Journal of

eISSN: 2574-8114

Mini Review Volume 2 Issue 6

1Institute for Nanomaterials, Advanced Technology and Innovation, Technical University of Liberec, Czech Republic

2Faculty of Mechatronics, Technical University of Liberec, Czech Republic

Correspondence: Lubos Hes, Faculty of TextileEngineering, Technical University of Liberec, Czech Republic

Received: July 28, 2017 | Published: September 27, 2017

Citation: Hes L, Dolezal I. Testing of air permeability of distant knitted fabrics in the direction of their plane. J Textile Eng Fashion Technol. 2017;2(6):547-549. DOI: 10.15406/jteft.2017.02.00083

Air permeability of textiles is a component of their thermophysiological comfort. However, the current research methods and devices enable the testing of this parameter only for air flow running perpendicularly to the fabric plane. This methodology is not applicable for all textile products, e.g. home upholstery or car seats. The objective of this study is a description of an unique measuring procedure enabling the determination of air permeability or air resistance of these fabrics in the direction of their plane, based on simple modification of the commercial air permeability tester. The advanced method was used for testing of the in-plane air permeability of selected distant knit.

Keywords: in-plane air resistance, distant knits

Air permeability is a parameter which can characterize certain component of physiological comfort of clothing as well of many other textile products, such as upholstery, car seats, bed clothing, etc.1 Air permeability of a fabric is a measure of how well it allows the passage of air through it. The air permeability is important for a number of technical textiles such as industrial filters, tents, sailcloths, parachutes, and airbags.2

The standard measure of air permeability is the speed of air passing perpendicularly through the sample depending on its surface area and pressure drop. Currently, the research methodology based on standard devices give possible to test this feature only in a perpendicular arrangement of air flow from the sample fabric. Unfortunately, this methodology is suitable for testing textiles intended for clothing and some of the technical textiles only. In this case, the air flow is consistent with the actual conditions of the fabric use.

However, this standard measurement procedure does not always correspond to the real conditions of the use of seats, upholstery and cushions, where the fabric bottom sufrace is mostly impermeable and the air should escape in the fabric plane direction only. Therefore, in these fabrics, testing of air permeability of in the direction of their plane is important. As no paper published in textile journals was found to deal with this measurement technigue, it was necessary to inform the textile experts about this unique testing method, which allows the dertermination of air resistance of these fabrics in the direction of their plane.

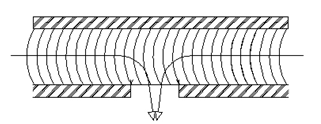

In the study, a commercial air permeability tester based on the measurement of air velocity passing through the tested sample due to the negative pressure in the sucking tube according to the ISO 9327 was used. The principle of the new testing methods depends in closing (plugging) the upper sucking tube by a circular planar sheet, which also covers the top surface of the tested sample. The details of this modification were published in.3 Thus, the shape of the sample inserted in the tester gas has the following form (Figure 1) (Figure 2) (Table 1).

Figure 1 Sample arrangement in the in-plane permeability testing in the FX 3300 tester, where air enters into the sample through a central hole and escapes through the circumference of the circular sample.

Figure 2 Sample arrangement in the in-plane permeability testing in the FX 3300 tester, where air enters into the sample through a surface hole and escapes through the circumference of the circular sample.

Sample |

Structure |

Thickness h |

Monofil |

Sq. Mass MS |

Volum. Mass |

100% PES distant knit |

Chain stitch satin |

9,0 mm |

Diameter 0,1mm |

0,897 g/m2 |

99,7 g/m3 |

Table 1 Parameters of the tested distant knitted fabric

The fabric thickness presented in the table is the free state thickness. In the next experiments, the studied distant knitted fabric was subject to stepwise increasing pressure, in order to reduce the fabric thickness, incrase the fabric filling coefficient F and decrease the fabric geometrical porosity ε, as follows:

, (1)

Where ρ is the density of the polyester (1400 kg/m3)

Simple theory of testing the fabric in-plane air permeability

Textile fabrics are considered as the solid body with channels. Channels in the i - plane direction of fabrics are long enough to complete the development of the laminar velocity profile, thus enabling the determination of the dimensionless Reynolds number Re:

(2)

Where Um - mean air flow velocity [m/s]

dh - hydraulic diameter of a pore [m]

ν - kinematic viscosity of the air [m2/s]

According to kinetic theory, if the Reynolds number is below 2320, the flow in the tube is laminar and in such case λ=64, n=1. Then the friction coefficient f can be calculated

(3)

Where λ-coefficient of laminar or turbulent flow and

n-a coefficient indicating the flow regime.

Thus the pressure drop ΔP in the channel can be determined as follows

(4)

Where ΔP-pressure drop [Pa] of the flow through a duct over the thickness of the fabric h and

ρ-air density [kg/ m3]

For next calculations, the porosity ε should be determined, and used for calculation of the average air flow rate Umand air velocity through pores U with diameter dp and section A:

(5)

Where η-dynamic viscosity of the air [Pa.s],

(6)

The total flow rate of the air Q [m2/s] where m is number of pores per square meter

(7)

Then, the required air permeability of the fabric P [m/s] follows from the equation

(8)

Where Af is the tested fabric area [m2], in our case presenting the total (average) section area of all the in-plane air channels inside the circular sample. Outer diameter of the circular sample in our case was 90 mm and should be optimized. The diameter of the central hole was 50 mm.4

Figure 3 Air resistance of the studied distant knit with a central hole as the function of the measuring pressure ΔP and the fabric thickness.5

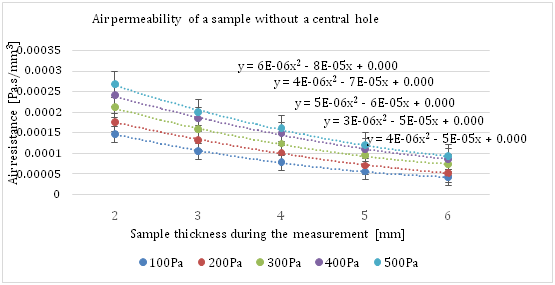

Figure 4 Air resistance of the studied distant knit without a central hole as the function of the measuring pressure ΔP and the fabric thickness.5

Results achieved by testing the selected PES distant knit revealed smooth dependencies of the determined hydraulic (air) resistance on the used testing parameters, thus confirming the reproducibility of this new simple measurement technology, which can be used in design of car seats, bed mattresses, upholstered furniture etc. It was found, that in the studied case, the preapration of the central hole was not necessary, as the results for the case with and without the central hole are similar. More experimental results confirming the above positive statements are available in the research project by P Ondrova.5 The (probably) new simple modification of the air permeability testing procedure can be easily applied in any air permeability tester, like.6

The authors express their thanks to Ms. P. Ondrova for her help in the experimental part of the presented study. This work was supported by CZ Ministry of Education, Youth and Sports under Grant No. LO1201.

Author declares there is no conflict of interest in publishing the article.

©2017 Hes, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.