MOJ

eISSN: 2572-8520

Research Article Volume 2 Issue 6

1Department of Civil Engineering, University of Khartoum, Sudan

2Senior engineer, Ministry of Road and Bridges, Khartoum, Sudan

Correspondence: Magdi ME Zumrawi, Associate Professor, Department of Civil Engineering, University of Khartoum, Sudan

Received: April 01, 2017 | Published: June 13, 2017

Citation: Zumrawi MME, Margani KM (2017) Improving Maintenance Practice for Road Network in Sudan. MOJ Civil Eng. 2017;2(6):202-207. DOI: 10.15406/mojce.2017.02.00054

Efficient maintenance of roads networks is highly important to conserve them. In Sudan, the maintenance practice of roads is predominantly based on emergency maintenance. Recently, many challenges are facing this practice which required urgent and necessary improvements to be undertaken. Ten major national roads representing the road network in Sudan were selected for this study. A visual field survey was conducted for evaluating the current condition of these roads. The investigation determined types, severity, and percent of distresses observed on each road and diagnosed their possible causes in order to suggest efficient maintenance measures. The results of the field survey showed that 24% of the roads are in poor condition, 33% are in fair condition, and 43% are in good condition and the major distresses observed are cracking and raveling failures of road surface. Finally, recommendations are provided to support the government and national road authority in Sudan to have a promising maintenance practice for road network.

Keywords: Pavement distresses; Maintenance practice; Road network; Improvements

The road network in Sudan serves as a major channel of transportation and contributes in economics and social benefits. Sustaining these benefits over time requires maintaining the road network in time and proper manner. Without adequate and efficient maintenance roads can quickly deteriorate. Delayed maintenance, and the resulting poor state of repair, makes roads more difficult to use. This results in loss of economic and social development opportunities.

In recent years, Sudan's government paid great attention on road maintenance as a priority issue related to conserve the road network. Ministry of Roads and Bridges (MRB) is responsible for maintenance of national and strategic roads of the country. The maintenance practice of the road under MRB is predominantly based on emergency maintenance process where several maintenance activities like routine maintenance, recurrent maintenance, and periodic maintenance are rarely carried out.

The objective of this study is to provide an overview of road maintenance practice in Sudan, the challenges it face and suggestions for addressing these challenges. To meet this objective, the study conducted an over review of road maintenance method currently practice in Sudan, carried out field survey of pavement distresses on some existing national roads, diagnosed the possible causes so as to suggest a proper maintenance measures.

Background

Maintenance is a series of activities designed to keep a road network serviceable by reducing the deterioration of pavements. Pavement maintenance includes routine, preventive and corrective interventions.1,2 Routine maintenance is usually performed annually and includes interventions such as crack sealing and filling, patching and pothole filling. Preventive maintenance is usually performed to improve the functional surface properties without significantly changing the structural properties of the pavement. The best time to apply the interventions is considered to be before significant distress is exhibited.3 Typical preventive maintenance includes fog seal, chip seal, slurry seal, micro-surfacing and thin overlay. Corrective maintenance includes overlays, rehabilitation and reconstruction. Corrective maintenance can change the structural properties of the pavement and costs more, but the effects (both immediate and long-term) are usually greater. Structural distresses such as rutting can only be addressed by corrective maintenance. Corrective maintenance is usually triggered when maintenance thresholds are reached MTAG,4 although earlier performed corrective maintenance may help to reduce road user costs.5

Maintenance is important because poorly maintained roads lead to destruction of the value of road assets and its corresponding impact on government accounts and higher costs for road rehabilitation in the future, higher vehicle operating costs, fuel costs, and reduced road safety, and reduced access resulting in poorer healthcare and fewer employment and educational opportunities.

Maintenance cost

Properly maintaining a road network requires regular and appropriate maintenance works. Delaying such maintenance erodes the value of this important public asset and results in unnecessarily large costs at some later time. If maintenance is not carried out in a timely manner, entire road sections may fail completely, requiring full reconstruction at a much higher cost than the cost of preventive maintenance.2

The annual maintenance costs represent a small proportion of the cost of new construction and rehabilitation costs; 2 to 3% for a paved road, and 5 to 6% for an unpaved rural road. It is unfortunate that despite the rather clear cut case for investing in preventive maintenance, the amounts spent on maintenance activities remains low in most middle and low income countries.7 While unpaved roads deteriorate more or less uniformly over their design life, it is well known that the deterioration in the condition of paved roads does not follow a linear trajectory over time.8 Newly paved roads slowly deteriorate, depending on the volume and mix of traffic, the climate and weather conditions, over the first half to two-thirds of their life. After this, without adequate maintenance, the pavements deteriorate much more rapidly and eventually break apart completely.8 The South African National Road Agency Ltd. (SANRAL)9 estimates that repair costs are six times maintenance costs after three years of delayed maintenance, and 18 times the maintenance costs after five years. To avoid such escalating costs, SANRAL first “allocate[s] its available funding resources to ideal maintenance actions (e.g., reseals and overlays), and thereafter to more extensive maintenance actions (e.g., rehabilitation), and finally to new construction.9

Deferred maintenance refers to the dollar amount of maintenance and rehabilitation work that should have been completed to maintain the pavements in acceptable condition but had to be deferred due to reduced maintenance funding or policy changes for the preventative maintenance and/or pavement rehabilitation programs. Pavements that remain untreated can deteriorate at a faster rate. The cost of repairs increases disproportionately as the condition of the pavement decreases over its life. According to the Federal Highway Administration (FHWA),10 deferring pavement preventive maintenance or rehabilitation can lead to a substantial increase in required repair costs.

Defects in flexible pavements

Defects are indicative of road distress and impaired efficiency. They may be due to poor performance of constituent materials, errors in design or construction, environmental and climate factors as well as to particularly heavy traffic. Two types of defects may be distinguished: functional and structural. Functional defects express shallow degradation of the wearing course of pavements; this degradation reduces both vehicle grip to the road and evenness of the road surface and thus influences traffic safety. Factors responsible for this type of degradation and giving rise to skid resistance problems include reveling or polishing of aggregates; surface exposure of bitumen, and detachment of aggregates. Smoothness problems comprise longitudinal undulations, transverse undulations or ruts, hollows or bulges, dips on extensive surfaces and edge cracking. Conversely, structural defects arise in the supporting courses of the superstructure. They are due to deterioration of its load-bearing capacity and have major effect on pavement durability. Defects of this type include surface cracks, longitudinal, and transverse cracks, alligator cracks and failures.11,12

Defects or distresses that occur on the pavement’s surface can pose a hazard to traffic and drivers safety. Cracking, potholes, rutting, raveling, asphalt bleeding and depressions are examples of pavement distresses which if left untreated, will eventually develop into more serious pavement failures. Roads deteriorate over time due to external factors such as, climate, usage and aging. Generally, the older the pavement is, the more rapidly it deteriorates. It has been claimed that, road deterioration is affected by a combination of factors including, the original design, material types, traffic volume and its axle load characteristics, environmental conditions, age of pavement, and maintenance policy implemented.13 Many researchers investigated the possible causes of different forms of pavement distresses,14-16 as shown in Tables 1 & 2.

Category |

Distress Type |

Cracking |

Longitudinal, fatigue, transverse, reflective, block, edge |

Deformation |

Rutting, corrugation, shoving, depression |

Deterioration |

Delimitation, potholes, patching, raveling, stripping, polished aggregate, pumping |

Mat problem |

Segregation, bleeding |

Distress |

Causes Brittle asphalt material. |

Potholes |

Weakness of asphalt surface components. |

Depression |

Poorly compacted pavement layers. Heavy loadings of unstable granular bases/sub bases. |

Unstable asphalt mixes due to high temperature or low binder viscosity. |

|

Rutting |

Poorly compacted pavement layers. Heavy traffic loading of unstable granular bases and sub bases, over stressed sub grade. |

Raveling |

Stripping due to water action. |

Bleeding |

Mix design deficiencies where too high asphalt content and very low voids results in excess asphalt forced to the surface. |

The methodology adopted for this research includes reviewing available data and information on the aspects of road maintenance practice in Sudan and the budges provided to meet current and future maintenance requirements, then conducting field survey of pavement condition for selected national roads which represent the road network in Sudan.

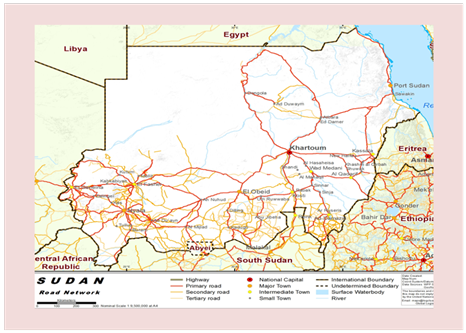

Sudan has a widespread national road network which connects the different states of Sudan. This road network has total length about 30,000 km, where only 20% are paved. The road network is divided into two groups, as shown in Figure 1:

Figure 1 Map of Sudan Road Network.16

The available documents and reports of relevant information about road maintenance; the type and frequency of required maintenance, the efficiency of carrying out maintenance, how it is carried out, using what technology, and the adequacy of the current processes for meeting future requirements. The data and information on how road maintenance is financed and the adequacy of financing to meet current and future maintenance requirements were collected. These records were reviewed to help in assessment of the road maintenance practice in Sudan.

Field survey

The type and severity of distresses were visually inspected for each road section. External indicators of pavement distresses caused by loading, environmental factors, design and construction deficiencies were observed. Distress type and severity levels were observed during the field survey. The inspection was carried out by driving a car at the normal speed in a road section during normal traffic flow. Ride quality was used to determine severity level of some distresses such as rutting, raveling, and polishing. Other types of distress including cracking, potholes, depression, and patching, either measured in linear meter or square meter. Measuring the quantity of each distress present and recording the data was conducted by walking over the sidewalk or the shoulder of the road section being surveyed.

The national road network has total length 30,000 km and only 6000 km are paved roads (20% of the total length). In this study, the field survey covered 3250 km which represents about 54% of the total length of paved roads in order to assure the reliability of the data. The visual survey conducted and the row data were collected, analyzed, and interpreted and the results are presented hereafter.

Pavement failures

The most common pavement failures recorded include cracking, rutting, potholes, raveling, depressions, polishing and patching. The quantity and the area covered by each distress were determined. When comparing this area to the total area of pavement sections, the distress percentage can be calculated. Figure 2 shows the variation of all inspected distresses on the surveyed roads. The relative percentage of each distress compared to the paved surface area of the length covered by the visual survey is plotted in Figure 3. In this figure, it can be observed that cracking and raveling have high percentages, 7.7% and 4.7% respectively. On the other hand, rutting and patching are minor distresses with low percentages, 1.3% and 1.8% respectively. Cracks have different sizes from small hire line cracks to major cracks of 25 mm or more. The cracks observed of different patterns and shapes such as alligator cracks, block cracks, longitudinal and traverse cracks, and fatigue cracks. The raveling defect of medium to high severity covered large areas of the damaged pavement sections. The investigation of these failures, to find out the possible causes of cracking and raveling failures indicated that the surveyed roads suffer a lot from cracking failure due to excessive traffic loading of heavy trucks and trailers and insufficient pavement thickness. The raveling defect of medium to high severity level covered relatively large areas of damaged sections of the roads. The main cause of this distress refers to deficiency in asphalt concrete mixture and inadequate compaction.

Pavement Condition Index (PCI)

A new concept for rating number of roads based on their surface conditions is necessary to be established. The rating system consists of identification a number for each surveyed road and rating score according to its pavement condition and the average percentage and level of severity of the distresses.

The Pavement Condition Index (PCI) is defined as a numerical indicator which rates the pavement condition. The suggested scale is supposed to measure the present pavement condition observed on the surveyed road. The description of pavement condition is a function of PCI value. The lowest "PCI" value from 0 to 25 represents "Poor" pavement and the highest PCI value from 75 to 100 is the "excellent" pavement, as shown in Figure 4.

For the purpose of easy and proper assessment of current pavement condition, the suggested "PCI" was considered in the analysis to relate each road with its surveyed distresses such as cracking, raveling, polishing, depression, potholes, patching and rutting. For each road, there is an estimated value of PCI for the total percentage and level of severity of the distresses that were measured in the field survey as shown in Table 3. From this table it is observed that highest average percentage of distresses occurred on Kassala -Haia-Port Sudan road compared to other national roads. Accordingly, the most significant cause of failure is overloading traffic and insufficient pavement thickness. Moreover, Omdurman-Dongula road showed a reduction in percentage of distresses about 34%. The main reason for this reduction may be due to the rehabilitation executed in 2010. The results of field survey showed that four roads of total length 781 km which represents 24% of the surveyed roads are in poor condition, three roads represents 33% are in fair condition, and 43% are in good condition.

Road |

Road Name |

Length |

Distress Relative Percent |

PCI |

|

R1 |

Khartoum - Elkamlin |

160 |

3.3 |

44 |

Fair |

R2 |

Khartoum - Atbra Barbar |

350 |

2.8 |

67 |

Good |

R3 |

Khartoum - Kosti - El Obied |

550 |

2.8 |

56 |

Good |

R4 |

Omdurman - Dongula |

500 |

2.5 |

70 |

Good |

R5 |

Sinnar - Jabal Moia Kosti |

110 |

3.7 |

18 |

Poor |

R6 |

Khartoum - Rabak Aljabalian |

330 |

3.8 |

14 |

Poor |

R7 |

Medani - El Gedarif Kassala |

350 |

3.4 |

30 |

Fair |

R8 |

Kassala - Haya - Port Sudan |

560 |

3.4 |

30 |

Fair |

R9 |

Sinnar - Sinja - El Damazine |

235 |

3.6 |

20 |

Poor |

R10 |

Wad Madani - Sinnar |

105 |

3.7 |

15 |

Poor |

Table 3 Analysis results of field survey of the studied roads

As mentioned before, ministry of roads and bridges (MRB) is responsible for maintaining the national roads. Most of the maintenance and rehabilitation works are carried out by private contractors. Based on the intensive review of the available documents, it is clear that there are many challenges faced the maintenance practice in Sudan, these are outlined hereafter. Lack of a maintenance management system - There is limited data to support a systematic assessment of the maintenance needs of the road network. This lack of data makes it difficult to prioritize maintenance projects, or to forecast future preventive maintenance needs. There is also no adequate pavement deterioration models that can be used to forecast future pavement conditions. Without the necessary data or a pavement deterioration model means that it becomes very difficult to obtain a required budget for maintenance activities. Delays in addressing the maintenance needs of the road network - Routine and periodic maintenance is postponed till such time that rehabilitation works are needed. It seems that overlay is used to resurface roads in need of maintenance, without considering the structural integrity of the underlying pavement layers. Flawed technical solutions are applied to solve maintenance problems - It seems that in Sudan surface treatments are applied every 3 to 4 years. This is surprising as in many countries properly applied surface treatments can easily last for up to 10 years. This suggests that the way surface treatments are being applied is not appropriate as they have a much shorter life expectancy than what is normally the case, resulting in higher expenses. Lack of funding to finance maintenance activities - As a result of the lack of funding, several of the larger maintenance works have to be financed via a capital investment plan, where the “maintenance” projects compete with other projects. Sometimes they get the needed funds, and sometimes they do not. This introduces uncertainty about whether a given set of maintenance activities can be undertaken, quite regardless of the urgency of undertaking these maintenance works.

Overloading of trucks-Almost 40% of the trucks and trailers in Sudan exceed the weight limits specified for the roads. This accelerates the pavement deterioration process. Normally, the agency that is in charge of the operations and maintenance of the road networks is also in charge of enforcing the weight limits. Dependence of government tax revenues-A significant part of the budget for maintenance is financed from general tax revenues allocated by the government. The volume of these funds varies from year to year creating uncertainty about the total revenues available for maintenance activities in a certain year. This uncertainty makes it difficult to properly plan annual maintenance activities.

Availability of materials-There is a lack of suitable local materials for road maintenance and the high cost of cement is an issue. The lack of appropriate materials means that maintenance works are often delayed and more expensive than what normally should be the case. Problems with contractors - While the local contractors are technically qualified, in practice there are problems with the quality of the works that are delivered.

None.

The author declares no conflict of interest.

©2017 Zumrawi, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.