Open Access Journal of

eISSN: 2575-9086

Research Article Volume 6 Issue 1

Laboratories, Indoor Environmental Consulting and Labs (IECL), Australia

Correspondence: Dr. Alexander D Wilkie, Laboratories, Indoor Environmental Consulting and Labs IECL, 5/158 Murarrie Road, Murarrie, Queensland, Australia, Tel (61)499889319

Received: October 01, 2023 | Published: October 17, 2023

Citation: Wilkie AD, Venz L, Letters S, et al. Pin-less moisture meter comparison to pin-type moisture meters in gypsum board and the effect of backing materials on pin-less readings. Open Access J Sci. 2023;6(1):110-115. DOI: 10.15406/oajs.2023.06.00201

Moisture meters are invaluable tools used in the building inspection industry. Little comparative data is available for pin-type (resistance) verse pin-less (capacitance) moisture meters. There is also a lack of data for pin-less moisture meters in regard to the effect of backing materials on the readings obtained. We present data comparing four common moisture meters used in building inspections and investigate the effect of backing materials on readings in gypsum board. Moisture readings taken by the Trotec and CEM meters correlated well with moisture readings taken with resistance measurements and comparison to gravimetric moisture content. The moisture meters varied in their responses to backing materials with the Trotec showing the smallest effects and the CEM showing the largest. Different moisture meters may be useful in different applications, and inspectors must carefully consider results from pin-less readings to obtain relevant data of moisture investigations.

Keywords: building inspection, resistance moisture meter, capacitive moisture meter, gypsum board, drywall, plasterboard, moisture measurement, moisture meter comparison

GMC, gravimetric moisture content, WME, wood moisture equivalent, ERH, equilibrium relative humidity

A key component of building inspection is moisture testing.1–3 Moisture testing is an extremely valuable tool in identifying leaks and moisture issues in structures in order to prevent damage to the structure or potential hazards to occupants such as mould growth. Indeed, identification and remediation of moisture issues is widely regarded as the primary factor in successful remediation of mould issues in buildings.3,4 The presence of moisture is associated with increased risk of respiratory symptoms.5 Gypsum board (also known as plasterboard and drywall) is the material primarily being tested in this study as it constitutes the bulk of building materials subjected to moisture investigations in the course of building inspections.

Moisture testing is conducted through use of moisture meters, which are available in several types – in the context of building inspections primarily pin and pin-less types.6 Pin-type meters operate through measuring the conductivity of the material – based on the principle that water is a better conductor than building materials (e.g., pine or gypsum board). Pin-less-type moisture meters use capacitance (or dielectric constant) to measure the moisture content of the material based on the assumption that the tested materials dielectric constant remains static and low as compared to that of water which is comparatively high – therefore changes in the measured value in the tested materials correspond to changes in moisture content7 (Table 1). It should be noted that other methodologies for measuring moisture content exist, but are less suitable for on-site measurements.8

Material |

Dielectric constant |

Air (dry) |

1.00059 k |

Water |

80 k |

Wood (dry) |

1.4-4 k |

Gypsum (dry) |

2.99 k |

Metal |

Infinite (does not suppress an electric field) |

Table 1 Dielectric constants of common building materials

Pin-type moisture meters have the advantage of being able to provide a comparable value based on the electrical resistance of the material, and is often used in building inspection with set values of what is typically considered dry. It should be noted that it is better practice to obtain dry readings from similar materials during inspections to use as comparison. Moisture readings are commonly converted to WME (wood moisture equivalent) allowing determination of moisture content of multiple materials. However, despite their proven usefulness they have a major flaw – their use damages the material tested as two probe pins must be inserted into the substrate.

Pin-less-type moisture meters address this flaw as they do not damage the material tested. However, the results they obtain are not as comparable as with pin-type meters – especially due to the instruments not using consistent scales. Multiple factors other than the moisture content can affect the reading such as the thickness of the material (adding to the volume of the material in the scanned area) any backing material (for the same reason), or the presence of metal in the tested area.

Measuring ERH (equilibrium relative humidity) of materials is probably the most suitable measurement of moisture to assess the material for its potential to support microbial growth.9 However, this measurement requires the material to equilibrate with a pocket of air on the surface of the material and as such take time in order to reach equilibrium.10 Because of this delay, the use of ERH in building inspections is limited and not very practical.11

Some research has been conducted in comparing pin to pin-less-type moisture meters,7,12,14 however there is little published on how backing materials affect the results from pin-less meters as compared to pin-type meters. This study aims to provide practical information for building inspectors to be able to better utilise pin-less type moisture meters in an effort to reduce the invasiveness of currently used moisture testing techniques. We also propose a small-scale strategy to sample material using linear sampling spaced 10cm apart which will reduce error caused by metal or backing material interference.

Moisture meters and measurements

Pin-type (resistance) moisture readings were collected using Delmhorst TotalCheck and Protimeter MMS2 moisture meters set to material types of Douglas Fir and WME% respectively. These settings were selected as the most comparable from the two instruments. Pin-less (capacitance) moisture readings were collected using Delmhorst TotalCheck (Scan mode) and Protimeter (Pin-less mode), Trotec T660, and CEM DT-128M moisture meters. The pin-less meters were selected as common moisture meters used by building inspectors with different styles of probe – contact plate for Delmhorst and Protimeter pin-less readings, and ball-type for Trotec and CEM.

Experiments were designed to include comparisons to gravimetric moisture content (GMC) where possible. While gravimetric readings are the most reliable,9,15 the tested material must reach equilibrium in order to obtain an accurate moisture content.7 Therefore, higher moisture contents than can be achieved through equilibration must involve direct wetting of material13 and due to uneven drying patterns moisture determination by weight is impractical.

Comparison of moisture meters in gypsum board

Two experiments were conducted. To provide comparative data across the entire range of moisture content multiple grouped data points from pin-type (Delmhorst TotalCheck and Protimeter MMS2) and pin-less (Delmhorst TotalCheck and Protimeter MMS2, Trotec T660, and CEM DT-128M) moisture meters were collected from gypsum board at multiple different moisture contents. The pin-type reading was taken using the same pin holes ensuring good contact of the pins to the substrate, and pin-less-type readings were taken across the exact point of the pin reading. 200 x 200 mm sections of 10 mm gypsum board were placed in separate containers with different amounts of water applied to cloth in the container in order to achieve different levels of relative humidity for the boards to equilibrate to over the course of 2 days. Moisture readings were then collected with the various meters, and the weight of each section recorded and compared to their dry weights to obtain GMC.

Effect of backing material

The effects of different backing materials on moisture readings in the face material were examined. To simulate multiple layered construction types of gypsum board as a backing material either dry (<15% WME) or wet (>30% WME) gypsum board was placed behind a piece of gypsum board at different moisture contents separated by a thin layer of plastic to prevent moisture transfer between the boards. To simulate structural pine as a backing material either dry (<10% WME) or wet (>20% WME) structural pine was placed behind a piece of gypsum board at different moisture contents separated by a thin layer of plastic to prevent moisture transfer to the board. To simulate steel framing as a backing material a section of u-channel steel frame was placed behind a piece of gypsum board at different moisture contents separated by a thin layer of plastic to prevent moisture transfer to the board and to be consistent with the aforementioned experimental setups. Sections of gypsum board were then tested with the various moisture meters according to the above setups to determine moisture content, and GMC was determined also.

Pin-less moisture meter penetration depth

In order to determine the maximum range at which the moisture meters can detect moisture each meter was set in a testing apparatus in which the meter could be slowly moved toward a metal plate (used to simulate a source of moisture), and the distance at which values begin to register on the instrument can be recorded. A metal plate was selected as a proxy for a moisture source due to the known large effect on conductance type measurements and the ease of constructing the apparatus.

Statistical analysis

Unpaired t tests were performed using GraphPad QuickCalcs online software (Graphpad Software Inc.) and Graphs and boxplots were generated using Microsoft Excel (Microsoft Inc.). Coefficients of determination (R²) were calculated using Microsoft Excel (Microsoft Inc.). Separate experiments were performed N number of times as listed in each figure and table.

Pin-less vs pin-type readings in gypsum board

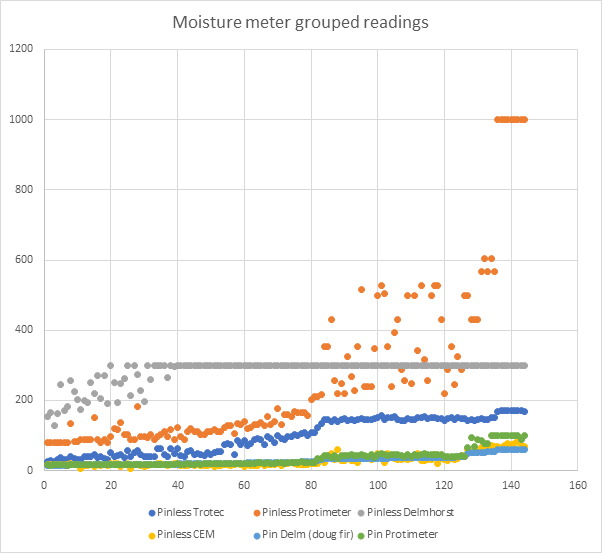

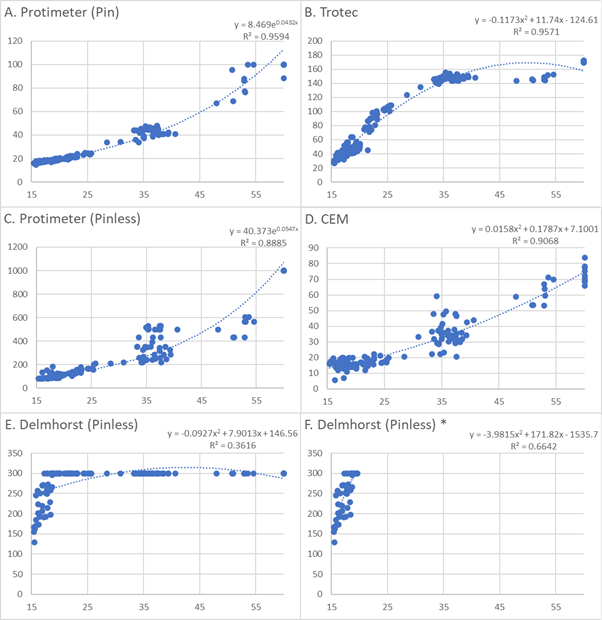

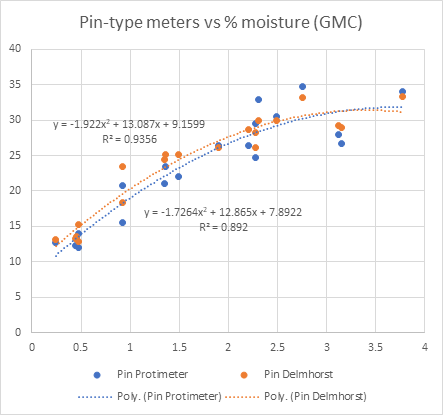

Grouped data readings from each meter were collected at different moisture contents. The results are shown in Figure 1a and 1b. Very good correlation was observed between both pin type meters (R²=0.96). Good correlation was also observed with the Trotec (R²=0.96) and CEM (R²=0.91) meters as compared to the Delmhorst pin readings. Reasonable correlation was observed between the Delmhorst pin meter and the Protimeter pin-less readings (R²=0.89) on the lower end of the scale – but became highly erratic in the upper end. Poor correlation was observed between the Delmhorst scan mode (R²=0.36) and the pin type readings – due to the meter reaching its maximum pin-less value at only approximately 20% WME. Figure 2 shows moisture meter readings as compared to gravimetric moisture content (GMC) of the gypsum board pieces. Correlation of the moisture meter readings to GMC in descending order were as follows: Delmhorst pin (R²=0.86), Protimeter pin (R²=0.83), Trotec pinless (R²=0.80), Protimeter pinless (R²=0.78), Delmhorst pinless (R²=0.68); CEM pinless (R²=0.47).

Figure 1a Grouped data points from each moisture meter. Dark Blue – Trotec T660, Orange – Protimeter MMS2 (pin-less), Gray – Delmhorst TotalCheck (pin-less), Yellow – CEM DT-128M, Light Blue – Delmhorst TotalCheck (pin), Green – Protimeter MMS2 (pin). Data was sorted in ascending order by Delmhorst pin readings. N=5.

Figure 1b Protimeter pin readings plotted against Delmhorst pin readings (x-axis)(A). Pin-less moisture meters plotted against Delmhorst pin readings (x-axis) (B, C, D, E). Delmhorst (Pin-less) * readings omitting values recorded for pin readings above 20% (F). Equations for trendlines and R² values are shown on graphs. N=5.

Figure 2 Moisture meter readings as compared to % moisture (GMC) of plasterboard. Dark Blue – Trotec T660, Orange – Protimeter MMS2 (pin-less), Gray – Delmhorst TotalCheck (pin-less), Yellow – CEM DT-128M, Light Blue – Delmhorst TotalCheck (pin), Green – Protimeter MMS2 (pin). Equations for trendlines and R² values are shown on the graph. N=11.

Effect of backing material

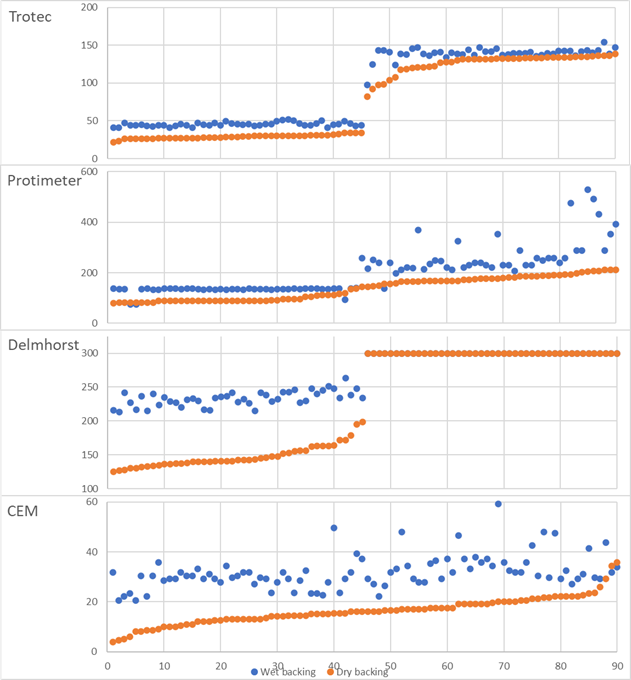

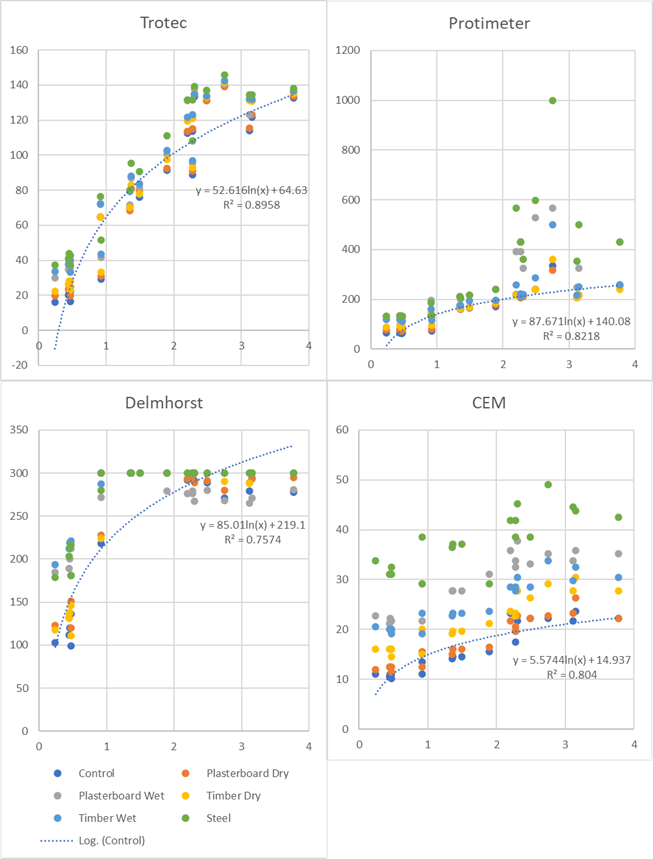

The addition of either wet or dry gypsum board backing material during pin-less moisture readings consistently showed higher readings grouped readings for each of the meters tested (Figures 3,4a). Wet gypsum board backing material had a greater effect on the difference. Pin-type readings taken during this experiment correlate well with GMC (Figure 4b). Dry structural pine as a backing material also consistently increased the moisture readings of each of the meters, and wet structural pine also exerted a greater effect. Steel channel frame had a pronounced effect producing far higher readings in all of the meters tested as compared to the control (Figure 4b).

Figure 3 Paired data for dry plasterboard backing (orange) as compared to wet plasterboard backing (blue) at different moisture contents of the face plasterboard for each of the pin-less moisture meters. Data was sorted by the dry backing readings. N=5.

Figure 4a Grouped data from each pin-less moisture meter for differing backing materials as compared to % moisture (GMC) (x-axis). Trendlines for the controls, equations and R² values are shown on each graph. N=10.

Figure 4b Grouped data from both pin-type moisture meters from the differing backing materials experiment as compared to % moisture (GMC) (x-axis). Trendlines for the controls, equations and R² values are shown on each graph. N=10.

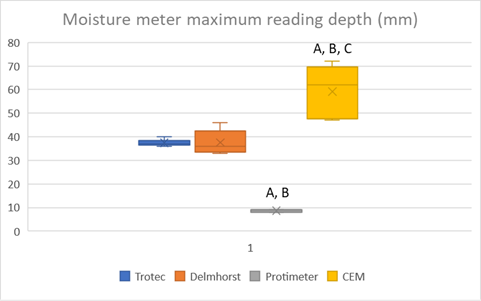

Pin-less moisture meter depth of measurement

To assess the depth at which the meters begin to detect the presence of moisture each of the pin-less moisture meters were tested. The moisture sensor on each meter was slowly moved closer to a metal plate (known to cause a strong signal for this type of measurement principle) and stopped when the meter began to detect changes in the values. The distance from the meter to the metal plate was then measured. Figure 5 shows the results of the test.

Figure 5 Moisture meter maximum penetration depths. The maximum detection range of each meter was assessed by slowly advancing the meter toward a metal plate and recording the distance at which each meter starts displaying increasing values. N = 5. A- significance as compared to Trotec (P<0.005), B- significance as compared to Delmhorst (P<0.005), C- significance as compared to Protimeter (P<0.0001).

Pin-less meters appear useful in providing comparative data. As long as the construction setup (e.g., baseboard on top of gyprock sheeting fixed to a timber base plate) is consistent pin-less meters can isolate issues by collecting multiple data points – potentially even in backing materials. While pin-type meters do possess higher accuracy and repeatability – they are not without issues. Primarily, damage to the tested substrate remains an issue both to the person conducting testing, and the owner of the tested material.16 Additionally, hidden metal presents a limitation which can interfere with results such as pushing the pins through the material too far and hitting metal backing and some specialized gyprock may even be foil/metal backed. An issue that was noted during this experiment was that repeated use of pin-type moisture meters in the same testing holes can lead to variability in readings. Repeated use of the same testing point pin holes tends to enlarge the holes thus causing poor contact to be made by the pins and the substrate. This can be mitigated with careful use of the probe – ensuring that both pins are making good contact with the substrate. Alternatively – testing approximately the same location by creating new pin holes can be performed – but is not optimal as slightly different points are being tested which may compromise comparability and causing further damage to the material. Conversely – pin-less meters can test the same location multiple times without causing damage, and the exact same sampling location can be used. Care must be taken to ensure the same location is being sampled – especially with the meters taking readings from an unknown point on the back of the instrument (e.g., Delmhorst and Protimeter). Other considerations for pin-less meter readings must be adhered to such as angling of the ball-type sensors perpendicular to the surface, applying consistent pressure and ensuring the instruments have completed their calibration cycles prior to sampling.

Our data indicated very good correlation between both the Delmhorst and Protimeter pin type readings (Figure 1b R²=0.96). These findings are in agreement with others findings on resistance type meters.11,13,15,17 The WME scale on the Protimeter and the Douglas Fir scale on the Delmhorst were selected as the most appropriate comparative readings between the two meters for use on gypsum board. While the Delmhorst meter had a drywall setting for the pin type readings the Protimeter did not - therefore the Delmhorst meter was set to the default of Douglas Fir and the Protimeter to WME% as the two most relatable options. Readings taken from the pin-less Trotec meter showed good correlation with both pin type readings as can be seen by the relationality in the comparison graph (Figure 1b, R²=0.96). Without accounting for other on-site factors (such as metal fasteners in the wall assembly, or the wall stud locations) readings taken from the Trotec meter should be able to distinguish moisture issues.

The CEM meter likewise should be able to distinguish moisture issues. The data as compared to the pin-type readings did not have quite as high a correlation (Figure 1b, R²=0.91) as the Trotec meter. It should be noted that the CEM meter required frequent re-calibration as the results would drift over time as could be observed by the meter no longer reading 0 when away from testing materials. Furthermore, the scale used by the meter may not provide enough spread to determine different moisture content of gypsum board reliably. However, this meter may present more useful data on backing materials as its scan penetration depth was greater than the other meters (Figure 5). Indeed, data collected from the different backing materials showed a consistent spread of data points for the materials tested and may have useful applications in investigations of backing materials and wall assemblies (Figure 4a).

The Protimeter pin-less readings also correlated well with both pin-type meters on the lower end of the scale (Figure 1b, R²=0.89). However, when the moisture content is above 60 on the instrument scale the instrument switches to ‘relative’ readings – which were wildly variable. This finding highlight that this instrument is more useful in a certain range of moisture contents. The Delmhorst scan mode correlated adequately with the pin type readings below 18% WME – but above this value all readings showed the max value for the meter of 300 (Figures 1a and 1b). Due to this factor the correlation was low (Figure 1b, R²=0.36). However, operating in its usable range (<20%WME) the correlation was much improved (Figure 1b, R²=0.66). This meter may still be useful in different contexts as more of a moisture sensor rather than a moisture meter.

Comparisons of the moisture meter readings to GMC (Figure 2) showed the highest correlation with both pin-type meters (Delmhorst R²=0.86, Protimeter R²=0.83), as would be expected from others findings.11,13,15 The Trotec pinless meter also showed good correlation with GMC with R² values of 0.80 and 0.78 respectively. The Delmhorst pinless readings showed reasonable correlation (R²=0.68) with GMC. The CEM meter trailed in correlation to GMC as compared to the other meters with an R² of 0.47. Data from the pin-less moisture meters varied considerably between meters. This finding is consistent with other studies on pin-less moisture meters.7,11 Depending on the context, each meter used in this study may have useful applications. The Trotec and CEM meters produced a reasonable similarity to the pin type readings; and the Delmhorst and Protimeter meters also showed applicability to the pin type readings when operated in the correct range of moisture contents.

The addition of backing material consistently increased the values of pin-less moisture meter readings. Figure 3 shows a good visual representation of how changing the backing material from dry gypsum board to wet gypsum board affects readings in the face gypsum board. Figure 4a shows grouped readings from different backing material setups as compared to GMC. Steel framing had the most marked effect – as would be expected based on the principle of operation of the meters and the dielectric constant of metal being infinite (Table 1). In both gypsum board backing or structural pine backing wet material exerted a larger effect as compared to their dry counterparts, as would be expected. However, these observations do not necessarily negate the usefulness of pin-less sampling – they do require careful thought in how they are used.

Our data indicate that both the Trotec and CEM meters showed good correlation with pin type readings (Figure 1b) and the Trotec meter tracked gravimetric moisture content well across the entire range of measured values (4a). The Protimeter pin-less readings also followed the GMC readings – especially on the lower end of moisture contents. The Delmhorst meter did not follow the GMC readings as closely – largely due to the readings reaching their maximum at relatively low moisture contents. Of the two meters that followed the GMC values most consistently, the Trotec showed less variation in measured values due to interference by backing materials. Of the meters tested this makes the Trotec meter the most appropriate for measuring the moisture content of face gypsum board while minimising interference of other wall assembly components. While the CEM meter lagged behind the others in comparison to GMC values, it generated consistent jumps in readings depending on the backing material. This may make the CEM meter useful in providing insight to wall assemblies and hidden moisture behind the face gypsum boards.

We recommend a better sampling strategy using pin-less meters – the goal of which is to minimise the interference of backing material in the readings taken. For each reading 3 measurements should be taken in a horizontal line with each point spaced consistently apart (e.g., 10cm). Any backing material – regardless of moisture content will increase the recorded values – as was observed in our data. Therefore, the lowest of the three measurements is the most likely to not be influenced by backing material and should therefore be used. This methodology should avoid bias to the pin-less moisture reading from wet or dry timber framing, metal framing, or metal fasteners. Multi-layered gypsum board construction should provide fairly even results as the setup is similar throughout the depth of measurement of the pin-less instruments. This methodology should mitigate the effect of moisture reading mistakenly being higher due to vertical framing, and metal fasteners. It should also be applicable to floor and ceiling readings provided the surfaces are level. However, a problem is presented in attempting to determine backing material running horizontally. For example – if sampling the base of a wall the base plate of the frame may interfere with measurements. With this principle in mind, it is inappropriate to apply this method using a vertical line as this may miss moisture issues as water will settle horizontally. Additionally – It may potentially miss a vertical column of wet material – which may be misinterpreted as vertical framing. Careful measurements of the width of the vertical column may help differentiate between framing material and moisture – especially if the width varies. Combining this methodology with a mindful inspector should be able to isolate moisture issues while causing as minimal damage to the material as possible.

Lastly, it is worth highlighting some rarer interfering factors to moisture testing. Salts have the potential to disrupt not only pin-less readings – but can also affect pin-type readings. Salts alter the conductivity of the material and can also affect the dielectric constant.18 Similarly, some wall coverings can affect readings. The niche product EMF (electro-magnetic field) blocking paint is becoming more popular and due to its conductive nature will affect both pin and pin-less readings. Lead based paint may also affect the results – due to the conductivity of lead. It is therefore important to consider the electrical properties of the material.9 In a non-conductive covering the thickness of the coating (e.g. wall paper or even different numbers or thicknesses of coats of paint) may alter the readings.11 It is therefore important for inspectors to be consistent with how they sample – comparing like to like. As an example, a wet area such as a bathroom will likely have different backing material to a bedroom, and meters will differ in the measurements between these two types of material. The final consideration we will mention here is the depth of penetration of the different pin-less meters. Many of the pin-less moisture meters do not list the penetration depth of the signal with any specificity (e.g., 20-40 mm listed in the manual for the CEM meter). Testing of the 4 meters indicated the maximum distance at which each meter could detect a steel plate varied from averages of 9 mm (Protimeter) to 59 mm (CEM) (Figure 5). From this data, objects inside wall cavities or indeed on the opposing side of the cavity could potentially affect results. Even holding the Trotec or the CEM meters by the far end from the sensor caused the meters to show readings higher than the calibrated 0 values highlighting that calibration of the instruments must be performed with caution to avoid the user influencing the results. Following calibration, it is important to hold the meter in the same way to avoid influencing the results. As a final note to building inspectors, sampling using pin-less meters in both outside and inside corners will affect results as in both cases more material is in contact with the instruments sensors range.

We have presented data useful to inspectors on how several common moisture meters compare in testing moisture of gypsum board. Pin-less moisture meters can provide useful data in a non-invasive manner, but must be used by thoughtful operators to obtain reliable data. Sampling in a horizontal line in triplicate for the lowest reading should provide a more reasonable indication of moisture in the tested surface while minimising potential bias. Comparative data from similar building assemblies using pin-less moisture meters are a useful tool for inspectors to isolate moisture without damaging materials.

Future directions

Testing of non-invasive moisture meters in different materials – such as structural timber and concrete should be conducted to provide valuable information to inspectors on interactions of these meters in real world application. Moisture determination of concrete slabs remains a difficult, invasive and time-consuming process using the currently accepted relative humidity in-situ probe methodology. Use of pin-less moisture meters for assessment of moisture content of concrete slabs may help obtain timely results for inspectors without relying on relative humidity in-situ probes which take at least 24 hours to equilibrate and also damage the substrate, and provides an interesting opportunity for research useful to building inspection.

The authors would like to thank IECL and NLR Restorations for funding this research.

None reported.

©2023 Wilkie, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.