Journal of

eISSN: 2574-8114

Mini Review Volume 1 Issue 6

Department of Fabric Manufacturing, National Textile University, Pakistan

Correspondence: Hafsa Jamshaid, National Textile University, Faculty of Textile Engineering, Department of Fabric Manufacturing, Faisalabad, Pakistan

Received: April 18, 2017 | Published: June 1, 2017

Citation: Jamshaid H. Basalt fiber and its applications. J Textile Eng Fashion Technol. 2017;1(6):254-255. DOI: 10.15406/jteft.2017.01.00041

Technical textiles are new horizon for achievements in textile industry and it has become talk of the town in the recent past. Technical textiles have a variety of applications and industries. Meeting end product specification is a big challenge especially for industrial goods. Technical textiles are a rapidly developing and growing at a brisk pace in the textile industry. Textiles are replacing traditional materials in various sectors of the national economy. Growing environmental awareness throughout the world has triggered a paradigm shift towards designing materials compatible with the environment. The growing use of polymer composite materials in various field of technical textiles applications demands the development of products able to fulfill both technical and ever-stricter environmental requirements.1,2 Fiber reinforcements in composite material are generally used to improve the mechanical properties and environmental resistance when exposure to extreme environment takes place. The most common fiber reinforcement in resin is glass fiber .There is other types of fibers for reinforcement such as carbon fiber and plastic fibers. The glass and carbon fibers as reinforcements in composites is of greater use as they possess excellent mechanical and thermal properties, and durability but a question is always raised when it comes to environmental issues.

The study of natural fiber has become increasingly important in recent years due to the growing awareness of the need to protect ecological and environmental resources, including shrinking forest resources.3,4 Despite the advantages of natural fibers over traditional ones (low cost, low density, acceptable specific strength properties, reduced tool wear and biodegradability), they suffer from several drawbacks, such as their hydrophilic nature (which affects the compatibility with hydrophobic polymeric matrix), the scattering in mechanical properties and the low processing temperature required. As a consequence, new reinforcement materials are currently studied. Such a new reinforcement could represent by basalt fiber.5,6 Mineral fibers from basalt are not new, but their suitability as reinforcement in polymer composites is a relatively new issue. This emerging mineral fiber is natural, safe and easy to recycle. Basalt fibers have good physical and chemical properties, as well as good adhesion to metals, epoxies and glues. Not only do they boast good mechanical and chemical resistance, but also exhibit excellent thermal, electric and acoustic insulation properties. Due to all these favorable properties, Basalt fiber can be used in several applications in technical textile. In this paper brief introduction of its properties and applications of basalt fiber have been discussed.

Basalt fiber is known as green industrial material. Basalt fiber is colloquially known as the “21st-century nonpolluting green material”. Basalt is a natural material that is found in volcanic rocks originated from frozen lava, with a melting temperature comprised between 1500˚C and 1700˚C.7,8 Basalt fibers are 100% natural and inert. Basalt products have no toxic reaction with air or water, are non-combustible and explosion proof. When in contact with other chemicals they produce no chemical reactions that may damage health or the environment. They have been tested and proven to be non-carcinogenic and non-toxic. Basalt fiber can be classified as a sustainable material because basalt fibers are made of natural material and during its production no chemical additives as well as any solvents, pigments or other hazardous materials are added. . Basalt fibers are environmental friendly as recycling of is much more efficient than glass fibers.9,10 Basalt fibers & fabrics are labeled as safe according to both the USA and the European occupational safety guidelines. Its particles or fibrous fragments due to abrasion are too thick to be inhaled and deposited in the lungs, but care in handling is recommended.11

Today, basalt fiber research, production and most marketing efforts are principally based in some of countries once part of the Soviet Union (Georgia, Ukraine, the same Russia) and in China.12−14 In 2000 the joint Ukraine-Japanese enterprise of BCF production was established. In addition to Japan, South Korea, China, Austria and USA are working on BCF technology. The EU and some other countries have basalt fiber research programs.

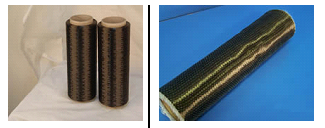

Basalt applications are well known from roman age where this material was used in its natural form as a paving and building stone. The French Paul Dhé was the first with the idea to extrude fiber from basalt and he received U.S paten in 1923 shown in Figure 1.15 Basalt is known for its excellent mechanical properties, resistance to moisture absorption, resistance to corrosive liquids and environments, durability in service and great versatility. A wide range of applications of basalt and its products include its uses in civil engineering, automotive, boat building, wind turbine blades, and sporting goods in Figure 2.16−18

Figure 1 Basalt fiber products 15.

Figure 2 Application of Basalt fiber 16−18.

Basalt can be used in tubes, bars ,pipes fittings, internal heat and sound insulation of floors, walls, frame walls, boiler shells, tanks, chimneys, fire protection structures, etc due to its strong applications in construction materials. The properties which are considered for the selection of a material in construction sector are good hardness, high mechanical properties, corrosion resistance, extended temperature range and very good insulation properties. High-quality basalt roving, fabrics and chopped strands are used in the production of CNG cylinders, brake pads, mufflers, headliners and other parts for interior applications in automotive industry. In the preparation of friction materials, basalt chopped strands are good in use. When the brake pads based on basalt fiber are compared with glass and other fibers, it have better and more stable friction coefficient. Basalt fibers provide many benefits as filler for car mufflers showing great silencing properties and good resistance to thermal cycling. In 1990s, it was the first time; a Japanese automobile industry came in contact with Kyiv industry for making of new exhaust system. It was done on purpose as; the engines of the new models had a higher temperature of exhaustion, under which fiber glass which was traditionally used for those purposes was destroyed. Heat-resistant basalt fibers were used in Toyota's car mufflers. This was a huge success, since then the world renowned car producer Toyota, is using basalt fiber as sub- muffler's stuffing for their cars.

Basalt products can be used for chemical and wear-resistant protective coating for the tanks, pipelines (mostly oil pipe lines), High Pressure Vessels, Waste-water Filters, and Corrosion Resistant Tanks & Pipes. Basalt composite pipes can transport petroleum and petroleum products, gases, aggressive liquids, loose materials, hot and cold water supply. Basalt products are highly suitable for the production of different sporting goods like hockey sticks, tennis rackets, skis, snowboards, arrows and a wide range of products due to their high mechanical properties.19-21

Basalt fibers have a great potential to be the next generation materials. The global basalt fiber market is estimated to grow at a CAGR of 13.1% from 2015 to 2020 due to their extended and successful use in infrastructure, automotive industry and consumer applications. At the estimated growth rate, the market is expected to be worth $200 million by 2020. Comprised of single-ingredient raw material melt, basalt fibers are superior to other fibers in terms of thermal stability, heat and sound insulation properties, vibration resistance and durability. Basalt fibers and composites have potential advantages for various applications. Basalt fibres is considered as environment friendly and non-hazardous materials. It is not a new material, but its applications are surely innovative and its good mechanical, chemical and thermal performance has made its use possible in a wide range from building and construction to energy efficiency, from automotive to aeronautic. Hence, basalt has gained increasing attention as a reinforcement material especially compared to traditional glass fibres.

None.

Author declares there is no conflict of interest in publishing the article.

©2017 Jamshaid. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.