eISSN: 2574-8092

Research Article Volume 2 Issue 6

1Department of Hydrodynamics, National University of Shipbuilding Admiral Makarov (NUOS), Ukraine

2Department of Mechanical Engineering, Malek University of Technology (MUT), Iran

3Department of Irrigation and Reclamation Engineering, Tehran University, Iran

Correspondence: Mohammad Moonesun, Department of Mechanical Engineering, Malek University of Technology (MUT), Iran

Received: May 03, 2017 | Published: August 10, 2017

Citation: Moonesun M, Ghasemzadeh F, Korol Y, et al. Effective depth of regular wave on submerged submarines and AUVs. Int Rob Auto J. 2017;2(6):208-216. DOI: 10.15406/iratj.2017.02.00037

This paper evaluates the effective depth of waves on the submarine at the depth of water. At the depth called the "Wave Base" which equals to l/2 the wave effects become so small that motions are negligible. This paper aimed to recommend a minimum safe depth for calm and stable motions of a submarine. This paper concludes the depth of 0.1l could be recommended as an operational safe and approximately calm depth for submarines. For this study, a torpedo shaped submersible is analyzed in some depths accompanying by regular surface wave. By increasing the depth, the reduction of submarine motions is evaluated. The results of this research can be used for AUVs, research submersibles and naval submarines. This analysis is performed by CFD tools of Flow–3D (V.10) software based on solving the RANS equations and VOF method.

Keywords: CFD, regular wave, submarine, motion, flow3d, VOF

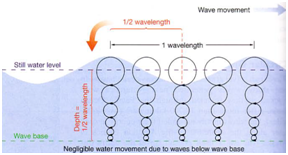

Water wave is an orbital wave in which particles moves in an orbital path. These waves transmit energy along the interface between two fluids of different density. Orbital motion dies out quickly below the surface. At some depth below the surface, the circular orbits become so small that motion is negligible. This depth is called the "Wave Base". Wave base can be regarded equal to one–half the wavelength (l/2) measured from still water level (Figure 1). Only wave length controls the depth of the wave base, so the longer the wave, the deeper the wave base. The decrease of orbital motion with depth has many practical applications. For instance, submarines can avoid large ocean waves simply by submerging below the wave base. Even the largest storm waves will go unnoticed if a submarine submerges to only 150meters.1 Floating bridges and floating oil rigs are constructed so that most of their mass is below wave base, so they will be unaffected by wave motion. In fact offshore floating airport runways have been designed using similar principles. Additionally, seasick scuba divers find relief when they were submerged into the calm, motionless water below wave base.1 Therefore, deep water defines as depth more than l/2. The hydrodynamic forces of ocean surface wave on the submerged bodies are studied in a number of fields of engineering such as:

Figure 1 Orbital motion in waves.1

In the field of submarine hydrodynamic near the free surface effect or in snorkel depth (or periscope depth) three general categories could be considered:

Finally after the literature survey, it can be stated that approximately all references are based on potential flow for in viscid fluid. For modeling the 3D object and calculating their hydrodynamic coefficient, some methods such as strip theory and conformal mapping should be used which are basically incompatible with submerged body (without water plane area). Other activities for adjusting these potential flow solutions to submerged bodies such as33 has clarified that, this manner can be useful only in the early stages of design. In the early stage of design, some estimated and approximated values are sufficient. For the next stages and earning the better careful results and exactly modeling the 3D form of submarine, numerical prediction of CFD method can be a good selection. Some especially explanation of numerical methods for modeling the submarine near the free surface is presented in.32 These methods are more time consuming than analytical methods but have better results. Accordingly, our study and manner of this paper is focused on the CFD method. There is several CFD software which can model the ocean waves (regular and irregular waves) such as: Flow–3D, IOWA and Open FOAM. This study uses Flow–3D software.

In this study, the dynamic pressure fluctuation has been evaluated by a commercially available CFD solver, Flow–3D, developed by Flow ScienceInc.43

Governing equations

For solving the governing equations of fluid flow, Flow–3D uses a modification of the commonly used Reynolds–average Navier–Stokes (RANS) equations. The modifications include algorithms to track the free surface. The modified RANS equations are shown as:

Continuity: (1)

Momentum: (2)

Turbulences model

More recent turbulence models are based on Renormalization–Group (RNG) methods. The empirically predicted coefficients of k–ε model are explicitly derived in RNG model.

Numerical methodology

The commercially available CFD package Flow–3D uses the finite–volume method to solve the RANS equations.43 The computational domain is subdivided using Cartesian coordinates into a grid of variable–sized hexahedral cells. The average values for the flow parameters (pressure and velocity) for each cell, are computed at discrete times by staggered grid technique (Versteeg & Malalasekera 1995). The free surface is computed using a modified volume–of–fluid (VOF) method.43

Obstacle generation

The FAVOR (Fractional Area/Volume Obstacle Representation) method, outlined by Hirt and Sicilian (1985) and Hirt (1992), is a porosity technique used to define obstacles.

Free surface modeling

One of the most accurate methods to track the free surface of water is the VOF method. The VOF method evolved from the marker–and–cell method (Harlow and Welsh 1965) but is more computationally efficient. The VOF method is described in Nichols and Hirt (1975), Nichols et al. (1980), and Hirt and Nichols (1981).

Setting the proper values for Y+

Generally in dynamic modeling under the ocean wave effects, viscosity has a little effect and is negligible. Due to this fact, the potential flow has a wide range of applications in sea keeping engineering problems. When the viscosity has a little role, therefore, the boundary layer modeling and setting the proper Y+ values cannot be important, but it is explained here briefly. The amount of Y+ should be adjusted according to the thickness of boundary layer so that, at least laminar sub–layer could be covered correctly and completely. Then the first cell (mesh) could be situated out of it. Furthermore, there are some advises about proper values of Y+ in papers and scientific references. Therefore, the fluid velocity before the related thickness of Y+ will be easily solved and estimated by wall functions but the velocity at the out of this region will be modeled by meshing based on RANS solving. The thickness of laminar sub–layer δ'can be calculated from this formula:

for Re<109

The Y+ is a non–dimensional parameters which gives wall distance estimation (Y):

At first, a value for Y+ is assumed. Then the gained amount of Y should not be smaller than δ' and not be smaller than the advised values otherwise the Y+ should be increased. It should be clarified that the δ' and Y depends on Reynolds number and will be changed in every longitudinal location. Therefore, these values will be different in every cell in the domain because velocity will be changed in every node and will be determined after solving the RANS equations. Therefore, it is estimation for checking the values of Y+. In our problem for length of 1.3m (at the location of the end of the body), speed of 1.56 m/s, ν of 10–6 m2/s (at 20oC), it will be calculated: Re=2.1e6, Cf =0.0033, and If we consider Y+=1, then Y=0.015mm which is considerably less than δ' and is not acceptable. In Ref44 good and extended discussions are performed about proper and advisable values of Y+ in a submerged submarine. According to these advises, after the checking the thickness of laminar sub–layer, we can keep the Y+=20 at the end part of the body as a good choice and can consider the distance of the first cell to the wall according to that. At the bow Y+=50 is advised and considered. At the middle part of the body, Y+=30 is advised. Consequently, the range of Y+=20~50 can be considered as a proper range for meshing the domain and keeping the wall distance at a proper range. At a very small area at the stagnation point in the end frontal area of the bow Y+ is considered equal to 5. These values are shown in Figure 2.

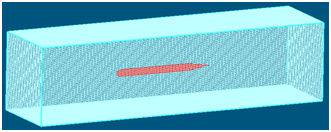

In this study a torpedo shaped submersible (Persia–110) is considered. The general form and dimensions of this model are shown in Figure 3. This model has 1 DOF, free to pitch. The model has a volume of 8.38 liter, total area of 0.36m2 and weight of 8.38kg and transverse moment of inertia (Iyy) of 1.3kg.m2.This models is the same in several depths in CFD method and the same for validation experiment in towing tank marine laboratory.

For validating the results of Flow–3D modeling, an experimental test has been performed on the model Persia–110 in the towing tank of Admiral Makarov University, which has 33(m) length, 2.5(m) width and 1.3(m) draft Figure 4. The towing tank is equipped with a trolley which operates in 0.05–6m/s speed with accuracy of ±0.02m/s. A three degree of freedom dynamometer is used for force and moment measurements. The calibration of the dynamometer was performed by calibration weights and several case studies. The model is fixed without any DOF. The test is in still water and water inside the tank is fresh water. The experiment was performed in surface condition at the draft of 7cm and speed of 1m/s. The CFD modeling was adjusted exactly according to the experimental conditions. Comparison of Figure 5a & Figure 5b shows a good agreement between experimental and CFD results. The variations of free surface have a good compatibility. The comparison of the resistance in these two conditions is represented in Table 1. The difference of about 6.6percentages is reasonable and acceptable. This validation case clearly shows the capability of a CFD tool, Flow–3D to reasonably predict the hydrodynamic problems of incompressible flow.

Figure 4a Marine laboratory of Admiral Makarov University.

Figure 4b Model Persia-110.

Figure 4 Towing tank and model.

Figure 5 Comparison of the results of the experiment and CFD method.

(a) Test in the surface draft of 7 cm and speed of 1 m/s (b) CFD modeling in the same conditions of experiment

Resistance in experiment |

1.67(N) |

Resistance in CFD |

1.79(N) |

Difference |

6.60% |

Table 1 Comparison of resistance

The general configurations and dimensions of domain are shown in Figure 6. The length and width are 12 and 2.6meters. Depth is 4 meters (3.5 for draft and 0.5 for freeboard). The boundary conditions are: Input: wave, Output: Specified pressure and other sides are symmetry. The model is situated in different depths of "h" according to Figure 6a. There are two mesh block: one block for the total domain with coarse meshes and other block for fine meshes around the object body. The accuracy of the shape of the body depends upon the fine meshes (Figure 6b, Figure 6c). For producing the wave, the input boundary condition is "Wave". Flow–3D can produce regular and irregular waves. The produced wave and the situation of the object under the waves are shown in Figure 6d. The reason of selecting each parameter is mentioned below.

(a) Dimensions of Domain (in meter).

(b) Boundary conditions in domain.

(c) Fine meshes in Mesh Block2.

(d) Generated wave and position of submarine.

Figure 6 Schematic of the simulation in FLOW-3D.

Meshes

As mentioned above, there are two meshing block. The dimensions of mesh block2 are: 4*1*1 meters. By changing the location of the model, the situation of the mesh block 2 has been changed. For selecting the proper mesh numbers and mesh independency evaluation, several mesh numbers were analyzed (Figure 7). This diagram shows that for mesh numbers after 500.000 the variation is very little and after 800.000 remains almost constant. Therefore in all conditions of analyses in this study, the mesh number considered 800.000 which are 300.000 for mesh block1 and 500.000 for mesh block 2. Therefore mesh block 2 contains fine meshes around the object. Generally it should be notified that in wave problem, it doesn't need for very fine meshes for modeling the boundary layer because the frictional forces are very small compare to the wave pressure forces. All meshes are hexahedral and without skew. Aspect ratio is 1, expansion factor between mesh block 1 and 2 equals to 2 and inside every block is 1. Mesh planes are coincided in the adjacent meshes.

Wave modeling

The defined Input boundary condition is a regular wave. General definitions of regular wave are represented in Figure 8. Here these parameters are defined in Flow–3D: wave amplitude 0.18meters, wave period 1 second and mean fluid depth (according to the depth of domain) is 3.5meters and current velocities are regarded zero. Based on these definitions, deep water condition is compatible because d/l>0.5. For deep waters according to the formula of l=1.56T2 the wave length is 1.56meters. Wave speed according to C=1.25 is 1.56m/s. The orbital radius of wave articles path(R) according to this formula is depended on the distance from water surface (h): R= A.e–kh and k=2p/l. The variations of article radius versus depth were shown in Figure 1 and here can be stated as:

Figure 8 Linear wave definition.43

Simulation time

For selecting the proper simulation time, the time history of variation of pitch angle was studied in 100 seconds (Figure 9). This diagram shows that there are two overshoot points (maximum and minimum) and except these values, other variations are smooth and inside a certain limit. These overshoots happen because of initial momentum of inertia. For saving the time, these overshoot points were eliminated and simulation time was considered 20 seconds.

Domain dimensions

In this problem, the specifications of wave are very important for determination of domain dimension.

Length: The considered wave length is about 1.56meters. For better forming of wave before arriving to the object, more than two complete waves are considered in 5meters. About the same value is considered after the object equal to 5.7 meters. By considering the 1.3meter length of the object, the total length of domain is achieved 12 meters.

Breadth: The considered breadth is equal to object length (L=1.3m) to each side and the total breadth is 2L.

Breadth: As mentioned above, the wave base is approximately equal to l/2. This study aims to evaluate the wave effects on the submarine at the depth of 2l. For avoiding the bottom effects, the draft of domain is considered 3.5meters. The wave amplitude (A) is 0.18 meter, thus the freeboard above water level is considered 0.5meter. Therefore the depth of domain is considered 4 meters. Settings of simulation are abstracted in Table 2.

Elements |

Boundary Conditions |

Descriptions |

|

Conditions |

with free surface and linear wave - domain with inlet, outlet and symmetry - without heat transfer- without current velocity |

||

Dimensions |

L*B*D=12*2.6*4m- draft 3.5m |

||

Domain |

Cubic |

Grid |

structured grid- hexahedral cells-without skew- two mesh block- more fine meshes in mesh block 2 around the object- Mesh number of 800.000, aspect ratio 1, expansion factor between blocks 2 and inside blocks 1. Y+=15~30 |

Settings |

Simulation time: 20 sec- Time step=0.005-0.013sec |

||

Fluid |

- |

Incompressible fluid (fresh water)- tempreture:20 deg- ρ=999.841 kg/m3- turbulent modeling: Standard k-ε |

|

Object |

GMO |

Submarine, length:1.3m, Diameter:0.1, 1DOF free to pitch angle |

|

Input |

Inlet |

Linear wave, wave amplitude 0.18 m, wave period 1sec, mean fluid depth 3.5m |

|

Output |

Outlet |

Specified pressure (Specified fluid level: 3.5m) |

|

Symmetry |

Symmetry |

In 4 faces |

|

Initial conditions |

Fluid level: 3.5m |

Table 2 Settings of simulation.

Considered Conditions for Analyses

For studying the wave effects on the submarine, several depths for submarine situation (h) are considered according to Figure 6a and Table 3.

Submarine Depth (m) |

Description (Equivalent to) |

|

1 |

0 |

Body tangent to free surface |

2 |

0.05 |

Rs (or) 0.03l |

3 |

0.1 |

Ds (or) 0.06l |

4 |

0.15 |

1.5Ds (or) 0.09l |

5 |

0.25 |

2.5Ds (or) 0.16l |

6 |

0.35 |

3.5Ds (or) 0.22l |

7 |

0.55 |

5.5Ds (or) 0.35l |

8 |

0.75 |

7.5Ds (or) 0.48l |

9 |

0.95 |

9.5Ds (or) 0.61l |

10 |

1.6 |

@l |

11 |

2.4 |

@ 1.5l |

12 |

3 |

@ 3l |

Table 3 Considered conditions for analyses

Method of extracting the results

According to the diagram of Figure 9, there is a disordered and irregular variation of pith angle versus time. Usually in sea keeping studies, Root Mean Square (RMS) analysis is used. Therefore, here the RMS value of pitch angle is calculated in every depth, after eliminating the overshoot points. RMS is calculated as Eqn.9:

(9)

Results

The time history of pith angle in 12 conditions is analyzed. Figure 10 shows two samples of time history for h=0.1 and 0.35 meter. Table 3 represents the results for each depth. The percentage of decrease in last column is based on comparison to h=0 therefore; average= . It should be notified that the static pitch angle of this submarine is 0.34 degree.

Discussion and analysis

It is obvious that by increasing in the depth, the wave effect decreases and pitch angle approaches to static trim angle. The last column of Table 4 can smoothly describe the percentages of reduction in pitch angle. In depth of 0.03l there is 33% reduction and in depth of 0.06l there is 51% reduction. Intense gradient of pitch angle will be continued until the depth of 0.09l which experiences 59% reduction. After this depth, there is a gentle variation. Values of RMS at the depths ofl, 1.5l and 2l are equal to static trim angle which meant no effect of waves on the submarine. Almost around the depth of l/2 the wave effect is negligible. The reason of this phenomenon is based on the principle of "wave base" which described in Introduction. It means that if a submarine dive to the depth more than l/2, doesn't experience the wave effects. For long swell waves, the value of l/2 may be more than the collapse depth of the submarine and be impossible. In this condition, if submarine dives to the depth about 0.1l, it can avoid the 60% of motions and shakes. For instance, in a swell wave (which is very similar to regular waves) with a period of 15seconds, the wave length is 351meters. The half wave length is about 175meters which may be dangerous depth for a submarine and it can be catastrophic. Despite that, if submarine dives to the depth of 0.1l equal to about 35meters, can navigate in very calm and more stable conditions.

Depth (m) |

Depth (l) |

RMS (degree) |

Percentage of Decrease (%) |

|

1 |

0 |

0 |

3.43 |

0 |

2 |

0.05 |

0.03 |

2.29 |

33 |

3 |

0.1 |

0.06 |

1.67 |

51 |

4 |

0.15 |

0.09 |

1.42 |

59 |

5 |

0.25 |

0.16 |

1.38 |

60 |

6 |

0.35 |

0.22 |

1.22 |

64 |

7 |

0.55 |

0.35 |

1 |

71 |

8 |

0.75 |

0.48 |

0.82 |

76 |

9 |

0.95 |

0.61 |

0.44 |

87 |

10 |

1.6 |

1 |

0.1 |

97 |

11 |

2.4 |

1.5 |

0.03 |

99 |

12 |

3 |

2 |

0 |

100 |

Table 4 RMS values for considered conditions

In conclusion, the results could be abstracted in the Figure 11 which fairly shows the gradient of motions versus depth of submergence. Depth of l/2 could be considered as the absolutely calm depth but the depth of 0.1l could be recommended as an operational safe and approximately calm depth for submarines.

|

l |

Wave length (m) |

|

θ |

Pitch angle (degree) |

|

δ |

thickness of boundary layer (m) |

|

δ' |

thickness of laminar sub layer (m) |

|

τw |

Wall shear stress (N/m2) |

|

ν |

kinematic viscosity (m2/s) equals to 0.000001 for water at 20oC |

|

A |

Wave amplitude (m) |

|

AUV |

Autonomous Underwater Vehicle |

|

Cf |

skin–friction coefficient |

|

CFD |

Computational Fluid Dynamics |

|

d |

Depth of water (m) |

|

Ds |

Diameter of submarine body |

|

DOF |

Degree Of Freedom |

|

GMO |

General Moving Object |

|

h |

Distance from top of the object (submarine) to the water surface (m) |

|

IHSS |

Iranian Hydrodynamic Series of Submarines |

|

L |

Length of object (submarine) |

|

R |

orbital radius of wave articles path (m) |

|

Re |

Reynolds Number (–) |

|

Rs |

Radius of submarine body |

|

RMS |

Root Mean Square |

|

VOF |

Volume Of Fluid |

|

U |

Speed between submarine and fluid (m/s) |

|

u* |

friction velocity (m/s) |

|

Y |

wall distance (m) |

|

Y+ |

non–dimensional wall distance (–) |

None.

Author declares that there is none of the conflicts.

©2017 Moonesun, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.