eISSN: 2574-8092

Mini Review Volume 4 Issue 5

Federal State Budgetary Educational Institution of Higher Education, Kerchstate Maritime Technological University, Russia

Correspondence: AB Maximov, Federal State Budgetary Educational Institution of Higher Education, Kerchstate Maritime Technological University, Russia, Tel +7 978 0657377

Received: June 22, 2018 | Published: October 30, 2018

Citation: Maximov AB, Gadeyev AV. Thermally reinforced steel flat product. Int Rob Auto J. 2018;4(5):343-345. DOI: 10.15406/iratj.2018.04.00148

This article examines the main types of thermally reinforced flat products. Some regularities of rupture of inhomogeneous material are defined here. The work reveals that reinforced spaces tilted at an angle of 45 degrees to the initial direction of crack movement more efficiently lead to braking and stopping of the main cracks due to their rerouting and splitting. Single sided speed cooling of sparingly alloy steel of 14Г2 type allows obtaining increased hardness on one side of a sheet which provides high wear resistance with the other side of a sheet to undergo cutting procedures easily. Such combination of working characteristics can be applied in machine building.

Keywords: thermally reinforced sheet, selective cooling, carbon and low-alloy steel, hardness, cooling rate, crack, crack splitting

Improvement of a combination of mechanical properties of a plate sheet from carbon and low-alloy steel is one of the main tasks of metallurgy. One of the most relevant characteristics of mechanical properties of steel is cracking resistance. Increasing of metal cracking resistance at static and dynamic loads is achieved by means of well-known methods, such as raising barriers to the movement of a crack, creating conditions for crack splitting, compression fields and other.1−3 One of the methods of crack braking is barriers in the form of a structure stronger than a matrix. It is realized in thermally reinforced sheet rolling. An objective of the article is to analyze the main types of thermally reinforced steel flat and their working characteristics.

To get thermally reinforced sheet after hot rolling or after special heating up to selective cooling on a sheet area is held.4 It results in creating of macro portions of different structures in the given configuration.

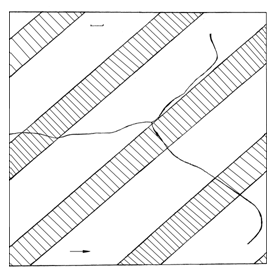

A series of papers is devoted to a research of mechanical properties and crack propagation in thermally reinforced sheet.5−11 It is established that creating on the way of a moving crack inclining cuts-off with strength 1,5 times or twice higher than matrix strength results in splitting of the main crack into secondary ones and their further braking. It is characteristic that the main crack crosses the first reinforced area practically without any change in its trajectory and advancing the second one its splitting occurs. The secondary cracks do not cross the reinforced area. They spread along the cut-off and stop. The most efficient crack braking occurs on the inclining cuts-off forming an angle of approximately 45degrees to the direction of fatigue crack propagation. Figure 1 shows changing of direction of the main crack propagation in a model material while crossing inclining reinforced areas. In a work6 on steel 09Г2 sheet samples there was produced a matrix ferrite-pearlite structure with hardness up to HV120-130 and a ferrite-bainitic reinforced area with hardness up to HV320-350 by means of selective cooling along the surface. Table 1 illustrates mechanical properties of steel 09Г2 according to a total area of reinforced areas. Hardness value in the interval 130-150HV corresponds to rate control, hardness of 320-350HV corresponds to hardening on the upper bainite with the following tempering at the temperature of 200ºC. Accept selective cooling after heating or selective heating and subsequent cooling thermally reinforced material can be obtained with deliberately diverse structure in thickness. It is achieved by means of single sided speed cooling of sheet products.12,13 In a work14 samples of steel 14Г2 plate after heating up to 930-950ºC were subjected to single sided speed cooling. As a result, speed cooled side had a fine bainite-pearlite structure with hardness up to 400-430HV, and the opposite side had a ferrite-pearlite structure with hardness up to 280-300HV corresponding to normalization. Control samples were subjected to normalization. Samples were tested for longitudinal stability on a scheme of eccentric narrowing. Table 2 demonstrates test results. If reinforced areas are subjected to compression deformation when being tested, the capacity of the sample is 30-50% higher than when undergoing the tensile of reinforced areas. In this case critical tension is virtually equal to that of standard samples. In coal-mining machine building sheet and plate steel of Cт3сп and 10ХСНД grades is used for manufacturing of separate units of coal-mining machines, power driven chains and transporter equipment. Amplification of chemical formula leads to appreciation of a product and impairs its constructability, especially weld ability, without raising its durability. Surfacing providing hardness up to 40-50HRC is used to increase local durability.

Figure 1 Trajectory of crack propagation in a model of inhomogeneous material; Direction of pipe length, ///// - reinforced areas.8

A total area of reinforced areas, % |

Ultimate tensile strength, , MPa |

Flow limit, , MPa |

Percentage extension, , % |

0 |

480 |

330 |

30,0 |

25 |

585 |

400 |

24,0 |

50 |

690 |

465 |

18,5 |

75 |

800 |

530 |

13,0 |

100 |

910 |

600 |

7,5 |

Table 1 Influence of a total area of reinforced areas on mechanical properties of steel 09Г2.2

Types of heat treatment |

Maximum |

Critical |

Maximum |

Ratio of a cross-section compressed |

|

Single sided cooling |

1* |

47,2 |

31,0 |

35,7 |

70,5 |

2* |

31,2 |

22,3 |

52,0 |

52,4 |

|

Normalization |

29,0 |

21,5 |

20,3 |

49,5 |

|

Table 2 Parameters of loading of samples when being tested for longitudinal stability.14 *1 – narrowing of a reinforced part of a sample, 2- tensile of a reinforced part of a sample

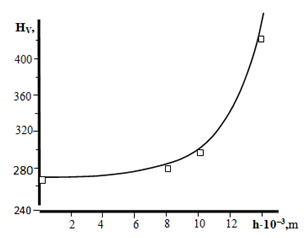

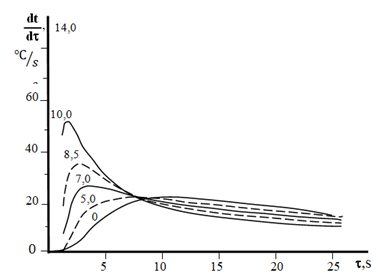

In this case critical tension is virtually equal to that of standard samples. In a work15 single sided speed cooling of samples from 14Г2 steel results in changing of hardness over the thickness from 45-35HRC to 26-28HRC. Figure 2 presents estimated distribution of speed cooling over the thickness of a cooled sample. Such kind of cooling across the cross-section of a sample causes forming of a diverse microstructure, whose hardness is presented in Figure 3. By virtue of sparingly alloy steel of 14Г2 steel type single sided speed cooling provides sufficiently high hardness and subsequently durability in combination with good mechanical cutting on the opposite side.

Figure 2 Distribution of hardness over the thickness of a cooled plate.15

Figure 3 Distribution of speed cooling over the thickness of a plate. Figures at curves are the distance from uncooled surface in mm.15

On the base of analysis of existing schemes of a thermally reinforced sheet, it has been shown that tilted cuts-off of a section of two structures of different strengths facilitate braking and rerouting of the main crack. It is possible to get sheet products of sparingly alloy steel of 14Г2 type with one side being highly hard and durable and the opposite side being good for mechanical cutting procedures.

None.

The author declares there is no conflict of interest.

©2018 Maximov, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.