MOJ

eISSN: 2572-8520

Review Article Volume 3 Issue 6

Department of Applied Mechanics, Motilal Nehru National Institute of Technology Allahabad, India

Correspondence: Ajitanshu Vedrtnam, Allahabad, Department of Applied Mechanics, Motilal Nehru National Institute of Technology Allahabad UP, India, Fax 053-222-712-00

Received: May 09, 2017 | Published: December 18, 2017

Citation: Vedrtnam A, Pawar SJ. Numerical analysis of impact fracture of laminated glass - a review. MOJ Civil Eng. 2017;3(6):391-394. DOI: 10.15406/mojce.2017.03.00086

Laminated glass (LG) is a sandwiched composite structure, composed of two pieces of outer glass layers and one or more pieces of the polymer films (interlayer) sandwiched in-between of the glasses. Impact strength of LG is the most significant mechanical property due to architectural, glazing, automotive, and decorative applications. Recently, a good no of numerical simulations are reported for impact failure analysis of LG. The purpose of this mini review is discussion on numerical algorithms for modeling the principal damage pattern and glass-ply cracking in LG. It is observed from this review that quantitative works need to be carried out to validate the capacity of numerical algorithms in the impact failure analysis of the LG.

Keywords: architectural glass, EVA, laminated composites, PVB, wind shield

LG, laminated glass; DE, discrete element; FE, finite element; DEM, discrete element method

LG comprises of two layers of glass and one or more layers of polymer film (inter-layer) that is sandwiched in-between by putting under heat and pressure. Inter-layer improves mechanical properties like impact strength, fracture toughness and failure mode of LG.1 As area of impact increases there is possibility of increment of the impact resistance. The fracture of LG is designed so as to the Inter layer keeps together broken pieces that can possibly cause dangerous incidents or accidents. The LG dampens the energy of impact and improves the brittle fracture behavior when compared with monolithic glass. This functionality forces designers to use LG wherever there may be an injury risk due to glass fracture. A good no of theoretical studies,2‒8 experimental studies9‒22 numerical studies,10,23‒45 LS DYNA and ABAQUS based studies18‒36 and discrete element (DE)/finite element (FE) based studies are reported to analyze impact failure of LG. The present work is focused on reviewing the numerical algorithms used to model the impact fracture of LG.

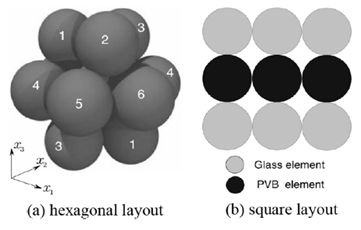

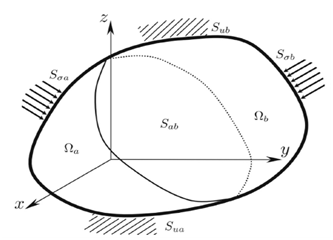

Impact failure analysis of LG is commonly done experimentally followed by numerical simulations. The failure processes of LG due to impact analyzed during pre-failure, failure and post-failure stages. Analytical models are commonly employed to describe the mechanical performance of LG for the pre and post-failure stages.46‒50 The post-failure response of LG is also explained by numerical simulations51,52 and experiments. The literature frequently focuses on the principal damage pattern and glass-ply cracking. The commonly used numerical algorithms sighted in the literature for impact simulation are element deletion method (EDM), the continuum damage mechanics (CDM), the discrete element method (DEM), the combined discrete/finite element methods (DEM/FEMs), the extended finite element method (XFEM) and the cohesive zone model (CZM). The adhesion modeling is usually simulated using shared node method, the penalty-based methods and the intrinsic CZM. The EDM consist of removal of the mass of elements from the global mass matrix or set the stress of elements to zero, so as to represent the failure of these elements (used in LS-DYNA). This method is used.53,54 Xu et al.55 developed a numerical model on LG-PVB subjected to low-speed impact. The LG was impacted by a standard head form impact or at the speed of 8 m/s based on the LS-DYNA platform. The results were compared with the dynamic experiments of LG-PVB under head form impact to find the most accurate FE model. Pyttel et al.56 have found failure benchmark norm for the LG when subjected to impact loading. It has been stated that a hazardous energy threshold should be reached during a finite expanse before failure took place. To regulate the norm and estimate its precision, various tests with curved and plain samples of LG were performed. The comparison between simulated and measured result showed that the norm works sound.56 The CDM includes depiction of the damage effect of a material by its stress-strain behavior.57 Sun et al.58,59 constituted a model considering the contribution of damage to the constitutive law for the modeling of glass-ply cracking. Zhao et al.60 used this model to simulate the damage of LG panel under the impact loading. The web-shaped, star-shaped and shear damage fracture pattern were observed during simulation. Sun et al.58 also used this model to numerically find the windshield design parameters (thickness and curvature) on its stone-impact resistance.61 The DEM includes discretizing the solving domain into a cluster of discrete elements (DEs), and describe the movements of DEs by Newton's second law. The interactions between DEs are usually handled by using contact algorithms. Zang et al.62 used 3D discrete element method to study the impact fracture of LG. The glass and PVB of LG planes were discretizing to uniform rigid spherical elements (Figure 1). This investigation showed that the accuracy of the 3D model and numerical analysis were significantly validated in the elastic range in comparison to FEM.62 The combined discrete and FE methods overcome the inability of DEM to describe the large deformation behavior of the inter-layer. Therefore, as shown in Figure 2, Lei et al.62 proposed a DEM/FEM based on a penalty method. As shown in Figure 2 the solving domain is decomposed into two parts (Ua and Ub) with a common interface. Sab Sua Ssa, Sub and Ssb are correspondingly the displacement and traction boundaries of sub-domain Ua and Ub. Fig. 17 shows the glass plies discretized into a series of DEs and the inter-layer discretized into a series of FEs.63

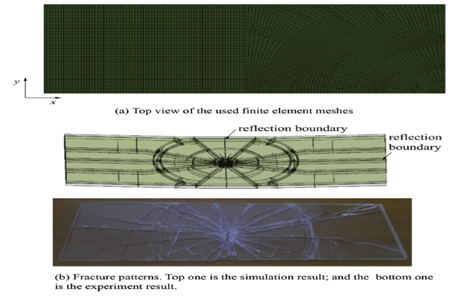

Xu & Zang35 developed four-point combined FE/discrete element (DE) algorithm for the brittle fracture study of the LG. In this study, the penalty method was applied to calculate the interface force between two sub domains, the FE and the DE sub domains. It was found that on comparing the impact fracture tests with the simulation results, there were changes in the amount of the cracks of upper and lower glass, but the location of cracks and propagation paths are similar to the investigation outcomes. Hence, it is concluded that the theory stated was effective to forecast some macroscopic fracture features such as the crack location and the crack diffusion.63 Four algorithms were suggested to combine DEs and FEs (Nodel combine algorithm,63 surface-center algorithm,64 freely combined algorithm65 and four-point combined algorithm)66 as shown in Figure 3. The XFEM includes cracking simulation by extending the shape functions of the conventional FEM with extra enriched functions in the cracking area.67‒72 The cracks can be represented independently of FE meshes and crack growth modeling doesn’t require re-meshing in XFEM. Jaśkowiez73 performed numerical modeling for delamination in LG by XFEM. XFEM was used to input discontinuity to the approximation field. The developed model was found suitable for three-dimensional delamination analysis.73 The CZMs includes idealizing fracture as a gradual process of separation in the small region ahead of the crack front. CZM is governed by a phenomenological traction-separation law and used frequently for performing failure analysis.74‒77 Chen et al.16 simulated the impact fracture of a LG under drop-weight impact. The common glass-ply crack patterns were captured in the simulations with a special designed FE meshes (Figure 4). It is reflected from the Figure 4 that the propagations of radial cracks are somewhat constrained in the areas away from the impact point when brick elements are adopted for the LG model.77

It is clear from the review that a lot of research work is done in the field of laminated composite glass that includes analytical models, experimental studies, and software simulations. The principal damage pattern, glass-ply cracking is analyzed using six numerical algorithms (EDM, CDM, DEM, DEM/FEMs, XFEM and CZM). The DEM/FEMs, XFEM and CZM used for small-size LG specimens for the glass-ply cracking modeling whereas EDM can be applied to the impact failure analysis of bigger size of LG. Further, it is suggested that quantitative works should to be carried out to validate the capacity of numerical algorithms.

None.

None.

The author declares that there is no conflict of interest.

©2017 Vedrtnam, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.