In this article, a method for robust Fault Detection and Isolation (FDI) is presented. The scientific interest of this work is use of one tool (Bond Graph) not only for modelling of hybrid system, parametric and measurement uncertainties but also for generation of robust fault indicators and thresholds. For this task, first, the hybrid bond graph (HBG) model is established to model the hybrid system using the controlled junctions. Secondly, all parametric and measurement uncertainties are modeled on the HBG model in derivative causality, from this model and using the causal and structural properties of the bond graph tool, the generation of the fault indicators (residues) and thresholds is done directly, those fault indicators called Generalized Analytical Redundancy Relations (GARRs) are valid at all modes and derived systematically from an HBG model. An application to an hydraulic is used to illustrate this method.

Keywords: hybrid bond graph, fault diagnosis, fault indicators, robust, parameter uncertainties, measurement uncertainties

Current systems engineering, industrial and technical processes are increasingly complex; they include sub-systems of various fields of energy. The Bond Graph (BG) is a multi-physics modeling tool based on analogy and exchange of energy power able to model with a single language, systems, regardless of their physical nature. This modeling aspect has been the subject of several publications.1−3 The BG has been used not only for modeling but also for fault detection and isolation (FDI) of complex systems.4−6 The majority of complexes engineering processes are equipped with sensors, actuators, integrated digital circuits and software. In order to protect the complex engineering systems, safety, reliability, availability and maintenance become important to detect rapidly anomalous behavior of the system after the occurrence of a fault, isolate causes of malfunctions, failures and generate alarms: most complex industrial systems are hybrids. Fault diagnosis for hybrid systems has been the subject of intensive research and several approaches have been developed in the literature for the diagnosis of hybrid systems. In 1994, Mosterman and Biswas8 have developed an approach which extends the BG theory,7 called Hybrid Bond Graph (HBG) to model the discrete mode changes of hybrid systems, in addition to the junctions of BGs, the HBG methodology uses controlled junctions. In literature, several studies have been proposed9−12 based on HBG approach for the diagnosis of hybrid systems. The majority of these works does not address robustness. Ghoshal et al.,13 have presented a method for robust diagnosis taking into account parameter uncertainties using pseudo-bond graph to model and diagnosis a hybrid thermo-fluid system, the Linear Fractional Transformation (LFT) form is used to model parameter uncertainties directly on pseudo-bond graph model. The method was tested and the simulations results are given. In the work of Borutzky,14 a method of robust FDI is presented based on incremental bond graph for hybrid systems, the principle of the method is the generation of thresholds taking into account parameter uncertainties and changes in the discrete mode. An application to a converter circuit to illustrate the method is given. And In,15 the author, showed that the incremental bond graphs can be used to determine adaptive mode-dependent ARR thresholds in order to obtain robust diagnosis, the bond graph model for hybrid system and mode identification are presented. The method was illustrated by an application on a power electronic system. In,16 we have developed a method based on HBG-LFT to obtain a robust diagnosis for hybrid systems. The system is modeled using HBG and the parameter uncertainties are modeled graphically using LFT form, the residues and adaptive thresholds are generated from HBG-LFT model. These residues are robust to parameter uncertainties and valid at all modes, the method was tested on a hydraulic hybrid system, and in,17 we have studied robustness with respect to measurement uncertainties by modeling these uncertainties directly on the HBG model. In the work presented in this manuscript; we will consider both parameter and measurement uncertainties18,19 for hybrid system modeled by HBG approach to detect defaults. The innovative interest of the present research is essentially based on the use of the HBG tool for first; modeling the discrete mode changes, second; modeling of the parameter and measurement uncertainties graphically, and third; obtain a robust diagnosis by exploiting the causal and structural proprieties, thereby, the systematic generation of robust fault indicators is systematic. The rest of the article is organized as follows: modeling of parameter and measurement uncertainties by bond graph approach is presented in Section 2 and the proposed method for robust diagnosis taking into account parametric and measurement uncertainties based on hybrid bond graph approach in Section 3. Section 4 presents an application on a hydraulic system to validate this method and a conclusion is given in section 5.

Modeling of parametric uncertainties

In order to model parametric uncertainties by bond graph approach, two methods are presented in.16 In this work, the method used is based on (bond graph- Linear Fractional Transformation BG-LFT) representation. The principle of this method is to replace the BG elements by the corresponding BG-LFT elements to obtain two parts; nominal part and uncertain part. The nominal part is used for calculation of residue, and the uncertain part for the thresholds. Figure 1 shows a BG- R element in the LFT form. An R element in resistance causality with uncertainties can be presented as following Equation (1):

(1)

With: and are respectively, the nominal value, the multiplicative uncertainty, the additive uncertainty, the effort and the flow variable of R element. is a fictive input that represents the effort added by the parameter uncertainty. The LFT form in robust diagnosis has advantages among them:

- The causality and the structural proprieties of the elements on the nominal model remain unchanged by introducing the uncertainties.

- The nominal and uncertain parts are separated, and the parameter uncertainties are easily evaluated and explicitly represented in the graphical tool.13

Figure 1 R element in resistance causality using LFT form.

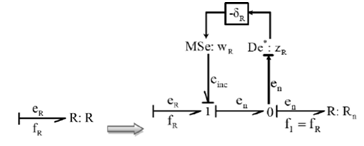

Modeling of measurement uncertainties in a BG context

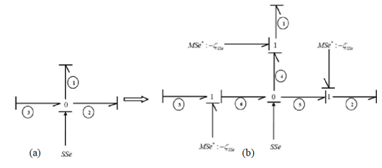

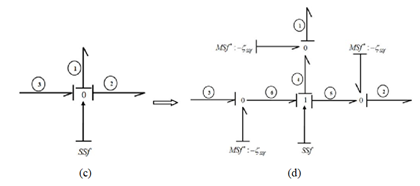

Mostly, the information provided by sensors are noisy or obtained with a certain precision, therefore, take account of measurements uncertainties is necessary in the diagnostic scheme in order to avoid the problems related to false alarms and no detections. The interest of using this approach based on BG theory for modeling the measurement uncertainties is to use the properties of the tool (BG) to generate residues and thresholds. In BG methodology, the ARRs are considered as residuals. Theoretically, the residues are equal to zero in normal situation, without considering the uncertainties and model errors. The presence of uncertainties on the sensors uncertainties, and if the measurement errors are an additive and bounded error, then, the residual can be bounded by two thresholds. The latter can be obtained using the BG model. Using the BG theory, measurement errors are modeled by replacing the junction containing the detector by its equivalent (Figure 2). The measurement error is replaced by a virtual source of flow (effort) according to the detector De(Df ).14 Figure 2 shows modeling of measurement uncertainties, the obtained equations are given in Equation (2) and (3).

(2)

The following references are given for more details on the modelling of parameter uncertainties14,16,18,19 for measurements uncertainties, based on BG methodology.

Figure 2 Measurement uncertainly modelling and their equations.

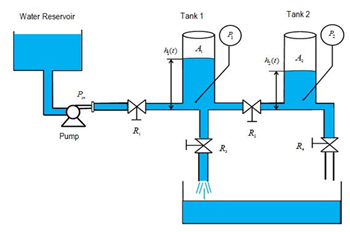

The objective of this part is to show the proposed method on a hydraulic system: the hybrid system is modeled by hybrid bond graph (HBG) approach with controlled junctions, the DHBG model is obtained by attributing derived causality on the HBG model, then; the parametric and measurement uncertainties are modeled on the obtained DHBG model, the generation of fault indicators is established, residues and thresholds, simulation tests are given to show the residuals with and without defaults. In the following, these steps are detailed. The proposed method is applied to a hybrid hydraulic system shown in Figure 3: The generation of Robust Global Analytical Redundancy Relations (GARRs) with respect to parametric and output (measurements) uncertainties is presented.

Figure 3 The hybrid Two-Tank system.

First step: Modeling of the hybrid system: the system is composed of two tanks, regulated centrifugal pump modeled as a source of pressure pin(t) [Pa] and four valves represented by R1, R2, R3 and R4. A1[m2] and A2[m2] are the cross-section areas of the two tanks. The system contains two pressure sensors (p1(t) and p2(t)) to measure the pressure at the button of tank A1 and tank A2 , respectively; this pressure is proportional to the liquid level, according to:

(4)

Whereis the density of liquid, [kg/m3]; g is the acceleration due to gravity , [m/s2], hi (t) is liquid height in the tank, [m].

Each valve has two states ON and OFF. The valves’ dynamics is given by:

when the valve is closed

(5)

When the valve is opened. Where the liquid-flow through the valve, [m3/s]; is the pressure difference across the valve , [Pa] and is the coefficients of discharge,.

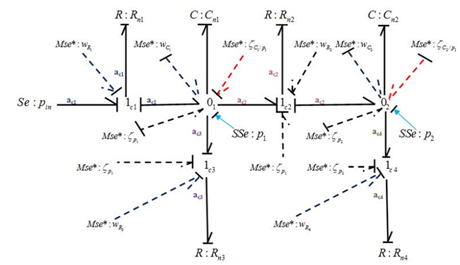

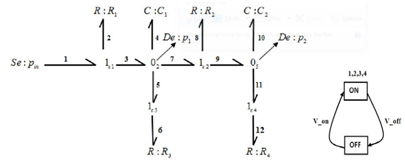

In the HBG model of Figure 4; the two tanks are modeled by two storage components with coefficients The valves are modeled by a set of resistor with parameter ; j=1,2,3,4, and controlled-junction with boolean variable j =1,2,3,4, representing the state of controlled junctions.

Figure 4 The two-tank acausaled HBG and the finite state automaton of controlled junctions.

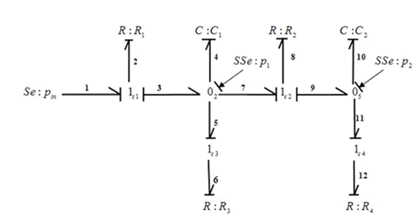

Second step: The DHBG (Figure 5) is obtained by affecting all controlled junctions by their preferred causalities, to do this:

- The output variables of the controlled junctions 1c3,1c2 and 1c4 are assigned as inputs of R3 , R2 and R4 respectively because these junctions have no source adjacently connected to them.

- The output of 1c1 is assigned as input variable of 1-port component R1 since the source Se is connected to1c1.

- The source Se and the storage components C1, C2 are assigned in preferred derivative causality and the sensor is reversed (dualized).

Figure 5 The two-tank DHBG.

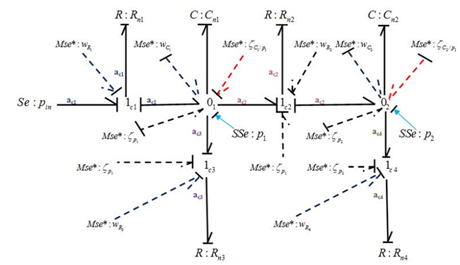

Third step: The parameter and measurements uncertainties are graphically modeled on the DHBG model. The Figure 6 shows this representation of uncertainties. Two GARRs can be derived from the model of Figure 6;

Figure 6 The model of the two tank system in preferred derivative causality with measurement and parameter uncertainties.

The first candidate GARR is

And the second candidate GlobalARR:

And the second candidate GlobalARR:

These GARRs can be decomposed in two separate parts; the first nominal, called residue and the second uncertain used to calculate the thresholds.

with: are discrete variables representing the state of controlled junction 1cj

for are respectively the measurement errors on the first pressure sensor p1 and on the second pressure sensor p2 , These measurement errors are bounded as follows: and the virtual inputs of measurement uncertainties .

, Where: and are respectively the fictitious inputs of parameter uncertainties and the virtual inputs of measurement uncertainties, are the multiplicative uncertainties on the two storage components C 1,C 2 and fixed as 5% and , are respectively the measurement errors on the first pressure sensor p1 and on the second pressure sensor p2, then errors measures are added to the exact values of the measures of the system. The results presented below show the residues in presence of parameter and output (measurements) uncertainties in normal and faulty operation. The nominal values of parameters used in the simulations of the model are shown in Table 1. Different scenario of simulations was performed to test the effectiveness of the proposed method.

Symbol |

Description |

Value |

Ai |

Cross-sectional area of Tanki (i=1,2) |

-2 |

g |

Acceleration due to gravity |

|

|

Discharge co efficient of first valve |

|

Discharge co efficient of second valve |

|

Discharge co efficient of third valve |

|

Discharge co efficient of fourth valve |

Table 1 Model parameters of the two-tank systems

First scenario

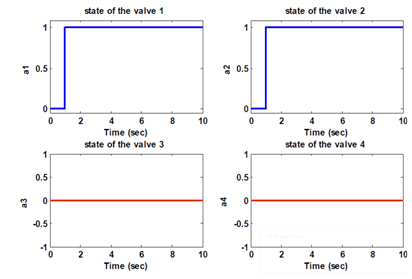

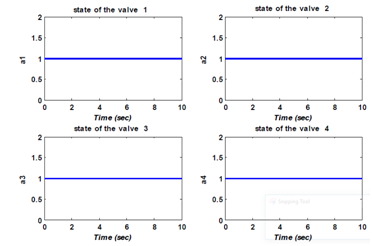

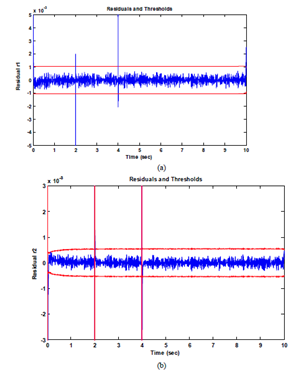

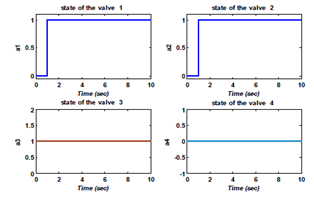

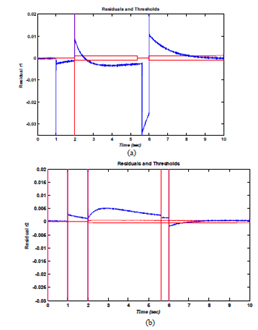

Test1: Normal operation (without default), the valves 1 and 2 are open at t=1s, the valves 3 and 4 are closed. The states of the four valves are shown in Figure 7. The residues r1, r2 in presence of parametric and measurement uncertainties without default are presented in Figure 8: we note that the residues are equal to zero and do not leave the thresholds. The mode change is observed at t=1s.

Figure 7 The states of the four valves.

Figure 8 The residues without default.

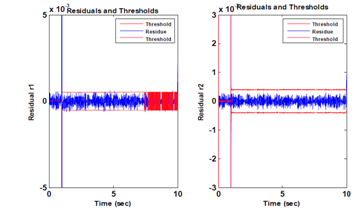

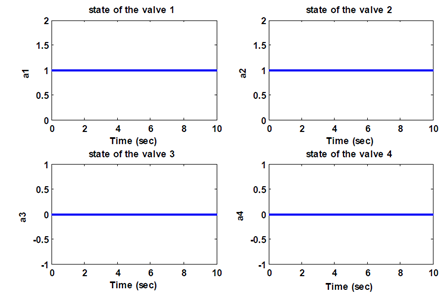

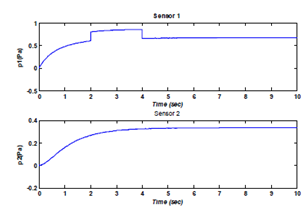

Test2: Figure 9 shows the residues in normal operation and the valves 1 and valve 2 are open, and the valves 3 and the valve 4 are closed. The states of the valves are presented in Figure 10.

Figure 9 The residues without default.

Figure 10 The states of the four valves.

Second scenario

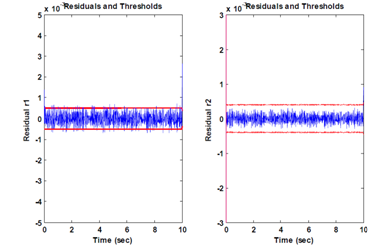

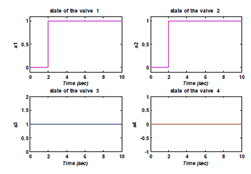

Test1: Faulty operation (with default), the four valves are open. The states of the four valves are shown in Figure 11. A default of 0.2 [Pa] on the first sensor p1 is occurred between t=2s and t=4s, the responses of residues are shown in Figure 12 & Figure 13 shows the outputs of the system. We note that the default is detected by the two residues. These residues exceed the thresholds during the presence of default.

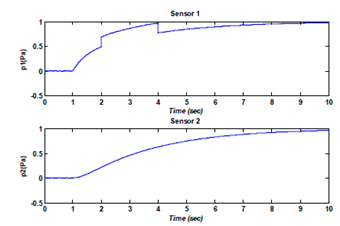

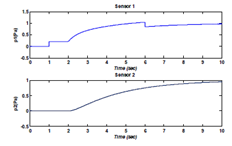

Test2: Now the default is considered with the following operation; the mode change is at t= 1s. The operation of the system in different states of the valves (opening of the valve 1 and 2 at t = 1s, the valve 3 open and the valve 4 is closed). The sensors are in Figure 14, the states of the valves are in Figure 15. The reaction of residues is shown in Figure 16. In this test, at t = 1s the mode change at t = 1s and detection of default at t = 2s and 4s.

Figure 11 The states of the four valves.

Figure 12 The responses of residues.

Figure 13 The outputs of the system.

Figure 14 The outputs of the system.

Figure 15 The states of the four valves.

Figure 16 The responses of residues r1, r2.

Test3: Figure 17, 18, 19 show the results of this test. In this case, the default is occurredat t= 1s and t=6s (Figure 17) and the mode change at = 2s (Figure 18). The residues r1, r2 are equal to zero and different when the fault is occurred. We note that the two residues are sensitive to the sensor default exceeding the thresholds, thus, generating a false alarm. We can say that the fault has been detected by these two residues r1, r2 (Figure 19).

Figure 17 The sensors.

Figure 18 The stats of the valves.

Figure 19 The responses of residues r1, r2.