International Journal of

eISSN: 2475-5559

Research Article Volume 5 Issue 1

Department of Mechanical Engineering, University of Lagos, Akoka, Lagos, Nigeria

Correspondence: M G Sobamowo, Department of Mechanical Engineering, University of Lagos, Akoka, Lagos, Nigeria, Tel +2347034717417

Received: January 01, 2020 | Published: March 16, 2020

Citation: Sobamowo MG, Yinusa AA, Akinshilo AT, et al. Homotopy analysis method to MHD-slip flow of an upper- convected maxwell viscoelastic nanofluid in a permeable channel embedded in a porous medium. Int J Petrochem Sci Eng. 2020;5(1):11?20. DOI: 10.15406/ipcse.2020.05.00118

The expanding applications of viscoelastic fluids in biomedical engineering and industrial processes require proper under and physical insights into the flow phenomena of the fluids. In this work, simultaneous effects of slip and magnetic field on the flow of an upper convected Maxwell (UCM) nano fluid through a permeable micro channel embedded in porous medium are analyzed using homotopy analysis method. The results of the approximate analytical solution depict very good agreements with the results of the fifth-order Runge-Kutta Fehlberg method (Cash-Karp Runge-Kutta) coupled with shooting methodfor the verification of the mathematical method used in analyzing the flow. Thereafter, the obtained analytical solutions are used to investigate the effects of pertinent rheological parameters on flow. It is observed from the results that increase in slip parameter, nano particle concentration and Darcy number lead to increase in the velocity of the upper-convected Maxwell fluid while increase in Deborah’s, Hartmann, and Reynold numbers decrease the fluid flow velocity towards the lower plate but as the upper plate is approached a reverse trend is observed. The study can be used to advance the application of upper convected Maxwell flow in the areas of in biomedical, geophysical and astrophysics.

Keywords: slip analysis, upper-convected maxwell flow, viscoelastic nano fluid, magnetic field, porous medium

The vast areas of applications and the importance of the viscoelastic fluid flow in modern science and engineering such as gaseous diffusion, blood flow through oxygenators, flow in blood capillaries have continue to aroused the research interests. Complex rheological fluids such as blood, paints, synovial fluid, saliva, jam which cannot be adequately described by Navier Stokes. This lead to the development of complex constitutive relations to capture the flow behaviour of the complex fluids.1 Among the newly developed fluid models of the integral and differential-type models, Upper convected Maxwell fluid model has showed to be an effective fluid model that capture these phenomena of fluids especially of those with high elastic behaviours such as polymer melts. Since highly elastic fluids have high Deborah number.2,3 In the analysis of Maxwell flow, Fetecau 4 presented a new exact solution for flow though infinite micro channel while Hunt5 studied convective fluid flow through rectangular duct. Sheikholeslami et al.6 investigated magneto hydrodynamic field effect on flow through semi-porous channel utilizing analytical methods. Shortly after, Sheikholeslami 7-9 adopted numerical solutions in the investigations of nanofluid in semi-annulus enclosure. Flow of upper convected Maxwell fluid through porous stretch sheet was investigated by Raftari and Yildirim.10 Entophy generation in fluid in the presence of magnetic field was analyzed by Sheikholeslami and Ganji 11 using lattice Boltzman method while Ganji et al.12 used analytical and numerical methods for the fluid flow problems under the influence of magnetic field. The flow of Viscoelastic fluid through a moving plate was analyzed by Sadeghy and Sharifi 13 using local similarity solutions. Mass transfer and flow of chemically reactive upper convected Maxwell fluid under induced magnetic field was investigated by Vajrevulu et al.14 Not long after Raftari and Vajrevulu 15 adopted the homotopy analysis method in the study of flow and heat transfer in stretching wall channels considering MHD. Hatamiet al. 16 presented forced convective MHD nano fluid flow conveyed through horizontal parallel plates. Laminar thermal boundary flow layer over flat plate considering convective fluid surface was analyzed by Aziz 17 using similarity solution. Beg and Makinde 18 examined the flow of viscoelastic fluid through Darcian microchannel with high permeability.

Most of the above reviews studies focused on the analysis of fluid flow under no slip condition. However, such an assumption of no slip condition does not hold in a flow system with small size characteristics size or low flow pressure. The pioneer work of flow with slip boundary condition was first initiated by Navier.19 Such an important condition (slip conditions) occur in various flows such as nano fluids, polymeric liquids, fluids containing concentrated suspensions, flow on multiple interfaces, thin film problems and rarefied fluid problems.19–31 Due to the practical implications of the condition of flow processes, several studies on the effects of slip boundary conditions on fluids flow behaviours have been presented by many researchers.19–32Abbasi et al.33 investigated the MHD flow characteristics of upper-convicted Maxwell viscoelastic flow in a permeable channel under slip conditions. However, an analytical study on simultaneous effects of slip, magnetic field, nano particle and porous medium on the flow characteristics of an upper-convected Maxwell viscoelastic nano fluid has not been carried out in literature. Therefore, in this work, slip flow analysis of an upper-convected Maxwell viscoelastic nano fluid through a permeable micro channel embedded in porous medium under the influence of magnetic field is analyzed. The nonlinear partial differential equations governing the flow phenomena are converted to a nonlinear ordinary differential equation using similarity transformation. Thereafter, the ordinary differential is solved using homotopy analysis method.

Model Development and Analytical Solution

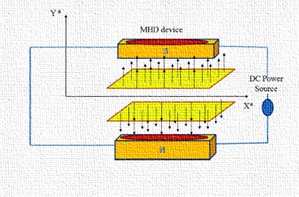

Consider a laminar slip flow of an electrically conducting fluid in a microchannel is considered. Along the y axis, magnetic field are imposed uniformly, as described in the physical model diagram (Figure 1) It is assumed external electric field is zero and constant of electrical conductivity is constant. Therefore, magnetic Reynolds number is smalland magnetic field induced by fluid motion is negligible.

Figure 1 Flow of upper-convected Maxwell fluid between in permeable channel embedded in porous medium.

Based on the assumptions, the governing equation for the Maxwell fluid is presented as [8]

T−pI+S (1)

Where the Cauchy stress tensor is T and S is the extra-stress Tensor which satisfies

S+λ(dsdt−LS−SLT)μAL (2)

The Rivlin-Ericksen tensor is defined by

AL=∇V+(∇V)T (3)

The continuity and momentum equation’s for steady, incompressible two dimensional flows are expressed as

∂ˉu∂x+∂ˉv∂y=0 (4)

ρnf(u∂u∂x+v∂u∂y)=−∂P∂x+∂Sxx∂x+∂Sxy∂y−σnfB2(t)u−μnfuKp, (5)

ρnf(ˉu∂ˉv∂x+ˉv∂ˉv∂y)=−∂P∂x+∂Syx∂x+∂Syy∂y−μnfˉvKp, (6)

where the effective density ρnf and effective dynamic viscosity μnf of the nanofluid are defined as follows:

ρnf=(1−ϕ)ρf+ϕρs, (7)

μnf=μf(1−ϕ)2.5, (8)

σnf=σf[1+3{σsσf−1}ϕ{σsσf+2}ϕ−{σsσf−1}ϕ], (9)

Sxx,Sxy,Syx and Syy are extra stress tensors and ρ is the density of the fluid.

Using the shear-stress strain for a upper-convected liquid, The governing equations of fluid motion is easily expressed as

∂u∂x+∂v∂y=0 (10)

u∂u∂x+v∂u∂y+λ(u2∂2u∂x2+v∂2u∂y2+2uv∂2u∂x∂y)=vnf∂2u∂y2−σnfB2(t)uρnf−νnfuKp, (11)

where flow velocity component (u,v) are velocity component along the xand y directions respectively. Since flow is symmetric about channel center line, attention is given to the flow region 0<y<H. Appropriate boundary condition is given as [14]:

y=0:∂u∂x=0,v=0 (12)

y=H:∂u∂y=−βu, v=Vw (13)

where Vwand β are the wall characteristic suction velocity and sliding friction respectively.

The physical and thermal properties of the base fluid and nano particles are given in Table 1 and Table 2, respectively.

Base fluid ρ (kg/m3) Cp ( J/kgK) k (W/mK) σ(Ω-1m-1) |

Pure water 997.1 4179 0.613 5.50 |

Ethylene Glycol 1115 2430 0.253 1.07 |

Engine oil 884 1910 0.144 4.02 |

Kerosene 783 2010 0.145 4.01 |

Table 1 Amplitude in mill volts of the Lead-1 of electrocardiography in sheep

Nanoparticles ρ (kg/m3) Cp ( J/kgK) k (W/mK) σ(Ω-1m-1) |

|||

Copper (Cu) 8933 385 401 59.6 |

|||

Aluminum oxide (Al2O3) 3970 765 40 16.7 |

|||

SWCNTs 2600 42.5 6600 1.26 |

|||

Silver (Ag) 10500 235.0 429 |

|||

Titanium dioxide (TiO2) 4250 686.2 8.9538 |

|||

Copper (II) Oxide (CuO) 783 540 18 |

|||

Table 2 Amplitude in mill volts of the Lead-1 of electrocardiography in sheep

The similarity variables are introduced as:

η=yH, u=−Vwxf'(y); v=Vwf(y); k=μHβ (14)

With the aid of the dimensionless parameters in Eq. (14), the constitutive relation is satisfied. Equation (2-4) can be expressed as:

f'''−(M2+1Da)f'+(1−ϕ)2.5((1−ϕ)+ϕρsρf)Rew(f'2−ff'')+De(1−ϕ)2.5(2ff'f''−f2f''')=0 (15)

And the boundary conditions as

η=0:f''=0;f=0 (16)

η=1:f'=−kf'':f=1

where Rew=VwHυ is the Reynolds number, De=λV2wυ is the Deborah’s number, M2=σB20Hμ is the Hartman parameter, Da=KpH is the Darcy’s number. For Rew>0 corresponds to suction flow while Rew<0 correspond to injection flow respectively.

Equ. (13) is a third-order differential equation with four boundary conditions. Through a creative differentiation of Eq. (12). Hence introducing fourth order equation as:

fiv−(M2+1Da)f″+(1−ϕ)2.5((1−ϕ)+ϕρsρf)Rew(f′f″−ff‴)+De(1−ϕ)2.5(2f′2f''−2ff″2+f2fiv)=0 (17)

The above Eq. (17) study satisfies all the four boundary conditions

Application of the Homotopy Analysis Method to the Flow Problem

The homotopy analysis method (HAM) which is an analytical scheme for providing approximate solutions to the ordinary differential equations, is adopted in generating solutions to the ordinary nonlinear differential equations .Upon constructing the homotopy, the initial guess and auxiliary linear operator can be expressed as

f0(η)=−12(3k+1)η3+3(2k+1)2(3k+1)η (18)

L(f)=f'''' (19)

L(16c1η3+12c2η2+c3η+c4)=0 (20)

Where Ci(i=1,2,3,4) are constants? Let P=∈[0,1] connotes the embedding parameter and is the non-zero auxiliary parameter. Therefore, the homogony is constructed as

Zeroth-order deformation equations

(1−P)L[F(η;p)−f0(η)]=pℏH(η)N[F(η;p)] (21)

F(0;p)=0;F''(0;p)=0;F(1;p)=1;kF''(1;p)+F'(1;p)=0 (22)

N[F(η;p)]=d4F(η;p)dη4+(1−ϕ)2.5((1−ϕ)+ϕρsρf)Rew[dF(η;p)dηd2F(η;p)dη2−F(η;p)d3(η;p)dη3]

−M2d2F(η;p)dη2−1Dad2F(η;p)dη2+De(1−ϕ)2.5[2(dF(η;p)dη)2d2F(η;p)dη2−2F(η;p)(d2F(η;p)dη2)2+(f(y;p))2d4F(η;p)dη4]

(23)

when p=0 and p=1 we have

F(η;0)=f0(η);F(η;1)=f(η) (24)

As p increases from 0 to 1. F(y;p) varies from f0(y) to f(y). By Taylor’s theorem and utilizing Eq. (26),F(y; p) can be expanded in the power series of p as follows:

F(η;p)=f0(η)+∞∑m−1fm(η)pm,fm(η)=1m!∂m(F(η;p))∂pm|p=0 (25)

where ℏ is chosen such that the series is convergent at p1; therefore, by Eq. (24) it is easily shown that

f(η)=f0(η)+∞∑m−1fm(η) (26)

Math order deformation equations

L[fm(η)−χmfm−1(η)]=ℏH(η)Rm(η) (27)

Fm(0;p)=0;F''(0;p)=0;Fm(1,p)=0;kF''m(1;p)+F'm(1,p)=0 (28)

Rm(η)=f''''m−1+m−1∑k=0[(1−ϕ)2.5((1−ϕ)+ϕρsρf)Rew(f'm−1f''k−fm−1−kf'''k)+De(1−ϕ)2.5f'm−1−k(k∑l=0(2f'k−lf''l))−De(1−ϕ)2.5fm−1−k(k∑l=0(2f''k−lf''−fk−lf''''l))] −M2f''m−1−1Daf''m−1 (29)

Now the results for the convergence, differential equation and the auxiliary function are determined according to the solution expression. So we assume

H(y)=1 (30)

The analytic solution is deve,loped using the MATLAB computational stencil. Hence the first deformation is expressed below

f1(η)=ℏ{−5672De(1−ϕ)2.5η9(3k+1)−32(−0.0071649(1−ϕ)2.5((1−ϕ)+ϕρsρf)Rew−0.042857De−0.0023810(1−ϕ)2.5((1−ϕ)+ϕρsρf)Rew−0.085714Dek)η727k3+27k2+9k+1−32(−0.15(M2+1Da)k2−0.1(M2+1Da)k−0.016667(M2+1Da)+0.3Dek2+0.3De(1−ϕ)2.5k+0.075De(1−ϕ)2.5)η527k3+27k2+9k+1+1840[(378De(1−ϕ)2.5k3−1890(M2+1Da)k3−189(1−ϕ)2.5((1−ϕ)+ϕρsρf)Rewk2+2268DDe(1−ϕ)2.52−1638(M2+1Da)k2−90(1−ϕ)2.5((1−ϕ)+ϕρsρf)Rewk−462(M2+1Da)k+468De(1−ϕ)2.5k)η31+54k2+12k+108k3+81k4+(−9(1−ϕ)2.5((1−ϕ)+ϕρsρf)Rew+52De(1−ϕ)2.5−42(M2+1Da))1+54k2+12k+108k3+81k4]−11120[(−8(1−ϕ)2.5((1−ϕ)+ϕρsρf)Rew−96(1−ϕ)2.5((1−ϕ)+ϕρsρf)Rewk−1764(M2+1Da)k3+1440De(1−ϕ)2.5k2+77De(1−ϕ)2.5k−364(M2+1Da)k)η1+54k2+12k+108k3+81k4+(−1428(M2+1Da)k2+3528De(1−ϕ)2.5k3−216(1−ϕ)2.5((1−ϕ)+ϕρsρf)Rewk2−28(M2+1Da)+7De(1−ϕ)2.5)η1+54k2+12k+108k3+81k4]} (28)

Similarly, f2(η), f3(η), f4(η), f5(η)… are found but they are too large expressions that cannot be included in this paper. However, they are included in the results displayed graphically.

Convergence of the HAM solution

It is established that the convergence and the rate of approximation for the HAM solution strongly depend on the value of the auxiliary parameter.34–37The present problem shows a wide of acceptable range of values of for the difference controlling parameters of the model as shown in (Tables 3a-3d.).

M DA K=0.1 K=0.9 |

0.5 2.0-2.0 < 0.2 -1.4< <0.4 |

1.0 1.0-1.4<ℏ <0.3 -1.1< ℏ <0.0 |

2.0 1.0-1.1< 0.5 -0.8 < ℏ <0.0 |

2.0 0.5-0.8 < ℏ <0.0-0.6< ℏ <0.0 |

3.0 0.5-0.6< ℏ <0.0-0.5< ℏ <0.0 |

Table 3a The results of admissible range of values for ℏ whenRew=-7.5 De= 0.12, ϕ=0.08

M Da k =0.1k=0.9 |

0.5 2.0 -0.8< ℏ <-0.4 -0.7< ℏ <-0.4 |

1.0 1.0 -0.7< ℏ <0.4 -0.8< ℏ <-0.4 |

2.0 1.0 -0.1< ℏ <0.0 -1.0< ℏ <-0.1 |

2.0 0.5 -1.2< ℏ <0.1 -1.0< ℏ <0.0 |

Table 3b The results of admissible range of values for ℏ whenRew=7.5 De= 1.10, ϕ=0.08

M Da k =0.1k=0.9 |

0.5 2.0 1.5< ℏ <0.1 -1.8< ℏ <0.0 |

1.0 1.0 1.7< ℏ <0.1 -1.4< ℏ <0.1 |

2.0 0.5 -0.7< ℏ <0.1 -0.7< ℏ <0.0 |

2.0 0.5 -0.6 < ℏ <0.0 -0.5< ℏ <0.0 |

3.0 0.5 -0.6< ℏ <0.0 -0.5< ℏ <0.0 |

Table 3c The results of admissible range of values for ℏ whenRew=-7.5 De= 1.10, ϕ=0.08

M Da k =0.1k=0.9 |

0.5 2.0 -1.8< ℏ <-0.5 -19< ℏ <0.0 |

1.0 1.0 -2.2< ℏ <-0.5 -2.0< ℏ <0.0 |

2.0 0.5 -0.7< ℏ <0.0 -1.5< ℏ <0.0 |

3.0 0.5 -1.0< ℏ <0.0 -1.4< ℏ <0.1 |

Table 3d The results of admissible range of values for ℏ whenRew=7.5 De= 1.10, ϕ=0.08

Numerical Procedure for the analysis of the governing equation

Eq. (15) is a fourth-order ordinary differential equation which is in this work is analyzed numerically using fifth-order Runge-Kutta Fehlberg method (Cash-Karp Runge-Kutta) coupled with shooting method. Since Runge-Kutta method is for solving first-order ordinary differential equation, the fourth-order ordinary differential equation is decomposed into a system of first-order differential equations as follows:

f'=p, (29)

f''=p'=q, (30)

f'''=q'=w,

fiv=w'=z, (31)

z=(M2+1Da)p−(1−ϕ)2.5((1−ϕ)+ϕρsρf)Rew(p2−fq)−De(1−ϕ)2.5(2fpq−f2w)

The above Eqs. (29)-(31) can be written as

a(η,f,p,q,w,z)=p, (32)

b(η,f,p,q,w,z)=q, (33)

c(η,f,p,q,w,z)=w, (34)

d(η,f,p,q,w,z)=z (35)

e(η,f,p,q,z)=(M2+1Da)p−(1−ϕ)2.5((1−ϕ)+ϕρsρf)Rew(p2−fq)−De(1−ϕ)2.5(2fpq−f2w) (36)

The iterative scheme of the fifth-order Runge-Kutta Fehlberg method (Cash-Karp Runge-Kutta) for the above system of first-order equations is given as

fi+1=fi+h(283527648k1+1857548384k3+1352555296k4+27714336k5+14k6) (37)

pi+1=pi+h(283527648l1+1857548384l3+1352555296l4+27714336l5+14l6) (38)

qi+1=qi+h(283527648m1+1857548384m3+1352555296m4+27714336m5+14m6) (39)

wi+1=wi+h(283527648n1+1857548384n3+1352555296n4+27714336n5+14n6) (40)

zi+1=zi+h(283527648r1+1857548384r3+1352555296r4+27714336r5+14r6) (41)

where

k1=a(ηi,fi,pi,qi,wi,zi)l1=b(ηi,fi,pi,qi,wi,zi)m1=c(ηi,fi,pi,qi,wi,zi)n1=d(ηi,fi,pi,qi,wi,zi)r1=e(ηi,fi,pi,qi,wi,zi)

k2=a(ηi+15h, fi+15k1h, pi+15l1h, qi+15m1h, wi+15n1h, zi+15r1h)l2=b(ηi+15h, fi+15k1h, pi+15l1h, qi+15m1h, wi+15n1h, zi+15r1h)m2=c(ηi+15h, fi+15k1h, pi+15l1h, qi+15m1h, wi+15n1h, zi+15r1h)n2=d(ηi+15h, fi+15k1h, pi+15l1h, qi+15m1h, wi+15n1h, zi+15r1h)r2=e(ηi+15h, fi+15k1h, pi+15l1h, qi+15m1h, wi+15n1h, zi+15r1h)

k3=a(ηi+310h, fi+340k1h+940k2h, pi+340l1h+940l2h, qi+340m1h+940m2h, wi+340n1h+940n2h, zi+340r1h+940r2h)l3=b(ηi+310h, fi+340k1h+940k2h, pi+340l1h+940l2h, qi+340m1h+940m2h, wi+340n1h+940n2h, zi+340r1h+940r2h)m3=c(ηi+310h, fi+340k1h+940k2h, pi+340l1h+940l2h, qi+340m1h+940m2h, wi+340n1h+940n2h, zi+340r1h+940r2h)n3=d(ηi+310h, fi+340k1h+940k2h, pi+340l1h+940l2h, qi+340m1h+940m2h, wi+340n1h+940n2h, zi+340r1h+940r2h)r3=e(ηi+310h, fi+340k1h+940k2h, pi+340l1h+940l2h, qi+340m1h+940m2h, wi+340n1h+940n2h, zi+340r1h+940r2h)

k4=a(ηi+35h, fi+310k1h−910k2h+65k3h, pi+310l1h−910l2h+65l3h, qi+310m1h−910m2h+65m3h, wi+310n1h−910n2h+65n3h, zi+310r1h−910r2h+65r3h )

l4=b(ηi+35h, fi+310k1h−910k2h+65k3h, pi+310l1h−910l2h+65l3h, qi+310m1h−910m2h+65m3h, wi+310n1h−910n2h+65n3h, zi+310r1h−910r2h+65r3h )

m4=c(ηi+35h, fi+310k1h−910k2h+65k3h, pi+310l1h−910l2h+65l3h, qi+310m1h−910m2h+65m3h, wi+310n1h−910n2h+65n3h, zi+310r1h−910r2h+65r3h )

n4=d(ηi+35h, fi+310k1h−910k2h+65k3h, pi+310l1h−910l2h+65l3h, qi+310m1h−910m2h+65m3h, wi+310n1h−910n2h+65n3h, zi+310r1h−910r2h+65r3h )

r4=e(ηi+35h, fi+310k1h−910k2h+65k3h, pi+310l1h−910l2h+65l3h, qi+310m1h−910m2h+65m3h, wi+310n1h−910n2h+65n3h, zi+310r1h−910r2h+65r3h )

k5=a(ηi+h, fi−1154k1h+52k2h−7027k3h+3527k4h, pi−1154l1h+52l2h−7027l3h+3527l4h,qi−1154m1h+52m2h−7027m3h+3527m4h, wi−1154n1h+52n2h−7027n3h+3527n4h, zi−1154r1h+52r2h−7027r3h+3527r4h )

l5=b(ηi+h, fi−1154k1h+52k2h−7027k3h+3527k4h, pi−1154l1h+52l2h−7027l3h+3527l4h,qi−1154m1h+52m2h−7027m3h+3527m4h, wi−1154n1h+52n2h−7027n3h+3527n4h, zi−1154r1h+52r2h−7027r3h+3527r4h )

m5=c(ηi+h, fi−1154k1h+52k2h−7027k3h+3527k4h, pi−1154l1h+52l2h−7027l3h+3527l4h,qi−1154m1h+52m2h−7027m3h+3527m4h, wi−1154n1h+52n2h−7027n3h+3527n4h, zi−1154r1h+52r2h−7027r3h+3527r4h )

n5=c(ηi+h, fi−1154k1h+52k2h−7027k3h+3527k4h, pi−1154l1h+52l2h−7027l3h+3527l4h,qi−1154m1h+52m2h−7027m3h+3527m4h, wi−1154n1h+52n2h−7027n3h+3527n4h, zi−1154r1h+52r2h−7027r3h+3527r4h )

r5=d(ηi+h, fi−1154k1h+52k2h−7027k3h+3527k4h, pi−1154l1h+52l2h−7027l3h+3527l4h,qi−1154m1h+52m2h−7027m3h+3527m4h, wi−1154n1h+52n2h−7027n3h+3527n4h, zi−1154r1h+52r2h−7027r3h+3527r4h )

k6=a(ηi+78h, fi+163155296k1h+175512k2h+57513824k3h+44275110592k4h+2534096k5h,pi+163155296l1h+175512l2h+57513824l3h+44275110592l4h+2534096l5h,qi+163155296m1h+175512m2h+57513824m3h+44275110592m4h+2534096m5h,ni+163155296w1h+175512w2h+57513824w3h+44275110592w4h+2534096w5h,zi+163155296r1h+175512r2h+57513824r3h+44275110592r4h+2534096r5h)

l6=b(ηi+78h, fi+163155296k1h+175512k2h+57513824k3h+44275110592k4h+2534096k5h,pi+163155296l1h+175512l2h+57513824l3h+44275110592l4h+2534096l5h,qi+163155296m1h+175512m2h+57513824m3h+44275110592m4h+2534096m5h,ni+163155296w1h+175512w2h+57513824w3h+44275110592w4h+2534096w5h,zi+163155296r1h+175512r2h+57513824r3h+44275110592r4h+2534096r5h)

m6=c(ηi+78h, fi+163155296k1h+175512k2h+57513824k3h+44275110592k4h+2534096k5h,pi+163155296l1h+175512l2h+57513824l3h+44275110592l4h+2534096l5h,qi+163155296m1h+175512m2h+57513824m3h+44275110592m4h+2534096m5h,ni+163155296w1h+175512w2h+57513824w3h+44275110592w4h+2534096w5h,zi+163155296r1h+175512r2h+57513824r3h+44275110592r4h+2534096r5h)

n6=d(ηi+78h, fi+163155296k1h+175512k2h+57513824k3h+44275110592k4h+2534096k5h,pi+163155296l1h+175512l2h+57513824l3h+44275110592l4h+2534096l5h,qi+163155296m1h+175512m2h+57513824m3h+44275110592m4h+2534096m5h,ni+163155296w1h+175512w2h+57513824w3h+44275110592w4h+2534096w5h,zi+163155296r1h+175512r2h+57513824r3h+44275110592r4h+2534096r5h)

r6=e(ηi+78h, fi+163155296k1h+175512k2h+57513824k3h+44275110592k4h+2534096k5h,pi+163155296l1h+175512l2h+57513824l3h+44275110592l4h+2534096l5h,qi+163155296m1h+175512m2h+57513824m3h+44275110592m4h+2534096m5h,ni+163155296w1h+175512w2h+57513824w3h+44275110592w4h+2534096w5h,zi+163155296r1h+175512r2h+57513824r3h+44275110592r4h+2534096r5h)

Using theabove fifth-order Runge-Kutta Fehlberg method coupled with shooting method,computer programs are written in MATLAB for the solutions of the Eq. (14). The results for step size, h = 0.01 are presented in the following section.

The results of the solutions of the nonlinear model with the aid of homotopy analysis method (HAM) is compared with the results of the fifth-order Runge-Kutta Fehlberg method (RKFNM) coupled with shooting method as shown in in (Table 4). As observed from the Table, good agreement is established between the results of the numerical and homotopy analysis methods.

η |

Rkfnm |

ham |

|rkfnm-ham| |

|

0 |

0 |

0 |

0 |

|

0.05 |

0.070154 |

0.0701 |

2.89E-07 |

|

0.1 |

0.139997 |

0.139998 |

5.69E-07 |

|

0.15 |

0.209217 |

0.209218 |

8.33E-07 |

|

0.2 |

0.259219 |

0.259218 |

1.08E-06 |

|

0.25 |

0.344546 |

0.344548 |

1.29E-06 |

|

0.3 |

0.410038 |

0.41004 |

1.47E-06 |

|

0.35 |

0.473672 |

0.473674 |

1.61E-06 |

|

0.4 |

0.535148 |

0.535146 |

1.71E-06 |

|

0.45 |

0.594153 |

0.594155 |

1.75E-06 |

|

0.5 |

0.650402 |

0.650404 |

1.75E-06 |

|

0.55 |

0.7036 |

0.703599 |

1.7E-06 |

|

0.6 |

0.75345 |

0.753452 |

1.61E-06 |

|

0.65 |

0.79968 |

0.799682 |

1.47E-06 |

|

0.7 |

0.842013 |

0.842014 |

1.29E-06 |

|

0.75 |

0.880181 |

0.880182 |

1.08E-06 |

|

0.8 |

0.913929 |

0.913929 |

8.45E-07 |

|

0.85 |

0.94301 |

0.943011 |

6.05E-07 |

|

Table 4 Comparison of results of numerical and homotopy analysis method for f(η), whenDe 0.1,Da-1 M 0,K 0.1,Rew=4

Using copper nanoparticle and water, the results obtained from the analytical solutionare shown graphically in Figs. 2-9, when Rew8,De0.1,M2,,Da2 and ϕ=0.01 , unless otherwise stated. Figure 2. illustrate the influence of nano particle concentration (ϕ) on the flow process. As shown from the Figure 3, the quantitative increase of the nano particle concentration causes increase in the velocity distribution. It is very important to indicate viscoelastic nature of the fluid. Therefore, the effects of Deborah’s number on the flow process are depicted in Fig. 3. It illustrated in that increase in Deborah’s number (De) which illustrates the UCM as highly elastic fluid (such as polymeric melts) depicts decrease in fluid flow velocity.

The influence of magnetic field parameter on flow of the UCM fluid under is depicted in (Figure 4). As observed in the figure, the numerical increase of the magnetic or Hartmann parameter (M) shows decreasing velocity profile. This is because the applied magnetic field produces a damping effect (Lorentz force) on the flow process. This damping effects increases as the quantitative or numerical value of the Hartmann number increases. It should be noted that the effects magnetic field parameter is maximum towards the upper flow channel. In order to shown the effect of the permeability of the porous medium on the flow, effect of Darcy parameter (Da) on fluid transport is illustrated in (Figure 5) Increasing Darcy number demonstrates increasing velocity profile as shown in the figure.

(Figure 6) shows the effect of fluid slip parameter (k) on the velocity of the fluid flow. It should be noted that the slip parameter depicts that the fluid velocity at the boundary is not at equal velocity with fluid particles closest to flow boundary due to large variance in macro and micro fluid flow. As observed from the (Figure 6) increasing the slip parameter leads to decreasing velocity distributions of the process. In order to show the relative significance of the inertia effect as compared to the viscous effect, the effect of Reynolds number on the flow phenomena is illustrated in the (Figure 7). It is established form the graphical display that increasing Reynolds number (Rew) causes decrease in flow profile which effect is maximum towards the upper plate.

It is shown that increasing the Reynolds number causes decrease in velocity distribution but as flow reaches the mid plate around (not determined accurately) an increasing velocity distribution is seen. However, effect is minimal towards the upper plate. Also, influence of magnetic field on radial velocity is depicted in (Figure 9). as shown significant increase in velocity is seen due to quantitative increase of Hartmann parameter (M) towards the lower plate while as upper plate is approached a reverse trend is observed.

In this work, analysis of upper convective Maxwell (UCM) nano fluid flow through a permeable microchannel embedded in a porous medium and under the influence of slip condition has been presented. Important fluid parameter effect such as Deborah’s number, Darcy parameter and Hartman parameter were investigated on flow. that increase in slip parameter, nano particle concentration and Darcy number lead to increase in the velocity of the upper-convected Maxwell fluid while increase in Deborah’s, Hartmann, and Reynolds numbers decrease the fluid flow velocity towards the lower plate but as the upper plate is approached a reverse trend is observed. The results obtained in this work may be used to further UCM fluid in applications in biomedical, astrophysics, geosciences etc.

Data availability Statement

The data used in this work can be found in open documents in public domain.

The authors express sincere appreciation to University of Lagos, Nigeria for providing material supports and good environment for this work.

This research was performed as part of the employment of the authors under the University of Lagos, Nigeria.

The authors declare that there is no conflict of interest regarding the publication of this paper.

©2020 Sobamowo, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.