis), the eco-efficiency element is then related to a particular lifecycle. Based on this selection, we propose a list of actions to carry out on the product. For each of them, opportunities are listed using a systematic approach to facilitate and guide the brainstorming sessions. The lists of opportunities are derived from traditional innovation tools such as MAL'IN13 by incorporating environmental constraints. These points correspond to the main contribution of this paper, technical problems could be resolved using more classical tools like Triz innovation, MAL'IN, etc. for the concept research. Finally, the new solutions can be evaluated using tools provided in the literature, such as LCA LiteLCA, FactorX, etc.

None.

The author declares that there is no conflict of interest.

©2022 Ledoux, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.