Open Access Journal of

eISSN: 2575-9086

Research Article Volume 5 Issue 1

1Instituto Nacional de Investigaciones Forestales, Agrícolas y Pecuarias. Cotaxtla, Field Experimental Station, Veracruz– Córdoba free highway, known address, Z.C. 94270, Municipality of Medellín de Bravo, Veracruz, México

2Universidad Autónoma Agraria Antonio Narro, Antonio Narro Avenue 1923, Z.C. 25315, Buenavista, Saltillo Coahuila, México

Correspondence: Marco Antonio Reynolds Chávez, Instituto Nacional de Investigaciones Forestales, Agrícolas y Pecuarias. Cotaxtla, Field Experimental Station. Veracruz–Córdoba free highway, known address, Z.C. 94270. Municipality of Medellín de Bravo. Veracruz, México, Tel 01+52 (5538718700)

Received: September 15, 2022 | Published: September 28, 2022

Citation: Reynolds CMA, Burela CA, López LJA, et al. Multipurpose technology for simultaneous preparation of primary and secondary tillage of the soil (first phase: prototype design). Open Access J Sci. 2022;5(1):71-75. DOI: 10.15406/oajs.2022.05.00178

During the last decade in Mexico, the profitability of basic grain crops has decreased considerably due to low productivity caused by unfavorable soil and climatic conditions, which are aggravated by climate change. In addition, the variability of the international economic environment and the rise in fertilizer and fuel prices are factors that seriously affect the production of these food products. In this context, it is important to generate new practices and technological innovations that contribute to reducing these factors. There is an enormous technological lag in soil preparation. At present, the disk plow is still by far the most widely used implement for primary soil preparation in food production, causing high rates of soil loss due to erosion, hard layers, minimal use of moisture and, consequently, low productivity. On the other hand, it requires high power requirements, excessive operation times and high fuel consumption. The purpose of this research was to design a multipurpose prototype for the simultaneous preparation of primary and secondary tillage of the soil for crop establishment, with the objective of reducing operation times and fuel consumption, but without detracting from the quality of the labor soil and increasing yields. The results show the design of a Multipurpose prototype, as a mechanical equipment integrated by three sections (chisel plow + harrow + lump breaker), which are combined for the simultaneous preparation of primary and secondary tillage of the soil. This technology consists of a single step of soil conditioning (minimum tillage) for crop production, specifically basic grains.

Keywords: multipurpose equipment, soil preparation, combined tillage

During the last decade in Mexico, the sowing area has decreased considerably due to low productivity caused by unfavorable edaphic and climatic conditions, that are even more accentuated with climate change; this situation has caused substantial ecological and economic losses and a national deficit in the production of basic grains (corn, beans, rice, soybeans and sorghum) which has aggravated the economic and social situation of agricultural producers.1

Soil resource conservation is a topic, that has gained much interest in recent years due to the growing demand for food for the agricultural sector; according to the Food and Agriculture Organization of the United Nations, demand in this sector will have to increase 50% by 2050 and more than 80% of the increase in production; for that year will come from land that is currently cultivated with certain levels of restrictions.2 Currently in Mexico, 93 million hectares, equivalent to 47% of the national soil, present some type of degradation caused mainly by agricultural and livestock activities and deforestation.3 Despite the importance of soil conservation and the environmental services it offers, there is a clear lack of technologies aimed at conserving the physical, chemical and biological fertility of the soil, which present a holistic approach that minimizes soil degradation and favors the rapid adoption of sustainable conservation practices.4 It should be noted that the current trend of the various production systems is oriented to extensive and intensive use of the soil resource, which has increased its physical, chemical and biological degradation, to the detriment of its productivity. Faced with this problem, it is important to generate new crop management practices that, in addition to being efficient, can be quickly adopted by producers, since the limited application of innovations for soil agricultural practices translates into high production costs, limits the yield and quality of harvests and reduces the possibilities of making an agro-system sustainable. For the specific case of the technological component of "soil preparation”, it is important to note that many of the implements and equipment were designed for conditions in other countries.5,6 It should also be considered that in Mexico 74% of the national agricultural production is cultivated in rainfed crops, so it is undoubtedly exposed to climate change and factors that threaten production, highlighting the affectation of productivity and water, soil and energy resources (information published in.7

For the establishment of a crop, it is traditionally required to prepare the root bed and the seedbed, activities commonly known as primary and secondary tillage. These operations are performed separately and sometimes, depending on the type of management, equipment availability and soil conditions, each operation is performed one or more times, generating high costs (fuel consumption, excessive operation and transfer times) and low labor quality, which results in low profitability and a smaller planting area. On the other hand, an operator or tractor driver, without diagnosis or technical support, generally consists of soil preparation, so the effect on soil structure is usually negative, making the sustainability and sustainability of agricultural production more vulnerable.

Globally, in the intensive production of basic grains, soil preparation is the agricultural practice that represents the highest unit costs in food production and the one that consumes the greatest quantity/dimensions of energy in the form of "fossil fuel" in the world.8,9 Between the years 2010 and 2017, due to the increasing cost of fuels almost 100% of agricultural projects have reduced their profitability. On the other hand, there is no technological response or innovations that substitute or optimize the cost in soil tillage management. Another factor is the degree of mechanization of the Mexican countryside; an analysis of the national scenario carried out10 leads to the conclusion that: based on an agricultural frontier of 24 million hectares, with a mechanizable area of 18.6 million hectares, 360,000 tractors of 50 to 80 horsepower would be required. If the assumptions of the scenario were valid, the current fleet would have 217,300 active tractors, which represents 60% of the mechanization needs. This means that the modernization of the Mexican countryside is going slowly and/or in reverse given the deficit of tractors specifically and adding the lack of technological development and innovations for agricultural activities in crop establishment. Of the 238,830 tractors in Mexico, 54% exceeded their useful life, given that maintenance and operation is costly, according to the National Agricultural Survey.11

This means that only machinery with low power capacity is available for agricultural operations of soil preparation and cultural work, limited to small equipment. The purpose of this research, is to design a tillage technology for integrated soil preparation through a multipurpose prototype, capable of simultaneously performing three operations in one, (plowing, harrowing and lump breaker), with the use of tractors with 80 horsepower (predominant in Mexico) and optimizing fuel consumption and effective operation time by up to 50%, improving the quality of soil tillage and crop productivity compared to conventional systems currently used.

Location of the development site

The present research work was carried out in the year 2021-2022 at the Engineering and Agricultural Mechanization Unit of the Cotaxtla Experimental Station, belonging to the National Institute of Forestry, Agricultural and Livestock Research (INIFAP), which is located at the coordinates (18°56'20''N, 96°11'30.3''WO) of the Municipality of Medellin de Bravo, Veracruz, Mexico.

The development of this technology for soil preparation consisted of two phases:

First Phase: Conceptual design of the prototype

Second Phase: Construction and technical evaluation of the prototype

First Phase: Conceptual design of the prototype

A wide range of formal methods have been devised and used for the generation of conceptual design ideas;12 bring together in their paper the experimental evidence needed to support claims about the effectiveness of these methods in promoting idea generation in engineering design. Conceptual design is a technique with great application in the innovation, creation and improvement of machines, tools and products. In it, the problem statement was defined and the characteristics and specifications required for the design are clearly determined. A review of the state of the art is made and the scopes that condition the design are established in order to select a general solution, obtaining at the end a sketch or plan of the machine, prototype or product.

The general process to be followed in the conceptual design is summarized in the following seven stages, described by13 and translated by.14

Clarification of conceptual design objectives

In this stage, the set of objectives that the machine or prototype must satisfy are defined. These are presented below:

Functionality

Reliable operation

Maintain a high level of ease of operation, safety and no structural failures.

Adequate geometry

That the prototype has the appropriate and necessary dimensions for its correct operation.

Simple production

That the prototype is foreseen to have an easy maintenance and technical and economical accessibility in the components or parts that are subject to wear.

High performance level

Establishment of prototype functions

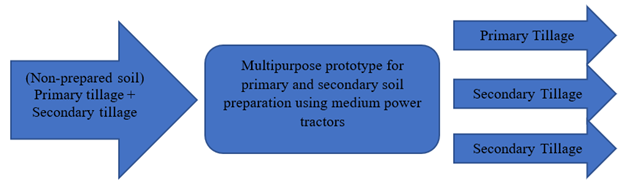

Based on the general objective of the project, the main functions that the prototype should perform was established. In Figure 1, a diagram showing the function of each of the three sections represents the general function of the design. For the development of this design proposal, the general function of the Multipurpose prototype was performed, integrated by three components and each component integrated by a tillage operation: 1) vertical primary tillage with the use of chisels for deep soil breaking: based on the parameters of vertical tillage,15–18a and the principles of the critical depth theory,19,18b secondary or shallow tillage with the use of discs for soil aggregate disturbance: based on the principle of operation of discs with medium concavity and arranged in two cross sections and using between discs a smaller differential in the advance angle, which has been reduced, instead of being wider, so as to reduce the parallelism to the cutting direction of the tool, which generates a better cut of the clod and consequently optimizes the result. The concavity of the discs, as well as their angular offset, allows the discs to move and break up the soil they cut. 3) The third operation is soil loosening or fluffing by coupling a heavy roller with helical tips to the rear part of the harrow to cause repeated impacts that, together with the adequate soil moisture and forward speed, achieve better performance and better leveling of the soil. This operation is complementary and would perform the function of the harrow crossing of the second operation, since the prototype is required to consist of the preparation in a single pass.

Figure 1 General function of the design (Technological Innovation for the simultaneous application of primary and secondary soil tillage).

Determination of requirements and their characteristics

During this process, the engineering parameters and physical characteristics of the elements and components were considered. These characteristics determine the product attributes, which, in turn, satisfy the design requirements. To consist of this task, the quality function deployment method was used, which essentially deals with converting the element requirements into engineering characteristics such as: weight, length, width, number of chisels, number of disks, working width, spacing between components, required power, structure materials, maximum allowable stresses and safety factor.

Determination of characteristics

For this process, it is necessary to specific consider the cost factor, function ability and useful life of the design. This activity is an asymmetry of these factors and depends on how it is being visualized, as it can be not so costly, costly and very costly; but it can equally be a combination of these three factors. The activities (5, 6 and 7) of the overall conceptual design process will be applied once the evaluation part has been completed and corresponds to the second phase of this research.

The overall process used in the conceptual design resulted in:

Clarification of objectives

Development of a multipurpose technology for the simultaneous preparation of primary and secondary soil tillage in basic crops and with the use of medium power tractors, which optimizes fuel consumption and effective operation time by up to 50% compared to conventional systems currently used.

Establishment of functions

Preparation of primary tillage (performed with chisel plow), preparation of secondary tillage (performed with harrow) and for the harrow cross pass, use a third component that consists of a mulching or clod disintegration (performed with a clod or lump breaker). Since this equipment is intended to consist of primary and secondary soil preparation in a single step.

Setting requirements

Minimum power supply power limit= 80 Hp

Maximum prototype length limit = 2.25 m (8 ft)

Maximum working width= 1.20 m

Three-section design (plow+harrow+lump breaker)

Chisel plow (3 chisels)

Disc harrow (12 discs)

Towed lump breaker with spikes in helical form with the advance of traction or power source.

Determination of design features

Compact prototype, with good workability, ease of operation (evaluation by the tractor driver), ease of coupling and those other regulations and specifications established by the National Center for Standardization of Agricultural Machinery (CENEMA-INIFAP).

Ergonomics and design rigor are also considered in this process.

For this particular design, a strong and compact prototype is required as characteristics that was defined by the type of user or target population.

Development of objective clarification of the conceptual design

Functionality

First input of the prototype design

Primary soil preparation should consist of three-chisel plow.

Secondary soil preparation should consist of 12-disc harrow.

The use of the lump breaker complements the secondary tillage or what would become the second pass or cross harrowing.

The prototype should consist of primary and secondary soil preparation in a single pass.

The minimum power provision shall be limited to 80 Hp.

Reliable operation

The prototype must be restricted to mechanical devices that do not put the user at risk, avoid tips outside the chassis, cutting components and that facilitate its coupling or disassembly.

Adequate geometry

It should be considered that the prototype has the appropriate dimensions for its correct operation.

Second design input

Definition of the way of coupling to the tractor (category II hitch).

Definition of total length, width and height of the prototype (2.25x1.10x1.10 meters).

Definition of length, width and height for each of the three sections.

Definition of the technical characteristics of the structure (length, width and thickness).

Definition of the components and the number of components (three chisels, 12 discs and a lump breaker, cleaners).

Definition of the weight per component and section of the prototype (commercial standard).

Definition of the total weight of the prototype.

Simple production

The prototype is expected to have a practical design, easy to operate and maintain and with elements subject to minimum wear.

High performance level

To have a Technological Innovation

To obtain optimal costs for the prototype and effective operation time.

To raise the cost-benefit ratio.

Development of the establishment of functions

Development of objective establishment of the functions of conceptual design

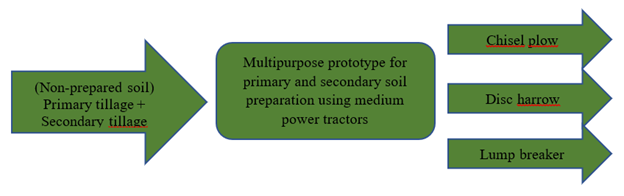

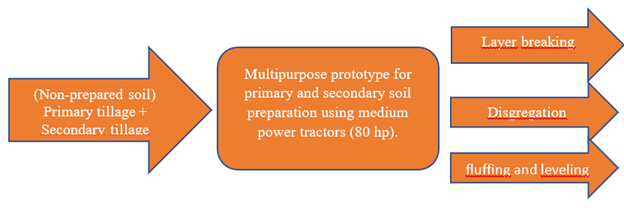

Based on the overall objective of the project, the main functions that the prototype was to consist of were established. In Figure 2 and 3, a diagram is represented in terms of input and output actions. We can observe how the functions of the prototype are being adjusted and the needs of the prototype are being described. In Figure 3, the function of each section is already described.

Figure 2 Overall design function (Mechanical components for primary and secondary soil tillage application).

Figure 3 General function of the design (Specific tillage operations of each sections of the prototype.

Development of the requirements setting and its characteristics.

Section One: Chisel Plowing

Guideline: Parameters of Vertical Primary Tillage

Function: breaking up hard soil layers

The shape of chisels was semi-straight.

Second section: disc harrow

Guideline: parameters of horizontal secondary tillage

Function: to break up the clod

Third section: spike-lump breaker

Guideline: vertical tillage parameters

Function: aggregates fluffing and leveling

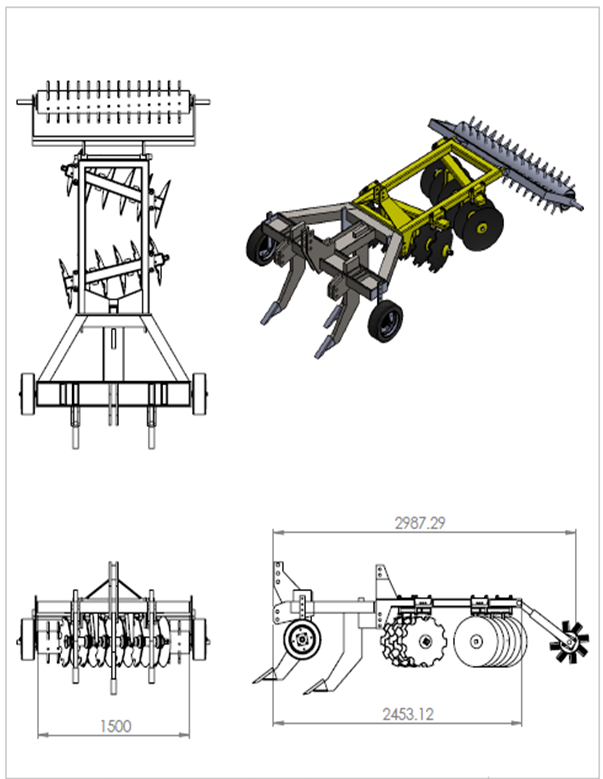

(0.46 m x 1.63 m frame with 0.22 m) diameter lump breaker, with a sectioning of 7 rows with spikes distributed every 0.10 meters, for a total of 14 spikes per row and 98 total spikes Figure 4, Table 1.

Figure 4 Shows a close-up of the conceptual design of the multipurpose prototype for the simultaneous preparation of primary and secondary soil tillage. Scale 1:1 meters.

Technical configuration |

Quantity/dimensions |

Components |

Sections |

Three |

Plow+harrow+lump breaker |

Prototype |

3.20 x 1.10 x 1.10 m |

Length, width and height |

Multi-purpose |

||

Plow |

Three |

Semi-straight chisels two front + one back with wings |

Limiting wheels |

two |

Depth adjustment |

Chassis |

Trapezoidal platform with double frame for front shallow chisels and rear deep chisels |

Double platform frame for coupling the shallow chisels at the front and deep chisels at the rear. |

Harrow |

12 |

discs |

Chassis |

1.4 x 0.70 x 1.1 meters in length, width and height |

Main frame for coupling the harrow discs. |

Spike lump breaker |

Seven-row sectioned lump breaker with spikes distributed every 0.10 m, for a total of 14 spikes per row and 98 total spikes |

Spike lump breaker |

Chassis |

0.46 x 1.63 m with 0.22 m diameter pipe |

Lump breaker frame |

Coupling |

One |

To tractor third point |

Coupling |

Two |

To the third point between sections |

Power required |

80 hp |

Power source |

Weight |

400 kg |

Peso total |

Table 1 The technical configuration of the multipurpose prototype is presented, as a result of the conceptual design in order to prepare the plans for the construction phase

A general and component plan of the design of the Multipurpose prototype, which includes three sections (chisel plow + harrow + weeder) for the simultaneous preparation of primary and secondary tillage of the soil, was elaborated. The purpose of this equipment is to consist of the integral preparation of the soil for crop establishment in a single step. The equipment is coupled with a category II hitch to the third point of the tractor and has the versatility of operating the three components integrally or by components individually. The purpose of this design is to reduce the effective operating time and fossil fuel consumption, as well as to improve the quality of soil tillage and consequently improve productivity. On the other hand, if this design is successfully built and evaluated, it can be a great technological contribution to improve food production in Mexico.

None.

The author declares there is no conflict of interest.

©2022 Reynolds, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.