eISSN: 2576-4500

Mini Review Volume 4 Issue 2

Cranfield University, UK

Correspondence: A Zare Shahneh, Cranfield University, UK

Received: April 08, 2020 | Published: May 29, 2020

Citation: Shahneh AZ. Improving aircraft cabin air quality by reducing Tri-Cresylic Phosphate. Aeron Aero Open Access J. 2020;4(2):57-60. DOI: 10.15406/aaoaj.2020.04.00107

Bleed air ECS extract air from engine compressor and is subject to increase the toxic chemicals in the cabin air. One of the most harmful of them is Tri-Cresylic Phosphate (TCP). It is a common anti-wear additive used in jet engine oils and exposure to this chemical increases the risks of various adverse health effects. Additionally, the European Aviation Safety Agency (EASA) which implements and monitors safety issues in aircrafts has yet to come up with an exposure limit for TCP’s. The effect of TCP and its filtration is analyzed and showed that by means of Carbon Active filters can be reduced.

Keywords: TCP, bleed air, filters, fresh air supply, fume event, aero-toxic syndrome

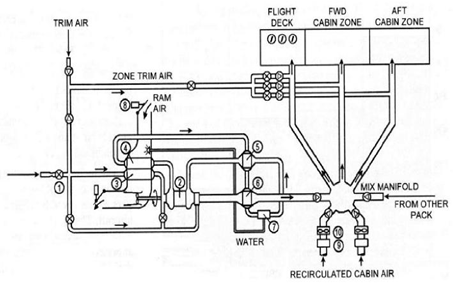

Current studies in cabin air quality have led to solutions to decrease the impact of air pollution in aircraft cabins. The air-cleaning system is partially capable to remove contaminants from the cabin air supply. As a result the contaminants within the cabin are of one of concerns in the Aerospace Industry.1 In recent years the cabin air has been the reason for several complaints made by aircraft frequent flyers primarily pilots and air crews having chronic health issues because of low-level exposure to toxic chemicals. The contaminants are currently of great concern and it needs to control volatile organic compounds, body odors, carbon dioxide and carbon monoxide to provide clean air is one of the functions of the Environmental Control System (ECS). The air that is fed into the cabin is generally a combination of air that is bled-off the jet engines and re-circulated air. This purification is generally carried out by various air filters. The filters and the air purification technologies used by aircraft have considerable reduced contaminants from the cabin air. HEPA filter which is able to remove up to 99.97% of airborne particles with 0.3micrometers in diameter is used. The pressure drops in this filter depends to the thickness but are generally marked as 300 Pascal. However, this type of filter is unable to filter out volatile organic compounds. Figure 1 illustrates the various components of an aircraft air-conditioning system where 1) flow control valve, 2) air cycle machine, 3) primary heat exchanger, 4) secondary heat exchanger, 5) re-heater, 6) condenser, 7) water collector, 8) ram air, 9) re-circulating filter, 10) re-circulating fan.

Figure 1 Typical aircraft air-conditioning system.2

TriCresyl Phosphate, a toxic source of contamination (TCP)

Pilot, cabin crew and passengers have reported their concerns regarding various chemical contaminants which have made them ill. The aviation workers have reported symptoms such as nausea, tunnel vision, fainting, memory loss, fatigue etc.3 Jet engine oil contains an organophosphate known as Tri-Cresylic Phosphate, a neurotoxin capable of damaging the central and peripheral nervous system where still is using in jet engine and lubricating oils for its load bearing and anti-wear properties.4,5 TCP is an organophosphate compound. It is basically an ester of cresol and phosphoric acid. It has three isomers as shown in Figure 2. It can have ten isomers of TCP using combination of different types. A couple of examples of TCP are shown in Figure 3 below.

This organophosphate compound is a renowned neurotoxin. It can cause acute toxic effects because of the presence of acetyl and butryl-cholinesterases. As TCP is an organophosphate it can cause effect such as delayed neuropathy which would not shoe until couple of weeks of the exposure. It can result in health effects such as abdominal pain, nausea, diarrhea and fatigue. Because of its severe side effects and neurotoxicity TCP are not included on commercial products on purpose. Therefore, in this thesis ways to monitor and filter out TCP’s from cabin air is studied. Despite its severe drawbacks it is heavily used in industrial applications such as flame retardants and fluid additives. TCP has been added to jet oils at 3% over the last three decades because of its advantages. Although some of it can decompose during its use the ones that are left can get into the cabin air due to oil leakage in the engines. Recently there had been plenty of public reactions regarding this issue in which aircraft crew and passengers have been exposed to this TCP chemical as the bleed air system extracts air from the compressor stages of the aircraft.

Aero-toxic syndrome

Aero-toxic symptoms is a medical condition allegedly caused by exposure to contaminated bleed air resulted in either acute short term or chronic long term illnesses.6 The Table 1 shows a list of such health issues. However, the symptoms the different aircraft personnel suffered from varied from one person to another and as a result the medical doctors are still unable to consider this as scientifically proven. Toxic fumes that enter the cabin from the aircraft engines–compromises the health of aircraft crew and passengers contaminated air affects up to 200,000 people every year. Symptoms includes: balance issues, nausea, tremors, breathing problems, fatigue, memory loss, neurological illness, brain damage, severe headaches.7

|

Respiratory |

Neurological |

Systemic |

Psychiatric |

Dermal |

|

Cough |

Headache |

Nausea, vomiting |

Anxiety |

Rash |

|

Shortness of breath |

Slowed mental processing |

Fatigue |

Sleep disturbance |

|

|

Chest tightness |

Difficult multi-asking |

Muscle weakness |

Depression |

|

|

Wheezing |

Memory impairment |

palpitations |

PSD |

|

|

Concentration difficult |

Diarrhea |

|||

|

Visual changes |

||||

|

Tremor |

||||

|

Gait problems |

||||

|

Paraesthesais |

||||

|

|

Balance problems |

|

|

|

Table 1 Chronic symptoms because of exposure to contaminated bleed-air

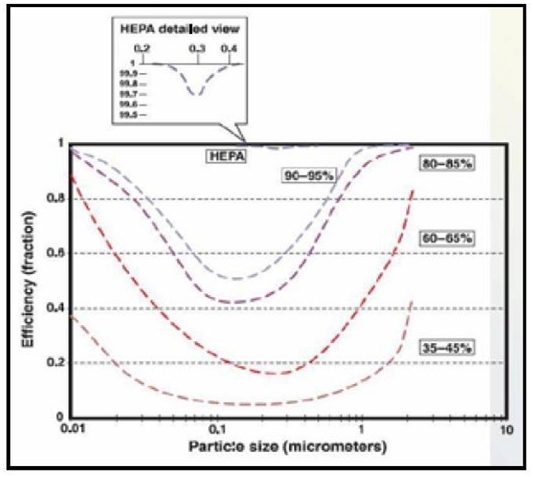

Aircraft filters

Aircraft currently use recirculation filters to remove particles in the air. Aircraft also use filter to reduce bio-effluent levels, volatile organic compounds and other toxic chemical substances that are present in aircraft cabin. In such case High efficiency particulate air (HEPA) filters are currently used to provide a healthy environment inside the cabin. HEPA filters were first invented in the early 1940’s to stop the diffusion of airborne radioactive contaminants.8 HEPA filtration technology is used to control particle contaminants inside the aircraft cabin and provide a healthy breathing environment for the passengers and the crew. First in this chapter the mechanisms of this filter would be studied to see if it is sufficient to provide clean air inside the cabin. According to U.S environmental sciences and technology HEPA filters are designed to provide a very high right of efficiency of about 99.97 % for particles as small as 0.3 microns in size. However, they are also capable of filtering out particles that are even smaller than 0.3 microns.9 On the other hand, the European Standard, EN 1822 Part 1 gives a range for the efficiency which is between 99.95% and 99.97%. It provides details such the labelling, specification and performance testing for air filters. Besides HEPA filters it also details for Efficiency Particulate Air filters and Ultra Low Penetration Air Filters.

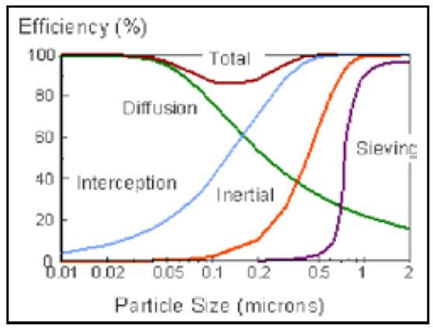

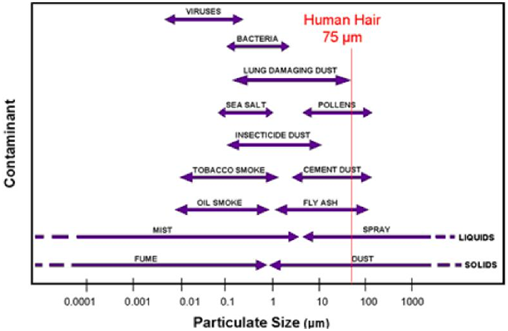

The performance of HEPA filter is described by pressure drop, permeability, lifetime resistance against environment and efficiency. Measurement of HEPA filter efficiency is mainly based on the size of the particles. HEPA filters provide an efficiency of at least 99.97% as shown in Figure 4. Figure 5 shows HEPA filter efficiency where Figure 6 shows the particle size range.

Figure 4 Filter efficiency in different methods against particle size (microns).10

Figure 5 HEPA filter efficiency against particle size.10

Figure 6 Particle size chart.10

Charcoal filter for removing TCP

It can be summarized that although HEPA filters are excellent in removing airborne particles. However, they cannot remove volatile organic compounds such a TCP from the cabin air. Therefore, activated carbon absorbent charcoal filters have been chosen as the best option that should be used in aircrafts which uses bleed air technology. This type of activated carbon filters has high efficiency to absorb gaseous contaminants to a high temperature of about 80°C and it also does not consume electrical power from the aircraft. One disadvantage of such a system is that the filters need to replace periodically during maintenance as it gets ineffective with deposit of contaminants. This activated carbon filters can be placed in three places as discussed and shown in the Figure 6. First option would be to place the filters downstream of engines but the temperature here is quite high for activated charcoal filters that are currently available. Second option would be place them between the cooling packs and the mixed manifold. This is by far the best option as the temperature here is under control and suitable for carbon filters as well as all ‘bleed air’ would also be filtered in the process. Finally, the filter can also be placed after it has passed through the mixed manifold and can also be considered an option.

Activated carbon filter are currently developed by Pall Aerospace which are very light weight. They are very effective in absorbing volatile organic compounds which include TCP’s. They have shown a removal efficiency of about 73% for TCP’s in the gaseous phase. They have an initial removal efficiency of greater than 80% as declared by Toluene which states the standard of absorption in this field. The design specification and the airflow rates to design such activated carbon filters should be similar to the Boeing 737HEPA filters that are currently used. The specification of activated filter is shown in Table 2.

|

Design requirement |

HEPA cabin air recirculation filer features |

|

Boeing part number |

S161N300-1 |

|

Purolator part number |

1762992 |

|

FAA-PMA |

Yes |

|

Aircraft applicability |

B737-300/400/500/600/700/800/900; B757-200/300 |

|

Efficiency |

99.97% on 0.3 micron particles |

|

Rated airflow |

1000 CFM (B737, B757-200); 1200 CFM (B757-300); |

|

Recommended service internal |

C-Check (min 6000 flights hrs. @1200 CFM) |

|

Skydrol® tested |

Yes |

Table 2 Specification of HEPA carbon active filter (European source)

The quality of cabin air is one of the most important design criteria during aircraft design as it can have both short and long term adverse health effects for the crews and passengers. There are various sources for cabin air contamination which include de-icing fluids, exhaust fumes and paints amongst many others. However, the sources which seem to have the most detrimental health effects are the jet engine oils, lubricants and hydraulic fluids used in the engines. These sources emit various chemicals and of which TCP is one which has resulted in chronic health conditions particularly for aircraft crew members. At present, there it is still a worldwide debate going on whether actually TCP contaminants the cabin air. However, based on the reports published and the health effects such as nausea, skin irritation, fatigues it can be concluded that TCP is the prime factor as these symptoms are quite similar to the ones caused by TCP. The TCP which emits toxic fumes when heated to decomposition can cause severe neurological effects on the brain and the nervous system. However, till date it is still continued to be used because reasons such as:

To tackle this issue research work carried on contaminates in the aircraft cabin makes us aware that the cabin air is not safe as some agencies, organizations, medical doctors and manufacturers claims. Firstly an online monitoring method has been chosen to measure and detect TCP and secondly studies have been undertaken in terms of future filter technology. HEPA filter is the method that is currently used to filter airborne particles in the cabin. However, it only filters re-circulated air and is unable to filter organophosphates such as TCP. Hence, activated carbon absorbent filters have been chosen as a replacement to provide purified air inside the cabin.

Some of the recommendations to monitor and overcome this ongoing issue are listed below:

None.

Author declares that there is no conflict of interest.

©2020 Shahneh. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.