MOJ

eISSN: 2573-2919

Mini Review Volume 5 Issue 1

Department of Environment, Independent Researcher, India

Correspondence: Dr Ashok Kumar Rathoure, Department of Environment, Independent Researcher India, Flat #107, Akshar Park-A, Near Dhara Complex, Behind Atopnagar Bhatar Road, Surat (Gujarat), India, Tel 9450501471

Received: October 08, 2019 | Published: January 20, 2020

Citation: Rathoure AK. Zero liquid discharge treatment systems: prerequisite to industries. MOJ Eco Environ Sci. 2020;5(1):1-10. DOI: 10.15406/mojes.2020.05.00170

Industrialization is necessary for country’s economic growth. Increase in industrial development has elevated water consumption and is resulting in depletion of water resources. On the other hand, water pollution is a major issue. People have long been trying to find cost effective and reliable ways to treat wastewater and recycle or reusing the treated water has become a necessity. Zero Liquid Discharge (ZLD) is an ideal situation of complete closed loop cycle, where discharge of any liquid effluent is eliminated; it is a remarkable effort of every industry who implements it to meet with the environmental regulation in a challenging way. However, it is facing some challenges for its implementation including its high costs and energy efficiency. Here in this review, we have presented various ZLD technologies which are feasible for different industrial sectors and some innovative technologies by which the precious water can be saved and recycled at source.

Keywords: zero liquid discharge, pharmaceuticals, textiles, fertilizers, ZLD technologies

ZLD, zero liquid discharge; MBR, membrane bio-reactor technology; ATFD, agitated thin film dryer; TDS, total dissolved solids; BOD, biochemical oxygen demand; CPCB, central pollution control board; MD, membrane distillation; SHFCC, solid hollow fiber cooling crystallization; ZLDD, zero liquid discharge desalination; MD-C, membrane distillation-crystallization; FD, freeze desalination

Booming megatrends in industrialisation and urbanization are creating higher stress on the environment, including the world’s freshwater resources. In many areas, globally and particularly in fast-developing and emerging economies like India, rapid growth in industries and manufacturing units are creating a threat to water quality and tremendous strain on water supplies. Concerns related to water availability risks are increased in regions prone to water scarcity.1

As these trends intensify, industries that use large amounts of water and generate high quantum of wastewater are under growing pressure to implement more sustainable water management strategies which uses less amount of water, minimise impacts to receiving waters and mitigate operational risks. This results in driving developments in technologies in the global water treatment market.1

ZLD systems are getting greater attention as useful wastewater treatment/water management solutions for complex industrial wastewaters. It is a water treatment process in which wastewater is treated, purified and further recycled. The ZLD process completely eliminates liquid discharge from industry thus reduces and eliminates possibility of pollution discharge concerns and regulatory disposal norms.2

An efficiently designed ZLD (Zero Liquid Discharge) System is used for minimising the quantum of wastewater requiring treatment and also to produce a stream of water suitable for reuse in processing plants.3 A general approach for ZLD is to increase concentrationof wastewater and further crystallize to a solid.

ZLD technology was initially developed for power plants, in USA and later implemented globally. During early seventies, high salinity of the River Colorado due to discharge from power plants, developed the need for imposing Zero Liquid Discharge. Regulators were primarily concerned with discharge from scrubbers and cooling tower blow downs in power plants.

First ZLD installed was of 114-454m3/hour units, based on evaporation/crystallization. Initially low-cost ponds were used for evaporation of Reverse Osmosis (RO) reject. In Germany, ZLD systems for coal-fired power plants were a result of strict regulations and laws in the 1980s.4

Annually, worldwide investment of around 200 million USD is represented by construction of zero liquid discharge plants. Currently, there are many concentrator/evaporator systems in numerous industries round the globe. It is spreading widely to water scarce regions and to highly sensitive and polluted environments.4

Countries like China and India, where water scarcity exists and recycle/reuse of industrial water is less (i.e. water recovery ratio is less), probably require to develop solutions for ZLD systems. The ZLD market is likely to see further increase in activity based on increased water scarcity and pressure from the regulators.

India

All textile units were required to install ZLD systems which were producing wastewater effluent greater than 25 kLD as issued in draft policy by the Government in 2015. As stated by Vishnu et al.,5 ZLD systems were already implemented by 29 dyeing industries in the Tirupur city of Tamil Nadu by 2008, where not only water was recovered but also salts were recovered which were directly used in dyeing processes. Conferring to a current technical report, the market for ZLD in India was approximated to around39 million USD in 2012 and was projected to continuously increase from 2012 to 2017 at a rate around 7%. In this market, the power, petrochemical, textile and brewing and distillery industries are the key application areas.6

Legislation related to ZLD in India as given by Saha7:

ZLD system

It is a system consisting of unit processes or unit operations or their combination, such that there is no discharge of liquid effluent from an industry, process plant, project etc. It indicates there is no liquid discharge since the effluent is effectively treated, recycled and reused. Zero liquid discharge is generally accomplished by concentrating the wastewater utilizing numerous technologies together with membrane-based and multi effect evaporation-based systems.8 ZLD comprises of:

Generally, the incentives behind implementation of ZLD vary depending on terrestrial location and application. United States, China, and India form majority of markets for ZLD with highest economy and largest populations to be served.

ZLD technologies

Main aim of ZLD is to recover useful products and salts from rejects, apart from recovery of maximum water for recycle. Major ZLD Technologies are as follows:

As per Gujarat Pollution Control Board, India (2016), ZLD technologies, their respective uses, advantages, disadvantages and application are given in Table 1.

ZLD Technology |

Use |

Advantages |

Disadvantages |

Application |

Membrane Bio Reactor (MBR) |

Used as biological secondary treatment for reduction of organic load. |

Secondary clarifier not required. |

Capital cost is more than other aerobic biological technologies (ASP, SBR, MBBR). |

Textile Industry |

Treated water quality is better than conventional ASP, MBBR and SBR. |

Membrane replacement after five years. |

CETPs |

||

Post treatment of sand filtration not required. |

Oil Refineries |

|||

Fertilizer Industry |

||||

Solvent recovery – Air Stripper |

Used for recovering solvents/ammonia recovery by providing air. |

Conventional proven method for removal of solvents. |

Applicable only when large quantity of solvent with low solubility in water is present in wastewater. |

Recovery of useful solvents, ammonia in pharmaceutical industry |

Economical when solvents with low solubility in water are present in wastewater. |

Difficult to capture solvent when in low concentration. |

Pesticide Industry |

||

Chemical Industry |

||||

Solvent Recovery – Steam Stripper |

Used for recovering solvents by using steam. |

Solvent recovery is more compared to air stripping. |

Not suitable for water miscible, high boiling solvents. |

Recovery of useful solvents, ammonia in pharmaceutical industry |

Solvents can be reused or are saleable. |

Useful even less quantity of solvent present in wastewater |

Scaling occurs in column which is to be cleaned periodically. |

Pesticide Industry |

|

Chemical Industry |

||||

Ultra Filtration (UF) |

Used for removal of colloidal matter and bacteria and viruses. |

Removes suspended, colloidal particles, bacteria, viruses. |

Does not filter dissolved solids, gases and organics. Frequent backwash, membrane cleaning. |

Pre-treatment to RO in all ZLD plants. |

Used as pre-treatment to RO. |

Best pre-treatment for RO. |

Replacement of membranes after 5 years required. |

||

Reverse Osmosis (RO) |

Used for removal of salinity (TDS) and residual organics by passing wastewater through semi-permeable membrane by applying high pressure. |

Most effective treatment for removal of salinity (TDS) with more than 99% salt rejection. |

Very high capital cost. |

Used in all industrial sectors for TDS removal and recycling the water. |

Clean technology and no handling of chemicals like acid/alkali like ion exchange technology. |

High energy consumption due to high pressure pumps. |

|||

Permeate water is free of ions and can be used in industrial processes. |

Membrane replacement required after application of 3 years. |

|||

Cleaning of membrane frequently due to membrane fouling |

||||

Reject Water |

||||

Multiple Effect Evaporator (MEE) |

Used to evaporate wastewater to separate water and salt by using heat of steam in sequence of vessels. |

Proven method for recovery of water from saline water and separation of salt. |

Very high operating cost due to steam requirement. |

Pharmaceutical Industry, Textile Industry, Pesticide Industry, Dyes and Dye Intermediates, Steel Industry, Fertilizer Industry |

Mechanical Vacuum Compressor (MVR) |

Water vapour generated in the evaporator is compressed to higher pressure which acts as heat source for evaporation. |

Eliminates thermal energy requirement. |

Suitable only for liquid with narrow boiling point rise (BPR). |

Textile Industry |

Useful when steam not available. |

Suitable when ready steam is not available in the industry. |

|||

Low operating cost. |

||||

Crystallizer |

Used to dry high TDS water or products using heat. |

Used for recovery of salts like Sodium Sulphate, Sodium Chloride, Sodium Thiosulphate, Zinc Sulphate etc. |

Scaling and corrosion of unit is a problem. |

All industrial sectors. |

Simple Evaporation method of single effect evaporation. |

Requires frequent cleaning. |

|||

Agitated Thin Film Dryer (ATFD) |

Used to dry high TDS water or products using fast revolving rotor in a heating jacket. |

Good heat conductivity so can be applied for highly viscous fluids. |

Scaling and corrosion of unit is a problem. |

Application in salt recovery in Dye and Dye Intermediates |

Gentle evaporation and high evaporation rate. |

Textile Industry |

|||

Continuous cleaning of heating surface. |

Pharmaceutical Industry for final drying before disposal. |

|||

One passes Evaporation. |

||||

Incinerator |

Used for burning the concentrated effluent by thermal energy |

Useful method for very high strength (High COD) effluent which is difficult to biodegrade. No further treatment is required. |

Requires very high energy. |

Pharmaceutical Industry |

Operational cost is high. |

Dye and Dye Intermediates |

|||

Capital cost is high. |

Pesticide Industry |

|||

Viable for only small quantities of effluent. |

|

Table 1 ZLD technologies

Major factors

Major factors for adopting ZLD technologies by industries are as given below6:

Accurate analysis of generated effluent

For efficient working of ZLD system, it is necessary to obtain accurate analysis of effluents generated from industries. Some of the major parameters to be determined as per Ahirrao8 are given below:

Benefits

Challenges

There are several challenges being faced for development and implementation of ZLD. Some of these9 include:

Therefore, techno-economic contemplations are necessary for developing a zero liquid discharge approach.

Drawbacks

The most noteworthy drawbacks of ZLD systems include

Sector-wise concept of ZLD and treatment options

As per Central Pollution Control Board (CPCB),10 New Delhi (2015), sector-wise treatment options for industries is given in Table 2. The sector wise options shows that the specific industry need to installed ZLD system as per their waste-water characteristics and their use. Here in India, the CPCB has advised to install the ZLD system to all industries and made it mandatory to reuse the water after treatment.

S. No. |

Sector |

Treatment options |

Remarks |

1 |

Distillery |

1. Bio-methanation followed by RO/MEE followed by incineration (slop fired). |

ZLD Achievable |

2. Bio-methanation followed by RO/MEE followed by drying (spray/rotary). |

|||

3. Concentration through MEE followed by coprocessing in cement/thermal power plant. |

|||

4. Bio-methanation and RO followed by MEE followed by bio-composting. |

|||

2 |

Tannery |

Primary treatment + secondary treatment+ pre-treatment for RO + Reverse Osmosis + MEE |

ZLD Achievable |

(recovery of permeate, crystallised salt, reuse of the recovered condensate) |

|||

3 |

Pulp & Paper |

Primary treatment + Degasification + RO, 2 stage + NF and UF + Evaporator, Concentrator/Crystallizer |

Black Liquor totally to be ZLD in any plant. |

4 |

Sugar |

Restricting effluent generation to 100 Litres/ton cane crushed. |

Water conservation & irrigation protocol as alternate to ZLD |

Water consumption to be restricted to 100 Litres/ton initially and further to 50 Litres/ton cane crushed. |

|||

Condensate polishing unit mandatory Recycle of excess condensate to process or ancillary units. |

|||

Water management/audit to reduce spray pond/cooling tower blow downs and excess condensate. |

|||

Irrigation protocol for disposal into land applications |

|||

5 |

Pharmaceuticals |

High COD, Low TDS Effluent treatment system |

ZLD Achievable |

High COD, High TDS Effluent treatment system |

|||

6 |

Textiles |

1. Ozonation + bio-oxidation + sand filtration + activated carbon adsorption + micro filtration + reverse osmosis(3 stage) + multiple effect evaporator |

ZLD Achievable |

2. Chemical precipitation + bio-oxidation + chemical precipitation + sand filtration + Activated carbon adsorption + micron filtration + reverse osmosis (3 stages) + multiple effect evaporator |

|||

3. Chemical precipitation + bio-oxidation + sand filtration + dual media filtration + micron filtration + reverse osmosis (3 stages) + multiple effect evaporators |

|||

7 |

Refineries |

API, primary treatment, secondary treatment and tertiary treatment. The tertiary treatment is mainly Reverse Osmosis and permeate is utilized and rejects are discharged into cooling tower |

Water conservation, Reuse & partial ZLD |

8 |

Fertilizer |

Chemical treatment+ Reverse Osmosis (Rejects as filler material and permeate in the process) |

Water conservation, Reuse & partial ZLD |

9 |

Dye & Dye Intermediates |

Chemical Treatment+ MEE |

ZLD Achievable |

Table 2 Sector-wise treatment options for industries

Membrane distillation (MD) and solid hollow fiber cooling crystallization

A novel hybrid system of integrating membrane distillation (MD) and solid hollow fiber cooling crystallization (SHFCC) has been successfully developed for simultaneous production of fresh water and inorganic salt crystals from NaCl brine solutions. Porous PVDF hollow fibre membranes consisting of PTFE particles are spun for the MD subsystem, while non-porous PVDF hollow fibres are fabricated as heat exchangers for the SHFCC subsystem. To optimize the operation parameters, the Taguchi's method is utilized for experiment design including three key factors; namely, feed temperature (Tf), distillate amount (Wd) and water amount to wash away the scallant (Ww). As per researcher, the best combined parameters to maximize the crystal harvested at Wd = 14g and Tf = 50˚C. Narrowly distributed NaCl crystals with a small mean size of 35–45µm are successfully generated by the hybrid system, and a relatively long-term MD-SHFCC operation of 15 cycles is conducted to verify the system stability and feasibility by Luo et al.,11

Zero liquid discharge desalination

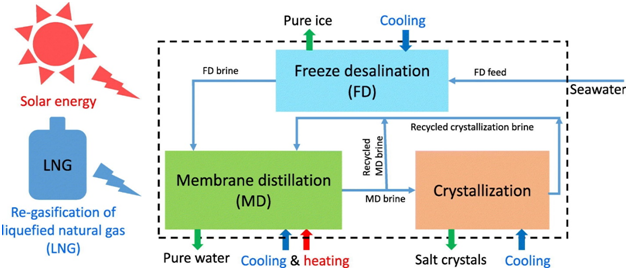

Zero liquid discharge desalination (ZLDD) is a sustainable solution to the global water scarcity problem. It provides high water recovery, zero waste generation and valuable salt production. Lu et al.,12 have developed a mathematical model of a novel ZLDD system that consists of freeze desalination (FD) and membrane distillation-crystallization (MD-C) also developed based on the theories of heat and mass transfer as well as experimental results. To improve the energy efficiency of the system, effects of important parameters, such as the feed temperature, concentration, and distillate temperature of MD and the recovery ratio of FD on system operating curves and energy consumptions have been systematically investigated with the aid of mathematical modelling. For a lab-scale hybrid ZLDD system operating at optimized conditions with a daily seawater processing capacity of 72kg, 50% of its heating energy can be supported by a 50.5m2 solar panel and its cooling energy can be 100% provided by re-gasification of 207-kg liquefied natural gas.12 Figure 1 has presented how the desalination works and sea water converted into pure potable water.

Figure 1 Zero liquid discharge desalination.12

Ammonia manufacturing industry

Wastewater generation from a typical ammonia manufacturing industry is given in Table 3. Typical water balance diagram of an ammonia manufacturing plant is given in Figure 2. All the wastewater generated from industry is recycled/reused in the plant itself. Therefore, it works on the ZLD concept i.e. no effluent goes out of the industrial premises. Sewage to be generated during construction as well as operation phase from construction labour and additional technical staff will be treated in existing facility. Effluent from proposed expansion plant in form of condensate will be sent to Phosphoric Acid plant for reuse in process. No additional effluent will be sent out of company premises. All the effluent water from process shall be reused and utilized fully in the phosphoric acid plant for processing. No water from process shall be discharged outside the manufacturing unit hence it will be a ZERO effluent discharge unit (Figure 2).

S. No. |

Activity |

Wastewater generation (KLD) |

Treatment/remarks |

1 |

Domestic |

2 |

Treated in existing septic tank/soak pit. |

2 |

Industrial |

||

Steam Condensate/ Process Condensate |

337 |

312 KLD with in proposed plant (AS-I) will be recycled in process and balance 25 KLD will be sent to Phosphoric Acid plant for reuse. Hence, complete recycle in plant process. |

|

Cooling Tower Blowdown |

48 |

Sent to Phosphoric Acid plant. For reuse in dust suppression/process hence, complete recycle in plant process. |

|

Net Total |

0 |

No additional effluent is sent out of company premises. |

|

Table 3 Wastewater generation from ammonia manufacturing plant

Pharmaceutical industry

Water balance diagram and flow diagram of ETP of a typical pharmaceutical industry is depicted in Figure 3 and Figure 4 respectively. Effluent generation from industrial activities is 110.8 KLD. Total effluent generation from the industry is segregated into high COD/TDS and low COD/TDS concentration streams. High concentrated wastewater stream from manufacturing process is treated in stripper followed by Multiple Effect Evaporator. Treated water from stripper along with WTP reject is sent to MEE. Condensate water from MEE is sent to ETP along with other low COD/TDS waste streams i.e. cooling, washing and boiler. After treatment in ETP followed by RO, permeate from RO is reused for cooling and reject is sent to MEE. Hence, there is no discharge of treated effluent from the industry and unit maintains Zero Liquid Discharge.

Textile processing cluster

The quantity of wastewater generation from a typical textile processing cluster depends upon the quantity of water used for various purposes. Water balance, flow diagram of CETP and flow diagram of common sewage treatment plant of a typical textile processing cluster are depicted in Figures 5–7 respectively. The effluent generated is treated in the CETP and reused for textile process. Wastewater generated from the domestic activities is treated in common sewage treatment plant and treated water is utilized for toilet flushing and greenbelt maintenance. Therefore, no wastewater is discharged outside the cluster premises and the proposed project is operated on zero discharge condition. The blow down water from the boiler is treated in the RO system followed by deaerator. The condensate return after the evaporation and steam loss is recycled for boiler make-up, until there is any source of contamination or dissolved solids contained within the system. Hence, industry can achieve the ZERO liquid discharge system. The most important factor is to check the output parameters before using this water into any process. As per the ZLD systems installed in various industries in Gujarat, they are using the waste water after treatment into the process and other miscellaneous uses like drum and reactor washing, floor washing, dust suppression, green belt watering, etc.13

The concerns over the environmental impact of water pollution have increased, and also ground water resources are gradually being depleted. In the current situation, it is required to recycle the wastewater generated from industrial outlets. On other hand, environmental authorities are being directed to establish “Zero Liquid Discharge (ZLD) plants” in all industrial sectors. Hence, for waste minimization, resource recovery, toxic industrial wastewater treatment and mitigation of potential impacts on water quality of receiving streams, ZLD (Zero-Liquid Discharge) is being thought of an evolving technology. Reduction in water pollution and augmentation of water supply are being carried out by implementation of ZLD (a significant wastewater management strategy) globally. Application of ZLD systems at industrial scale are limited due to increased energy consumption and their cost even though their capability for minimising water pollution and maximising water resources.

None.

None.

The authors declared that there no conflicts of interest.

©2020 Rathoure. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.