Journal of

eISSN: 2469 - 2786

Review Article Volume 3 Issue 1

Correspondence: Hamid Mukhtar, Institute of Industrial Biotechnology, GC University Lahore Pakistan, Tel 9.23334E+11

Received: July 18, 2016 | Published: November 16, 2016

Citation: Sundus H, Mukhtar H, Nawaz A. Industrial applications and production sources of serine alkaline proteases: a review. J Bacteriol Mycol Open Acces. 2016;3(1):191-194. DOI: 10.15406/jbmoa.2016.03.00051

In the modern world, demand for the eco friendly products resulted in replacement of chemical methods with enzymatic methods. Alkaline protease is one of the important groups used in various industries like leather, detergents, textile, food and feed etc. Bacillus sp. is mostly used for production of alkaline proteases having industrial importance. Most of industrially used alkaline proteases are thermo stable having optimum activity lies between 50°C to 70°C. Application of statistical methods for the optimal production of alkaline proteases produced better yield. This review highlights the production and applications of serine alkaline proteases.

Keywords: proteases, applications, industry, thermostable

One of the most important commercially available enzymes comprised of proteases. These proteases have a wide range of applications in different industries like detergent, leather and food industries. Out of all the commercial enzymes sold every year proteases consists of 60%. Out of all those proteases the most selling one is serine alkaline protease with a average of 89%.1 Proteases are produced from various sources like plants, animals and microorganisms, but its large scale production implies microbial community. Proteases from Bacillus sp. (microbial proteases) is mostly used for industrial purpose.

Proteases can be classified on the basis of chemical nature of their active site as serine proteases and metallo-proteases. Serine proteases are composed of serine residue forming a catalytic triad with aspartic acid and histidine in active site. The enzyme gets inactivated by phosphate esters so they are inhibited by phenylmethylsulfonyl fluoride (PMSF), diodopropyl flourophosphate (DFP) and chymostatin. Subtilisin is a major group of serine proteases, they remains active at pH 10 and also have nucleophilic attack ability on peptide bond by serine residue at active site. Subtilisin Carlsberg and subtilisin novo are important types usually obtained from Bacillus sp.2 Serine proteases production from halophilic sources like halobacterium specie is also reported.1 These proteases can also be classified on basis of endo and exo enzymes with respect to their catalytic action on protein substrate. They are further classified like serine, aspartic, cysteine or metalloproteases based on catalytic activity.3

Among all proteases, serine alkaline proteases have wide applications in detergent industry as a cleaning agent.4 Serine alkaline proteases are resistant to a wide range of change in temperature as well as pH and usually do not get denatured by detergents and toxic metals. A major production of alkaline proteases which commercially present is from Bacillus sp. because it has ability to tolerate pH and temperature variance. This specie also has ability to secrete alkaline proteases which is from industrial point of view.5 Proteinaceous stains like of blood, chocolate, milk and keratin are digested by alkaline proteases so it is widely used as detergent and leather processing agent. These protease based detergents have better cleaning dust removal ability. Use of these enzymes in leather industry do not cause environmental pollution problem. Its dehairing property is mostly used in leather processing industry. Chemical dehairing methods used in leather industry involve the use of hydrogen sulphide and other chemicals that are pollutant. Due to environmental risk enzymatic dehairing process is used instead of chemical treatment. Proteases react to swell hair root by degradation of follicle protein causing removal of hair.1 These serine proteases have applications in tannery, waste water treatment, silver recovery and resolution of amino acids mixtures.6 In animals proteases present in pancreas help in food digestion.

Submerged and solid state fermentation can be used for alkaline proteases production. Media composition7 mainly carbon and nitrogen source8 and parameters like temperature, pH, agitation speed9 influence the enzyme production. Each microbe producing alkaline protease require different conditions and medium. Alkaline proteases production require some metal ions in the form of salts in production media. Bacillus subtilis protease production is enhanced by supplementing FeSO4.7H2O and MgSO4.7H2O.10 For making cost of fermentation media reasonable, production of proteases is done using industrial wastes like gram husk, chick pea, wheat bran, rice husk, cotton stalk, crushed maize and date wastes.11,12 Mostly production of alkaline proteases is done at pH 8-9 and temperature 32-45 °C. Some physiochemical parameters need to be optimized for maximum production of alkaline proteases. Researchers optimize the production parameters to achieve maximum yield by counting upon the available resources. Various statistical methods have been developed to optimize these variables and their interactions using a minimum number of experiments.13

Various researchers characterized alkaline proteases from different sources to use them for specific purposes. Alkaline proteases due to its high pH range and high thermo stability have many applications in detergent and leather industry. Bacterial alkaline proteases have pH range 9-10 and optimum temperature 50-700˚C while fungal protease shows pH range 9-10 and temperature range 37-500 °C. Bacterial proteases have high thermostability than fungal sources. At temperature 60-700 °C up to 3 hours bacterial alkaline proteases remains active.14 Alkaline proteases also require divalent cation like Ca+2, Mg+2 and Mn+2 or a combination of these for elevated activity. Cations protect the enzyme against thermal denaturation and active conformation of enzyme remains maintain at high temperature. EDTA inhibit the alkaline proteases so sulfonation of serine residue in active site results in the loss of activity.15 EDTA inhibits metallo type alkaline proteases by chelating the divalent metal ion in its active site.

Proteases are one of the most important groups of both industrially and academically important enzymes accounting for around 65% of annual enzyme market.16 They have a history of applications in food and detergent industries where the alkaline proteases hold the biggest share of the enzyme market worldwide.17 Alkaline protease use as ingredient in detergents is largest application of this enzyme. They also have applications in leather industry, medical diagnostics, recovery of silver from X-rays, food and feed industry etc. Due to their widespread applications, many industries have started its production at commercial level. The Table 1 shown below gives applications of alkaline protease.

Product Name |

Industrial Use |

Applications |

Savinase |

Detergent industry |

Remove protein based stain |

Alcalase |

Textile industry |

Silk degumming |

SEB Tender 70 |

Meat industry |

Tenderization of meat |

Peptidase |

Feed industry |

Bitterless protein hydrolysate |

SEB soak |

Leather industry |

Soaking |

Proteinase K-16 |

Detergent industry |

Protein removal |

Table 1 Applications of proteases in different industries

Alkaline proteases greatly contributed to the improvement and development of industrial detergents. These detergents are effective at any pH and temperature condition that are helpful in industrial cleaning. Enzymes that are used in laundry industry include proteases, lipases, cellulases and amylases.18 These proteases help in the removal of any stain like blood, egg, gravy even in high pH conditions.19 Biotechnologists faced many problems regarding application of proteases; one major of them is compatibility issue with various other detergents. Recently, alkaline proteases from Bacillus cereus, Bacillus pumilus strain CBS, Streptomyces sp. strain AB1, Bacillus licheniformis, Aspergillus flavus, Aspergillus niger, Bacillus brevis, Bacillus subtilis AG-1 have exhibited excellent detergent compatibility in the presence of certain stabilizers such CaCl2 and glycine.20 Subtilisins related to thermo stability and resistance to chelators, survive to extremes of high alkalinity and chelator concentration.21 Alkaliphilic Bacillus strains have been used for the isolation of oxidatively stable serine protease to prevent loss of activity when used in detergents.

In Pakistan, leather and leather-based industries are the second largest exporting sector, contributing significantly to the national economy. There are more than 600 tanneries with 200,000 employed workers, processing 47.7 million hides and skins with an export income of US$ 719 million annually and contribute 5 % to the GDP. Although, leather industry is economically important, but the process of leather making has been clearly proved to be environmentally objectionable due to the discharge of effluent rich in BOD, COD and large quantities of toxic chemicals.22

Proteases play a vital role in the treatment of the raw leather in tanneries. Soaking involves removal of blood, dung and dirt from hides and some structural changes. Most effective of leather treatment is the use of alkaline serine proteases. Alkaline proteases play an important role in solubilization of albumin and globulin, opening up of contracted fibrous proteins and washing dirt and excessive fat at soaking stage.23

The conventional method used for depilation involves the use of sodium sulfide and hydrated lime and is described as lime-sulfide process. A paste made by sodium sulfide and hydrated lime is applied on the flesh side of the skin. The objective of this treatment is the removal of hair by hydrolysis of mucoids, swelling of collagen fibers and elastin digestion. This process is clearly objectionable worldwide now because release of dangerous chemical compounds in huge amount.22

Proteases, which are mostly produced by bacteria are stable in alkaline range, have become more and more widespread for the depilation and opening up of the hide. These proteases may be used in conjunction with alkalies such as lime, sodium carbonate and with reducing agents such as sulfides or mercaptans at pH 10-14. Depending on the nature of finally prepared leather, the treatment can last for 6-24 hours. Enzymatically aided dehairing processes help to increase the surface area and facilitate the cleaning and the dying of the leather. Use of protease having high pH activity can enter in to the skin with more ease.22 Bacillus subtilis produced proteases with keratinolytic activity that replace sodium sulfide in dehairing process of leather industry.23

Traditionally, bating is an enzymatic process mainly involving the use of pancreatic enzyme preparations containing trypsin. Today, microbial proteases have replaced the use of trypsin, as they are more economical. Quality of the finished leather mainly depends upon the bating efficiency.24 Leather shavings and dust produced during the finishing and preparation of end products mainly consists of collagen protein. It may be degraded with collagenases to get amino acids and oligo peptidases.25,26

A high stability in the presence of organic solvents is a feature which is highly desired in applications involving biocatalysis in non-aqueous medium for peptide synthesis. Alkaline proteases from Aspergillus flavus, Bacillus pseudofirmus SVB1, Pseudomonas aeruginosa PseA have shown promising results for potential of peptide synthesis due to their organic solvent stability.16 In addition to demonstrating high organic tolerance, alkaline proteases from B. pumilus strain CBS and Streptomyces sp. strain AB1 are potentially strong candidates for use in peptide synthesis in low water systems.24

For therapeutic purposes, immobilized alkaline proteases isolated from Bacillus subtilis are used for ointment composition, non-woven tissues, soft gel medicinal formulas, gauze and new materials.25 Proteases isolated from Aspergillus oryzae helped in diagnostic aid to correct certain enzyme deficiency syndrome. Alkaline fibrinolytic proteases t used to degrade fibrin have future in anticancer drugs. Alkaline proteases have also found usage in the medical arena. The elastolytic property of a serine protease from Bacillus subtilis has been used to prepare elastoterase. This formulation is used in the treatment of abcesses, burns, carbuncles and other wounds.27

Poultry and leather industry wastes are rich in keratin that is densely packed and stabilized by hydrogen, hydrophobic interactions and disulfide bonds.26 These keratin wastes are degraded by chemical and mechanical hydrolysis but it is not eco friendly. Enzymatic degradation by using alkaline proteases is best method.27 Bacillus species is the most widely reported bacterial source of keratinases for feather degradation. Other reported bacterial sources of keratinases are Pseudomonas sp. MS21, Microbacterium sp., Chryseobacterium sp. and Streptomyces sp. Fungal keratinases obtained from Aspergillus Oryzae, Chrysosporium indicum, Trichophyton mentagrophytes, Microsporum sp., Trichophyton sp., Aspergillus terreus, Scopulariopsis sp., Fusarium oxysporum have also been studied towards the degradation of keratin.28

Owing to their ability to break down proteins, alkaline proteases have been widely used for the production of high nutrition-value protein hydrolysates Proteases are added food and feed mixture to better nutritional value. In medicine, these are used for digestive disorder and food allergies.29 These hydrolysates produced from variety of substrates like whey, meat, soy and casein. Meat hydrolysates usually have bitter taste when hydrolysis degree is above 10%. These have been used in the fortification of soft drink and fruit juices and as a part of infant food formulations.29 However, the most important application of proteases in the food industry is in the process of cheese-making. Lactic acid bacteria are used for the purpose of milk coagulation, an essential feature for yogurt production. These bacteria are dependent on their proteolytic enzymes which hydrolyze casein and fulfill their requirement of a nitrogen source for growth. Alkaline proteases from Streptococcus cremoris, Amycolata sp. and Amycolatopsis sp. have been used for cheese production industrially.30

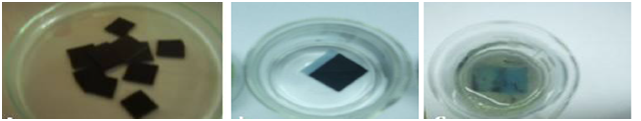

Photographic and X-ray films contain in the gelatin layer, approximately 2% silver. This silver needs to be recovered, and is conventionally retrieved by burning the films which has dire environmental hazards. Alkaline proteases can carry out the hydrolysis of the gelatin layer allowing the polyester base of the film to be recycled as well as assisting the retrieval of silver. Proteases from Bacillus sp. have been used for the purpose as shown in Figure 1.31

Figure 1 Decomposition of gelatin and release of silver.31

Control (X-ray film) Edge of film lose color clean bluish sheets after enzyme treatment

The industrial importance of serine alkaline protease have made researchers more focused towards alkaline proteases to discover its novel properties for fulfilling the increasing demand of global enzyme market. Proteases have promising future in different industrial applications. Having more insight of working of these enzymes will prove beneficial for commercial purpose.

None.

The author declares no conflict of interest.

©2016 Sundus, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.