It should be noted that numerous studies rough pipes from Nikuradse studies show that at relatively high roughness turbulent flow is essentially different from the flow in smooth pipes. In US8538738, processes have been described to provide for prediction of the transition from laminar to turbulent flow on the surface.9 Rajnarayan and Sturdza9 disclosed the methods, systems and devices for estimating conversion from laminar to turbulent flow on the surface manipulating mode shape parameters. In his stratification takes place four flow regimes: laminar (for small Reynolds numbers, regardless of the roughness that occurs in law Poiseuille) turbulent flow (for intermediate Reynolds numbers, the law of hydraulic resistance for smooth tubes) turbulent flow (for intermediate numbers Reynolds by hydraulic resistance, which is a function of the relative roughness

(the ratio of the average height of the roughness to the radius of the tube; D = 2R0 - а larger internal diameter of the pipe) and the Reynolds number) for self (at high Reynolds numbers by a factor of hydraulic resistance, which is a function only of the relative roughness). At sufficiently high relative roughness is eliminated the turbulent regime with regularity characteristic for smooth pipes. A similar situation occurs for tubes with turbulence.1–4 Liu10 discussed the anti-drag protecting agents move the turbulent heat transfer property of the pipeline to laminar flow heat transfer property.

For tubes with a relatively low surface roughness height of the projection asymptotic behavior of the flow resistance described by the known empirical relation Nikuradse:

(1)

The dependence of the hydraulic resistance for rough pipes, not only on the relative roughness, and the Reynolds number

, described by the empirical formula is the best way Colebrook, which can be written as follows:

(2)

Thus, in the empirical correlations for the coefficient of hydraulic resistance of flow in rough pipes a logarithmic velocity profile.

Hydraulic resistance coefficient for flow in straight circular tubes is determined as follows:

(3)

where

- pressure drop;

- diameter;L - length of pipe;

- density of coolant;

- average expenditure speed;

- friction velocity.

For a straight circular pipe value speed is determined by the following integral equation:

(4)

where

- relative transverse coordinate

.

The integration is performed for two sites: from zero to the boundary of the viscous sublayer

and for the core flow:

(5)

or

Consequently, for the integration of the last expression is necessary to determine the velocity profiles

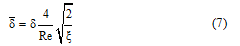

for each of the sub-layers. The boundary of the viscous sublayer can be determined by the following:

where

- constant.11,12

The equation of motion in a straight circular pipe roughness can be written as follows:

(8)

where

- full kinematic viscosity;

- shear stress at the wall.

Full kinematic viscosity based on the superposition principle is the sum of molecular viscosity; the turbulent viscosity is independent of roughness and depends on the distance from the wall, the turbulent viscosity, depending on the roughness. We must now derive formulas for the total of determining the coefficient of kinematic viscosity. The molecular kinematic viscosity is determined by the properties of the coolant and is ν. The turbulent kinematic eddy viscosity in a circular tube, which is independent of the roughness can be postulated as a function of distance from the wall of the tube follows. Turbulent kinematic viscosity determined as the product of the mixing l the characteristic speed-dynamic speed on the current radius:

(9)

The mixing l can be postulated as follows:

(10)

where

and-

constants.11,12

Next, we have to express the dynamic speed of the current

radiusthrough dynamic speed on the tube wall

:

(11)

therefore:

(12)

or

(13)

Given the relationship, we obtain the final expression for the turbulent kinematic viscosity

, which is independent of roughness:

(14)

The turbulent kinematic viscosity

, depending on the roughness is determined by the product of the characteristic length L the characteristic speed - dynamic speed

at the current radius:

(15)

Under this theory focuses mostly pipe roughness equal height h. In fact, there is a certain roughness height variation. Experiments show that with small dispersion

(standard deviation of the average) roughness height holds a rather abrupt transition from the smooth pipes to the regime of rough tubes, with large dispersion will be a smooth transition, since there will be a gradual withdrawal of the roughness of the viscous sublayer in the thickness of the wall layer. The characteristic length L for the kinematic eddy viscosity, which depends on the roughness for roughness height, is equal to:

(16)

The final expression for the turbulent kinematic viscosity, which depends on the roughness:

(17)

Hence, the equation of motion in a straight circular pipe roughness (8) becomes (18)

(18)

In the future, should write (18) in the dimensionless form:

The desired velocity profiles

obtained by integration of (20) provided a smooth closing of the borders sub layers under the following conditions:

(21)

(22)

Integration is performed for the two sub-layers: 0 to the boundary of the viscous sublayer

, for which a constant

and from the above limits

to 1, where

on the boundary condition soft closing

.

Hence, the equation for the coefficient of hydraulic resistance in rough tubes can be written as follows:

(23)

After the integration and mathematical calculations, we obtain the final equation for the transcendental of determining the coefficient of hydraulic resistance for round rough pipes:

(24)

The double integral in (24) cannot be expressed in a class of elementary functions. The form of the transcendental equation (24) indicates that, in calculating the hydraulic resistance in the round rough pipes is used in more complex and accurate ratio than current based (somehow) on the logarithmic velocity profile. The solution of equation (24) is best to produce numerically. As noted earlier, in this paper are modeled mostly pipe roughness with projections of equal heights. However, with the help of the model the possibility of similar modeling and when there is some deviation of the roughness height of their average value. If the variance of the mean values of roughness height

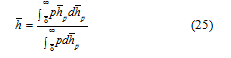

is different from zero, the average height of the roughness can determine this (thus determined diffuse boundaries “roughness-viscous sublayer”):

Figure 5 Reported bird strikes and parts mostly hit(* FAA wildlife strike data base).

where

- values of the relative roughness height with a probability density

.

Therefore, to calculate the average height of the roughness

, beyond the limits of the viscous sublayer

σ

¯

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGafq4WdmNbae

baaaa@37D1@

, need to know the probability law roughness height distribution in the pipe. For example, for a normal distribution of roughness heights transcendental equation for the pressure drop in a round of rough pipe is as follows:

(26)

Where

-Gaussian error function (integral probabilities).

In the future, should make calculations of hydraulic resistance for pipes with rough walls on received in the solution (24) for different heights of roughness and Reynolds number. This compares to bring the calculated values obtained by formula Colebrook and data for tubes with turbulators other things being equal (equal to the Reynolds number and the relative roughness height and turbulence). It should be noted that the above recent data have significant limitations on the height of vortex generator, while the equation obtained in this work, we have to great heights of roughness. Table 1 shows the calculated data for the hydraulic resistance in straight round rough tubes, obtained from the solution of the transcendental equation (24) for the relative heights of the turbulators

and

.

For comparison, the similar values obtained by formula Colebrook and values for a smooth tube, obtained from the dependence Filonenko. From the data in Table 1, it is clear that the theoretical solutions are close to the formula of Colebrook for the relatively low heights of roughness. For a much wider range of heights roughness values of hydraulic resistance for round rough pipes are given in Table 2 and Table 3, in which, for comparison, the only similar relevant data, calculated by the empirical relationship Colebrook and values of hydraulic resistance for a smooth pipe from the empirical formula Filonenko. For clarity of presentation in Table 2 values of hydraulic resistance for rough pipes are given in the form of

according to

for

Table 3 similar data are given in absolute units. As shown in Table 2 & Table 3, at relatively low altitudes of roughness at high Reynolds numbers (about 106) hydraulic resistance values for rough pipes, calculated on the developed theory, approximately coincide with those values calculated by the formula Colebrook, for medium Reynolds numbers (about 105) calculation formula Colebrook gives higher values.

When compared to the average roughness height theoretical values of hydraulic resistance in rough pipes are approximately equal empirical values obtained from the dependence of Colebrook, at medium and high Reynolds numbers, at low Reynolds numbers (about 104) Colebrook empirical formula gives higher values. For tubes with relatively large roughness height calculated from the empirical formula Colebrook provides even inflated data on hydraulic resistance has in the entire range of Reynolds numbers. Therefore, on the basis of the data presented, we conclude that empirical correlations have a significant disadvantage compared with dependencies developed in this study, for large values of the relative roughness height h/R0. The disadvantage of the existing theoretical and empirical relationships should be recognized that they are limited by the relative roughness height: they do not allow determine the hydraulic resistance for pipes with very high altitudes turbulence, which can be characterized, for example, rough pipes of small diameters. In the future should bring estimates of the hydraulic resistance in rough tubes, obtained by the developed dependencies, for very large values of the relative roughness height: h/R0=0.15¸0.30. Table 4 shows the calculated values of hydraulic resistance for rough pipes are very large relative roughness height (h/R0=0.15¸0.30) for the typical range of Reynolds numbers (Re = 104¸106); for comparison, the corresponding values of hydraulic resistance for smooth pipe ξSM (h/R0=0).

The data presented indicate that the pressure drop in rough tubes great height roughness increases at low Reynolds numbers from about 2.4 to 2.9 times compared to the smooth tube with increasing height roughness with h/R0 =0.15 tо h/R0 =0.30, for medium Reynolds numbers, this increase is already about 4.1 and 4.9 раз respectively, for the big-about 6.3 tо 7.6. When the Reynolds number increases with 104 tо 106 hydraulic resistance of rough pipes compared to a smooth tube increases by about 2.6 times for the considered range of relative roughness height, with an increase in the relative roughness height twice (about h/R0=0.15 tо h/R0=0.30) corresponding increase in the relative pressure drop of about 1.2 times. Consequently, the increase in the height of roughness and an increase in the Reynolds number is a significant increase in pressure drop in rough tubes to the smooth tube. The discrepancy between the solution for the hydraulic resistance for rough pipes, obtained in this study, with the decision based on a logarithmic velocity profile is of the order (10¸15)% for the relatively high roughness height at low Reynolds numbers, with a decrease in the height of roughness and an increase Reynolds discrepancy disappears.

In the future, it is necessary to conduct a comparative analysis of the estimated values of hydraulic resistance for rough pipes and tubes with turbulators other things being equal (equal heights roughness h/R0 and turbulence, the equality of the Reynolds number Re). Table 5 the values of hydraulic resistance for round rough pipes, calculated as on the developed theory and the empirical formula Colebrook, which are compared with experimental data for pipes with periodic transverse in turbulence flow in circular pipes1 provided h/R0=idem and Re = idem (h/R0=0.01¸0,13; t/D=0.25¸1.00; Re = 104¸2*105); for comparison the hydraulic resistance for a smooth tube, calculated from the empirical formula Filonenko. Comparative analysis of the hydraulic resistance in rough pipes and tubes with turbulence presented in Table 5 show that for small relative roughness height

pressure drop in rough tubes at low Reynolds numbers is about the same as in the tubes with turbulators equal altitudes throughout the range considered the relative pitches between turbulence and at high Reynolds numbers-about twice as much.

At an average altitude of relative roughness

pressure drop in rough tubes approximates hydraulic resistance in the pipes with turbulence: a small step between turbulence

at high Reynolds numbers, the average step

-at medium Reynolds numbers, a large step

- at low Reynolds numbers.

At high altitudes, the relative roughness

hydraulic resistance of rough tubes approximately the hydraulic resistance in the tubes with turbulators with a big step between turbulence at high Reynolds numbers.

Hydraulic resistance of rough tubes with large relative roughness height for the remaining cases-for small, medium and large steps between turbulence at low and medium Reynolds numbers, as well as small and medium-sized steps between turbulence at high Reynolds numbers-always much lower than for pipes with turbulence, other things being equal, (h/R0 = idem and Re = idem). For very high roughness height

hydraulic resistance of rough pipes is much lower than for tubes with turbulators other things being equal for all the considered range of geometrical parameters of turbulence and flow regimes coolants (h/R0=0, 11¸0,13; t/D=0.25¸1.00; Re =104¸2*105).

The data in Table 5 to hydraulic resistance data for rough pipes for very high Reynolds numbers

indicate that, for low and medium heights roughness theoretical solution obtained in this work, and the empirical formula of Colebrook give approximately equal results, and for high and very high heights roughness dependence Colebrook clearly gives higher values.Hence, it is proved that the theory has generated over the existing empirical formulas distinct advantage in the high and very high relative roughness height and very high Reynolds numbers (h/R0>0.10; ReÎ[106¸109]).

h/R0 ↓ |

ξ ↓ |

Re→ 4×104 |

6×104 |

8×104 |

105 |

106 |

107 |

formula Filonenko |

0,02204 |

0,02008 |

0,01885 |

0,01797 |

0,01161 |

0,00812 |

1/70=1,43×10-2 |

theoretical solution |

0,03226 |

0,03328 |

0,03374 |

0,03400 |

0,03486 |

0,03494 |

formula Colebrook |

0,03571 |

0,03528 |

0,03484 |

0,03466 |

0,03398 |

0,03392 |

1/50=2,00×10-2 |

theoretical solution |

0,03705 |

0,03769 |

0,03798 |

0,03816 |

0,03874 |

0,03879 |

formula Colebrook |

0,03935 |

0,03887 |

0,03863 |

0,03848 |

0,03794 |

0,03789 |

Table 1 Hydraulic resistance in round rough pipes, calculated from the solution of the transcendental equation (24) for the relative heights of the turbulators h/R0=1/70 and 1/50

h/R0 |

lg(100. ξ) |

lg(Re) |

4,0 |

4,2 |

4,4 |

4,6 |

4,8 |

5,0 |

5,2 |

5,4 |

5,6 |

5,8 |

6,0 |

1,97×10–3 |

theory |

— |

— |

— |

— |

— |

— |

— |

0,242 |

0,270 |

0,284 |

0,291 |

Colebrook |

— |

— |

— |

— |

— |

— |

— |

0,316 |

0,308 |

0,302 |

0,298 |

3,97×10–3 |

theory |

— |

— |

— |

— |

— |

— |

0,341 |

0,359 |

0,368 |

0,374 |

0,377 |

Colebrook |

— |

— |

— |

— |

— |

— |

0,389 |

0,382 |

0,377 |

0,374 |

0,372 |

7,94×10–3 |

theory |

— |

— |

— |

— |

— |

0,440 |

0,451 |

0,457 |

0,461 |

0,463 |

0,465 |

Colebrook |

— |

— |

— |

— |

— |

0,469 |

0,463 |

0,459 |

0,457 |

0,455 |

0,454 |

1,67×10–2 |

theory |

— |

— |

— |

0,537 |

0,548 |

0,555 |

0,558 |

0,560 |

0,562 |

0,563 |

0,563 |

Colebrook |

— |

— |

— |

0,572 |

0,565 |

0,560 |

0,557 |

0,555 |

0,554 |

0,553 |

0,553 |

3,27×10–2 |

theory |

— |

0,632 |

0,643 |

0,648 |

0,652 |

0,654 |

0,655 |

0,655 |

0,656 |

0,656 |

0,656 |

Colebrook |

— |

0,679 |

0,670 |

0,664 |

0,660 |

0,658 |

0,656 |

0,655 |

0,655 |

0,654 |

0,654 |

6,67×10–2 |

heory |

0,754 |

0,755 |

0,756 |

0,756 |

0,756 |

0,756 |

0,756 |

0,756 |

0,756 |

0,756 |

0,756 |

Colebrook |

0,796 |

0,789 |

0,784 |

0,781 |

0,779 |

0,778 |

0,777 |

0,777 |

0,777 |

0,776 |

0,776 |

0 |

Filonenko |

0,497 |

0,443 |

0,392 |

0,344 |

0,298 |

0,255 |

0,213 |

0,174 |

0,136 |

0,100 |

0,065 |

Table 2 Hydraulic resistance (in the form of log (100 ξ)) in round rough pipes, depending on the Reynolds number (in the form lg(Re)), calculated from the solution of the transcendental equation (24) for a wide range of turbulence heights h/R0=1/15÷1/507

h/R0 |

ξ |

Re |

104 |

1,58×104 |

2,51×104 |

3,98×104 |

6,31×104 |

105 |

1,58×105 |

2,51×105 |

3,98×105 |

6,31×105 |

106 |

1,97×10–3 |

theory |

— |

— |

— |

— |

— |

— |

— |

0,01745 |

0,01861 |

0,01921 |

0,01956 |

Colebrook |

— |

— |

— |

— |

— |

— |

— |

0,02072 |

0,02032 |

0,02005 |

0,01987 |

3,97×10–3 |

theory |

— |

— |

— |

— |

— |

— |

0,02195 |

0,02285 |

0,02335 |

0,02365 |

0,02383 |

Colebrook |

— |

— |

— |

— |

— |

— |

0,02448 |

0,02408 |

0,02383 |

0,02366 |

0,02355 |

7,94×10–3 |

theory |

— |

— |

— |

— |

— |

0,02752 |

0,02824 |

0,02866 |

0,02891 |

0,02906 |

0,02916 |

Colebrook |

— |

— |

— |

— |

— |

0,02943 |

0,02904 |

0,02879 |

0,02862 |

0,02852 |

0,02845 |

1,67×10–2 |

theory |

— |

— |

— |

0,03443 |

0,03533 |

0,03585 |

0,03616 |

0,03635 |

0,03646 |

0,03653 |

0,03658 |

Colebrook |

— |

— |

— |

0,03730 |

0,03671 |

0,03633 |

0,03608 |

0,03592 |

0,03582 |

0,03576 |

0,03572 |

3,27×10–2 |

theory |

— |

0,04289 |

0,04395 |

0,04451 |

0,04484 |

0,04503 |

0,04515 |

0,04523 |

0,04527 |

0,04530 |

0,04532 |

Colebrook |

— |

0,04770 |

0,04676 |

0,04615 |

0,04575 |

0,04549 |

0,04533 |

0,04523 |

0,04516 |

0,04512 |

0,04509 |

6,67×10–2 |

theory |

0,05673 |

0,05690 |

0,05697 |

0,05700 |

0,05701 |

0,05702 |

0,05702 |

0,05702 |

0,05702 |

0,05702 |

0,05702 |

Colebrook |

0,06251 |

0,06150 |

0,06085 |

0,06044 |

0,06017 |

0,06001 |

0,05990 |

0,05983 |

0,05979 |

0,05976 |

0,05974 |

0 |

Filonenko |

0,03144 |

0,02774 |

0,02466 |

0,02207 |

0,01986 |

0,01797 |

0,01634 |

0,01492 |

0,01367 |

0,01258 |

0,01161 |

Table 3 Hydraulic resistance in round rough pipes, depending on the Reynolds number, calculated from the solution of the transcendental equation (24) for a wide range of relative heights of turbulators

h/R0 |

Re |

104 |

5×104 |

105 |

5×105 |

106 |

0,15 |

0,07511 |

0,07358 |

0,07338 |

0,07323 |

0,07321 |

0,20 |

0,08177 |

0,07988 |

0,07964 |

0,07945 |

0,07943 |

0,25 |

0,08691 |

0,08480 |

0,08454 |

0,08433 |

0,08430 |

0,30 |

0,09104 |

0,08879 |

0,08851 |

0,08828 |

0,08826 |

0 |

0,03144 |

0,02093 |

0,01797 |

0,01311 |

0,01161 |

Table 4 Hydraulic resistance in round rough pipes, calculated from the solution of the transcendental equation (24) for very high relative roughness heights (h/R0=0.15÷0.30), depending on the Reynolds number

h/R0 |

t/D |

ξ |

Re |

104 |

2×104 |

4×104 |

105 |

2×105 |

4×105 |

106 |

107 |

109 |

0,01 |

0,25 |

Kalinin |

0,04588 |

0,03618 |

0,02953 |

0,02135 |

0,01795 |

0,01472 |

— |

— |

— |

0,50 |

Kalinin |

0,04240 |

0,02980 |

0,02595 |

0,02135 |

0,01795 |

0,01359 |

— |

— |

— |

1,00 |

Kalinin |

0,03322 |

0,02847 |

0,02416 |

0,01975 |

0,01601 |

0,01359 |

— |

— |

— |

— |

theory |

— |

— |

0,02709 |

0,02997 |

0,03071 |

0,03106 |

0,03125 |

0,03137 |

0,03138 |

— |

Colebrook |

0,03765 |

0,03448 |

0,03258 |

0,03130 |

0,03083 |

0,03059 |

0,03045 |

0,03036 |

0,03035 |

0,05 |

0,25 |

Kalinin |

0,10378 |

0,08780 |

0,07495 |

0,05907 |

0,05087 |

0,04403 |

— |

— |

— |

0,50 |

Kalinin |

0,09176 |

0,07716 |

0,06801 |

0,05427 |

0,04818 |

0,03737 |

— |

— |

— |

1,00 |

Kalinin |

0,04430 |

0,03884 |

0,04072 |

0,03594 |

0,03292 |

0,02453 |

— |

— |

— |

— |

theory |

0,05039 |

0,05134 |

0,05170 |

0,05189 |

0,05194 |

0,05197 |

0,05199 |

0,05199 |

0,05200 |

— |

Colebrook |

0,05629 |

0,05471 |

0,05389 |

0,05338 |

0,05321 |

0,05313 |

0,05308 |

0,05304 |

0,05304 |

0,10 |

0,25 |

Kalinin |

0,18351 |

0,16762 |

0,16019 |

0,14625 |

0,13166 |

0,11424 |

— |

— |

— |

0,50 |

Kalinin |

0,19933 |

0,19156 |

0,16287 |

0,15230 |

0,12164 |

0,10442 |

— |

— |

— |

1,00 |

Kalinin |

0,14301 |

0,12771 |

0,12305 |

0,09964 |

0,07122 |

0,05133 |

— |

— |

— |

— |

theory |

0,06580 |

0,06531 |

0,06505 |

0,06489 |

0,06484 |

0,06481 |

0,06479 |

0,06478 |

0,06478 |

— |

Colebrook |

0,07376 |

0,07264 |

0,07207 |

0,07172 |

0,07161 |

0,07155 |

0,07152 |

0,07149 |

0,07149 |

0,11 |

0,25 |

Kalinin |

0,19996 |

0,18890 |

0,18122 |

0,16369 |

0,15410 |

0,13286 |

— |

— |

— |

— |

theory |

0,06797 |

0,06735 |

0,06703 |

0,06684 |

0,06677 |

0,06674 |

0,06671 |

0,06671 |

0,06671 |

— |

Colebrook |

0,07692 |

0,07586 |

0,07531 |

0,07499 |

0,07188 |

0,07482 |

0,07479 |

0,07477 |

0,07477 |

0,12 |

0,50 |

Kalinin |

0,26894 |

0,24557 |

0,22597 |

0,20461 |

0,15710 |

0,14594 |

— |

— |

— |

— |

theory |

0,06996 |

0,06924 |

0,06887 |

0,06865 |

0,06857 |

0,06853 |

0,06851 |

0,06850 |

0,06850 |

— |

Colebrook |

0,08002 |

0,07900 |

0,07848 |

0,07816 |

0,07806 |

0,07801 |

0,07797 |

0,07796 |

0,07795 |

0,13 |

1,00 |

Kalinin |

0,31640 |

0,26473 |

0,22373 |

0,17792 |

0,14214 |

0,11323 |

— |

— |

— |

— |

theory |

0,07180 |

0,07099 |

0,07058 |

0,07033 |

0,07025 |

0,07020 |

0,07018 |

0,07017 |

0,07016 |

— |

Colebrook |

0,08306 |

0,08207 |

0,08157 |

0,08127 |

0,08117 |

0,08112 |

0,08109 |

0,08107 |

0,08107 |

0 |

— |

Filonenko |

0,03144 |

0,02612 |

0,02204 |

0,01797 |

0,01559 |

0,01366 |

0,01161 |

0,00812 |

0,00460 |

Table 5 Comparative analysis of hydraulic resistance values for round rough pipes calculated according to the developed theory, according to the empirical Colebrook formula and experimental data for pipes with periodic transversely located turbulators in round tubes for h/R0 =0.01÷0.13; t / D=0.25÷1.00; Re=104÷4.105

None.