Journal of

eISSN: 2574-8114

Research Article Volume 9 Issue 1

1ThermaNOLE™ Comfort Lab, Jim Moran College of Entrepreneurship, Florida State University, USA

2College of Health and Human Sciences, Department of Human Development and Family Science, Florida State University, USA

Correspondence: McQuerry M, ThermaNOLE™ Comfort Lab, Jim Moran College of Entrepreneurship, Florida State University, USA, Tel 850-644-6838

Received: February 10, 2023 | Published: February 22, 2023

Citation: McQuerry M, Grzywacz, JG. Thermal comfort assessment of active cooling technology for agricultural end use: a field study. J Textile Eng Fashion Technol. 2023;9(1):14-19. DOI: 10.15406/jteft.2023.09.00327

Migrant agricultural workers endure harsh environmental conditions for extended periods of time while working in crop and livestock production. Despite their elevated risk for heat-related illnesses and injuries, agricultural workers’ clothing needs are rarely considered outside of pesticide use. The purpose of this field study was to explore the potential value of providing garments with printed cooling technology to agricultural workers as an engineering tool for reducing elevated risk for heat-related illness. An eight-day field study with 20 migrant farmworker participants measured thermal comfort perceptions at the end of each workday for a t-shirt with active cooling technologies, including phase change materials, compared to the same 100% polyester t-shirt with no cooling finishes applied. Participants reported greater perceived comfort when wearing the t-shirts with the printed cooling technology compared to the control shirts.

Keywords: comfort, phase change materials, agriculture, personal protective clothing, heat stress

Agricultural workers frequently toil in harsh environmental conditions for extended periods of time while working in crop and livestock production. Agricultural labor can be grueling due to the physical intensity of the job and the environmental conditions under which it is conducted. Much agricultural labor is done during the hottest times of the year resulting in a substantial risk for heat-related illness, a risk that will expand as environmental heat levels continue to rise.1 Major health problems have been documented related to the effects of exposure to extreme heat.2 These geographic areas are mostly tropical and sub-tropical, such as the southern parts of the United States, increasing the chances of occupational heat stress in these regions.

Heat-related injury in agriculture

Heat-related illnesses, ranging from modest experiences of heat stress to more concerning forms of heat exhaustion and heat stroke, have substantial consequences for agriculture. Heat stress and exhaustion impede work capacity and lower labor productivity, while more severe forms of heat exhaustion and heat stroke can produce permanent injury and death.2 Sahu, Sett, and Kjellstrom3 found that high environmental heat exposure for rice field workers in West Bengal significantly reduced work productivity by 4%.3 Depending on environmental temperatures, occupational accidents increase by 5.2%, 8.2%, and 30% when the maximum temperature is between 26.7-32.2˚C, 32.2-37.8˚C, and over 37.8˚C, respectively; all relative to a day with a maximum temperature between 15.6-21.1oC.4

In the United States (US), the agricultural, forestry, fishing, and hunting sector has the highest incidence of nonfatal occupational injuries and illnesses with an estimated rate of 43.3 cases per 10,000 full-time workers.5 Even more concerning is that this industry sector also has the highest incidence rate of heat-related fatalities at 3.06 per 1 million workers.6 Within this sector, field agricultural workers commonly experience heat-related illnesses. Mirabelli, et al.,7 found that 40% of the 300 agricultural workers included in their study reported symptoms of potential heat stress or heat exhaustion.7 Agricultural workers in the US are four times more likely to experience heat-related illnesses when compared to other occupational sectors,8 and 20-times more likely to die from extreme heat.9

Personal protective clothing for agricultural applications

Heat-related illness results from the confluence of environmental conditions, physical activity performed, and clothing worn. Workers' clothing can play a significant role in their protection and comfort (i.e., thermoregulation). In the US, a large portion of agricultural workers are part of the H-2A program which allows employers to bring foreign nationals to the US temporarily to fill agricultural jobs (U.S. Citizenship and Immigration Services, 2020; U.S. Department of Labor, 2010) While the H-2A program requires the provision of access to shelter, food, and transportation for workers, their clothing needs are overlooked.10,11

The impact of improper personal protective clothing (PPC) in agricultural settings has been demonstrated previously. Female pear farmers in South Korea experienced stressful conditions during long work hours worsened by wearing poorly constructed baggy clothes made of nylon.12 Over 70% of the pear farmers in this study voiced their discomfort with their clothing by indicating “special work clothing” was needed,12 suggesting the provision of PPC may enhance worker comfort and productivity, while also enhancing safety.

Little to no research has focused on assessing appropriate agricultural PPC outside of pesticide application which is a very limited part of the industry.13–16 One recently published article assessed the applicability of active cooling technology in relation to its long-term durability across 50 wash cycles.17 This study concluded the printed t-shirt with active cooling technology and phase change materials (PCMs) withstood a typical 50-wash consumer useful life in terms of dimensional stability, colorfastness, pilling resistance, and soiling.17 This study did not, however, assess the cooling performance of the PCMs in a wear setting with end users in the agricultural industry.

Of the limited literature focused on specific occupational personal-protective equipment (PPE), the majority focuses on other types of industries such as firefighting and construction applications.18–25 One study for construction workers compared a novel uniform with printed cooling technology to a commercially available uniform. Findings demonstrated that the printed uniform with cooling technology alleviated heat strain and improved comfort.26 Subjects in this study not only reported improved comfort perceptions when wearing the uniform with cooling technology, but their skin temperature in the chest and microclimate humidity (space between the skin and the garment) was also significantly lowered.26 These findings suggest that a cooling finish may lead to reduced heat strain in outdoor occupational settings, as evidenced by the lowering of participants’ physiological responses.

Printed cooling technology

Printed cooling technology consists of active cooling components (ACC) and phase change materials (PCMs).20 PCMs are compounds that change from a solid to a liquid when a specific temperature is reached and then reverse from a liquid to a solid when the temperature decreases.17,27 They are often microencapsulated and either extruded at the fiber level or applied as a topical finish to a fabric. PCMs are unique because they absorb thermal energy which cools the body and then later release latent heat, providing a warming effect.28 Requirements of PCMs is that they have a high latent heat capacity, the ability to change states multiple times, and are chemically and thermally stable.29 PCMs are inexpensive, readily available, and known to be safe for consumer use (non-toxic and non-corrosive); they are often applied in the form of paraffin waxes, hydrated salts, fatty acids, and even water/ice.27,29

Examples of ACCs include highly conductive metals or ceramics and encapsulated dissolvable alcohols.20 Highly conductive metals or ceramics remove the heat from the body quicker, while the alcohols, such as xylitol, cool when they come in contact with moisture vapor, like sweat.20 Both ACCs and PCMs have been implemented in specialized protective clothing since their development for space suits and military applications in the late 1980s.1 Today, PCMs and other cooling technologies can be found in all types of consumer apparel, from sports uniforms to running t-shirts.20 In addition to PCMs and ACCs, traditional cooling techniques include complex yarn cross-sections and fabric constructions that permit increased airflow and spread moisture over a larger surface area, which is known as wicking.20 It is important to note that most products available only contain one type of cooling technology; either PCMs or ACCs.20

The application of ACCs and PCMs for purposes of reducing heat-related illness among workers remains under-researched. Therefore, the goal of this study was to begin exploring the potential value of providing garments with printed cooling technology to agricultural workers as a potential engineering tool for reducing elevated risk for heat-related illness. To achieve this goal, this study sought to determine if adding a proprietary printed cooling finish on the back side of a short sleeve, synthetic t-shirt significantly improves the thermal comfort of agricultural workers.

Participants

This research was conducted by recruiting active male agricultural workers who had been working for at least a week. Participants were at least 18 and all participants were required to use the assigned clothing (t-shirt) and measurement instrumentation every day as instructed for the duration of the study. Twenty migrant, male, agricultural workers (age: 27±6.5years) were assessed during an eight-day field study near Valdosta, GA during the month of July. All subjects volunteered to participate in this study which was approved by the local research institution’s Institutional Review Board (IRB). All participants held an H-2A visa, 85% self-identified as Hispanic or Latino, and 100% spoke Spanish as their primary language. Therefore, study materials (e.g., study information, instructions for clothing, and data collection) were translated into Spanish. The research team members performing recruitment and data collection were native Spanish-speakers who regularly worked in research roles within the farming operations of the study location. Before obtaining informed consent, all study procedures and potential risks were explained to participants verbally and provided in written form. Once the subject agreed to participate in the study their shirt size was recorded, and they proceeded to complete an initial information collection survey.

Test garments

As most of the heat loss during exercise under hot, humid environmental conditions occurs in the upper extremity, regardless of gender, a shirt was chosen as the test garment for this study.20 Two 100% polyester t-shirts (control and cooling) were commercially manufactured utilizing the same pattern and design. The proprietary active cooling finish applied to the back, or skin, side of the cooling t-shirt was comprised of an encapsulated printed phase change material (PCM) (Figure 1).20 This finish also contained other active cooling agents, in addition to the PCM, creating a multistage cooling effect rather than relying on the PCM cooling mechanism alone. A microprinting technique was used to apply the cooling finish, which was the same color as the t-shirt. The print, which contains the cooling components, accounts for roughly 30% of the inner surface of the garment. The PCM utilized within the printed finish had a melting temperature between 26 and 32ºC and a latent heat fusion between 100 and 200J/g. The above fabrication resulted in two shirts that were identical in appearance, therefore, participants were not given any information regarding potential differences between the shirts. In addition to the above t-shirt, participants wore their own pants, socks, and shoes for the eight-day duration of the field study, all typical garments that they would normally wear during the summer crop season. Upon assignment of their first t-shirt, a member of the research team performed a fit check to ensure the shirt fit each participant in an appropriate manner (snug but not tight or overly loose fitting).

Figure 1 Inside view of the cooling shirt (left) with the printed active cooling finish on the back side of the fabric and the control shirt (right) without the printed finish.

Following the fitting, the t-shirts (control and printed) were randomly assigned to each participant for each of the eight days. At the end of each day, all t-shirts were collected by the research staff and were laundered together in a single load in the same residential washer and dryer, with the same detergent, for the entire study. Recommended care instructions were followed as the garments were washed on a normal cold cycle with a common liquid laundry detergent and tumble dried on low. After removal from the dryer, the shirts were folded neatly and placed in each participant’s bag along with their participant code and measurement instrumentation for the following day. In total, seven laundry cycles were completed during the duration of the trial (after day 1 through day 8).

Experimental conditions

Once recruited, each participant was assigned a unique study identification (1-20) and assigned to one of four groups, each group of five participants was case managed by one research staff member. T-shirt assignments were randomized such that participants wore the same shirt two days in a row before they were assigned the opposite t-shirt for an additional two days for a total of eight days. It should be noted that on the last day (day 8) of the trial, a longer daily exit survey was issued. The first four trial days were conducted consecutively followed by a four day break due to the weekend and inclement weather, after which the last four trial days were also conducted consecutively.

Measurements

Following enrollment, a baseline assessment was obtained via an interviewer-administered survey questionnaire. The baseline assessment collected participants’ age, sex, ethnicity, primary language, housing accommodations, laundering practices, agricultural work experience, and history of heat related illness. Participants were asked what work activities they routinely perform, along with the amount of time (hours) spent performing each activity. Their selection of work clothing and garment replacement frequency was also recorded.

Thermal comfort data were collected each trial day through an end-of-day interviewer-administered brief survey questionnaire. The daily survey measured perceived upper body comfort by asking, “How did you perceive your upper body comfort today?” with response options including “comfortable,” “slightly uncomfortable,” “uncomfortable,” “very uncomfortable,” and “extremely uncomfortable.” A separate question asked, “How did you perceive your upper body temperature today?” with response options ranging from “very hot” (+4) to “neutral” (0) to “very cold” (-4).29 Each workday, participants were asked “How hard was your work today?” with responses ranging from “extremely light” (2) to “extremely hard” (14). Participants were also asked to rate additional sensations of stickiness and clinginess.

Environmental conditions (dry and wet-bulb temperature, dew point, and humidity) were harvested from the nearest National Weather Service location for each day of the study. The maximum dry- and wet-bulb temperatures across the eight-day study period were 34.0°C (93.2° F) and 26.7°C (80.1°F), respectively. The maximum dew point was 25.0 and relative humidity was 98%.

Statistical analysis

Collected data were entered, cleaned, and prepared for analysis. Simple univariate statistics were calculated, and bivariate figures were created using Microsoft Excel. Each participant completed multiple end-of-day surveys resulting in “clustered” data that violate the assumption of independence among observations. Multivariate hierarchical linear models were fit for each dependent variable (i.e., perceived comfort, perceived body temperature) using SPSS version 27 to accommodate non-independence in the data. The main independent variable was the shirt worn, effect coded such that the control t-shirt was coded -1 and the PCM printed t-shirt was coded 1. Models also included the trail day, weather conditions, and the perceived hardness of the work performed.

Descriptives from the baseline assessment

All participants (N=20) were male and reported working in U.S. agriculture between one to 18 years. All participants had worked in the southeastern region of the U.S. (Georgia, Florida, or a nearby state) for more than four weeks before enrollment in the study suggesting likely acclimatization to the environment. Dominant crops worked in during the study were cucumbers and chili peppers.

Participants reported working 5 (75%) to 6 (25%) days per week, and 7-10 hours per day, on average. During their workday, all participants indicated they had access to regular breaks, a lunch break, and drinking water. However, only 55% reported having access to shade during the workday if they felt the need to take a break to cool down or were experiencing heat related illness symptoms.

In terms of physical activity performed, all participants indicated they spent most of the workday (6.5-8 hours) walking. Nearly all workers (80%) reported their work required bending over for 7-9 hours per day, while 70% reporting clipping and using hand tools 7-10 hours a day. There was more variation in reported lifting during the workday; about two-thirds reported any lifting, with some reporting as few as two hours per day and others reporting lifting 10 hours per day. About half the workers reported having to perform work overhead, and those overhead tasks were performed 8 – 10 hours per day. About one-quarter of workers reported spending 8-9 hours per day in the squatting position. All the above activities are performed outside, with participants reporting working directly in the sun 6.5-10 hours per workday.

All participants, as H-2A visa-holders, lived in grower-provided housing in either an apartment (25%) or dormitory/barracks (75%). About one-third of participants (35%) indicated having access to a residential clothes washer. None had access to a residential electric or gas dryer meaning all clothes would require line or flat drying. Nearly all participants (95%) indicated having access to running water, while 75% had access to a bath or shower in their housing area.

In relation to work clothing, 65% reported the shirts typically worn before the trial bothered them while working. Nearly all participants (90%) reported wearing loose, lightweight clothing, 85% reported wearing long pants, and 75% reported wearing a long-sleeved shirt underneath or overtop of a t-shirt or undershirt. Wearing long pants and long-sleeved shirts are recommended for preventing pesticide exposure as part of mandatory training required by the Environmental Protection Agency’s Worker Protection Standard. However, 75% reported removing their shirt (presumably the long-sleeved shirt) due to heat. Less than half of the participants (45%) wore a wide-brimmed hat. Almost all (17/20; 85%) responded there was a need for special work clothing for their agricultural occupation. The number one reason participants indicated they would wear specific work clothing was to “feel more comfortable” (53%) followed by to “prevent sunburn” 21% and to “improve work efficiency” (15%). In relation to what migrant agricultural workers would pay for such special work clothing, the most frequent response was in the $11-$20 range (27%) followed by $21-$30 (24%) and $31-$40 (21%) at the beginning of the study, prior to wearing the control and printed PCM t-shirts.

Subjective thermal comfort of agricultural workers

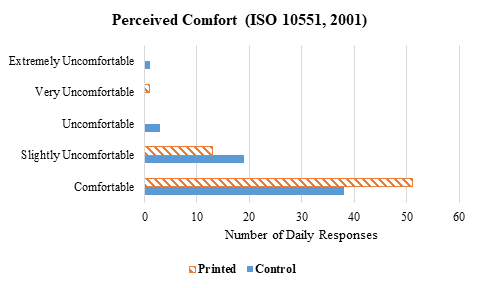

Across the twenty participants, the control t-shirt was worn 62 days and the PCM printed t-shirt was worn 64 days with variation attributed to inclement weather, participant illness, and other uncontrollable factors inherent to performing a field study. For perceived exertion, more participants rated their work as “light” when wearing the printed shirt. Simple bivariate comparison also suggests participants found the printed t-shirt with PCMs and ACCs to be more comfortable (79.7%) compared to the control t-shirt (62.3%) (Figure 2). Similarly, 31.2% of participants found the control t-shirt to be “slightly uncomfortable” while only 18.6% of participants reported the printed t-shirt to be “slightly uncomfortable.”

Figure 2 Number of responses indicating perceived comfort rating of each shirt type (control (solid) and printed (striped)).

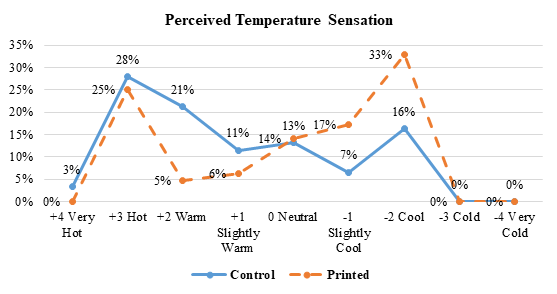

Similarly, bivariate comparison of response to the ISO 10551 (1995) temperature sensation scale suggested differences by shirt type (Figure 3). The printed t-shirt had lower ratings of warmth and higher ratings of coolness as compared to the control t-shirt.

Figure 3 Average perceived temperature sensation ratings for the control t-shirt (solid line) versus the printed t-shirt (dashed line).

Results from multivariate analyses accommodating non-independence in the data and adjusting for meaning covariates like daily variation in wet-bulb temperatures and dew point largely reproduce the results of the bivariate comparisons (Table 1). Participants’ perceived comfort was 0.22 units lower on days the control shirt was worn relative to days when the printed shirt was worn. The univariate standard deviation across all days of the trial was 0.65, indicating a small-to-medium sized effect (Cohen’s d, 0.22/0.65 = 0.34). Participants’ temperature sensation rating was 1.08 units warmer on days the control shirt was worn relative to days when the printed shirt was worn. The univariate standard deviation across all days of the trial was 2.01, indicating a medium sized effect (Cohen’s d, 1.08/2.01 = 0.54).

|

Perceived comfort |

Temperature sensation rating |

||

b |

SE |

b |

SE |

|

Intercept |

2.39 |

2.8 |

10.95 |

8.51 |

T-Shirt Worn |

||||

Printed |

Ref |

Ref |

Ref |

Ref |

Control |

-0.22 |

0.12† |

-1.08 |

0.36** |

Study Day |

-0.03 |

0.04 |

-0.13 |

0.11 |

Perceived Exertion at Work |

0 |

0.03 |

-0.08 |

0.08 |

Wet-Bulb Temperature |

0.27 |

0.10** |

-0.07 |

0.3 |

Dew Point |

-0.19 |

0.09* |

-0.14 |

0.28 |

Table 1 Estimated differences in perceived comfort and temperature sensation ratings by agricultural workers depending on type of shirt worn

† p = 0.06 * p < 0.05 ** p < 0.01

Bivariate comparisons of the control t-shirt had higher frequencies of all day clinginess and warmth while the printed t-shirt had the highest “all day” rating for stickiness. Frequencies for “never” experiencing these sensations were greatest for the control t-shirt in terms of stickiness and clinginess whereas the printed t-shirt had higher ratings of “never” experiencing warmth.

Overall cooling technology perceptions

On the last day of the study (day 8) participants were not able to perform regular agricultural work duties, despite donning the t-shirt, due to inclement weather. At the end of day 8, participants were given the final study exit survey and asked about the value of the t-shirts, if they bothered them while working, and if they would wear the t-shirts in this study to feel more comfortable, improve work efficiency, prevent sunburn, and prevent soiling. 85% of participants (17/20) reported the shirts in the study did not bother them.

When asked if they would “wear work clothing that improved your comfort and safety if it cost” and then provided a range of prices, the most frequently selected price range was $41-$50 (21%; 8/20 participants). 15.79% of participants (6/20) equally checked the $1-$10, $11-$20, $21-$30, and $31-$40 price ranges. Participants were asked to select all price ranges that they would be willing to pay for such a garment. Two participants even indicated they would pay $61-$70 with a single participant also reporting they would pay $71-$80 and even $81-$90 for comfort enhancing protective clothing.

Finally, 37.8% of participants indicated they would wear the shirts in this study to “feel more comfortable” with 26.7% reporting they would also wear these shirts to “prevent sunburn.” 20% reported they would wear the shirts to improve their “work efficiency” with only 6.7% reporting they would wear them for “preventing entry from outside dirt”.

The overall goal of this study was to explore the potential value of providing garments with printed cooling technology to agricultural workers as a potential engineering tool for reducing elevated risk for heat-related illness. This goal is motivated by substantial evidence that agricultural workers are particularly vulnerable to heat-related illness. Indeed, evidence suggests that field agricultural works are four-times more likely than other occupations to report a heat-related illness8 and over 20-times more likely to die from extreme heat.9

This is the first study to document the potential value of personal protective clothing (PPC) for agricultural workers. In this real-world field study conducted under high heat and humidity conditions, farmworkers reported greater perceived comfort and cooler perceived temperatures on days they wore t-shirts with printed cooling technology compared to control shirts of the same fabric without cooling technology. Importantly, the results held after statistical adjustment for environmental weather conditions. These results are consistent with a previous study of construction workers indicating that wearing a uniform with printed cooling technology alleviated heat strain and improved comfort.26 Our results mimic those of Choi and Ashdown12 suggesting agricultural workers’ clothes are perceived as being uncomfortable and interfering with productivity. However, our results extend this work by suggesting that worker comfort can be enhanced by providing clothing with printed cooling technology, and that comfort may result in greater efficiency and productivity.

Interestingly, stickiness and clinginess were rated as occurring more frequently for “some of the day” for the printed t-shirt. These results are likely due to the surface texture of the printed finish on the back side of the fabric which may increase friction with the skin causing sensations of clinginess and stickiness throughout the day. While these perceptions of thermal comfort may be negative if viewed independently, the frequent contact of the finish with the wearer’s skin would increase the ability of the PCM and ACC technologies to effectively cool the wearer, which is evidenced by the perceived temperature sensation and other thermal comfort ratings.

Given the field study nature of this experiment, the limitations due to uncontrollable environmental conditions (temperature, humidity, wind, etc.), weather, and work conditions (various exercise types and rates; work cancellations) should be considered when analyzing and interpreting the results of this research. While field trials may pose unique challenges, they provide the most accurate and realistic data available, beyond a controlled laboratory setting.31

This field study is the first of its kind to demonstrate enhanced wearer comfort for the agricultural end user when donning clothing with active cooling technology, including PCMs, under hot and humid use conditions. Future research should include the measurement of direct physiological responses including intestinal core temperature, mean skin temperature, sweat rate, and heart rate. Additional types of PPC should be explored including lower body garments to assess the impact when cooling a larger surface area of the body. The incorporation of ultraviolet protection should also be considered while maintaining affordability and accessibility to the migrant worker population.

None.

None.

Author declares there is no conflict of interest in publishing the article.

©2023 McQuerry, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.