Journal of

eISSN: 2574-8114

Research Article Volume 8 Issue 4

1Clothing and Manufacturing Technology Department, Vocational High School of Technical Sciences, Uşak University, Turkey

2Department of Textile Engineering, Faculty of Engineering, Uşak University, Turkey

3Department of Textile Engineering, Faculty of Engineering, Ege University, Turkey

Correspondence: Nefise Gönül ŞENGÖZ, Department of Textile Engineering, Faculty of Engineering, Uşak University, Uşak – Turkey, Tel +905335698875

Received: July 18, 2022 | Published: August 8, 2022

Citation: Bağci G, Şengöz NG, Kurumer G. Apparel Design from Middle and West Anatolia Hand-Woven Fabrics. J Textile Eng Fashion Technol. 2022;8(4):100-112. DOI: 10.15406/jteft.2022.08.00307

All throughout history people did hand-weaving to provide fabric for clothing but much less in our time. Hand-woven fabrics possessing different properties were produced in every country and in every area. Especially in Turkey, hand-weaving had become an art in due time, had developed, and had gained importance in economy and culture. As a result of rapid industrialization, hand-woven fabrics are now facing expiring even they are tried to be produced limitedly in the world as well as in some areas of Turkey. In this research, hand-woven fabrics in the Middle and West Anatolia cities (Kastamonu, Tokat, Uşak, village of Buldan in Denizli) are studied. The physical, chemical and visual properties of these sample fabrics are tested to decide what kind of garment can be produced from them. It is aimed to supply hand-woven fabrics to industry, mainly in ready wear production, by designing apparel suitable to today’s needs and fashion, to assure a rise in interest in them leading to a need in hand-woven fabrics and to achieve an increase in production of them, to provide clues for ready-wear producer and the end user, to prevent the expiring of hand-woven fabrics, but to continue to add to economy, culture and labor.

Keywords: hand-woven, hand-weaving Anatolia, middle and West Anatolia, ready wear production, apparel, fabric properties, fabric construction, cotton

For 8500 years,1 people did hand-weaving to provide fabric for clothing. Hand-woven fabrics made up of different fibers like wool, cotton, linen, etc. and possessing different fabric properties like thickness, warp and weft densities, weight, etc. were produced in every country and in every area in the world. Especially in Turkey, hand-weaving had become an art, had developed since historical times and had gained importance in the country’s economy and culture. Unfortunately, as a result of rapid industrialization, hand-woven fabrics in Turkey are now facing expiring even they are somehow produced limitedly in some locations. In the world, hand-weaving is also decreasing but is still done locally. To support hand-weaving worldwide various research are processed on their history, cultural changes, fabric properties, and on even digital creation.2–5 The objective of this research is especially to supply hand-woven fabrics to industry, mainly in ready wear production (RWP), by designing apparel suitable to today’s needs and fashion, to assure a rise in interest in them leading to a need in hand-woven fabrics and to achieve an increase in production of them, to determine the physical, chemical and visual properties of hand-woven fabrics in order to decide what kind of garment to produce from them, to provide clues for ready-wear producer and the end user, to prevent the expiring of hand-woven fabrics, but to continue to add to economy, culture and labor of the country.

The hand-woven fabrics in the cities of, which were once famous with their hand-woven fabrics in Turkish history, Kastamonu, Tokat, Uşak, the village of Buldan in Denizli,6–8 which are located in the Middle and West Anatolia are studied in this research,. Fabric samples are collected from these locations, keeping in mind that they will be appropriate for RWP. Totally there are 90 hand-woven fabric samples which are all in different weaves and constructions. The purpose in production of these hand-woven samples are originally to be benefited as handkerchief, home textiles like table cloth, bedsheet, etc. but are used to produce apparel in this research. The physical, chemical and visual properties of these samples are tested to decide what kind of garment to be produced from them. To support this objective different apparel styles are designed for 60 of them according to today’s styles and fashion. Among them, collections including the aesthetic drawings, technical drawings, etc. are prepared for 30 samples, 11 of them are sewn and 10 is presented in this manuscript.9

Despite industrialization the art of hand-weaving keeps being an important component in Turkish cultural life. Hand-weaving is done in different areas of Turkey. Hand-woven fabrics have very many different kinds produced with different methods, designs, constructions, colors, etc. Some of the most known cities where hand-weaving is done are Amasya, Ankara, Balikesir, Bursa, Çankiri, Denizli, İzmir, Kastamonu, Uşak, Sivas, Tokat, and Trabzon. Hand-wovens are produced less nowadays compared to the past. Although in the past it was an economical facility of the family, today with the development of technology and rapid industrialization, hand-weaving decreased and even started to expire. From this point of view, it is aimed to increase the interest in hand-woven fabrics, to suffice the needs in production and needs in fashion of apparel sewn from them in order to be convenient in RWP industry, to expand this art now and in the future, to prevent this rich culture from expiring, and to add to the country’s economy.9

Nowadays, hand-woven fabrics are partially used in home textiles and decoration like curtains, bedsheets, table cloths, rugs, kilims, etc. (Figure 1). In some locations, they are also used as underwear and outerwear. Since they are not economical, people do hand-weaving as a hobby or extra income for their homes, this leads to expiring of hand-woven fabrics specifically in Turkey and all over the world.

Locations studied in this research

In this research, hand-woven fabrics from the cities of Kastamonu, Tokat, Uşak, and the village of Buldan in Denizli in Turkey are studied. Their locations are seen on the map of Turkey in Figure 2 with the arrows indicating those cities accordingly.

Being an important fabric property hand-woven fabrics have to be elastic in order to cover the human body. Besides, the spaces between the warp and weft yarn intersections of the fabric help to keep the human body cool by permiting air move easily through them. On the other hand different colors and various yarns like straight flush and stable viscose are used to enrich the fabrics. The aim of this research is to utilize the possible usage of hand-woven fabrics in RWP. Besides this general information, detailed information about each fabrics chosen from different cities is explained in the following section.

Buldan hand-woven fabrics

In Buldan hand-woven fabrics are produced in some small workshops. They are used as home textiles and as home decoration including bedsheets, bedcovers, handkerchiefs, bathrobes, towels,, curtains, kilims, etc. These products are both sold locally, in the country, and some also exported. In history, they were also used in the Ottoman palace. People who do hand-weaving are now around 65 years of age, can produce almost 3.5m/day, but unfortunately complain that there are very few youngsters interested in this job.6

Some different scenes from Buldan hand-weaving looms and fabrics woven in those looms are given in Figure 3.9 The location of village of Buldan in Denizli is indicated with an arrow in Figure 2.

Kastamonu hand-woven fabrics

In Kastamonu, until the middle of the 20th century, there were numerous hand looms which had supported the clothing needs of the Turkish Army during the Independence War 1918-1922. Even fifty years ago, there was a hand loom in every house in Kastamonu, but today they all have expired, consequently the Turkish government also tries to expand them with some new projects. Old people in the city wish to pass their knowledge about the different colors, designs, natural dyes, and dying methods used locally to the young ones but they encounter no or few interests from them.

Cotton is the most used fiber in the hand-woven fabrics of Kastamonu, besides wool, mohair, linen, hemp, etc. natural fibers are used few. These hand-woven fabrics are used as home textiles and as home decorations in many cases together with few inner and outer clothing having ornaments like embellishment, crochet, embroidery, needle work, etc.7

Some different scenes from Kastamonu hand-weaving looms and their fabrics are given in Figure 4.9 The location Kastamonu is indicated with an arrow in Figure 2.

Tokat hand-woven fabrics

In Tokat, there are ancient findings that there had been hand-weaving in historical times in this city. Additionally in the time of Ottoman Empire, fabrics hand-woven in Tokat were very valuable and demanded by everyone for any purpose.10 Those fabrics were mostly produced from cotton, wool and hemp natural fibers and afterwards dyed naturally. Those fabrics were mostly used as inner and outer clothing. Today, some people still wear dresses made of these hand-woven fabrics locally because they are visually desired by them privately. This special fabric is called "Kutnu". Kutnu fabric is a combination of sateen and 2/2 ribs weaves, staple viscose yarn as warp (which was silk in the past), and navy blue or black cotton yarn as weft. In some villages they even spin the yarn by hand.8,11

Two different pictures of Tokat hand-woven kutnu fabrics are given in Figure 5.9 The location of Tokat is indicated with an arrow in Figure 2.

Uşak hand-woven fabrics

In Uşak, hand-weaving is diminishing day by day. Just a small amount of fabrics are produced in a very few hand-looms there. Some kilim production is done in those hand-looms, but machine looms are substituting them more in due time. The municipality of Uşak builds up some projects and gives courses to increase these facilities of hand-weaving. Cotton yarns are used with some few wool yarns, hand-spun yarn is still traditionally common in this area.

Some different scenes from Uşak hand-weaving looms are given in Figure 6.9 The location of Uşak is indicated with an arrow in Figure 2.

In the scope of this research the cities mentioned above and more are visited and different kinds of hand-woven fabrics, in various weaves, construction, color, properties, are collected. These sample fabrics reached upto 90 pieces. These samples are chosen specifically because they are thought to be suitable for RWP. For 60 of these sample fabrics apparel styles are drawn accordingly to today’s fashion and needs for young ladies’ summer dresses; for 30 of the 60 samples, a collection ready to be practiced in RWP is prepared. 11 of the 30 are studied with all the aesthetic drawings technical drawing, patterns, style definitions, piece lists, material needs, production line, cost tables, fabric analysis, design analysis, etc. and are sewn by the researcher herself. Style number and name is given to each of them. The physical, chemical, and visual properties of the fabrics and construction parameters are tested. 10 of them are presented in this manuscript.

Hand-woven fabrics are collected carefully, keeping in mind apparel production, taking into consideration mainly the formability, softness, elasticity, and thickness paremeters. On the other hand some fabrics are plain, some have designs, some are printed, some are loose woven, some tough. The pictures of the sample fabrics are given in Section 4.

Physical properties and construction parameters

The physical properties and construction parameters which are important from the view of the ready-wear producer are raw material, warp and weft density, fabric width, number of the total warp yarns, warp and weft twist, reed width and no., kind of the weave, weave report, warp and weft yarn count and weight of fabric, warp and weft yarn color report, warp and weft shrinkages (done according to Turkish Standards Institution (TSE) TSE 4073/Dec.1983 and TSE 392/April 1991). Other than these, warp and weft breaking strength and breaking elongation tests (tensile tests) of the fabrics are done according to TSE 253, yarn twist tests are done according to TSE 247, and washing fastness tests are done according to TSE 396/Oct.1989.

The results of these tests are given briefly below:

Fabric width: 49–108cm, Warp breaking strength: 196.92–539.76N

Reed width: 90.3–113.8cm, Warp breaking elongation: %14–%44.5

Reed no. : 42/2–116/2, Weft breaking strength: 94.14–332.64N

Weft density: 6.4–21picks/cm, Weft breaking elongation: %9.7-%59.8

Warp density: 10–43ends/cm, Warp shrinkage: %2-%21

Number of total warp yarns: 924-2880, Weft shrinkage: %2-%14

Weave kinds: Plain and 2/2 ribs, Warp yarn twist: 1120–1163T/m

Warp yarn count: Nm31–Nm66, Weft yarn twist: 283–788T/m

Weft yarn count: Nm20–Nm62, Washing fastness: Dark blue converted to blue and became shiny - 4, others none - 5

General speaking, the raw materials are usually natural fibers, like cotton and linen, and synthetic fibers, like colored stable viscose and straight flush. Wool and hemp natural fibers are used rarely, silk fiber was used in the past. In the same way, natural dyes were used in the past, but nowadays chemical dyes are used for different colors although color fastness of them are in changing levels. Generally light colors like cream and white, and live colors like red-white, red-blue are used in hand-weaving.

Body measurements and patterns

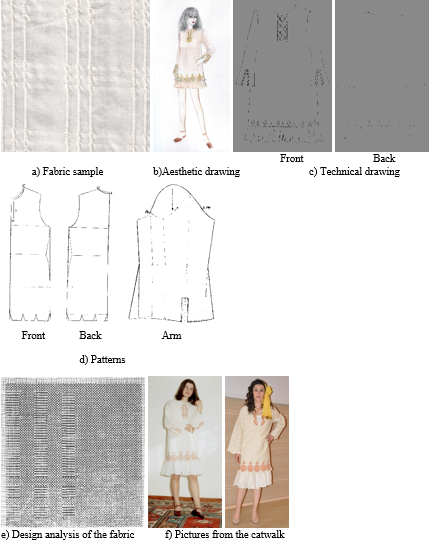

Before sewing the apparel, patterns are prepared according to the middle size (38) body measurements stated in TSE 4344/1983. Similar size measurements are applied to every style designed in this research. Size measurement chart and calculation details are not in the scope of this manuscript and so are not included here. One sample of technical drawing and patterns is given in Figure 7.

Figure 7 Fabric sample, aesthetic drawing of the style, technical drawing, patterns, design analysis, and the pictures from the catwalk for Style No.: 03.

Styles

The styles are designed by the researcher herself. By looking at the hand-woven fabrics, she could imagine and create a style which would look good and be in compliance with that fabric. For 30 sample fabrics, 30 different styles are designed, and 11 of them are sewn. Every style is given a number and a name,9 they are seen in Section 4, together with the style properties.

The fabric sample, aesthetic drawing of the style, technical drawing, patterns, fabric design analysis, and the pictures from the catwalk9,12–14 for Style No.: 03 are given as an example here in Figure 7.

Style No.: 01

Fabric from Buldan is used in Style No.: 01. This fabric is called “Kirinkil” and the name given to this style is “Spring Branch”. The properties of this style are round neck, tied from shoulders, and there are embroidery at the front and back collar.

This fabric is used a lot in home textiles locally, but some points have to be considered when used for apparel. First of all, it is very hard to do the embroidery on this fabric and it also harms the fabric. Other needle work and crochet hook ornaments should be used. Second, the warp and weft shrinkages are 21% and 12%, respectively, so the fabric is not suitable for machine washing, it has to be washed by hand, in warm water, but the shrinkage values have to be added to the pattern measurements at the beginning before cutting the fabric. The fabric sample, aesthetic drawing, and a picture from the catwalk for Style No.: 01 are given in Figure 8.

Style No.: 02

Another fabric from Buldan is used in Style No.: 02. This fabric is called “Striped Bedsheet” and the name given to this style is “Harem Pants”. The properties of this style are thin hangers at the shoulders, bridge buttonholes in the front, drapes at the sides of the pants, and it is separated at the waist.

This fabric is used a lot as bedsheets locally. Mainly three different counts of cotton yarn and many different colors are used in its production. In order to achieve a better appearance of the apparel inner primer has to be used because the fabric is very thin. Everyday styles can be applied except for very tight styles. Eventually this fabric is suitable for RWP. Warp and weft shrinkages are 17% and 14%, respectively, so, these values have to be added to the pattern measurements at the beginning, and should be hand washed. This is a cheap (economic) fabric. This fabric is cleaned (washed) and ironed easily. The fabric is self designed, so rather than ornaments, different accessories can be used to decorate the dress. Besides producing dresses, harem pants and shorts can also be produced from this fabric. The fabric sample, aesthetic drawing, and pictures from the catwalk for Style No.: 02 are given in Figure 9.

Style No.: 03

A different fabric from Buldan is used in Style No.: 03. This fabric is called “Self designed Buldan Fabric” and the name given to this style is “Kilim Designed”. The properties of this style are round neck, bridge buttonholes in the front, long arms, kilim embroidery at the hem of arms, collar, and skirt.

This fabric is used a lot as bedsheets locally. Cotton yarn is used and its yarn count is Nm50/2. Tensile strength of this yarn is very high. Besides being used in home textiles, this fabric can be used in RWP like dresses, shirts, vests, shorts, etc. Embroidery is successfully applied to this fabric. In this research kilim design is represented as the design of the embroidery and a modern looking style is established. Every kind of apparel can be produced from this fabric except for very baggy ones because the fabric is tough. Since the fabric is thick, there is no need for inner primer. There is nothing special for the production of apparel from this fabric. Its washing and ironing is easy. Warp and weft shrinkages are rather less, being 7% and 6%, respectively. The fabric sample, aesthetic drawing, and pictures from the catwalk for Style No.: 03 are given in Figure 7.

Style No.: 04

Another fabric from Buldan is used in Style No.: 04. This fabric is called “Shirt Fabric” and the name given to this style is “Blue Plaid”. The properties of this style are collets in the front and back, separated at the waist, V corsage, inner pocket in the front, thin hangers at the shoulders, and gathering in the waist.

This fabric is used in home textiles and shirts locally. Cotton yarn which is used in this fabric is very thin and they have high twist around 1000 T/m. It is suitable for ladies summer dresses. Inner primer has to be used also because the fabric is very thin. Clean sewing (English stitch) has to be used in the production of apparel from this fabric otherwise seam slippage will occur out. Matching the plaid lines is a little bit hard while sewing, consequently one has to be very careful in pattern preparation and cutting. Color fastness is very low, so this fabric has to be washed separately and cold. Warp and weft shrinkage values are 4% and 3.45%, respectively, rather suitable for machine washing. The fabric sample, aesthetic drawing, and pictures from the catwalk for Style No.: 04 are given in Figure 10.

Style No.: 05

Fabric from Kastamonu is used in Style No.: 05. This fabric is called “Handkerchief Cloth” and the name given to this style is “Red and White”. The properties of this style are collar like men’s jacket, collets in the front, separated at the waist, with short trousers, inner pocket in the front, short arms, and a belt.

This fabric is used for handkerchiefs, lady’s apparels and kitchen aprons locally. Natural dyes were used in the past for dying of yarns, but today, it is done by chemical dyes. Yarn count is Nm44/2. Warp and weft shrinkage values are 4% and 2%, respectively, fixing would be enough for this fabric before RWP. Plaids should be carefully matched and sewn. This fabric is suitable for every kind of style in everyday usage, but not for very baggy styles. The local colors of the fabric are red and white, and red and blue, which are in compliance with today’s fashion. Ironing and sewing of this fabric is easy. Color fastness is good, machine washing is advisable. The fabric sample, aesthetic drawing, and pictures from the catwalk for Style No.: 05 are given in Figure 11.

Style No.: 06

Another fabric from Kastamonu is used in Style No.: 06. This fabric is called “Striped Bedsheet” and the name given to this style is “Yellow Silver-Gilt Threaded”. The properties of this style are thin lace hangers at the shoulders, separate top and skirt, gathered at the waist, and embroidered in the front.

This fabric is used as bedsheets locally. Ground color is cream and the stripes are white. Every kind of style in dresses and shirts can be applied except very tight ones. Embroidery can easily be applied to this fabric and the fabric is easily ironed. Since the colors are cream and white and is constituted of cotton, it is suitable to be used in summer apparels and is healthy. Ornaments like embroidery fulfills the garment but different colored crochet hooks and needle work would serve as well because it adds valuable properties to the fabric and the style of the garment. Another ornament property of the Kastamonu bedsheet is a different embroidery and macrame called knots. These add a different value to the hand-woven fabric. Warp and weft shrinkage valuess are 6.5% both. The fabric sample, aesthetic drawing, and pictures from the catwalk for Style No.:06 are given in Figure 12.

Style No.: 07

A different fabric from Kastamonu is used in Style No.: 07. This fabric is called “Kastamonu Hand-woven Fabric” and the name given to this style is “Bowtied”. The properties of this style are gathering at waist of the trousers, elastic band at the waist, pockets outside on two sides, straight and large cuffs, V-collar vest, no buttons on the garment, front hem is curved and short.

This fabric is used in clothing locally. Raw material of the fabric is linen and cotton fibers. Warp yarn count is Nm32 and weft Nm20. It is woven plain and with different colored ribbons and they add a different value to the fabric. Everyday styles in the garment can be ideally applied to this fabric. Trousers and shorts according to the day’s fashion and needs can be produced and no inner primer is needed. Different embroideries can be applied to the plain garment to enrich the apparel. Sewing and ironing of this fabric is easy. The fabric sample, aesthetic drawing, and pictures from the catwalk for Style No.:07 are given in Figure 13.

Style No.: 08

Fabric from Tokat is used in Style No.: 08. This fabric is called “Tokat Thin Striped Hand-woven Fabric” and the name given to this style is “Stripe Stripe”. The properties of this style are : For vest, U-collar, slits at the sides, long, and has inner primer; For trousers, collet in the front and back, no belts, with trimming, and slit at the sides of trousers.

This fabric is also used in clothing locally. Raw material of the warp is stable viscose and the weft is cotton. In the past, it was silk in warp and cotton in weft. Since the fabric has its own stripes, it can be combined with other plain fabrics and different styles can be created. In this style, the top and the vest are sewn from the Tokat Thin Striped Hand-woven Fabric, but the trousers is made up of synthetic leather to be in accordance with this fabric’s in shiny effect. Sewing and ironing of this fabric is easily done but steam should not be used in ironing because water stains appear then. It is better to use the garment with inner primer since it makes the garment look fulfilled. Every kind of style for garment can be made from this fabric. The fabric sample, aesthetic drawing, and pictures from the catwalk for Style No.: 08 are given in Figure 14.

Style No.: 09

Another fabric from Tokat is used in Style No.: 09. This fabric is called “Tokat Hand-woven Fabric” and the name given to this style is “Long and Thin Paths”. The properties of this style are coupe in the front and back, V-corsage in the front, and thin hangers at the shoulders with needle work ornaments.

This fabric is used in clothing locally also. Raw material in warp is shiny stable viscose and weft is in cotton. Warp yarns have different colors according to the day’s fashion and needs, on the contrary weft yarns are usually in black and navy blue color. Sewing is easily made for this fabric but has to be careful while ironing, low heat have to used. Every kind of style for garment can be applied to this fabric including fancy ones except very tight ones. This fabric has a historical look and is very suitable to cocktail dresses. The fabric sample, aesthetic drawing, and pictures from the catwalk for Style No.: 09 are given in Figure 15.9,12–14

Style No.: 10

Fabric from Uşak is used in Style No.: 10. The fabric is called “Cheesecloth” and the name given to this style is “Black Scarf”. The properties of this style are the front and back bustiers doubled, makes a loop at the neck, the front and back of the skirt are of one piece, the front skirt is curved cut and tied at the waist.

This fabric is used as scarf locally. Raw material is cotton, warp and weft yarns are both Nm22, and plain woven. The fabric is colored by printing. This fabric can be supported by quilting, so the vest according to the day’s fashion can be designed besides being used in home textiles as well. The fabric sample and aesthetic drawing for Style No.: 10 are given in Figure 16.

The Style No., location, name of the hand-woven fabric, name given to the style, properties of the styles, local usage of that hand-woven fabric, and comments about the sewing and performance of the garment are summarized in Table 1.

|

Style No. |

Location |

Fabric name |

Style name |

Properties of the style |

Local usage |

Comments |

|

Style No. 01 |

Buldan |

Kirinkil |

Spring Branch |

Round neck |

Home Textiles |

Embroidery is done very hard and it harms the fabric also |

|

Style No. 02 |

Buldan |

Striped Bed Sheet |

Harem Pants |

Thin hangers at shoulders Bridge buttonholes in front Drapes at the side of the pants separated at the waist |

Bed Sheet |

Cotton yarn with three different counts and colors is used in production. |

|

Style No 03 |

Buldan |

Self-Designed |

Kilim Designed |

Round neck |

Bed Sheet |

Cotton yarn is used and count is Nm5012. |

|

Style No. 04 |

Buldan |

Shirt Fabric |

Blue Plaid |

Collets in front and back separated 'lithe waist V corsage |

Home Textiles And |

Cotton yarn which is very thin and has high...1st around 10H Um is used in this fabric |

|

Style No. 05 |

Kastannonu |

Handkerchief Cloth |

Red and White |

Collar like men's jacket Collets in front |

Handkerchiefs, Lady's |

Natural dyes were used in the past for the yarns, but today, yarn dying is done with chemical dyes. |

|

Style No.: 06 |

Kastamonu |

Striped Bed Sheet |

Yellow Silver-gilt |

Thin lace hangers at the shoulders Separated in waist |

Bed Sheet |

Ground color is cream and the stripes are white. |

|

Style No 07 |

Kastamonu |

Kastamonu Hand- |

Bowtied |

Gathering in waist of the trousers Elastic band in the waist |

Clothing |

Raw material of the fabric is linen and cotton. |

|

Style No.: 08 |

Tokat |

Tokat Thin Striped |

Stripe Stripe |

Vest U collar |

Clothing |

Raw material of the warp is viscose and the weft cotton. In the past, it was silk in warp and cotton in weft. |

|

Style No : 09 |

Tokat |

Tokat Hand-Woven |

Long and Thin Paths |

Coupe in front and back |

Clothing |

Raw material in wag is shiny viscone and weft in cotton. |

|

Style No : 10 |

I„Iak |

Cheesecloth |

Black Scarf |

Front and back bustiere doubled Makes a loop at neck |

Scarf |

Raw material is cotton, warp and weft yarns are both Nm22, and plain woven. |

Table 1 Style No., location, name of the hand-woven fabric, name given to the style, properties of the styles, local usage of that hand-woven fabric, and comments about the sewing and performance of the garment

Style No.: 11 - 30

Aesthetic drawings are accomplished for 30 of the fabrics but are not sewn. The name of the cities that the fabrics are collected, the fabric sample and aesthetic drawings for the Style No.: 11 - 30 are given in Figures 17–37.9

It is discussed in this manuscript that some of these hand-woven fabrics are used in home textiles like bedsheets, handkerchiefs, aprons, and scrafs, but some for clothing, eventually in this research garments were successfully produced from them. To summarize the properties of the styles, they are different from one style to the other as round, V, U or like men’s jacket collar, embroidered or not; tied from shoulders, with thin hangers or not, hangers may be of lace or with needle work ornaments; embroidered in the front and back, hem, and arms or not; buttonholes, bridge buttonholes, or no buttons; drapes at the side of the pants; separated at the waist; long or short arms; collets in front, back, or both; V corsage in front; pockets in or out; gathering in the waist; short or long trousers; belt or not; elastic band in the waist; straight and large cuffs; front hem curved and short; slit at the sides of trousers; inner primer; with trimming; coupe in front and back; front and back bustiers doubled; makes a loop at neck; front and back skirt are one piece; front skirt curved cut; and tied in the waist.

While sewing and preparing the garments, some important points are noted projecting to RWP. Cotton and linen yarn with different counts, twists, and colors are used in production of hand-woven fabrics. Raw material of the warp yarns may be cotton, stable viscose or shiny viscone, but few wool and linen, while the weft yarns are always cotton. Conventionally it was silk in warp and cotton in weft in the past. Fabrics are plain, natural or chemically dyed, printed, or self designed, so rather than ornaments like embellishment, crochet, embroidery, needle work, etc., different accessories can be used for those fabrics. The local colors of the fabrics are generally red and white, and red and blue, which are in compliance with today’s fashion. Some have cream ground color and white stripes. Light colors are suitable for summer use. Some fabrics are plain woven, some are 2/2 ribs, some with special weaves. Some are woven with different colored ribbons and they add a different value to the fabric. Some have stripes, so that they can be combined with other somehow plain fabrics leading to different style creations. Some fabrics have plaids. It has to be careful in sewing these fabrics to match the plaids, and precautions have to be taken in pattern preparation and cutting of fabric. Some fabrics have high warp and weft shrinkage values, so they are not suitable for machine washing, have to be washed by hand in warm water besides shrinkage values have to be added to the patterns at the beginning before cutting the fabric, or have to be decreased by hot fixing before RWP. Some are washed and ironed easily while in some others water stains occured in ironing. Some had high color fastness values, some low, the ones with low color fastness to washing have to be washed separately.

Embroidery can easily be applied to some fabrics, but is hard with others and harmed the fabric. Other needle work and crochet hook ornaments have to be used for them. Embroidery gives a modern look to the garment and enriches mainly the plain colored garment. Ornaments like embroidery fulfills the garment but different colored lace, crochet hooks and needle work would serve as well because they add appraisal properties to the fabric and to the style of the garment. Besides being used in home textiles, some fabrics can well be used in RWP like dresses, shirts, vests, shorts, harem pants, trousers, etc. Some fabrics are not suitable for very tight styles because the fabric is very loose, some for baggy ones because the fabric is very tough. It is better to use inner primer with loose fabrics in the garment since it makes appearance of the garment full. Everyday styles can ideally be applied to others. Some are shiny and have an historical look, they may be used in rarely used garments like cocktail dresses. Some fabrics can be supported by quilting, so the vest according to the day’s fashion can be designed. Some hand-woven fabrics are sewn very easily and some hardly, and clean stitch have to be used to prevent seam slippages. Some fabrics are ironed easily, likewise should be careful with some others because water stains occured, and with some others heat arrangement is important. Some are cheap (economic) fabrics, others not, and for some there is nothing special for the production of garment from that fabric. Some fabrics have high tensile strength and some low. The high ones should be used in everyday usage, the low ones in rarely worn garments.

While sewing and preparing the garments in this research, some important points are noted projecting to RWP. These such hints give idea to the ready-wear producer. Plaids, stripes and shrinkage values give ideas to the ready-wear producer to take precautions in pattern preparation and cutting of the fabric. Embroidery or needle work ornaments have to decided by them also, not to harm the fabric. Ready-wear producer have to decide on the style and season of the apparel for loose and tough fabrics, using primer for the loose ones, tight or baggy styles. For shiny and historical looking fabrics, they ready-wear producer may use them in rarely use garments like cocktail dresses. Also in some fabrics can use the alternative of supporting by quilting, so the vest according to the day’s fashion can be designed. The ready-wear producer have to use clean stitch for some hand-woven fabrics. The ready-wear producer have to be careful with some fabrics in which water stains occur while ironing. The ready-wear producer have to decide with which fabric to make cheap (economic) apparel and nothing special for the production of garment from that fabric so everyday styles can be ideally applied to them. The ready-wear producer have to decide to use the fabrics having high tensile strength in everyday usage, the low high tensile strength fabrics in rarely worn garments. Considering this research only one style was established from the 30 samples of hand-woven fabrics. The ready-wear producer may design different styles for the same fabric. In RWP, this will expand the market and some people will like one style and others will like the other, indeed increasing sales.

Shrinkage values and color fastness also gives ideas to the end user about hand washing or machine washing, or separately, or washing hot-warm-cold water. The end user can buy a cocktail dress to use rarely made up of shiny and historical looking fabrics. The end user have to be careful in ironing the fabrics where water stains occur or heat arrangement is needed.

Since the objective of this research is to make possible the usage of hand-woven fabrics in RWP, Buldan hand-woven fabrics seem to be very suitable with its designs, stripes, easy sewing and ironing. The visual properties, aesthetic properties, and colors of the hand-woven fabrics of Buldan match with today’s fashion trends. Fabrics from Kastamonu are mainly for handkerchief usage but are successfully applied to RWP. Red and blue colors, natural dyes in the past but chemicals now, are dominantly used in cotton hand-spun yarns. Plain thick fabric is hand-woven from thick yarns conversely thin bedsheets and handkerchiefs from thin yarns. Plaid fabrics are also seen in bedcovers, pillow covers and macrame tied in a special way locally. Tokat hand-woven fabrics are still being used in clothing. Uşak hand-woven fabrics can well be used in RWP. Fabrics with different colors and designs reflect an example of the conventional culture and also accepted in today’s fashion.

Perhaps the fashion designers and stylists prefer hand-woven fabrics although they are not sufficient and cannot be found easily. It is proven that the hand-woven fabrics studied in this research can successfully be used in RWP, now by taking into consideration the points stated above and in the future after achieving better physical and chemical properties.

The art of hand-weaving is facing expiring in Turkey as well as in the world. The researchers found out that the hand-woven fabrics in the Middle and West Anatolia were performed by people who learned it 40 or 50 years ago and aged now. It was determined that some municipalities try to promote this art by some projects. Since this art of hand-weaving does not gain much money, young people don’t want to this as a job while the elders are also doing it as a side income. The effects of industrialization is seen clearly. This research is done to supply hand-woven fabrics to be used in RWP by designing apparel suitable to today’s needs and fashion, to assure a rise in interest and need to hand-woven fabrics and to increase production of them, to determine the physical, chemical and visual properties of hand-woven fabrics to decide what kind of garment to produce from them, to provide clues for ready-wear producer and the end user, to prevent the expiring of hand-woven fabrics and continue to add to economy, culture and labor.

Hand-woven fabrics in the cities, which were once famous with their hand-woven fabrics in Turkish history, of Kastamonu, Tokat, Uşak, and the village of Buldan in Denizli which are located in the Middle and West Anatolia are studied. Hand-woven fabric samples of 90 different weaves and constructions are collected, selections are done keeping in mind which would be appropriate for RWP. These samples are originally hand-woven to be handkerchiefs, home textiles like table cloths, bedsheets, etc. but apparel, such as dresses, shirts, vests, shorts, harem pants, trousers, etc. are successfully produced from them in this research. The physical, chemical and visual properties of these samples are tested to decide what kind of garment to produce from them. 60 different apparel styles are designed according to today’s fashion and needs. 30 of them are prepared as a collection including the aesthetic drawings, technical drawings, patterns, fabric design analysis, etc., 11 sewn, and 10 presented here.

It is concluded that various natural and synthethic fibers can well be used in these fabrics. Besides, diverse yarn ranges with different properties can also be manufactured. There can be fabrics with changing fabrics weaves or colored ribbons included or stripes or plaids. These fabrics can also be plain, natural or chemically dyed, printed, or self designed. Some fabrics have high warp and weft shrinkage values. Some are cleaned easily by washing, others kept the water stains in ironing. Some had high color fastness, some low. Embroidery can easily be applied to some fabrics, but is hard with others and harmed the fabric. Other needle work and crochet hook ornaments have to be used. Some fabrics are not suitable for very tight styles because the fabric is very loose for summer, some for baggy ones because the fabric is very tough. Some are shiny and have an historical look. Some hand-woven fabrics are sewn very easily and some hardly. Some fabrics are ironed easily but should be careful with some others because water stains occur. Some are cheap (economic) fabrics and others not. Some fabrics have high tensile strength and some low.

Based on the findings of this research, some important points are conclude projecting to RWP where these such hints give ideas to the ready-wear producer. When a ready-wear producer decides to manufacture an apparel from hand-woven fabrics, that person can well use the concluded facts in this research for the desicion of pattern preparation and cutting of the hand-woven fabric, stitch type, kind of ornaments, where and when that garment will be used, washing, ironing, economy, style, etc. Nonetheless the end user will benefit about washing, ironing, where to wear, etc. conclusions identified in this research.

Among the sample fabrics used in this research, it is concluded that Buldan hand-woven fabrics seem to be very suitable to RWP with its designs, stripes, easy sewing and ironing. The visual properties, aesthetic properties, and colors of the hand-woven fabrics of Buldan match with today’s fashion trends. Fabrics from Kastamonu, Tokat and Uşak hand-woven fabrics can well be used in RWP, these fabrics with different colors and designs reflect an example of the conventional culture and also accepted in today’s fashion.

The fashion designers love and prefer hand-weaving fabrics, but these fabrics are not sufficient and not easily found. It is concluded that the hand-woven fabrics studied in this research can successfully be used in RWP and suitable for fashion designers, now by taking into consideration the points stated above, and in the future after achieving better physical and chemical properties, hand-woven fabrics promise for the future.

None.

None.

Author declares that there is no conflict of interest.

©2022 Bağci, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.