MOJ

eISSN: 2576-4519

Mini Review Volume 2 Issue 3

Instituto Politecnico Nacional, Mexico

Correspondence: Urriolagoitia Sosa Guillermo, Instituto Politecnico Nacional, Escuela Superior de Ingenieria Mecanica y Electrica, Seccion de Estudios de Posgrado e Investigacion, Unidad Profesional Adolfo Lopez Mateos Zacatenco, Avenida Instituto Politecnico Nacional s/n, Edificio 5, 2do. Piso, Col. Lindavista, CP. 07320, Mexico

Received: April 25, 2018 | Published: May 3, 2018

Citation: Marquet RRA, Urriolagoitia SG, Hernández VRA, et al. The importance of bio-fidelity in the biomodelling for a biomechanical analysis. MOJ App Bio Biomech. 2018;2(3):174–175. DOI: 10.15406/mojabb.2018.02.00062

The new technological advances and computational resources have allowed Biomechanics to use a fundamental tool for the Engineering area. This tool is the computational models, which are analysed by the Finite Element Method (FEM), to know the effects exerted by external agents on the models. Biomechanics has used this principle of modeling on anatomical members of living beings, these models are known as biomodels. Biomodels have evolved a lot since their inception, have improved their bio-fidelity to become models very similar to real structures. These biomodels of high biofidelity are more complex in their geometries and mesh. Therefore, when the biomodels are subjected to analysis by FEM, is possible to have a better understanding on how force systems interact in anatomical structures. Finally, high biofidelity has allowed a better biomechanical analysis and its results to be more precise and real since the mesh models have become more complex. This precision allows to improve and even customize the design of prostheses, orthoses and implants. Providing a better quality of life to patients.

Keywords: biomechanics, computational models, biomodels, biomechanical, anatomical

The study of Biomechanics has allowed man to understand and describe in a better way how the structural anatomical components of the human body responds to the natural movements of the body such as walking, holding something, jumping, to mention some movements. As well as the external agents that interact in the day to day affairs. Biomechanics studies of living beings from a mechanical point of view, that is, it considers each part of the body as if it were a system of links or segments.1 This is, in the case of the upper limb, what corresponds to the forearm would be the first link with the junction point at the elbow and the second link that is formed by the arm. These links, not being independent and connected, exert effects on the following links in a natural way, producing internal forces. Just as there are such internal forces, there are in turn several external agents that interact with the study member and for this reason with the biomechanical study, it is also compulsory to consider external agents that interact with the body. These agents can be the weight that the element must support, impacts such as the impact of a ball, the surface where a person walks, etc. Biomechanics is responsible for studying how anatomical structures are affected or modified by these systems of forces and these studies can be static, dynamic or kinematic.

Biomechanic studies have allowed the generation of devices such as prostheses, orthoses and implants, since, being mechanical devices, they must consider the conditions to which they will be submitted to be able to develop a correct design from them. Actually biomechanical studies have being supported on engineering tools such as three-dimensional computer models, analysis by numerical methods, movement measurement equipment, among others. One of the tools that have taken a boom are the computerized three-dimensional models. The three-dimensional models have taken a significant importance in the studies of Biomechanics, three-dimensional models computerized in engineering can be understood as mechanical parts drawn in a computer program, these pieces can go from a simple screw to a set or an assembly as the transmission of a car. For the case in which Biomechanics that studies living biological elements, these models have been called biomodels.

In the literature you can find biomodels of all kinds to which they are made from numerical analysis. Among the biomodels we can find large structures such as the femur, skull, knee, etc. and even small structures such as a tooth or a set of teeth.2

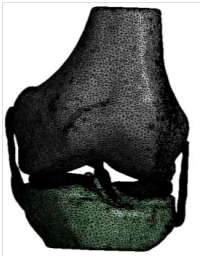

In the beginning, biomodels were crude and a considerable computational resource was required as the technologies were not as sophisticated as they are today. The biomodels that were generated resembled the anatomical structure but were not precise, some biomodels were formed with geometrical figures that fit them simulating the biological element. These crude biomodels were subjected to numerical analysis but the results obtained from this type of models were not so precise since the biomodel was similar but not equal. Figure 1 shows a biomodel of a knee published in 2003 where the author states that it has a discretized 495 elements and 709 nodes.3 Nowadays biomodels have evolved over time becoming biomodels with greater bio-fidelity, or in other words they are more similar to the real anatomical structures, this bio-fidelity is based on the increase of the computational resources and have allowed to perform a series of more complex numerical analyzes with a greater number of anatomical structures and with a discretization of higher order. By having numerical analyzes of more bio-faithful biomodels, it has been possible to understand how forces interact. This understanding has allowed the design of prostheses, implants and orthoses to be more discreet and effective, providing a better quality of life to the patient.4 Figure 2 shows a biomodel of a knee. The biomodel was generated in 2017 and it has ten anatomical structures with a high bio-fidelity with 678,177 elements and 1,167, 404 nodes.5 From these biomodels of high bio-fidelity it is possible to design and generate prostheses for each particular case, that is to say they become personalized and not generalized allowing the individual to better adapt to these. They are made with the ideal measures for each case of study. By having a better adaptation in size, functions, supports, etc., provide a better quality of life to users. By having such personalization characteristics it prevents a mismatch between the stump or the anatomical structure and the prosthesis, which generates a discontent of the user and is a reason why they do not use them with comfort or frequency (Figure 3).6

Figure 1Biomodel generated in 2003.3

Figure 2High bio-fidelity biomodel.5

A high bio-fidelity for biomodels allows to design more effective prosthetic elements and perform more complex numerical analyzes that allow to determine and understand how anatomical structures are affected by the effects of external agents. Biomodels of high bio-fidelity will complement the studies of various areas of Medicine such as Orthopedics, Sports Medicine and mainly Physical Rehabilitation and the design of Prostheses and Implants, with the help of the knowledge of the area of Engineering. The innovative technologies, have allowed the generation of biomodels of high bio-fidelity, will continue to evolve until reaching the point of making an almost perfect biomodel (speaking geometrically) and equal to the real one for each individual. This will allow performing the numerical analyzes and obtaining results to the effect to interact with living beings.

The authors thank the Instituto Politécnico Nacional and the Consejo Nacional de Ciencia y Tecnología for the support provided.

Authors declare that there is no conflict of interest.

©2018 Marquet, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.