International Journal of

eISSN: 2573-2838

Review Article Volume 6 Issue 5

1College of Electrical Engineering, Guangxi University, China

1College of Electrical Engineering, Guangxi University, China

2Department of Electrical Engineering, Xi'an Jiaotong University, China

2Department of Electrical Engineering, Xi’an Jiaotong University, China

Correspondence: Muhammad Zain Yousaf, College of Electrical Engineering, Guangxi University, Nanning 530004, China

Received: December 17, 2020 | Published: December 31, 2020

Citation: Yousaf MZ, Mustafa A. Maintenance effects on life cycle of large above storage tanks. Int J Biosen Bioelectron. 2020;6(5):130-136. DOI: 10.15406/ijbsbe.2020.06.00201

In the oil and gas industry, the above-ground storage tanks play a significant role in the continuous movement of petroleum products. Oil is a valued product; the storing tank must undertake regular maintenance. Characteristic AST inspection can be conducted under its usual operation, but the floor of large AST is challenging to access during in-service. Due to the inaccessibility of the floor, tanks need to be emptied and made out-of-service for inspection and repair. This is a known expensive way both in terms of earning and the maintenance procedure itself. In this paper, the review of this condition and procedure of the AST is discussed with the present limitation and possible improvements in inspection methods. The inspection of the floor is the main focus, because it is a prime factor that characterizes the out-of-service time. The petrochemical industry's main aim is not only to minimize the frequency and time of out-of-service interval, but can also shift towards in-service defect detection methods. In-service methods can save major time and expense of not entering the tank for inspection. Both in-service and out-of-service strategies are discussed for inspection of the floor to achieve the objective goals.

Keywords: above ground tanks (AST), non-destructive-testing (NDR), in-service; out-of-service, life cycle

An important objective in supply distribution is to meet user demands on time and in a cost-effective manner. A balance between supply and demand is required to achieve this goal. This has been achieved in forms of storage units that rectify any short-time fluctuation between demand and supply. The utility industries provide a compelling case of persistent flow in their chain of supply. In supply chain, water products, electricity provisions, petrochemical all have one point of continuous flow common: ‘switch the tap on and process starts. The case of water supply is an interesting, in which water is stored in tanks near inhabited safe areas. This large storage facilitates the water to locals via water pipes and downstream tanks. World energy consumption sectors have been divided in to different industries. Petroleum industry is the main division for meeting world energy consumption. Petroleum consumption increases as it grows for each country, particularly in developed and developing countries. Because of the Petroleum consumption, the supply and demand chain is becoming a very imperative factor. Storage units are a critical part of the trading of petrochemical products. World oil consumption per day is 93,250,000 barrel (Wikipedia), and in U.K it is 1,608,000 barrel/day. Large oil storage units are needed in order to store these huge amounts of consumption needed at this present. ASTs are the perfect choice to meet the demands to counteract the high levels of natural resource intake. ASTs storage capacities can rise from anything up to 1.5 million barrel per unit compared to underground storage, which have less storage capacity.1 The capacity of oil tank levels tends to decrease insignificantly for the supplier. According to their allocated restricted. Typically 60,000 liters for small tanks, to large sizes in the tens of millions.

Corrosion in the ASTs can cause failure. The failure to a tank can have an undesirable effect, especially with large tanks causing an impact not just to the environment but also to the local businesses. An example of this failure was in the Gulf of Mexico on the 24 May 2010, when an estimated oil spill of 4.9 million barrels leaked into the sea. This incident resulted in the loss of product and fines costing more than $100 billion to BP (British petroleum). It also affected the environment, including the marine, wildlife, atmospheric changes, health issues and tourism industry. BP faced adverse publicity, strong economic loss and criminal charges because of this. This also raised question about the integrity of BP supply chain. Only can the periodic maintenance of the tank assure the integrity to provide a safe supply. Both inspection and repair are the two critical factors for this to be a highly successful operation, while reducing the cost at the same time. In-service maintenance is a cost-efficient path, because the tank remains in a productive and income-generating state. But due to the accessibility, cost, and technology barriers, out-of-service methods are currently practiced in this day of age. Therefore this paper’s mains focus is on the ASTs, maintenance, improvements, and overall benefits to the current methods. This paper also covers the basics of future possible maintenance techniques and compares them to current methods. In ASTs, the floor is the most challenging part to access at the time of in-service maintenance. Vice versa, Out-of-service techniques are currently used. As time goes on, in-services maintenance technologies are advancing. This paper is to propose better ways for in-service maintenance as well as improvements needed for out-of-service methods. They are both advancing as we speak, each on their own merits.

The AST life cycle is demonstrated in diagram 1. The Life cycle of the AST starts with installation to its final decommissioning stages (the end of life). This is when the AST is going through its iterating process between in-service/out-of-service periods. During the in-service period, there are different technologies available that are continuously monitored. Monitoring information helps decide whether to either extend the in-service time or further investigate by switching to the out-of-service period (Figure 1).

AST out-of-service maintenance and productivity have a close relation between each other. As the out-of-service frequency is starts to increase, profit from life cycle of the AST decreases with it. During the current life cycle of the AST, the inspection is done when it is out of service. Commercially available inspection techniques don’t have the ability to allow inspection of the tank during in-service. Therefore unable to tell us anything about any corrosion that could be present in the tank at that moment of time. From time to time, it is feasible for the AST to be taken out-of- service for proper inspection. It is like a MOT of a car, to look for any signs of defects present from wear or tare. Different countries have different rules of regulation for out-of-service maintenance. Guidelines in API1 and EEMUA2 recommend out-of-service maintenance after every 10 years. Storage units are vast, making tiny pipe-type defects up-to few millimeters very difficult to detect on the floor, big as football sized ASTs. It is impossible to detect, until the tank is out of service, with technologies advancing. It can be possible in the near future for in-service inspections. By keeping that in mind, I have proposed a solution for optimizing the life cycle and productivity of ASTs. T-AST= T-x +T-y + T-out (Figure 2).

Figure 2 This diagram is suggesting optimization in output of the AST life cycle. Increasing in-service inspection time T-x and decreasing out-of-service inspection time T-out, optimization from the AST can be achieved. Life time of the AST is represented by T-AST, which is equal to T-x, T-y and T-out.

A way to increase efficiency is to use the advanced in-service inspection technologies and improve the current out-of-service inspection technologies.

The AST life cycle optimisation

The following three conditions can be applied when exiting the in-service period:3

By using highly-efficient in-service inspection techniques, the out-of-service period ratio can be decreased. Allowing the percentage of in-service inspection to increase, can enhance the prolonged life, cost, and efficiency of the AST.

Purpose of the AST life cycle optimisation

In present inspection methods, maintenance of these large tanks has three major limitations. The first limitation is emptying and cleaning the tank before the internal inspection can take place. This process shares 80 percent of the total cost of the maintenance.4 Most of the time, ASTs are taken out-of-service based on a schedule when the stored product is sold or requested. Depending on its size, a tank farm would have one tank out-of-service, and then the oil is shifted to the next tank until it is put back into service. Adding weeks of loss to production incurring extra costs to alternative storage facilities (Figure 3). Huge mass and complex shape of the AST make it impossible to access the floor from beneath, and if tanks are filled with products more difficulty is added. Is possible under certain circumstances. Expensive though. Accessing the floor of tank is most difficult when using the in-service maintenance procedure. Traditionally, out-of-service methods are being used. The tank is shut down and inspected, this is a highly costly step and decreases profit. Out-of-service period has the direct impact on supply and demand balance; it can cause fluctuation to the prices of oil. By achieving in-service inspection and repair methods, we can save time and money. In-service inspection with repair is the ideal solution for taking care of the ASTs, but the question arises is it possible? Accuracy, safety, costs and accessibility are the most important factors in choosing in-service rather than out-of-service methods.

Figure 3 Maintenance cost increased extremely higher when cleaning process, non-productive and reduced service time taken into account. Oil transferred from affected tank to another healthy tank, which adds cost of renting or buying spare tank as well. Outline of the out-of-service for maintenance in petrochemical industry showing steps taken before inspection and repair. Reduced service time is not only the costly step, but emptying and filling oil in alternative tank is in itself very expensive. (Original figure presented in [1]).

There are only two ways to inspect the ASTs during in-service period. One is to go inside of a big oil tank. The other solution is to inspect from the outside. The first option is not viable, as this is a health and safety concern. Second option is viable. As we don’t need to go inside, because it can be easily inspected from the outside using sensors. This will not only increase in-service time, but it will also increase the productivity of the AST life cycle. Though current monitoring technologies provide information, accuracy in pointing the defected section is not good. This leads to the out-of-service path for further investigation. Ideal in-service monitoring should give us information about the condition (oil leaks, cracks) of the AST quickly and point the defected sections accurately. By using advanced in-service inspection techniques, we can point to defective sections accurately. Figure 2 suggests the solution in which we can increase the in-service time by using in-commission inspection techniques. By doing this, the possibility of the out-of-service maintenance is decreasing. One more way of reducing the out-of-service period is to improve out-of-service inspection techniques. Before proposing the advanced in-service inspection techniques and ways to decrease the out-of-service period, it is important to understand the relationship between AST's maintenance and life.

Maintenance and life of AST

The rate of maintenance alongside the life of the AST depends upon each other. Minimum maintenance is required when the tank is newly manufactured.3 As the time goes by the integrity of the AST starts to decline and likely to cause decommissioning. One of the main reasons behind this is the corrosion of the tank. Interval maintenance is the only way to prolong the life and the quality of any AST. It can also decrease possible damage to it. Presently out-of-service period is an important and expensive procedure part of the maintenance process. In this period, the tank is emptied and cleaned for inspection. After inspection, it has three outcomes:3

The out-of-service period has added a lot of cost to its maintenance budget. As the tank gets old, the maintenance period starts to increase in time and becomes more frequent, having a knock-on effect for the in-service period and resulting in a negative impact on the total productivity and profit from any service period of the AST. It is interesting to see how maximum profit can be achieved from operational periods by reducing costly steps. However, is it possible to permanently remove the corrosion instead of maintaining the AST for the whole life cycle? (Figure 4).

Figure 4 Usually ASTs storage are made of steel. Main reason behind using are, they are cheap, strong and easily store large amount of oil. Left hand side shows the refining step to make steel, right hand side is showing corrosion effects on steels. Life cycle of ASTs and corrosion are related with each other. More corrosion in tank means short life cycle. (Original figure presented in [7]).

Corrosion and carbon steel tanks alternative

Carbon steel is the prime material used for its simply strong structure, low-cost, good strength, and huge storage of crude oil/ petroleum chemicals. The major setback against all these advantages is corrosion in any carbon steel type. The corrosion and fracture in the tanks are caused by the chemical and electrochemical reaction, which also affects the maintenance schedules and life cycle of the ASTs.5 If a non-corrosive material replaces carbon steel floor with the same quality and strength, then maintenance doesn’t require long and frequent out-of-service periods. This step will reduce the overall maintenance cost. Presently, carbon steel has no substitute, which takes over in terms of good quality, cost efficiency and strength to hold huge amounts of oil.3 Replacing carbon steel floor with non-corrosion material is a great idea, but keeping in mind the current limitation of cost and strength it is not practical. The only option left to make the life of an AST productive being cost efficiency, ways of inspecting AST should be made better. In return, which can develop the in-service procedure whilst reducing the out-of-service. The rest of the paper has discussed the inspection services and proposed improvements. It has been divided into two sections. Sections are:

Out-of-service inspection techniques for aboveground storage tank floor monitoring

There are different methods adapted for out-of-service maintenance, but most common techniques are based on commercial survey:

Commercially successful maintenance techniques are based on MFL method. Magnetic flux leakage approach has the ability to cover large percentage of floor area quickly1

For higher sensitivity automated ultrasonic is being applied. Ultrasonic approach is to suspect areas which are badly affected i.e. weld plates and those sites where MFL readings are not satisfactory. Both these technologies follow a procedure. Special cleaning require of the AST. This makes the tanks free from dirt; leftover products caused by corrosion and drying the floor.4 Tank owners prefer MFL devices for inspection because of their speed to sensitivity ratio. Though it still needs emptying and cleaning, keeping in mind the current limitations, it is the best practice solution.

Principles of MFL

Magnetic lines of force are produced within the plate, when a magnet is close to a steel. These magnetic lines (flux) preferably like to travel within the plates than the air. A suitable powerful magnet creates saturated flux within the plate. Coil or Hall Effect sensors can be used to detect corrosion in the tanks; the corrosion can be identified by any irregularities fluctuation in the magnetic flux.6 Coil sensors works on the principle of Faradays law and the Hall Effect sensors which generate a voltage signal dependent on flux density (Principle of Lorentz force). Magnetic flux leakage principle can be understood by solving Maxwell equations.6 The differential forms are (Figure 5)

∆.H =0 (1).

∆.B = J (2).

Possible improvement in out-of-service inspection technique (MFL)

The signal to noise ratio for MFL is very low. The fast approach and sensitivity give it an edge over the tank inspection industry. Different companies are finding ways to make improvements to its efficiency for MFL. The sensitivity of the MFL depends on different factors. Air coupling magnetic field, geometry, and position of defect, anticorrosive coating, and roughen material effects sensitivity.6 Air coupling magnetic field between sensors is quite big. This usually affects the sensitivity of MFL and results in false alarms. False magnetic fields can be reduced by using the shielding structure.6 This shielding structure has the potential to decrease inspection time and increase the sensitivity of MFL devices (Figure 6). Another proposed solution is improvements in the sensors of MFL. Generally, most of the MFL devices are using Hall sensors, but eddy current sensors can be used. The current motor speed of MFL devices for better sensitivity is constant. Using eddy current sensors, we don’t need to worry about constant speed, and we can move it at a fast rate. The old MFL sensors are able to detect up to 22mm in the width of steel, but with these sensors, it is possible to go up to 30mm.7 Though these steps can improve the inspection quality and speed, cleaning and emptying of the AST is still required. This means the tank has to be in an out-of-service period. The Only way to overcome this problem is to use in-service inspection techniques. The question is could in-service methods replace out-of-service inspections. Accuracy, accessibility, cost of in-service maintenance comes with its own restricted inspection. In the next section, I will discuss how in-service inspection techniques can out way the impact when in the out-of-service state. New technologies are developing now that have the potential to overcome the present limitation.

Figure 6 is illustrating the principle of Magnetic shield structure (Original figure presented in [8]).

In-service inspection and maintenance techniques for aboveground storage tank floor monitoring

According to the stats, quite a lot of tanks, which were emptied and cleaned, required less maintenance to be repaired. Statistics show that only 43% need repairing, whereas only 9% do not.4ASTs received less attention in the technical literature; thus, few papers have been presented on this issue. In recent years, little research has been done on in-service maintenance. Different ideas have been presented on how to inspect the ASTs, whilst they are in-service. Although research is still in progress to gain a better understanding why in-service maintenance methods can work. Currently ongoing recommendations to suggest better techniques, are being presented to better a solution in improving how we look after ASTs. Mostly concentrating in two major areas being detecting leaks and corrosion. Oil-Leak detection methods in the ASTs methods to detects leaks in the ASTS are.4

Precision volumetric testing

Is used to detect leaks in the storage tanks. But the location of leak cannot be easily identified.8 The two main drawbacks applied to this technique is quite significant. One being the changes to the ASTs, the other being the petrochemical volume. Due to the volume variation supply the demand can affect how the evaluation results are obtained. Effects to the ASTs floor, roof movement and temperature change stored chemicals have impact on the results of inspection.

Soil vapor monitoring measurement

Soils vapor testing the exterior surroundings of the AST for leaked product. This approach can detect very low level of leak, it cannot determine the time of leak or reason behind it. Accidental spills near the tank can have influence on readings in soil vapor monitoring.

Inventory control

Over a given period detailed record of inclusion and removal of product recorded. In same period, monitor level of product, any variation in records consider as a leak. Meter error, human error and temperature changes can easily influence records. Although non-intrusive techniques are very useful maintenance methods, and they can detect any leaks in AST. But they cannot identify location and depth of corrosion in a tank. This is a major drawback in these techniques. Next section of this paper is discussing possible corrosion detection methods during in-service period. It is followed by optimization flowchart in maintenance methods. In-service inspection methods for Corrosion detection. Possible methods to detect corrosion in the ASTs during in-service are

Ultrasonic guided wave tomography

Discussed out-of-service methods are quick but they lack the factor of in-service inspection demand. The tank owner’s preference is to have them in service, while inspection is carrying out. This can save money as no need of emptying tank, cleaning and then inspection. Researchers are putting their efforts to move towards in-service non-destructive testing applications. Small numbers of studies have been carried out and the research is still in progress due to the problems encountered. This section of paper is discussing the possible principle of using ultrasonic guided waves to inspect the floor of the ASTs. In this method, the generated and reflected waves are detected by transducers coupled to the annular plate's edge. Measurements are carried out in different sections and directions across the tank to get accurate reading. Obtained information is processed by tomographic reconstruction techniques to give information about defects or plate settling of the ASTs floor. Computer image modelling of tomographic techniques has been developed. This modelling considered the performance of transducers, the interaction between sound wave and the scattering of wave. Main advantage of the proposed method is the ability to detect corrosion on the tank floors without the need to empty and clean the tank while it is still in service.

Tomographic reconstruction

Across all ASTs floors, the transmission and receiving of waves been carried differ in their directions. The waves' amplitude is the function of attenuation due to corrosion and scattering effects in tanks (Figure 7).9 Ultrasonic guided wave tomography has been implemented on the small above-ground tank, but accuracy needs more improvement to the big tank. The experimental procedure was executed with steel plates (up to 6mm thick) on the 100m diameter tank and showed promising results.9 Things to improve in this technology are swift scanning, optimisation in resolution and signal to noise ratio (Figure 8).9

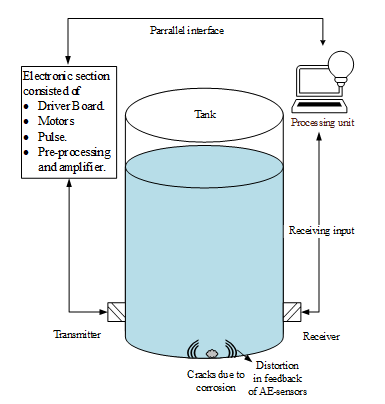

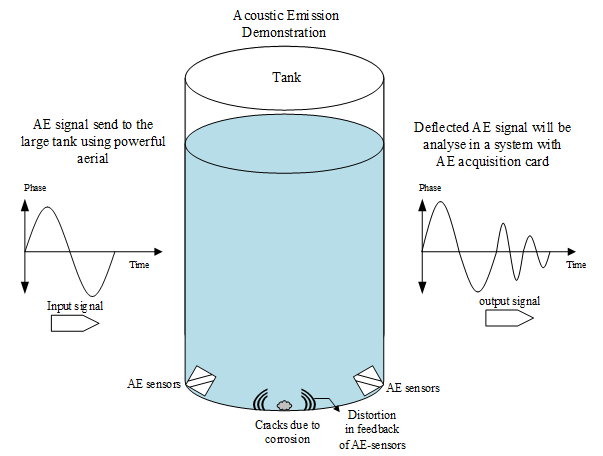

Figure 8 Pulse of energy from the floor material can be detected by attaching sensors on the floor outside of the tank. The sensors and floor is acoustically coupled, also special setup is required to improve transmission of the AE signals. (Original figure presented in [2]).

Acoustic emission

(AE) is the process in which sudden release of energy from a material will be detected in the form of elastic waves,11 and it has been widely used as a non-destructive-testing tool. In the recent years, the A.E application for detection of corrosion on the floor plate of ASTs is being adopted by petrochemical companies. The use of acoustic emission started first in the early 1980’s for examining the floor of the tanks.10 However, it was considered an unreliable method, as this technology progresses, the acoustic emission shows promising results. For in-service maintenance, tank owners don’t need complex testing methods to tell us about leaks or corrosion in the tank. They need a much prominent method that will update the floor's condition, so that any inspection to repair can be completed before any loss in the form of leakage or damage to the tank has occurred. A.E is a non-destructive method that can be used to monitor corrosion. In A.E, we don’t need to enter the tank to determine its condition. “AE testing has many benefits such as on-line testing, global monitoring, rapid inspection, and cost reduction”.2 This method has taken an on-line root for corrosion detection, and it still can’t be treated as an in-service inspection technique. This method may be defined as a semi-in-service technique. In this method, ASTs are still undergoing off-service for a small duration. Before the tanks are tested, they need to be shut down anywhere between 6 to 12 hours, including all agitators, heaters and oil pipes.4 AE has the potential to replace current inspection techniques because the large tank doesn’t need emptying or cleaning. However accuracy of the AE has raised some questions. Factors effecting the AE results are discussed below:-

Factors effect acoustic emission evaluation results

Every material has its own AE characteristic. Material AE characteristics can effects the attenuation and energy emitted to its rate of propagating signal. In A.E, sensors are installed outside of the ASTs. The oil or other medium may absorb propagation signals of A.E. Energy lost rate influence evaluation results. While using the AE method for inspection, the height of liquid should reach up to 80-100% of ASTs.11

P= ρgh (3)

Location precision discussion

Liquid’s height is proportional to the pressure of the floor. Density of the liquid = ρ, gravity acceleration= g and h=height of the liquid. For large ASTs the diameter has a bigger value. Release rate, amplitude and location are in relation with the ASTs diameter. This can easily affect evaluation for large diameter tanks. Corrosion cracks and ASTs material also varies with temperature change affecting the AE’s reading. Due to the short length of history we have, AE application within ASTs, testing tanks has not been so successful in this limited time. Factors such as height, medium and diameter have huge effects on evaluation to AE readings. ASTs generally have larger diameters. Taking in to account these effects, false source and lost source locations are easy to occur. Inspection results during experiments have shown that location precision problems still need improvement. Theory shows that 10-20% location precision is ideal.11 In most cases it can be satisfied by selecting suitable inspection time, right instrument parameters. But ideal location precision is not easy to achieve. Before formal AE inspection, electronic and other noise should be tracked to fulfill the test requirements. The area surrounding the tank must be relatively quiet too. At Refineries, AE can be prone to external noise. In summary, the primary job of AE testing is to tell whether a tank has any corrosion or leak. It cannot tell us the exact depth and severity of corrosion and cracks in ASTs. Though MFL is out-of-service technique, it can precisely tell us the depth of corrosion and cracks, up to 12mm in steel. It is more sensitive and accurate compared to AE, which we need to fulfill tests to the ASTs requirements.

Keeping in mind the current limitation of AE, it has potential for continuous improvement. The AE technique can spot faults on the ASTs floor decreasing the chance of emptying, cleaning and inspecting by other non-destructive testing (NDT) sources, thereby minimizing costs. If ASTs need opening for further investigation, MFL NDT may be used for inspection of floors in tanks. Ultra sound guided wave and AE are still in their developing phases. They need further improvements. These technologies can detect faults, but they don’t have the accuracy to tell us how bad the fault has gotten. Researcher is working to rectify this problem. Taking all these scenarios into account, I have proposed a new feasible inspection procedure in next section.

Flowchart of cmplete maintenance for ASTs.

Ultrasonic wave-guided Tomography or AE techniques can spot faults on the ASTs floor quicker both decreasing the chance of emptying, cleaning and inspecting by other non-destructive testing (NDT) sources, thereby minimizing costs. They can resolve any false results obtained from leak monitoring results. If results are not accurate, then opening of the tank is needed for further investigation, on the other hand MFL may be used for inspection of floors in tanks. In addition, automated ultrasonic or MFL robots may be adopted for wall and roof of tanks. British Sliver Wing Group has crawler devices, which can access wall and roof of ASTs.

Conclusion of flowchart

The above flowchart concludes that combination of quickness from Ultrasonic wave guided Tomography or AE, accuracy from MFL, can provide a much better result. If AE findings are satisfactory we don’t need to go any further, thus no need for any floor inspections by MFL. By following this procedure, costly maintenance and time consuming paths can also be avoided. This process can provide accurate evaluation and optimal maintenance for safety of ASTs.

Advance robotic inspection:

Another proposed solution is to use a robotic mouse for floor inspection. The micro mouse can be used with transmitters receivers attached to it as well as an added extra feature. It can move continuously covering vast areas of the tank whilst easily gathering data to be stored when receiving information from reflected signals to be analyzed at any point of time or be sending directly back to the control room via a wireless transmission for ease. This information can be analyzed by using some complex algorithm. No research has been done on this idea, so no information is available on an internet. Problem in making this technology can be following:-

We are stuck with ASTs currently there is no alternative available that can store large amount of oil to meet supply and demand chain. Significant cost required for maintenance of the AST. Distinct characteristic of maintenance is out-of-service period, yet maintenance technologies are improving now. Good information about the integrity of floor is the principle of maintenance. This paper put forward ideas in the direction that if we implant in-service inspection, it would enhance the AST life cycle's productivity. This can be done by improving in-service and out-of-service period ratio. Technologies have been discussed, which can do this. Principle of these technologies is to do in-service inspection without emptying and cleaning tank. Both economic and environmental benefits can be achieved by doing this. Major drawback with these technologies is SNR value, which is not accurate. By sophisticated improvements over a long time, it is potentially possible to extract information about the floor using in-service inspection. In order to understand source and characteristics of in-service inspections, still more laboratory and in-field work needed (Figure 9).11–13

I would like to thank my supervisor, Dr. John Mason of Swansea University, for his supervision, advice, and supports. Dr John Mason lets me cooperate with Mr. Neil of Silver Wing Group, who provides the useful information for me.

The authors declare that there is no conflict of interest.

©2020 Yousaf, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.