Journal of

eISSN: 2574-8114

Research Article Volume 7 Issue 2

1Department of Fashion Design and Textiles Studies, Tamale Technical, Ghana

2Kwame Nkrumah University of Science and Technology, Ghana

Correspondence: Samuel kwabena Donkor, Department of Fashion Design and Textiles Studies, Tamale Technical, Ghana

Received: March 14, 2021 | Published: April 20, 2021

Citation: Donkor SK, Asmah AE, Ocran I. Formulation of an organic solution for odour removal in rubber-gum resist technique. J Textile Eng Fashion Technol. 2021;7(2):62-69. DOI: 10.15406/jteft.2021.07.00269

The rubber-gum resist technique is a modern fabric colouration technique in the world of resisting fabric dyeing production. This innovative technique is an improvement upon the wax-resist method which makes use of polyvinyl acetate, latex and ammonia as constituents of its resist agent. The rubber-gum resist technique which provides a good printable effect in design registration also has an excellent advantage in rendering complex or minute details of a design with less difficulty. The setback of this technique which happens to be the challenge at the degumming stage factored into the choice of research design in the execution of the project. A series of explorations were conducted using organic fruit juices for the formulation of the solution that can remove the unpleasant smell from the dyed product as a result of the use of turpentine in the degumming process. The study adopted the qualitative research method which employed the descriptive and exploratory research design. The scope of the study covered the local rubber gum resist dyeing producers in the Kumasi metropolis. The findings of the explorations conducted have proven that the major challenge in the rubber-gum resist technique which happens to be the unpleasant smell deposited in the fabric due to the degumming process has been resolved using organic fruit juices. For the rubber-gum resist technique to live in the limelight, it is recommended that the results of this study should be incorporated into the practice of the rubber-gum resist technique in Ghana. Also, the introduction of resist fabric-dyeing art educational curriculum should make it a point to include the rubber-gum resist technique at the senior high schools through to the tertiary level to promote the practice of this innovative art discipline. Fusing this innovative technique into our textile educational system will help students to explore and gain much knowledge in the practice of the rubber-gum resist technique and will also serve as a source of employment.

Keywords: polyvinyl acetate (PVA), proof spirit, rubber-gum, turpentine, fruit juice

Resist fabric dyeing technique is only one old fabric colouration technique practised in most parts of the world. The history of resist dyeing and how long this method of fabric decoration technique has been in existence is very difficult to determine with accuracy (Klima, 1996). During the days of the early man (Prehistoric era), mud and other extractions from plants (starch) and animals (fats) were mainly used as resist agents for dyeing clothing (Yansa, 2004). After civilization, resist fabric dyeing produced other forms of innovative resist agents such as chemical, stencil, Kanto technique, rice paste, paraffin or bee wax and now the rubber-gum resist technique.

The rubber-gum resist technique which employs the use of an alternative resist agent other than the use of molten wax. This resist-dyeing technique makes use of latex (Para rubber), PVA and Ammonia solution as constituted of the innovative resist material. The latex material serves as a binder, the PVA material acts as a thickener and the introduction of the ammonia solution acts as an agent that prevents the latex material from coagulating when harvested. The major setback in employing the rubber-gum resist dyeing technique is the unpleasant smell deposited in the fabric during degumming. Under the wax method, hot boiling water is used in removing the wax from the fabric hence termed dewaxing. After the fabric has been gummed (application of resist material on fabric) under the rubber-gum resist technique, the gum needs to be removed from the fabric to make the positive area of the design visible and this process is termed degumming. The degumming agent used for the removal of the gum is turpentine. The gummed fabric is soaked in the turpentine solution for 20 minutes to weaken the adhesion power between the resist agent. This action subjects the fabric to an unpleasant smell that remains in the fabric for a very long period. Rubber-gum resist dyeing practitioners find it extremely difficult to continue with the practice due to this impediment and that was the justification for embarking on the study.

Resist dyeing is a fabric colouration technique that has been in use since ancient times. Eurasia and Africans in most parts of the globe practised different types of resist fabric-dyeing. Traces of resist dyeing impressions were discovered on the linen fabrics which were used in wrapping Egyptian mummies during the ancient period. Linen fabrics (predominantly linen) were coated with molten wax, scratched on the surfaces with a sharp tool and dyed with blood and ashes to create design impressions on the fabric by the ancient Egyptians (Farrer, 2011).

It was first also practised in other parts of Africa by the Yoruba tribe of Nigeria and the ‘Soninkes’ of Senegal. The ‘Yurobas’ used cassava paste as a resist medium for their works while in Senegal, the Soninke and Wolof tribes employed the use of rice paste as a resist medium because the cultivation of rice farmers was predominantly the main farming been practised in the two respective towns.

Asia and other parts of Europe employed the use of rice paste and wax for their works. There are many branches of resist dyeing practised all over the world through the technique which involves the use of molten wax is mostly used.

Under resist fabric-dyeing, there are various forms of resisting agents employed. These resist agents obtained are from natural and artificial sources. The various types of resist agents are namely raffia, starches (rice, corn and cassava), bee wax, synthetic glue resist agents, synthetic ropes, Clamp resist agents, paraffin wax resist agent, the rubber gum resist agent mud resist agent etc

Asmah et al.,1 affirmed that the rubber-gum resist agent constitute three respective proportions of materials; latex, ammonia and polyvinyl acetate. The latex material is obtained by making incisions on a matured rubber tree and collecting the milky solution. The milky solution tends to coagulate when exposed to air after a while. To prevent the latex material from coagulating, ammonia is introduced in the solution. The ammonia solution prevents latex material from coagulating, in that; it maintains raw material in its liquid state. The ammonia solution tends to neutralize the lactic acid secreted by bacteria when they attack the protein-membrane and this keeps the rubber particle negatively charged. The addition of polyvinyl acetate helps to slightly thicken the solution in a paste form to make printing less stressful.

According to Hargreaves (2003), an organic formulation can be traced back to Stone Age times, when hunter-gatherers attached flint arrowheads to shafts using a resin made from birch bark and beeswax. Today, formulated preparations are part of everyday life. Formulations based on surfactants are by far the most prolific, from shampoos and shower gels to emulsion paint and polishes. Young (2013) further explained that Formulation chemistry is the mixing of compounds or substances that do not react with each other but produce a mixture with the desired characteristics/ properties to suit a particular application or use. Many modern products contain a combination of several organic substances, each contributing an advantage to the finished product for a particular application. Any developed product must be commercially viable. A broad range of useful household products is the result of the science of organic formulations. Since no reactions happen in making the mixture, most formulations are prepared by measuring liquids by volume and solids by mass (weight).

This paper seeks to explore with organic juices to produce an organic solution to remove the odour deposited in the dyed fabric after degumming. The solution produced will help encourage and expand the practice of the rubber-gum resist technique since this challenge deters consumers from purchasing its products. The results of the study will serve as an innovative organic solution for the rubber-gum resist technique.

The research methodology employed for the study helped the researcher to conduct a series of explorations for data collection. The study employed the art studio-based research under the qualitative research which delved deep into the descriptive and exploratory research approach. The results of the explorations conducted were carefully documented and analysed before certain conclusions were drawn. The population for the study was carefully selected out of the larger population to be measured. Some rubber-gum resist practitioners selected were randomly sampled out of the larger population. Members selected for the study share the same characteristics of the larger population and can be said as a true representation of the population which will ensure that the findings of the investigation of the research can be generalized. The purposive sampling technique was used in selecting the materials for the study.

The material used for the study were proof spirit, latex, ammonia solution, lime fruit juice, cashew fruit juice, dyes, sodium hydrosulphite, sodium hydroxide, fabric and natural rose essential oil. Some of the tools and equipment employed by the researcher for the study was a printing and waxing table, a developed screen, squeegee, a measuring cup and some of the basic tools needed during dyeing(gloves, basins, apron to mention but a few).

Preparation of organic solution

Haven successfully executed all the dyed fabrics; the prime objective of the study was to formulate an organic solution for rubber gum resist fabric dyeing production. Some of the pertinent challenges which this resist fabric-dyeing technique presents are many but the researcher deemed it necessary to address the major challenge at the degumming stage where the dyed fabric produced is subjected to a noxious smell due to the degumming agent used. Preliminary explorations were conducted with organic fruit extracts for the formulation of an innovative organic solution for the rubber-gum resist technique. Some findings discovered out of the series of tests conducted revealed to the researcher that, juice extracts from lime, palm tree and cashew all gave awful results when they were applied respectively to sample fabric. Out of this development, the researcher also combined these fruit extracts to test their efficacy as agents in addressing this pertinent challenge discussed in objective one. The findings of the second phase of the tests revealed that the mixture of proof spirit, lime juice and naphthalene balls produced good results. After this revelation, the researcher decided to test the findings discovered on commercial packages of fabric.

For this study, a total of 24 yards of calico fabric was used for different fabric designs for the project. Lime fruit measuring up to 4 kilograms was used in the preparation of the solution because, for every 6 yards of fabric, 1 kilogram of lime is required in the formation of the odour-remover solution. A proof spirit measuring up to 2 litres and 0.5 litres of organic rose essential oil were the constitutes of the organic solution. The introduction of the organic rose essential oil was very necessary to better the fragrance finish of the dyed fabric. Though the researcher employed the use of organic rose essential oil, other organic fragrances, perfumes and lavender can also be used (Figure 1) (Figure 2).

The lime (4 kilograms) is chopped and placed in a basin containing 3 litres of water. The basis for this procedure is to soften the peel and the pulp to make extraction of the lime juice very easy. This action helps retain or even add up to the volume of the juice in the lime fruit. After this process, the chopped lime fruit remains in the water for 2 hours for subsequent processing. The organic rose essential oil is added to the proof spirit and stirred repeatedly (Figure 3).

Water quantity measuring up to 15 litres is added to the chopped lime fruits (Figure 4). This quantity of water is required because of the number of fabrics used for the study (Figure 5). The solution containing the organic rose essential oil and the proof spirit is poured into the chopped lime fruit solution.

Haven successfully mixed the two solutions; the solution is covered for up to an hour for a chemical reaction to take place between the acid and alcohol in the solution. After 1 hour,

The chopped lime fruit is squeezed into the solution and the waste material is disposed of (Figure 6) (Figure 7).

A mesh strainer was used in separating the pulp substances from the liquid and the solution is finally ready for the odour-removal process (Figure 8). These substances need to be taken out of the solution because they will dirty the fabric and might require additional working processes to get rid of them.

Odour removal process

This is the process of eliminating the unpleasant smell in the dyed fabric due to the use of turpentine solvent employed for degumming. The solution produced has a greater concentration of weak organic acid and alcohol. The researcher divided the odour-remover solution into two different containers for this process due to the number of dyed fabrics produced for the study. The main reason is to separate the darker coloured fabrics from the lighter coloured dyed fabrics because newly produced dyed fabrics still contain excess dyes on them which tends to run-off during washing.

The fabrics are immersed in their respective solutions for 20 minutes and after, they are thoroughly rinsed in the odour-remover solution before drying (Figure 9) (Figure 10). When taken out of the solution, the fabrics are dried directly without rinsing them in cold water and the reasons are that the odour-remover solution must fully dry with the fabric. During the drying process, the heat produced by the sun rays causes a reaction between the organic solution and the fabric. The heat and air needed for the drying process assist the chemical solution in eliminating the bacteria that causes the smell hence neutralize the unpleasant smell on the fabric.

The fabric is washed in soapy water after drying and finally rinsed in cold water and dried again to finish the process (Figure 11) (Table 1).

Fabric quantity |

Lime fruit(kg) |

Proof spirit (Ltr) |

Organic rose essential oil (ltr) |

Quantity of water |

3 yards of dyed fabric |

0.5kilograms |

0.5litre |

0.5litre |

3litres |

6 yards of fabric |

1kilogram |

1litre |

0.5litre |

6litres |

1 piece of dyed fabric |

2kilograms |

1litre |

1litre |

12litres |

Table 1 Solution ratio for different quantities of dyed fabric

This aspect of the paper discusses the initial explorations conducted by the researcher for the formulation of the innovative organic solution. It also throws more light on the generation and presentation of the data collected for the study and an interpretation of the findings. The main purpose of the study, however, was to produce an organic solution with natural fruit extracts to curb a pertinent challenge under the rubber-gum resist technique. The explorations conducted produced results which this study seeks to establish.

Exploration with proof spirit

The proof spirit which contains good concentration ethanol content was used in conducting the first exploration. The essence of this exploration was to use a higher percentage of alcohol to eliminate the micro-organism (Bacteria) that causes the unpleasant smell on the degummed fabric piece. The dyed fabric piece was soaked in the distilled organic alcohol liquor for 15 minutes. The results of this test revealed that, when the fabric is removed from the proof spirit solution, there is a proper fixation of the dyes on the textile and also the colours became brighter. Fixation of dyes on the finished dyed products happens to be only one great challenge since most of the dyes sold on the market show poor wash fastness properties due to the washing of the textile. The researcher also discovered that the ethanol content in the proof material pushes the dye molecule to remain in the pores of the fabric even though other research studies gave contrary results. The unpleasant smell in the fabric seems to be eliminated during the initial stage of the removal from the solution (Proof spirit), but after oxidation, the noxious smell produced by the turpentine solvent remains present in the textile after this action.

The test conducted shows that the micro-organisms that act on the fabric when soaked in the turpentine solvent are not eliminated by the alcohol power of the proof spirit material because, the chemical strength which comprises petrol, kerosene and thinner of the turpentine material cannot be removed by the high concentration of alcohol, hence, remain in the textile. The results of this test proved to be ineffective after which the fabric was dried and the researcher proceeded to conduct the second test.

Exploration with lime juice

The researcher conducted this exploration to test the efficacy of lime juice in removing the unpleasant smell deposited in the fabric due to the degumming process of the rubber-gum resist technique. The lime fruit has good triprotic acid contents in them and these acids are weak organic acids that cannot destroy the fabric when they come into contact.

Haven successfully conducted this test, the results clearly showed that this weak organic acid had a good property in killing the bacteria that cause the unpleasant smell on the fabric and serves as a preservative in many cleaning solutions. It must also be said that the mild smell of the lime juice also remained on the fabric after oxidation (after which the fabric was left to dry).

The result of this test was partially successful because the mild smell of the lime juice replaced the noxious smell of the turpentine solvent but couldn't fully resolve the main problem of the study. The researcher deemed it necessary to conduct another research using an organic fruit that has a higher pH level with a pleasant smell.

Exploration with cashew juice

Based on the findings of exploration two, there was the need for the researcher to conduct another exploration with the cashew fruit juice. Cashew fruits have ascorbic acid contents which have a higher pH level compared to lime juice.

The results of this test confirmed that, due to the high pH level of cashew fruit juice, the ascorbic acid contents in them were weak and couldn't remove the unpleasant smell of the fabric. After oxidation, the bad smell of the turpentine solvent remained present in the fabric even after subjecting it to thorough washing with soap. Another observation made was that, the cashew juice is somewhat astringent due to its tannin content, hence, causes a stain in fabrics. These stains were not too visible because of the colouration of the fabric. The researcher classified this exploration as unsuccessful and proceeded to conduct test four.

Exploration with mixed cashew and lime juice

The fourth exploration was conducted using cashew and lime juice. The researcher deemed it necessary to conduct exploration with a compound of lime and cashew juice. The test was conducted to test the usefulness of the chemical compound.

The findings gathered after this test was conducted gave awful results. The presence of the cashew juice content in the solution rather weakened the strength of the lime juice and rendered the whole solution ineffective. The pH level of the fruit juice of lime can reduce (Higher pH value) if diluted with a compound that has a higher pH level. The cashew juice has a higher pH level of 4.0-4.5 and tends to reduce the nitrogen ion content in lime juice. This test was also unsuccessful because the acidic level of the lime fruit juice which performed quite better in test two had its ph value increased and rendered not effective due to the mixture of cashew fruit juice.

The fabric sample used for conducting this test still contained an unpleasant smell even after oxidation had taken place.

Exploration with proof spirit and lime juice

The final exploration was a mixture of the proof spirit material and the lime juice. The researcher conducted this exploration to test the efficacy of alcohol and citric acid solution for the removal of the unpleasant smell in the textile (fabric). Alcohol and lime fruits are household materials used for disinfection and the removal of odour on even human and other things. Some of the observations made in the first and second exploration conducted showed that the proof spirit material has the organic potency to open the pores of the fabric but failed to remove the unpleasant smell. On the other hand, the lime juice also removed the unpleasant smell to an extent but the juice did not possess the organic strength to open the pores of the fabric and fully remove the unpleasant smell. The initial exploration conducted also revealed that when the lime juice comes in contact with the fabric, it leaves an extreme lime fragrance in the fabric because of the lime peels. Lime peels contain oils that are a bit yellowish when extracted, and this compound adds up as a constituent in the solution. After this development, the researcher employed the use of an organic rose essential oil to the solution to better the fragrance finish of the dyed product.

After the fabric was soaked in the solution for 20 minutes, removed and given an appropriate time to dry, it was observed that the alcohol in the solution acted as a catalyst to speed up the reaction and cause some form of agitation for the citric acid in the lime juice to force its way into the pores of the fabric to eliminate the scent. Dye colours on the fabric remained brighter and were well fixed. A further observation was that, after the fabric was finally washed in soapy water to remove the excess compounds deposited on the face of the fabric after drying, the unpleasant smell deposited on the fabric due to the degumming process was fully purged.

Testing the efficacy of the organic solution by the rubber-gum resist fabric-dyeing practitioners

The researcher deemed this exercise very important because the innovative material produced must be tested by rubber-gum resist fabric-dyeing practitioners sampled for the study. The prime objective of this activity was to test the efficacy of the formulated organic solution, its effect on the textile and the colourant (dyes). Sample quantities of the newly formulated organic solution were given to the population sampled for the study, graduates of the industrial arts department (KNUST), rubber-gum resist practitioners who have attained a senior high school certificate and small scale rubber-gum resist practitioners who are uneducated but learnt the craft through apprenticeship.

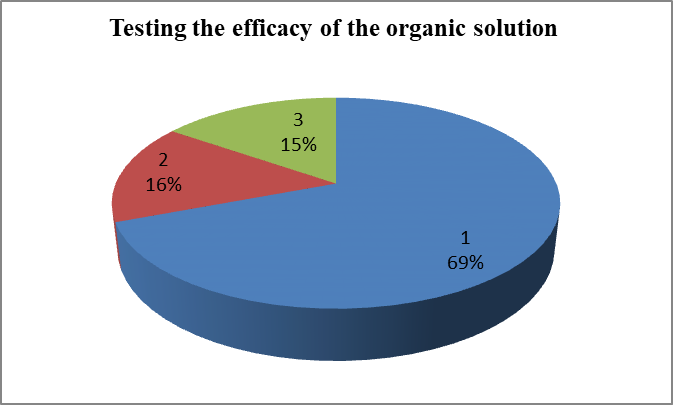

Figure 12 indicates the respective inputs made by the graduates of the industrial arts department after testing the effectiveness of the innovative organic solution produced by the researcher. The population size of rubber-gum resist fabric-dyeing practitioners sampled for the study constituted 13 practitioners, where 8 out of the 13 persons which constitute 62% of the population clearly stated that the innovative organic solution is a highly effective material. They also explained that the formulated organic solution completely removes the pungent smell deposited into the fabric during the degumming stage. They further asserted that the washing properties of the dyes in the fabric retained the colour, in that; the dyes did not fade out after being washed in the organic solution. The practitioners who constituted 16% (3 persons) and 15% (2 persons) of this sampled group were much interested in the colour fastness of the dyed fabric when in and out of the organic solution. They stated emphatically that, colour fastness to rubbing of the dyed fabric in a solution is the main test that is always required for every coloured fabric when it comes in contact with a chemical solution. The test revealed that the formulated solution does not remove or causes the dyed colourants on the fabric to run-off. They concluded that the innovative organic solution is a very good material and will help improve the rubber-gum resist technique.

Figure 12 Testing the efficacy of the organic solution (Graduates of the industrial arts department, KNUST). (Source: Researcher 2021).

The small scale practitioners who were classified in group 2 as senior high school graduates who practise the rubber-gum resist process also tested the newly formulated solution and made significant inputs for the success of the study. This second group constituted 20 rubber-gum fabric-dyeing practitioners who conducted the tests in their respective studios. The procedure for the formulation of the organic solution was given out to the practitioners by the researcher and their inputs were recorded in percentages.

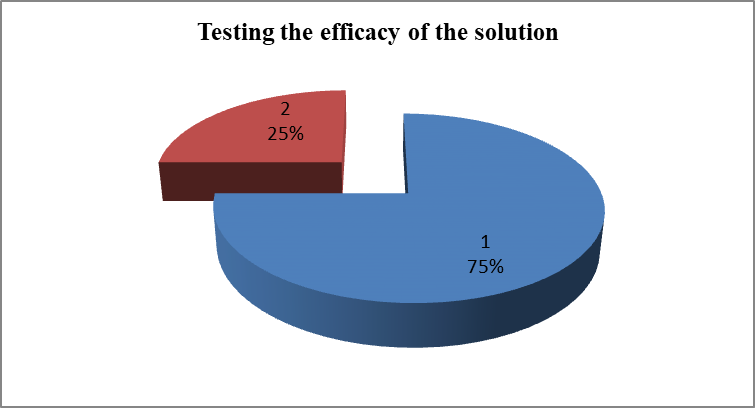

In Figure 13, the researcher employed the nominal response scale due to the level of education of this category of respondents. After conducting the test, 15 out of 20 practitioners who constitute 75% of the sampled population for this category asserted that the organic solution is very effective and completely removes the noxious smell in the fabric. They further explained that, aside from the pungent smell removal, other observations need to be established if the innovative organic material produced will not adversely affect the textile. Some of the respondents classified in this group gave one practical example that detergents (washing powder) cause dyes to run-off due to their chemical constitutes, hence the importance of this observation. The other 5 respondents who constitute 25% of the population stated emphatically that, the organic solution is a fairly effective material but can be bettered by other researchers who wish to embark on a related study. They further recommended that other researchers should explore organic fruit extracts to improve the innovative organic solution produced.

Figure 13 Testing the efficacy of the organic solution (Small scale practitioners who are senior high school graduates). (Source: Researcher 2021).

Testing the efficacy of the organic solution (small scale rubber-gum resist practitioners who are uneducated but learnt the craft through apprenticeship)

This category of respondents who constitute the least number of practitioners amongst the three groups also had a fair share of their inputs after testing the innovative organic solution. The 7 respondents who constitute 100% of the population sampled for the stratum 'C' revealed that the newly formulated solution is highly effective and eliminates the unpleasant smell deposited in the fabric after the degumming stage. Other aspects of the test which they treated with keen interest were the general outlook of the dye colourants on the textile after being treated in the organic solution. They discovered that the solution which contains ethanol and citric acid does not harm the textile or cause the dye colourants to run-off.1–40

The literature above clearly gives the researcher the conviction that the majority of the population sampled for this activity rated the organic solution as effective and can be employed to rectify the degumming problem. Per the inputs made by rubber-gum resist practitioners, dress designers and the product consumers, the researcher outlined the following recommendations;

The prime objective for this research study was to produce an innovative organic solution that can eliminate the unpleasant smell deposited in the fabric during the degumming process. The findings of the explorations conducted have proven that the major challenge in the rubber gum resist technique which happens to be the unpleasant smell deposited in the fabric due to the degumming process has been resolved. Even though the rubber gum resist technique has a great advantage in executing complex design patterns and design precision, some practitioners had to halt its practise due to the challenge encountered during the degumming stage. The formulated organic solution will help promote the practice of the rubber-gum resist technique in Ghana since some practitioner’s desert from its practise due to the challenge of the unpleasant smell in the finished product (dyed fabric). Interviews conducted in dyeing studios before the formulation of the organic solution clearly shows the relevance of the innovative organic solution in bettering the fragrance finish of dyed fabric products under the rubber gum resist technique. The variety of dyed fabric designs on the Ghanaian market will allow clients to select designs of their choice and this will go a long way to sustain the fabric dyeing business and provide local fabric dyeing practitioners with a good income to sustain their businesses since a touch of professionalism will be infused into the designs they produce. This will help check the problem of the importation of foreign fabric dyed products on the Ghanaian markets. The resultant products (dyed fabrics produced) which were used in producing different casual wears had a mark of professionalism in the fabric design since some fabric sellers doubted the results if they were truly rubber gum resist-dyed products. The precision in design and the transfer of design patterns with the aid of screens gave the end product unique results just like the imported dyed fabric products from Chinese manufacturers. With the inception of this innovative organic solution, indigenous fabric dyeing producers will employ the use of this solution to boost the rubber-gum resist dyeing business in Ghana.

Having critically observed the rubber gum batik process, the under listed recommendations have been made for consideration or implementation based on findings and results gathered in the studio investigations conducted.

None.

None.

Author’s declares that there is no conflict of interest.

©2021 Donkor, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.