International Journal of

eISSN: 2475-5559

Review Article Volume 2 Issue 5

1Department of Machine Elements and Tribology, Polytechnic University of Bucharest, Romania

1Department of Machine Elements and Tribology, Polytechnic University of Bucharest, Romania

Correspondence: Filip Ilie, Department of Machine Elements and Tribology, Polytechnic University of Bucharest, Romania, Tel 40214029411, Fax 40214029581

Received: May 15, 2017 | Published: June 2, 2017

Citation: Ilie F. Study of superficial layers obtained by selective transfer in the friction couples. Int J Petrochem Sci Eng. 2017;2(5):149-153. DOI: 10.15406/ipcse.2017.02.00048

In the friction process of two materials and in the presence of some proper lubricants, the wear process manifest itself as a material transfer from an element of the friction couple on the other, process specific to the selective transfer mechanism. The selective transfer can be sure achieved in a friction couple if there is a favorable energy, the relative movement and if in the friction area is a material made by copper and the lubricant is adequate (glycerin). The selective transfer mechanism is characterized by the physicochemical processes, which take place in the contact zones of the friction couples, and which to allow the selective transfer of some elements of the materials from a surface to the other, forming a thin superficial layer with the superior properties at wear and friction. This is a condition for any friction couple of high efficiently and a normal self-adjusting phenomena. The forming of this layer on the contact surfaces makes as fiction force to be reduced. It is in closely related to the structure formed by the selective transfer, between the metallic friction surfaces and with the properties these surface layers metallic.

The most important parameters concerning the physical state of the superficial layers are micro-tensions, the structure and its modification on friction surfaces, the structure defects as well as the way of distribution of the additions and of the alloying elements from alloy. The purpose of the present paper is research these parameters by the structural analysis with X-rays, as the research method of the thin superficial layers.

Keywords:selective transfer, superficial layer, structural analysis, intensity x-rays, width of diffraction lines, crystalline network constant

The selective transfer phenomenon is based on physic-chemical processes, which takes place in the contact zones of the friction couples which assure a thermodynamic instability of the lubricant and which allow the transfer of some materials. This transfer is achieved if there is a favorable energy and in the presence of relative movement, if in the friction zone is a material made by copper and the lubricant is adequate (glycerin or special lubricant).1–3

Phenomenological the selective transfer phenomenon includes follows:

This layer has the property that it assures an agglomeration of dislocations in deformation processes, in a way specific to the malleable materials and this way to protect the layer against destruction.4 The selective dissolution of the copper alloy elements provokes about in the crystalline network of this solid solution as in the chemical compounds a surplus of defects. Moreover, defects appear at the deformation of superficial zones and at the exit of dislocations from surface.5,6 The thickness of this layer is very small (1...5 mm) and it is extremely porous, thus its size are compared with the field of dislocation tensions.

Experimental researches regarding selective transfer revealed that on the friction surface forms a thin layer rich in copper that depends on working conditions.

The forming of this layer on the contact surfaces makes that the friction force to be decrease because of the structure formed by selective transfer between metallic layers from the surfaces. The research method is recommended to be made by structural analysis with X-rays.7-11 The metallic layer, which usually participates in the interaction with the X-rays and from which come the structural information, has a thickness of 10-1...10-3 mm.9 Similar information is can obtain and by the study superficial layers by diffraction with electrons.12-15 By this method is can research a thickness of 10-5... 10-6 mm. In the refs.7,9,11 Describe a research method of the solid bodies’ structure by structural analysis with X-rays with the variable incidence of the ray fascicle, which makes possible the investigation of thin metal layers with a thickness of 10-3...10-5 mm. The way of the radiation through metal is composed by the way of incident ray ri=h/sin α and the scattered ray rd=h/sin (2θ-α), where h-is the depth of penetration of the ray in the material and is calculated with the relationship:

…………………… (1)

With: µ - linear coefficient of absorption; α - angle of inclination between the research surface and the incidence ray; Θ - dispersion angle. From relation (1) we can notice that the thick of the researched metallic layer is determined by the angle of inclination of rays which fall on the sample surface Figure 1.

Figure 1 Research principle of the metallic layers with the help of the method of the rays fascicle with variable angle (a); research principle (b): anode with outbreak - 1; monochromator with crystal - 2; collimator - 3; sample - 4; detector (image viewer)-5.

In Table 1 are shown the results determining the layer thickness of copper h, participant in the reflection, for different incidence angles of the incident fascicle on the surface of the sample for Co radiations.

Radiation |

Wave Length |

q |

H Values in µm For α Suitable, in Degrees |

||||||

|---|---|---|---|---|---|---|---|---|---|

40˚ |

30˚ |

20˚ |

10˚ |

3˚ |

2˚ |

1˚ |

|||

Co |

1.789 |

25˚24’ |

4.1 |

4.0 |

4.0 |

3.7 |

0.9 |

0.7 |

0.3 |

Table 1 Thickness layer of copper.

Note: The calculation was made for the case when 75% from the radiation, which reaches on the surface are absorbed by the layers which participants in reflection.

We can notice that the modifying of the incident angle α in the domain from 40˚ to 1˚ lead to a reduction of the layer thickness by 13 times (from 4.1 to 0.4 µm). Therefore, by modify the wavelength of the radiation and incident angle is can research the layers structure on various depths.

By X-ray fascicle method with the variable incidence were researched samples bronze of aluminum/steel OL37 tested on Timken installation lubricated with glycerin, using the JXA-5A electronic microscope.

Before to be tested experimentally, the samples special manufactured, have been examined by analysis metallographic and chemical, with the purpose to know the structure in the crystalline network and chemical composition of alloying elements of bronze and steel that needs to be investigated. This thing had been made that after experimental, a new metallographic and chemical analysis of the steel samples on which transferred a layer by the bronze color to give information regarding the composition and the thickness of the superficial layer that shows up in the friction process in conditions of the selective transfer.2,10,12

The metallographic and chemical analysis of the steel samples with thin selective layer after they worked by friction in the selective transfer conditions shown that this layer has approximately the same structure and composition chemical with of the bronze where it came from. For example, if the aluminum bronze has about 83.5% Cu, 10% Al, 3% Zn, 2% Fe, 2% Mn, 0,3% Pb, 0,1% Sn, 0.05% As, at the transferred layer on the steel sample has about 85% Cu, 8.5% Al, 2% Zn, 2% Fe, 1.5% Mn, 0.2% Pb, 0.05% Sn, therefore is made an increasing of copper percent to the prejudice of the other alloying elements.

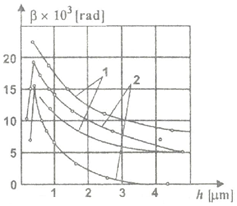

Structural analysis was made with the help of Co radiation. The angle α can be modified from 1 degree to 40 degrees. This area corresponds reflection of the superficial layers with a thickness about 0.2 -5 μm. As a parameter for the structural modifying in superficial zones has been chosen the width of real line of interference β being characteristic for pure metals and solid solutions, which are in balance. At the same time, it is a parameter for the dislocations density the existent in metal.2,3,16 In Figure 2 are shown the results regarding the modifying of the width of interference lines of the copper, at a different depth, after friction.

Figure 2 Variation of the diffraction lines width β of the copper with the depth h after a 0.5 hours (1) and 35.5 hours (2) solicitation by friction.

We can notice that interference lines can do modified very much depending on depth reported at the surface of the samples (about three times). Also, we can notice in very thin superficial layers of the samples obtained through friction a large number of defects of the structure. In Figure 3 is shown the modification of the width of the diffraction lines b in function of friction time.

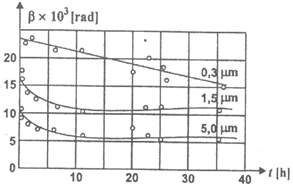

Figure 3 Variation of the width of the diffraction lines β of the copper layers at different depths in function of friction time.

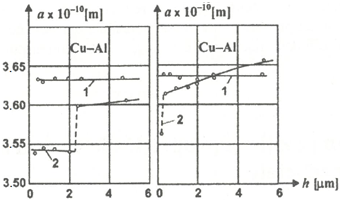

At the beginning of the friction after about 5 minutes, the width of the lines is determined by the size of the pressure from contact zone, which provokes and structural changes into a metal. In a layer with the thickness 0.3 μm the width of the diffraction lines lowers one time with of the testing duration. In layers with a thickness of 1.5 and 5.0 μm, then when the diffraction image is influenced by basic crystal, which is much more far from the surface, after 1-2 hours, provokes only a little reduction of the width of the lines. After duration of testing of 35.5 hours, β has changed very little. The decrease of the width of diffraction lines shows decreasing density of dislocations in the thin superficial layer of the copper-based alloy if it is researched after the friction solicitation. That helped to prove that at the friction in selective transfer conditions didn’t appear an agglomeration of dislocations which in the next friction process would lead to destruction by fatigue of superficial layers.2,3,16 In Figure 4 is shown the variation of the network constant, a, at the aluminum bronze depending on of the depth h from the surface of sample in a zone of 5 μm after a solicitation by friction with a pressure of 0.3 MPa.

Figure 4 Variation of the network constant, a, at aluminum bronze in function of the depth h after a 0.5 hours (a) and 2 hours (b) solicitation by friction: 1- at the depth of 5 μm; 2 - after a solicitation by friction at pressure 0.3 MPa; 3-after a 0.5 hours heating at 70˚C.

It can be observed that for a short period of time (0.5 hours), the crystalline network constant, a, at the copper from zones that are near to friction surface, it is reduced and it only 3.53∙10-10 m. Also, is ascertain that the network constant it changes after a supplementary heating of the sample if before was submitted to a friction solicitation.

The results regarding the modifying of the crystalline network constant of a sample from aluminum bronze, that submitted to a solicitation by friction for about 2 hours and after that it was warmed for 0.5 hours to 70˚C, are shown by the 3 curve from Figure 4. We can notice that a supplementary warming brings network constant only in the superficial layers very thin to its initial size. In the deeper layers, network constant remains at little values. Therefore, the research with a supplementary warming shown that there is a connecting between smaller values of the network constant near to friction surfaces for a sample solicited by friction and the point-form defects, especially in the zones with defects.

Because, point-form defects have a bigger thermic activity they are removed faster from into a metallic body by friction at relatively reduced temperatures, as a following of warming than other defects. For copper, for example, this temperature isn’t bigger than 150-200˚C.

Relatively low values, for the network constant a, in layers with a thickness bigger than 1 μm were formed by the elastically compression tensions, what they are born during friction, for their removed is need of a temperature of warming bigger.

The distributions way of the temperature and pressure in more deep active layers and selective dissolving process, which are present at friction in the conditions of the selective transfer, influences and size of the existent forces from superficial zones, which provokes the diffusion process of metal atoms. The volume of redistribution of the alloying elements during the friction process may be appreciated by modifying network constant a. The accuracy of such an appreciation is given from the report of the atomically sizes of the alloying elements and of copper atom and is the evidently at of bronze analysis on tin based, on aluminum based or brass. In Figure 5 are shown the results of the crystalline network constant at aluminum bronze at different depths from friction surface to 5μm, where we can clearly recognize that after friction solicitation the network constant of the alloys is considerably decreased. This thing is provoked by a poverty of the superficial layer in alloying elements (Al, Zn).

Figure 5 Variation of the network constant, a, at the aluminum bronze in function of the depth h from the friction surface after 2 hours solicitation by friction (a) and after a1- hour (b): 1 – initial state; 2 – copper layer.

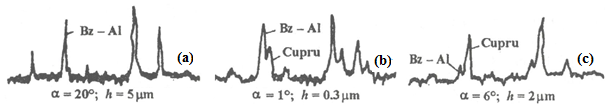

At a such analysis of the superficial, thin layers, which had been effected at a small incidence angle of the radiation on surface, to result that on the diagrams of X-radiation intensity doesn’t appear only one lines system how it happens usually, Figure 6, but it is noticeable two lines systems (Figure 6B & 6C) which it corresponds to an interference at the crystallographic planes of two materials: of the copper layer and of the basic alloy.2,3,16

Figure 6 Intensity diagrams of the X-radiation at the aluminum bronze/steel OL 37 couple, after a 2 hours solicitation by friction, lubricated with glycerin: in the initial state (a); after1 hour (b) and after 2 hours of friction solicitation with selective transfer (c).

The presence of two systems of lines in intensity diagrams of X-rays shows the presence of a distinct limit between the layers formed at the surface and basic material of samples. From intensity ratio of the lines different materials can be appreciated the thickness of the layer formed at the surface in conditions of the selective transfer. Intensity diagrams of the X-rays (Figure 6B) have been obtain by photographing of the visualize image of the thin superficial layers obtained by selective transfer, enlarged by 300 times with photo camera within electronic microprobe.

The variation of lines system shows that the thickness of the selective layer (obtained by selective transfer) is not equal in all zones, after a direction (on the surface length or width coated with thin superficial layer by transfer selective), situated at a certain depth from contact surface (Table 1). The diagrams from Figure 6 have been determined at aluminum bronze/OL37 steel after the solicitation by friction of 2 hours lubricated with glycerin and at various loads and velocities. The way in which the thickness of the selective layer varies in different time, speed and load conditions, after 2 hours of work by friction is shown in Figure 7.

Figure 7 Variation of the thickness of the layer made by selective transfer in the presence of glycerin in function of friction time t of the aluminum bronze at different sliding velocities and constant load (a) in function of load Fn and constant friction time for different sliding velocities (curves 1 at 0.93 m/s; curves 2 at 1.86 m/s; and curves 3 at 3.72 m/s).

It can be noticed that the layer thickness increases in time until touches an optimal value, after which oscillates around of this value, what shows that the selective transfer takes place and inverse (Figure 7A). Also, the layer thickness increases with load (<20N) until touches a maximal value, after which decrease very little with the load growing and with the tendency of stabilization for loads >40N, after an operating time of 2 hours (Figure 7B). After how to result from intensity ratios of the diffraction lines, the thickness of transferred layer after a testing of 2 hours is about 2μm. A quantitative appreciation regarding the thickness of the superficial, selective layers shows the growing in time until touches the maximum, after which the transfer is produced in the opposite direction remaining in function of time, within the limits of 2- 3μm, but oscillates very much. It can be reduced by 10 times and then to grow up again. These modifications of the thickness of layer correspond the observations on samples of steel OL37 which worked together with the copper based alloys by friction, tested on Timken installation, where the copper is linked by selective transfer on steel surface.

Research realized by the structural analysis with X-rays on friction surfaces from copper alloy together with steel, lubricated with glycerin and in relative movement, after a friction solicitation make possible the elucidation of structural modifying and getting information regarding the mechanism of the behavior a metal in conditions of the selective transfer.

The dislocations density can be estimated from the width of diffraction lines and has rather big values in the thin layers, and in already known friction conditions even maximal values. Then, appears a decrease and ascertains reduction of the width of diffraction lines. The decrease of the dislocations density in the layers close to the surface is the provoked by the plasticizing effect of adsorption.

During the friction process there takes place in the conditions of the selective transfer in general, two processes at the same time: forming a thin layer of friction with special properties and forming of a limit between the superficial layer and basic body. At the same time, the maximum defects of the structure it's moving in the zones deeper of the layer. This proves a change of the thickness of the superficial layer in the formation.

The decomposition products of glycerin, which acts as tension-active substances, decrease the superficial free energy as soon as they are adsorbed on the friction surface. By this facilitates the exit of dislocations from surface in the contact area. On the other hand, the research made shown up that the network constant, a, of the copper layer formed on the surface has 3.56×10-10 m and is close to the theoretical value 3.615×10-10m.These results are confirmed by friction tests and correspond to the data from specialty literature,16,17 at a fast solidifying of the copper from the liquid state, where a =3.54×10-10 m. A small network constant indicates a porosity of the superficial layers which formed during the friction process.

The results regarding the analysis of structural modifying in superficial thin layers prove that a selective transfer is characterized by certain structural transformations. This represents a necessary condition for the process of a state without wear. In this condition is included and the forming of a pure copper layer with special properties on the friction surface, in which dislocations density is higher as well as a bigger number of point-form defects. At the same time, it is reduced the amount of alloying elements in superficial layer too.

All experimental results show that the superficial, metallic, thin layers they’re in a metal stable state, which is characterized by a very great loosening. All experimental results show that the superficial metallic thin layer is in a metastable state, characterized by a very great rarefaction. The big density of defects assures a large mobility of the atoms, which at their time provokes a diffusing mechanism of the defects in the form superior layer. This corresponds a state of the metal, in the friction surfaces zones, which is the similar of the fluid state. The big density of defects assures a large mobility of the atoms and provokes a diffusing mechanism of the defects in the form superior layer. This corresponds a metallic state, in the zones of the friction surfaces, which is the similar of the fluid state. For this reason, friction and wear behavior of friction couples operating with selective transfer is very good (comparable to fluid friction).

None.

The author declares no conflict of interest.

©2017 Ilie. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.