Journal of

eISSN: 2573-2897

Research Article Volume 8 Issue 1

Professor of Antiquities Conservation, Conservation Department, Faculty of Archaeology, Cairo University, Egypt

Correspondence: Professor of Antiquities Conservation, Conservation Department, Faculty of Archaeology, Cairo University, Egypt

Received: December 03, 2022 | Published: January 2, 2023

Citation: Kareem OM. Evaluating The Role of Nila (indigo) Dye in Protection of Egyptian Linen Textiles from the Deterioration Factors. J His Arch & Anthropol Sci. 2023;8(1):1-7 DOI: 10.15406/jhaas.2023.08.00266

The indigo dyed linen textiles are one of the most popular textiles in most of historical periods in the Egyptian civilization. This study aims to investigate the role of indigo dye in preventing, reducing or inhibiting the deterioration of ancient Egyptian linen textiles. In this study linen textiles were experimentally dyed by indigo dye. Undyed and dyed linen were artificially aged by light, heat, soil and fungi. The change in the physical and chemical properties of the undyed and indigo-dyed linen textiles after being artificially aged were determined by various methods such as tensile strength and elongation, the crystallinity index (CrI) by using X-ray diffraction, the surface morphology by using Scanning Electron Microscope (SEM) and spectrophotometric measurements of the colour were calculated. The results confirm that indigo dye inhibits and reduces the deterioration of linen textiles. These results confirm that indigo dyed linen textiles are more durable than undyed ones. They may explain why archaeologists discover dyed linen textiles in better condition than undyed ones. Also, they explain why the Museums in Egypt have dyed linen textiles in better quality than undyed ones.

Keywords: Indigo dye, ancient Egyptian textiles, deterioration factors, artificially ageing methods

The majority of ancient Egyptian textiles are linen, which was preferred because it is durable and strong. Linen also reflects the sunlight, so it is considered cooler for the body in the hot climate of Egypt.1 Natural organic colorants have been used to dye textiles from thousands of years.2–4 The history of dyeing in Egypt starts in antiquity as dyed textiles from thousands of years B.C., have been found in Egyptian tombs. The indigo dye is one of the most popular in the most of historical periods in the ancient Egyptian civilization.4–8 It is known that the history of indigo starts early in its country of origin, India. The most popular name of indigo in ancient times was nila (indigo) that is mentioned as a dyestuff for blue. Nıla (Indigo) was one of the most important dye plants in ancient times.8–11 The indigo dye is belong to vat dyes. The dyestuff matter of indigo is extracted from the leaves of Indigoferatinctoria plant. The textile fabrics dyed with natural indigo exhibit superior light fastness. Such as vat dye group, indigo binds to the fibre through weak hydrogen bonds and Wan der Waals forces.12–13 The presence of the indigo on ancient Egyptian textiles confirms that there is trade communications between the Egyptian civelization and Indian civilization in Ancient times, as the origin of the nila (indigo) was India and then it transfered to Middile East and Egypt.

Vegetable textiles such as linen textiles undergo slow degradation due to many environmental factors, such as: temperature, relative humidity, water, light, air pollution, soil acidity, presence of various organisms, and so on. The ageing of textiles occurs as they slowly break down and constantly deteriorate. The deterioration signs of textiles are the gradual breaking down of long-chain fiber molecules into shorter chains, resulting in brittleness, loss of strength, changes in the color and other forms of natural deterioration.14–17 Light has the potential to be the most damaging of the environmental agents to museum objects. The most obvious effect of light damage on a textile object is the fading or bleaching. Another sign that may not be as easily detected is embrittlement, the actual progressive breakdown of molecular bonds that causes materials to lose strength and eventually become powdery. Even small amounts of light, well within the acceptable range, cause damage. Light damage is cumulative and irreversible.18 The effect of light damage depends on the type of light (ultraviolet and/or visible), intensity of the light, and duration of exposure. Many factors influence the effect of UV transition of textiles. Among the most important factors are fiber type, dyes and finishes.19 Textile objects are susceptible to destruction by microorganisms that come from soil, water and air. These microorganisms may lead to biodeterioration, which is a multistage and complex phenomenon that causes undesirable changes in the physical and chemical properties of textile materials. As a result of microbiological decomposition, stains, deposits, structural weakness and colour changes may appear in historical textile objects.20–22 Also it is demonstrated that fungal deterioration of the textile increase the carbonyl content and decrease the crystallinity of biodeteriorated ancient linen textile.23–25

Ancient dyed textiles are considered one of the most important archaeological materials, as they provide historical evidence on civilisations and development of their periods. For this reason, every effort should be made to preserve these textiles and to pass them to the next generation. In order to prevent, reduce, inhibit or mitigate the effect of all the deterioration factors that, every day, threaten an object's continued survival, it is important to assess how collections are deteriorated. It is also useful to understand the nature of the textile objects and the effects of their composition (such as dyes) on their behavior against deterioration factors. Archaeologists in Egypt discovered ancient dyed textiles in great quantities in comparison with the analogous undyed ones.26 I visited a lot of Egyptian museums and sites and I noticed that the extent of the deterioration commonly occurs on undyed textiles more than dyed textiles (Figure 1). One of the reasons behind this is that dye can be done as protective layer to the textile objects against the deterioration. This study aims to investigate the role of indigo dye in deterioration of linen textiles to understand if this dye played a role in preservation of ancient Egyptian linen textile or if this dye accelerated the deterioration of these textile objects.

Fabric: In this study, scoured, plain linen textile fabric was used (obtained from WOOLTEX manufactory, Egypt) (Table 1). The textiles did not contain dyes or auxiliary agents. They were not bleached and had the colour of natural fibres.

Structure |

Colour shade |

Nominal Wt. |

Thread/cm. |

Liner density (Tex.) |

% Of elongation |

Breaking strength |

||||

Plain weave |

L |

a |

b |

g/m. |

warp |

weft |

warp |

weft |

16 |

413.20 |

1/1 |

52.4 |

1.57 |

10.23 |

260 |

20 |

16 |

20 |

20 |

|

Newton |

Table 1 Specifications of used linen

Washing of linen textile fabric: To prepare the linen textile fabric before any treatment, the used linen textile fabric was washed in water and detergent. The liquor was used in ratio 100:1 (100 ml of water to 1g of textile fabric). The liquor was a 0.05% w/v solution of Synperonic N, (non-ionic surfactant). The linen textile fabric was immersed in the liquor and raised the temperature to 40°C; apply gentle agitation for 30 minutes. The linen textile fabric was rinsed in heated softened water lowering the temperature gradually. The final rinse was done in de-ionised water.5

Dyeing of linen textile fabric with Indigo: The textile fabrics were dyed with Nila (natural indigo) according to guidelines found in the literatures. 4–11,27–28 1 gr of natural indigo (nila) powder was grounded with 10 ml of water until the powder became a creamy. Then 50 ml of warm water was added into a bottle and mixed with 1gr of sodium hydroxide which was slowly applied with continuous stirring until dissolved. Then 50 ml of warm water was added into another bottle and gently slowly mixed with 1gr of sodium dithionite. Both solutions of the bottles were added to the prepared indigo, but small amounts of the sodium hydroxide solution and the sodium dithionite solution were reserved. After 1 hour, the dye was tested by dipping it in a glass rod according to Dalby.27 After preparing the vat dye according to Abdel-Kareem,11 the clean wetted linen fabric was lowered gently into both sides of the vat. It was kept there and moved gently for about 5 minutes. The linen fabric was taken out of the vat with a faint yellow colour, which later turned blue in the air within a few minutes. The dyed fabric was dried. Then it was washed in soapy water, rinsed very thoroughly in distilled water, and dried.

Preparation of samples: Undyed and indigo-dyed Linen textile samples were cut into 12 x 2 cm (length x width) warp test specimens. The warp of the specimens was produced by ravelling away yarns on each side forming 1.5 cm wide strips with a 2.5 mm fringe down each side. For each test, 5 samples were used.

Thermal ageing: It is confirmed that accelerating aging of a material by thermal ageing for 36 hours at 140ºC is equivalent to about 100 years of ageing under normal condition ageing in the museum. The dyed and undyed linen textile samples were artificially thermally aged at 140 °C in precision forced convection oven for 72 h according to Abdel-Kareem.23

Light ageing: In previous studies it was confirmed that 500 h of continuous exposure to artificial daylight is equivalent to about 100 years in a museum at 150 lx and equivalent to about 300 years in a museum at 50 lx.23 For ageing by exposure to light, tests were carried according to international standard tests for colour fastness (ISO 105-B02:1994).29 The dyed and undyed linen textile samples were mounted in standard specimen holders and were exposed to light irradiation for 500 h. Irradiation of the samples was carried out using Atlas Light Fastness Tester. In this study, the type of Atlas Fade-Ometer used is (XENOTEST®150S+). Exposure conditions were 50ºC and 55% of RH.

Soil Burial: The dyed and undyed linen textile samples linen samples were buried in soil according to standard test method for 14 days. The procedure developed earlier for soil burial test was followed.23

Fungal Deterioration: Microbiological testing was conducted using the pure culture method. The dyed and undyed linen textile samples were exposed to attack by pure culture of Alternaria tenuissima, Aspergillus nidulans, Chaetomium golobosum and Penicillium funiculosum by using Agar plate test. Fungi used in this study were selected on the basis of high cellulolytic (moulds), responsible for linen biodeterioration in Egypt. Petri dishes on medium Czapek-Dox agar modified without sugar was used. Medium was inoculated with spore suspension (14-day old culture) of each one of the tested fungi. Spore suspension of the fungus was spread on the surface of medium. The textile samples were putted on the inoculated surface of medium. The petri dishes containing cultures and linen samples were placed in the incubator at 28 ± 2 ◦C with a relative humidity of 65 ± 2%. for 14 days. Fungal deteriorated linen textile samples were picked out and washed with water to remove mycelium then they were dried in air room condition. Before testing specimens were conditioned at 20±2 °C and 65 % ± 2 RH.11,30

Tensile strength and elongation: Breaking strength and elongation at break of undyed and dyed linen samples before and after the deterioration by aging methods were measured. The breaking strength and elongation at break of all samples were tested using a Tensile Testing Machine Type Zwick 1445. These tests were done according to the ASTM (2000) D 5035-95.31 The initial distance of jaws was 50 mm and the testing speed was 25 mm/min, temperature was 23 °C, and R.H.65%. For each test, five samples were used and statistical data were calculated for all tested samples.

Colorimetric measurements: The color of undyed and dyed linen samples before and after the deterioration by aging methods was measured. Colour values of tested indigo-dyed and undyed linen samples were measured on Optimacth 3100 colour spectrophotometer using the CIELab colour system. The CIELab colour coordinates for L, a, and b values were detected. The differences in the color changes between aged and unaged linen samples were calculated. The components of color change were determined by DL, change in whiteness-blackness, Da, change in redness-greenness, Db, change in blueness-yellowness. Overall color change, DE, was calculated from the following formula: DE = [(DL)2 + (Da)2 + (Db)2]0.5.23

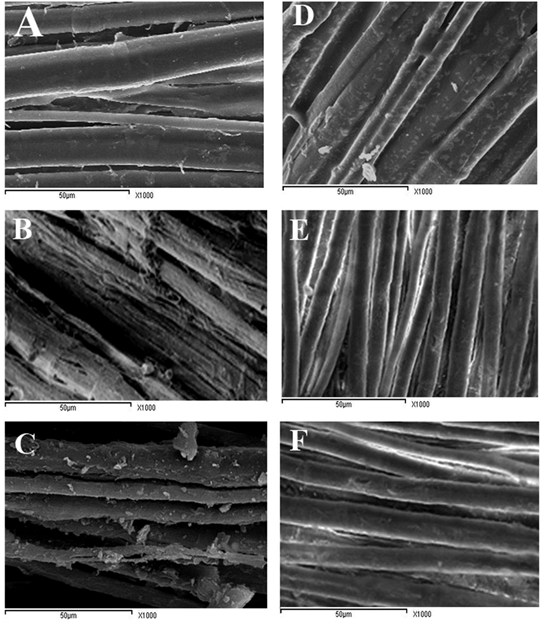

Scanning Electron Microscope (SEM): FEI Quanta 200 Netherlands Scanning Electron Microscope was used to study the surface morphology of undyed and dyed linen samples before and after ageing by different methods. Linen samples were mounted on aluminum stubs by double-sided sticky tabs, then gold coated of about 20 nm thick by sputtering method using vacuum coater (Polaron E6100. UK). Coated linen samples were examined in order to detect the morphological indication of degradation.23

Determination of the crystallinity index (CrI): X-ray diffraction analysis (XRD) of the undyed and dyed linen samples before and after ageing by different methods was carried out on a Philips X-ray diffractometer, type PW 1840, giving 40 KV Cu Ka radiation (λ=1.54Å) at 25 mA. The crystallinity index (CrI) of the tested samples was calculated from the equation, CrI = [(I002- Iam)/ I002] x100. Where I002 is the maximum intensity of the peak at 2θ = 22.5˚, Iam is the minimum intensity corresponding to the amorphous content at 2θ=18˚.32–34

Visual Observation: The visual observation is very important to a conservator as it gives information about the general condition of any object, then help in choosing the required methods for analysis, investigation and conservation methods. The visual observation of dyed and undyed linen samples after the aging, showed that all aging methods were affected on both dyed and undyed linen samples (Figure 2). The results show that the undyed linen samples deteriorate more than dyed ones. The results show that the fungi and soil are the most affected aging methods on both dyed and undyed linen. Both of dyed and undyed linen textile became darker after the heat aging. Both of dyed and undyed linen textile became lighter after the light aging.

Figure 2 The visual observation of the color changes of undyed and dyed linen textile samples after aged with tested aging methods, A-H) Undyed linen textile samples, A) Control without fungal growth, B) Heat (288 H), C) Light (600 H), D) Burial in Soil, E) Alternaria tenuissima, F) Aspergillus nidulans, G) Chaetomium globosum, H) Penicillium funiculosum, I-P) dyed linen textile samples, I) Control without fungal growth, J) Heat, K) Light, L) Burial in Soil, M) Alternaria tenuissima, N) Aspergillus nidulans, O) Chaetomium globosum, P) Penicillium funiculosum.

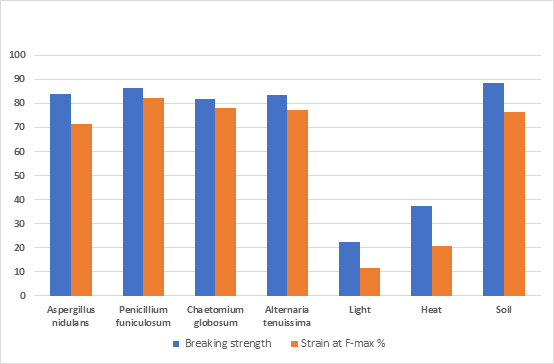

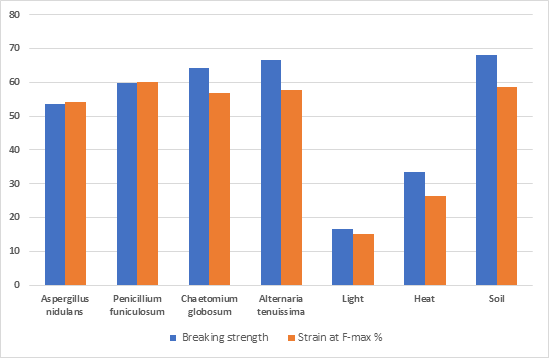

Breaking strength and elongation: Results of the effect of aging methods on breaking strength and elongation of undyed and dyed linen textile samples are presented in (Tables 2,3 and Figures 3,4). Determination of the effect of natural indigo dyeing on the deterioration process of linen textile was performed with reference to the deterioration of an undyed textile. Results of the effect of fungi on breaking strength and elongation of undyed and dyed linen textile samples show that all tested fungi caused noticeable losses in tensile strength and elongation of both dyed and undyed linen textile samples. The results show that the undyed linen textile samples were completely destroyed by fungi as the loss percent of breaking strength is about 85 % and the loss percent of elongation is about 75%. While the dyed linen textile samples were destroyed by fungi too but less than the undyed one as the loss percent of breaking strength for dyed textile is about 62 % and the loss percent of elongation is about 55%. That is mean that the indigo dye reduce about 20 percent of the deterioration of linen by fungi. However the results show that both dyed and undyed textiles became weaker and stiffer after the fungal deterioration. Comparative analysis of the biodeterioration level in structural changes between undyed and indigo-dyed linen textiles showed that as regards breaking strength, the undyed textile was destroyed more considerably. This result is in agreement with the results obtained by Błyskal.35

Figure 3 Show the loss % of breaking strength and elongation of undyed linen textile samples after aged.

Figure 4 Show the loss % of breaking strength and elongation of undyed linen textile samples after aged.

Samples |

Breaking strength (N) |

Strain at F-max % (elongation) |

||||

|

Mean |

S.D |

S.E |

Mean |

S.D |

S.E |

Without deterioration |

441.00 |

2.00 |

0.89 |

15.98 |

0.32 |

0.14 |

Aspergillus nidulans |

71.60 |

8.62 |

3.85 |

4.54 |

0.34 |

0.15 |

Penicillium funiculosum |

60.20 |

7.22 |

3.23 |

2.81 |

0.80 |

0.36 |

Chaetomium globosum |

80.20 |

7.81 |

3.49 |

3.49 |

0.69 |

0.31 |

Alternaria tenuissima |

72.40 |

9.07 |

4.06 |

3.66 |

0.97 |

0.43 |

Light |

341.40 |

2.65 |

1.19 |

14.16 |

0.71 |

0.32 |

Heat |

275.40 |

3.44 |

1.54 |

12.66 |

0.76 |

0.34 |

Soil |

50.20 |

7.08 |

3.17 |

3.76 |

0.50 |

0.22 |

Table 2 Effect of deterioration methods on breaking strength and elongation of undyed samples

Samples |

Breaking strength (N) |

Strain at F-max % (elongation) |

||||

|

Mean |

S.D |

S.E |

Mean |

S.D |

S.E |

Without deterioration |

413.20 |

2.93 |

1.31 |

23.60 |

1.02 |

0.46 |

Aspergillus nidulans |

191.60 |

8.73 |

3.90 |

10.80 |

1.17 |

0.52 |

Penicillium funiculosum |

166.20 |

8.86 |

3.96 |

9.40 |

1.50 |

0.67 |

Chaetomium globosum |

148.20 |

5.19 |

2.32 |

10.20 |

1.17 |

0.52 |

Alternaria tenuissima |

138.40 |

6.65 |

2.97 |

10.00 |

1.41 |

0.63 |

Light |

345.00 |

3.69 |

1.65 |

20.00 |

1.41 |

0.63 |

Heat |

275.40 |

3.44 |

1.54 |

17.40 |

1.02 |

0.46 |

Soil |

131.40 |

9.26 |

4.14 |

9.80 |

1.72 |

0.77 |

Table 3 Effect of deterioration methods on breaking strength and elongation of dyed linen samples

The obtained results show that light aging caused noticeable loss in breaking strength and elongation of both dyed and undyed linen textile samples. The results show that the loss % in breaking strength of undyed linen samples is about 23%. The loss % in breaking strength of dyed linen samples is about 16 %. It means that indigo dye little reduced the losses in breaking strength of dyed linen textiles than undyed one. These results indicate that indigo dyes inhibit the deterioration of linen textiles by light. However, this may be due to that the blue color can reduces the radiation passed throw the fibers and enhances protection of linen textile fabrics against light. These results are in agreement with the results obtained by Hustvedt and Crews. They confirm that the pigments in naturally pigmented cotton fibers provide protection from ultraviolet radiation and provide protection from the sun’s harmful rays.36

Results of the effect of the thermal aging on breaking strength and elongation of undyed and dyed linen textile samples show that the thermal aging caused noticeable losses in tensile strength of both dyed and undyed linen textile samples. The results show that the loss in breaking strength and elongation of all tested linen samples aged by heat is more than those aged by light but still less than the fungal deterioration. As the loss % in tensile strength of undyed linen samples is about 38. The loss % in tensile strength of dyed linen samples is about 33. These results are in agreement with the results obtained by Abdel-Kareem, who confirm that heat and light aging cause changes in both the physical and mechanical properties of linen textiles, and artificial heat aging is more destructive than artificial light aging.23 The results show that there are no noticeable effects for the color in reducing the degradation of linen textiles with heat. The results show that after heat ageing there is no significant differences in degradation rate of tensile properties for either undyed linen samples and dyed one.

The obtained results show that soil aging caused progressive losses in breaking strength and elongation of both dyed and undyed linen textile samples. The results show that the loss % in breaking strength of undyed linen samples is about 89%. The loss % in breaking strength of dyed linen samples is about 68 %. It means that indigo dye little reduced the losses in breaking strength of dyed linen textiles than undyed one. The results show that after the burial in soil the loss in tensile properties of dyed linen samples were significantly less than for undyed ones. These results confirm that indigo dye increased the resistance of linen to biodeterioration. However, the results show that the soil is the most progressive deterioration agent methods on both of dyed and undyed one. This results in agreement with Abdel-Kareem who confirm that soil test is the most effective artificially ageing methods on linen textiles.23

Colorimetric Measurements: Colour shades and colour differences of undyed and dyed linen samples before and after aging by different methods are presented in (Tables 4–5). The results show that all tested fungal strains resulted a noticeable change in the lightening of undyed linen, this indicated by the higher lightness values (L) in the biodeteriorated undyed linen samples in comparison to the control one. The most change in the parameter values (DL) of undyed linen was by Alternaria tenuissima (28.23), Aspergillus nidulans (22.53), Penicillium funiculosum (20.2). While the least change in the parameter values (DL) of undyed linen was by Chaetomium globosum (12.26). The results show that there is noticeable changes in the parameter values (DL) of dyed linen except those aged by Chaetomium globosum became (11.72). The results show that the fungal deterioration caused progressively change in the parameter values (Da, Db) of undyed linen samples, as they became more progressively green (-Da) or the redness was reduced, and progressively more yellow (-Db) or the blueness was reduced in character. While the results show that the fungal deterioration caused little changes in the parameter values (Da, Db) of dyed linen samples comparing with undyed ones.

Deterioration method |

Color Value |

The change of color |

|||||

|

L |

a |

b |

DL |

Da |

Db |

DE |

Without deterioration |

52.4 |

1.57 |

10.23 |

|

|

|

|

Aspergillus nidulans |

74.93 |

-41.46 |

-7.39 |

22.53 |

-43.03 |

-17.62 |

51.66 |

Penicillium funiculosum |

72.6 |

-33.67 |

-19.37 |

20.2 |

-35.24 |

-29.60 |

50.26 |

Chaetomium globosum |

64.66 |

-15.79 |

-17.6 |

12.26 |

-17.36 |

-27.83 |

35.02 |

Alternaria tenuissima |

80.63 |

-44.75 |

-30.92 |

28.23 |

-46.32 |

-41.15 |

68.09 |

Light |

60.62 |

1.74 |

10.8 |

8.22 |

0.17 |

0.57 |

8.24 |

Heat |

42.92 |

3.26 |

18.89 |

-9.48 |

1.69 |

8.66 |

12.95 |

Soil |

32.55 |

7.69 |

3.21 |

-19.85 |

6.12 |

-7.02 |

21.93 |

Table 4 Effect of deterioration methods on the color of undyed linen textile samples

Deterioration method |

Color Value |

The change of color |

|||||

|

L |

a |

b |

DL |

Da |

Db |

DE |

Without deterioration |

49.56 |

-3.85 |

-11.12 |

|

|

|

|

Aspergillus nidulans |

47.95 |

-6.8 |

-7.27 |

-1.61 |

-2.95 |

3.85 |

5.11 |

Penicillium funiculosum |

48.11 |

13.38 |

-13.2 |

-1.45 |

17.23 |

-2.08 |

17.42 |

Chaetomium globosum |

61.28 |

8.82 |

-3.63 |

11.72 |

12.67 |

7.49 |

18.81 |

Alternaria tenuissima |

49.76 |

17.44 |

-8.88 |

0.2 |

21.29 |

2.24 |

21.41 |

Light |

59.78 |

-77.31 |

-25.1 |

10.22 |

-73.46 |

-13.98 |

75.47 |

Heat |

45.2 |

13.12 |

8.3 |

-4.36 |

16.97 |

19.42 |

26.16 |

Soil |

47.98 |

22.99 |

-14.81 |

-1.58 |

26.84 |

-3.69 |

27.14 |

Table 5 Effect of deterioration methods on the color of dyed linen textile samples

The results show that most of dyed linen samples after the fungal deterioration became redder (Da) or the greenness was reduced, and more blue (-Db) or the yellowness was reduced in character. The results of the total colour changes (DE) show that the indigo dye, significantly reduced the colour change of linen samples caused by fungi. The total change (DE) of undyed linen samples was by Alternaria tenuissima (68.09), Aspergillus nidulans (51.66), Penicillium funiculosum (50.26) and Chaetomium globosum (35.02). While the total change (DE) of dyed linen samples was by Alternaria tenuissima (21.41), Aspergillus nidulans (5.11), Penicillium funiculosum (17.42) and Chaetomium globosum (18.81). These results confirm that indigo due reduce the fungal deterioration of linen. These results in agreement with the results obtained by Błyskal, who found that the dyeing of a woollen textile with indigo decreased the susceptibility of the dyed textile to microbial deterioration.35

The results show that the most effect of light aging was on dyed linen samples that undyed one. After light ageing undyed linen sample became lighter (DL) 8.22, slightly or no change in (Da + Db, and the total change (DE) was 8.24. While After light ageing of dyed linen sample became lighter (DL) 10.22, and it caused progressively change in the parameter values (Da, Db) of dyed linen samples, as they became more progressively green (-Da) or the redness was reduced, and progressively more yellow (-Db) or the blueness was reduced in character. The results show that the change of the parameter (Da) was -73.46, the parameter (Db) was -13.98, and the total color change (DE) was 75.47. These results confirm that the most effect of deterioration methods on the colour change of indigo-dyed linen is the light.

After the thermal ageing both of dyed and undyed linen samples became darker (-DL), redder (+Da), and more yellow (+Db) in character. The results of undyed linen samples after thermal ageing show that the change of the parameter (DL) was -9.48, the parameter (Da) was 1.69, the parameter (Db) was 8.66, and the total color change (DE) was 12.95. The results of dyed linen samples after thermal ageing show that the change of the parameter (DL) was -4.36, the parameter (Da) was 16.97, the parameter (Db) was 19.42, and the total color change (DE) was 26.16. These results show that the indigo dye is not effect too much on prevention of linen textiles from the thermal ageing.

After the burial in soil undyed linen samples became progressively darker (-DL) (-19.85), redder (+Da) (6.12), and bluer (-Db) (-7.02), and the total color change (DE) was 21.93. And the dyed linen samples became slightly darker (-DL) (-1.58), more progressively red (+Da) 26.84), and slightly blue (-Db) (-3.69), and the total color change (DE) was 27.14. These results confirm that the burial in soil affected on both dyed and undyed linen textiles.

Scanning Electron Microscope (SEM): The results of investigation the surface morphology of dyed and dyed linen samples by tested aged methods show that all aged methods cause deterioration and changes in the surface morphology of both dyed and undyed linen (Figure 5). However, the results show that the deterioration percent in the surface morphology of the linen depend on the aged method. The results indicate that the fungi and soil are more aggressive than the thermal and light ageing. By comparing the changes in surface morphology of dyed linen samples and undyed ones after the ageing it is clear that deterioration in the surface morphology of dyed one less than for those for undyed one. These results confirm that the indigo dye may play as a protective layer on the surface of the linen from the deterioration by aged methods.

Figure 5 SEM photographs of surface of linen samples after aged by different methods, A) Control undyed linen sample, B) undyed linen after damaged with Aspergillus C) undyed linen after damaged with heat, D) Control dyed linen sample, E) dyed linen after damaged with Aspergillus, F) dyed linen after damaged with heat.

The crystallinity index (CrI): The results of the crystallinity index (CrI) of undyed and dyed linen samples before and after aging by different methods are presented in tables (6-7). The percent of the changes in the crystallinity index (CrI) of undyed and dyed linen samples after aging by different methods are presented in Figure (6). Results of the effect of fungi on the crystallinity index (CrI) of undyed and dyed linen textile samples show that all tested fungi caused considerable losses in the crystallinity index (CrI) of both dyed and undyed linen textile samples. The losses percent of the crystallinity index (CrI) of undyed linen samples were by Alternaria tenuissima (44.84), Aspergillus nidulans (36.18), Penicillium funiculosum (52.54) and Chaetomium globosum (50.48). The losses percent of the crystallinity index (CrI) of dyed linen samples were by Alternaria tenuissima (32.13), Aspergillus nidulans (26.86), Penicillium funiculosum (29.80) and Chaetomium globosum (34.87). These results indicate that the fungi progressive deteriorate both amorphous and crystalline area in undyed and dyed linen fiber. The results confirm that the reduction in the crystallinity index (CrI) of undyed linen textile after the fungal deterioration are more than for dyed ones. The results show that there are no noticeable changes in the crystallinity index (CrI) of both undyed and dyed linen textile after light deterioration. This result is in agreement with other studies, which suggest that light ageing decreases the crystallite size of the longitudinal dimension of linen fabrics, while the size of their lateral dimensions and the crystallinity index remained almost unchanged. These results indicate that degradation did not proceed from the surface to the inner of the fibres, but longitudinally. The results show that there are no noticeable changes in the crystallinity index (CrI) of both undyed and dyed linen textile after the thermal deterioration. The results show that there is a progressive reduction in the crystallinity index (CrI) of both undyed and dyed linen textile after the burial in soil. The results show that the losses % in the crystallinity index (CrI) of undyed linen was 55.15 and for dyed linen was 32.60. These results confirm that the indigo dye reduce the losses % in the crystallinity index (CrI) of linen aged by the burial in soil.

Samples |

Intensity (Counts) of Peak Iam at Angles (2θ) 18º |

Intensity (Counts) of Peak I002 at Angles (2θ) 22.5º |

crystallinity index (CrI) |

||

|

Mean |

S.D |

Mean |

S.D |

|

Without deterioration |

4644 |

282 |

12036 |

748 |

61.41 |

Aspergillus nidulans |

4598 |

491 |

7562 |

750 |

39.19 |

Penicillium funiculosum |

4412 |

766 |

6227 |

994 |

29.15 |

Chaetomium globosum |

4601 |

691 |

6612 |

693 |

30.41 |

Alternaria tenuissima |

3515 |

872 |

5315 |

944 |

33.87 |

Light |

4665 |

907 |

11624 |

776 |

59.86 |

Heat |

5085 |

634 |

10985 |

657 |

53.71 |

Soil |

2844 |

573 |

3925 |

768 |

27.54 |

Table 6 Effect of deterioration methods on crystallinity index (CrI) of undyed linen samples

Samples |

Intensity (Counts) of Peak Iam at Angles (2θ) 18º |

Intensity (Counts) of Peak I002 at Angles (2θ) 22.5º |

crystallinity index (CrI) |

||

|

Mean |

S.D |

Mean |

S.D |

|

Without deterioration |

4644 |

282 |

12036 |

748 |

61.41 |

Aspergillus nidulans |

4598 |

491 |

7562 |

750 |

39.19 |

Penicillium funiculosum |

4412 |

766 |

6227 |

994 |

29.15 |

Chaetomium globosum |

4601 |

691 |

6612 |

693 |

30.41 |

Alternaria tenuissima |

3515 |

872 |

5315 |

944 |

33.87 |

Light |

4665 |

907 |

11624 |

776 |

59.86 |

Heat |

5085 |

634 |

10985 |

657 |

53.71 |

Soil |

2844 |

573 |

3925 |

768 |

27.54 |

Table 7 Effect of deterioration methods on crystallinity index (CrI) of dyed linen samples

It is found that all tested aged methods deteriorate both indigo-dyed and undyed linen textiles. Fungi and soil burial test are more progressive in deterioration of both indigo-dyed and undyed linen textiles than light and thermal aging methods. By comparing all the obtained data of indigo dyed linen textiles and undyed ones after aging by all tested aged methods, the study confirms that natural indigo dye reduces the deterioration of linen textiles. This may be because the indigo dye plays as a protective layer from the light deterioration. Also, the chemical composition of indigo dye may play a role in reducing and inhibiting the fungal deterioration of linen Textiles. Recent studies indicate that the healing properties of indigo dye may be due to the presence of substances such as indirubin in the dye.35 The current study confirms that the indigo dyed linen textiles more durable than undyed ones. This finding explains why the indigo dyed linen textiles (dated back to ancient Egyptian periods) in the Egyptian museums, are in good properties and qualities than undyed ones. It also explains why the archaeologists in Egypt discovered ancient dyed linen textiles in better quality in comparison with the similar undyed ones

None.

Author declares there are no conflicts of interests.

©2023 Kareem. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.