International Journal of

eISSN: 2573-2838

Research Article Volume 4 Issue 6

1Department of Physics and Material Science, Kwara State University, Nigeria

2Department of Pure and Applied Physics, Ladoke Akintola University of Technology, Nigeria

3Physics Department, The Polytechnic Ibadan, Nigeria

4Department of Surgery, Ladoke Akintola University of Technology Teaching Hospital, Nigeria

Correspondence: Adegbenro Sunday Ajani, Department of Physics and Material Science, Kwara State University, P.M.B 1530, Malete, Ilorin, Nigeria

Received: August 13, 2018 | Published: November 7, 2018

Citation: Ajani AS, Ogunbode OA, Adewumi AS, et al. Development of digital gait monitoring software for diagnosis of neuromuscular disorder. Int J Biosen Bioelectron. 2018;4(6):24910.15406/ijbsbe.2018.04.00135

Analysis of human gait is very useful in several fields of study with applications such as prosthetics, orthotics and diagnosis of neuromuscular disorder. Modern gait assessment relies on three basic methods; namely qualitative observation, quantitative measurement and biomechanical analysis. This research carried out the development of a user friendly application gait monitoring software incorporated in a developed complete gait monitoring system, for quantitative diagnosis of neuromuscular disorder. Microchip MPLAB Integrated Development Environment 2000 (MPLAB IDE 2000) was used for the firmware development of the software. The language for the program was written using Visual C++. The interface on the system was designed with a pull-down menu bar that consists of File, Edit, View, Tools, Settings, Help, and Gait Monitor Controller. The application software employs Direct Plotting and Fast Fourier Transform (FFT) for frequency (or Harmonic) analysis, Peak values and RMS Values. The Cadence Frequencies were recorded and stored for future purpose which is one of the major contributions of the project. The programmes were compiled and tested successfully, running well on Window operating systems, serving as interface for monitoring gait analysis of individual with a case of neuromuscular disorder.

Keywords: software, gait, neuromuscular, disorder

Human gait is observed as the pattern of walking an individual adopts during locomotion process controlled by the interaction of the nervous and muscular systems. It is categorized as either normal or pathological gait. Normal gait is attributed to the walking pattern of persons who have neither neuromuscular disorders nor articulate (joint) in their lower extremities, while the pathological gait refers to that of a person with a disorder or handicaps who respond to walking in an unconventional way. The analysis of gait is very applicable in several fields of investigation as well as application such as prosthetics and orthotics. In normal gait, the variation in most parameters will, in general be smaller than that in the pathological gait.1 This variation requires development of flexible, robust and user friendly application software for the diagnosis of neuromuscular disorder and measurement for effective analysis of pathological gait.

Development of firmware is one of the significant tasks in the design of software for diagnosis neuromuscular disorders. The basic procedure employed in the design is described in Figure 1.

Software development cycle

The procedure for writing an application is often described as a development cycle, since it is rare that all the steps from design to demonstration can be done flawlessly the first time. Most times, codes written are tested and then modified in order to generate an application that performs correctly. An Integrated Development Environment (IDE) permits the embedded systems programmer to move through this cycle without the rigors of switching between arrays of tools. The Microchip MPLAB Integrated Development Environment (MPLAB IDE) was used for the firmware development of this work. MPLAB IDE is a Windows Operating System (OS) software program that runs on computers to develop applications for Microchip microcontrollers and digital signal controllers. It is called an IDE because it supplies a single integrated “environment” to develop code of embedded microcontrollers. By employing MPLAB IDE, functions were integrated which allowed the developer to concentrate on completing the application without the interruption of separate tools and different modes of operation.

MPLAB IDE is a “wrapper” that organizes all the tools from a graphical user interface, automatically. Once codes are written, they can be converted to executable instructions and downloaded into a microcontroller to ascertain the performance. In this process, multiple tools were required: an editor to write the codes, a project manager to coordinate files and settings, a compiler or assembler that converts the source codes to machine codes and some sort of hardware or software that either connects to a featured microcontroller or simulates the operation of a microcontroller.

Implementation of embedded system design with MPLAB IDE

Developed system for embedded controllers is a system of programs that run on a desktop PC to write, edit, debug and program code, which fuses the intelligence of embedded systems applications into a microcontroller. MPLAB IDE runs on computers and contains all the components required to design and deploy embedded application system. The actual tasks for developing an embedded controller application are namely: Create high level design: Compile or assemble and link; and Test Codes and burn them into the device. These tasks are described as follows.

Once the codes are built, they need to be tested. MPLAB IDE has debuggers and free software simulators for all PIC MCU and dsPIC DSC devices to test the codes. If the hardware is not completed, it can begin by testing the codes with the simulator. The simulator can accept a simulated input into the microcontroller in order to model the firmware response to external signals. The simulator measures codes execution time, single step through code to observe variables and the peripherals, and trace the codes to generate a detailed record of the program performance. When the hardware is in a prototype stage, a hardware debugger, MPLAB ICE 2000 in circuit emulator, MPLAB REAL ICE in-circuit emulator, or MPLAB ICD 2 in-circuit debugger can be employed. These debuggers run the codes in real time on the application. MPLAB ICE 2000 emulator was used in this stage to replace the microcontroller in the target using a high-speed probe to give full control over the hardware in this design. MPLAB REAL ICE emulator and MPLAB ICD 2 debugger use special circuitry in-built Microchip MCUs with Flash program memory. They can “see into” the target microcontroller program and data memory. These debuggers can initiate and terminate program execution, helping to test the codes with the microcontroller in place on the application. When the application is run correctly, a microcontroller can be programmed with one of Microchip’s device programmers such as MPLAB PM3 or PICSTART Plus. These programmers are used to verify that the finished codes run as designed. The flow chart for data fetching and data capture are described in (Figure 2) (Figure 3) respectively.

The experimental results of the gait monitoring software for diagnosis are discussed in this section of the work.

Gait system software

Modern software design applies several techniques in order to achieve a program that is logically correct, efficient, easy to understand and maintain. Gait Monitoring System (GMS) was developed to acquire, analyze and show the gait results of any subject. This software was developed using Visual C++ and is running well on Window operating systems. It has a pull-down menu bar that consists of file, edit, view, tools, settings, help, and gait monitor controller.

Interfaces for the operation of the gait system software

The Gate Monitoring Software is developed in such a way that several interfaces incorporated can function with much simplicity without much ado from the user. These interfaces are dialog box for communication port and other component interfaces.

Dialog box for communication port

This section indicates the actual communication port that is opened for gait monitoring task. If the USB connection of the receiver is not properly done this interface displays ‘‘unable to connect’’. Figure 4 shows the dialog box for communication port.

Components interface for the gait monitoring system

This interface is the domain where actual data capturing is being carried out. This is explained through Figure 5

The Gait Monitoring System has the following features:

Menu bar for gait monitoring system

Menu bar for different commands of the Gait System is shown in Figure 6.

File menu

The file menu comprises of open gait file using fast Fourier transform (FFT) plot, open gait file using direct plot, save active result into gait file as, print, print setup, send and exit. Figure 7 shows the interface of the file menu of the gait system.

Tools menu bar

Tools menu bar, as described in Figure 9 contains the data capturing mode, data analysis mode and Gait monitor performance analyzer. The data analysis mode is subdivided into direct sample analysis plots and custom data analysis.

The first step here was to design a data recorder in tabular form, in which the measurements of individual can be recorded and saved through the data base program. The domain data form is captured by Table 1. Data collected from various subjects were run by the developed software and interpreted to make decisions. The format developed were both for normal and impaired subjects for conscious and unconscious moments of gait sessions. The details of the data collected are expressed (Table 2) (Table 3). The application software performs Direct Plotting and Fast Fourier Transform (FFT) for frequency analysis; and Peak values, RMS Values and the Cadence Frequencies were recorded and stored for further future investigation, which is one of the contributions of this research. This analysis however, requires a time consideration but it provides more precise information.

S/N |

Sample name |

Date of data collection |

Age |

Weight (Kg) |

Weight (m) |

Cause if gait abnormality |

Ground foot force readings |

|||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

First reading (Initial) |

Reading after a week |

|||||||||||

|

|

|

|

|

|

Left leg readings sensor 1 |

Right leg readings sensor 2 |

Left leg readings sensor 1 |

Right leg readings sensor 2 |

|||||||||

|

|

|

|

|

|

Peak value (mV) |

RMS value (mV) |

Mean Freq. (Hz) |

Peak value (mV) |

RMS value (mV) |

Mean Freq. (Hz) |

Peak value (mV) |

RMS value (mV) |

Mean Freq. (Hz) |

Peak value (mV) |

RMS value (mV) |

Mean Freq. (Hz) |

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Table 1 Study animal information: ID, gender, age, and dates of data collection for each study animal

S/N |

Sample name |

Date of data collection |

Age |

Weight (Kg) |

Weight (m) |

Sex |

Cause if gait abnormality |

Ground foot force readings |

|

|||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

First reading (Intial) |

Reading after a week |

|

||||||||||||||||||||||

Left leg readings sensor 1 |

Right leg readings sensor 2 |

Left leg readings sensor 1 |

Right leg readings sensor 2 |

|

||||||||||||||||||||

Peak value (mV) |

RMS value (mV) |

Mean Freq. (Hz) |

Peak value (mV) |

RMS value (mV) |

Mean Freq. (Hz) |

Peak value (mV) |

RMS value (mV) |

Mean Freq. (Hz) |

Peak value (mV) |

RMS value (mV) |

Mean Freq. (Hz) |

|||||||||||||

1 |

Adeoye A. |

16/3/17 |

55 |

66 |

1.72 |

M |

Porosis |

4408.3 |

3498.6 |

7.32 |

32010 |

3193.3 |

14.13 |

3708.3 |

2498.6 |

7.31 |

3701 |

2597.2 |

14.11 |

|||||

2 |

Ilugbile O. |

16/3/17 |

45 |

72 |

1.68 |

M |

Myelotis |

2820.1 |

1270.2 |

9.24 |

11013 |

3445.4 |

8.54 |

3820.2 |

2270.2 |

9.45 |

3801 |

2465.7 |

8.52 |

|||||

3 |

Aba A. |

16/3/17 |

22 |

65 |

1.65 |

M |

Malacia |

2868.2 |

1065.2 |

7.33 |

36764 |

2263.1 |

8.32 |

3762.1 |

2060.7 |

7.37 |

3775.6 |

2461.4 |

8.44 |

|||||

4 |

Sunday S. |

16/3/17 |

61 |

75 |

1.74 |

M |

Accident |

5348.2 |

1970.6 |

9.84 |

31471 |

1465.5 |

8.76 |

2348.7 |

1971.1 |

9.89 |

2349.3 |

2070 |

8.91 |

|||||

5 |

Adesokan S. |

16/3/17 |

21 |

57 |

1.72 |

M |

Sarcoma |

338.2 |

1892.6 |

6.66 |

29885 |

2403.4 |

14.75 |

3248.3 |

1892.9 |

7.47 |

3248.4 |

2003.7 |

14.81 |

|||||

6 |

David D. |

16/3/17 |

19 |

82 |

1.67 |

M |

Osteoma |

4835.3 |

3520.6 |

11.46 |

36443 |

2444.4 |

13.15 |

3834.3 |

2520.6 |

10.49 |

3714.7 |

2550.2 |

13.21 |

|||||

7 |

Adewale A. |

16/3/17 |

14 |

54 |

1.59 |

F |

Accident |

4521.5 |

3551.3 |

12.32 |

51012 |

2693.5 |

8.52 |

4321.2 |

2571.7 |

12.02 |

4501.2 |

2685.5 |

8.73 |

|||||

8 |

Ibiyemi A. |

16/3/17 |

28 |

63 |

1.55 |

M |

Accident |

4014.3 |

3239.3 |

9.38 |

39333 |

1465.5 |

8.38 |

3814.5 |

2439.2 |

9.39 |

3734 |

2536.2 |

8.33 |

|||||

9 |

Sheu S. |

16/3/17 |

44 |

72 |

1.74 |

M |

Arthrits |

2534.6 |

2233.5 |

6.24 |

28215 |

1702 |

6.89 |

334.8 |

1606.9 |

7.27 |

3221.8 |

1613.9 |

7.25 |

|||||

10 |

Ayodeji I. |

16/3/17 |

32 |

77 |

1.66 |

F |

Birth |

5143.4 |

3584.3 |

9.26 |

41520 |

2734.9 |

8.23 |

4123.3 |

2486.8 |

9.96 |

4120.1 |

2556.8 |

8.22 |

|||||

Table 2 Data obtained from the Gait Measurement of Pathological Subjects in March, 2017 at Private and Public Hospitals in Ogbomoso Metropolis, Ogbomoso, Oyo State, Nigeria, for a Period of 120 Seconds of Conscious Active Data Capturing

S/N |

Sample name |

Date of data collection |

Age |

Weight (Kg) |

Weight (m) |

Cause if gait abnormality |

Ground foot force readings |

|

||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

First reading (Initial) |

Reading after a week |

|||||||||||||||||||

Left leg readings sensor 1 |

Right leg readings sensor 2 |

Left leg readings sensor 1 |

Right leg readings sensor 2 |

|||||||||||||||||

|

|

|

|

|

|

|

Peak value (mV) |

RMS value (mV) |

Mean Freq. (Hz) |

Peak value (mV) |

RMS value (mV) |

Mean Freq. (Hz) |

Peak value (mV) |

RMS value (mV) |

Mean Freq. (Hz) |

Peak value (mV) |

RMS value (mV) |

Mean Freq. (Hz) |

||

1 |

Adeoye A. |

16/3/17 |

55 |

66 |

1.72 |

Porosis |

4408.1 |

3499.7 |

7.36 |

32017 |

3193.6 |

14.21 |

3708.8 |

2499.9 |

7.38 |

3701.5 |

2597.2 |

14.32 |

||

2 |

Ilugbile O. |

16/3/17 |

45 |

72 |

1.68 |

Myelotis |

2820.5 |

1270.8 |

9.28 |

11014 |

3445.8 |

8.61 |

3820.9 |

2271.8 |

9.49 |

3801.6 |

2465.7 |

8.73 |

||

3 |

Aba A. |

16/3/17 |

22 |

65 |

1.65 |

Malacia |

2868.7 |

1065.7 |

7.338 |

36767 |

2263.5 |

8.39 |

3762.7 |

2062.8 |

7.42 |

3775.9 |

2461.4 |

8.51 |

||

4 |

Sunday S. |

16/3/17 |

61 |

75 |

1.74 |

Accident |

5348.7 |

1972.3 |

9.89 |

31478 |

1465.9 |

8.84 |

2349.3 |

1973.5 |

9.99 |

2349.8 |

2070 |

8.96 |

||

5 |

Adesokan S. |

16/3/17 |

21 |

57 |

1.72 |

Sarcoma |

3348.8 |

1893.3 |

6.72 |

29882 |

2403.9 |

14.84 |

3249.2 |

1895.3 |

7.54 |

3248.7 |

2003.7 |

14.93 |

||

6 |

David D. |

16/3/17 |

19 |

82 |

1.67 |

Osteoma |

4835.7 |

3521.5 |

11.55 |

36447 |

2444.7 |

13.22 |

3834.9 |

2526.4 |

10.57 |

3714.9 |

2550.2 |

13.32 |

||

7 |

Adewale A. |

16/3/17 |

14 |

54 |

1.59 |

Accident |

4521.9 |

3551.7 |

12.37 |

51017 |

2693.65 |

8.59 |

4321.9 |

2573.6 |

12.83 |

4501.6 |

2685.5 |

8.77 |

||

8 |

Ibiyemi A. |

16/3/17 |

28 |

63 |

1.55 |

Accident |

4014.8 |

3239.8 |

9.41 |

39336 |

1465.7 |

8.45 |

3815.7 |

2454.6 |

9.48 |

3735.2 |

2536.2 |

8.38 |

||

9 |

Sheu S. |

16/3/17 |

44 |

72 |

1.74 |

Arthrits |

2535.5 |

2233.8 |

6.43 |

28216 |

1703.2 |

6.93 |

3335.5 |

1607.4 |

7.34 |

3223.5 |

1613.9 |

7.28 |

||

10 |

Ayodeji I. |

16/3/17 |

32 |

77 |

1.66 |

Birth |

5144.7 |

3584.8 |

9.34 |

41525 |

2735.6 |

8.24 |

4123.9 |

2487.3 |

9.98 |

4120.7 |

2556.8 |

8.31 |

||

Table 3 Data obtained from the Gait Measurement of Pathological Subjects in March, 2017 at Private and Public Hospitals in Ogbomoso Metropolis, Ogbomoso, Oyo State, Nigeria, for Period of 120 Seconds of Unconscious Active Data Capturing

To interpret gait result, it is imperative to provide further investigational computations, which will estimate the parameters of interest and describe the physical process being measured. This provides analytical solutions that give the evaluation of the test procedures to help in making decisions. In the computation of the different parameters, scaling of the raw data is expedient since a large volume of data and problems of discontinuities are mostly encountered. The data processing deals with more than just plotting, a general and specialized subroutines and computer programs must be written to achieve the desired goals. Apart from the scaling, other operation that is usually performed on the data is Fast Fourier Transform for frequency or harmonic analysis. Frequency analysis is an essential operation in data processing because it gives information about the significant frequencies contained in the data. This analysis requires a considerable amount of computer time and memory but supplies accurate information easily.

Result obtained from the experiment

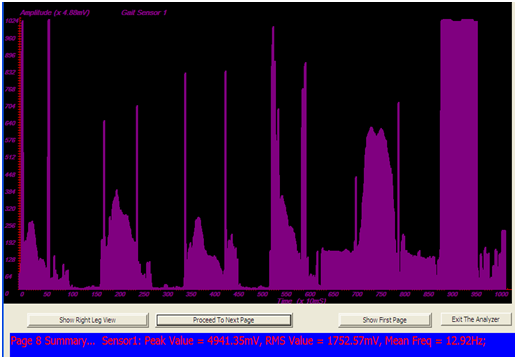

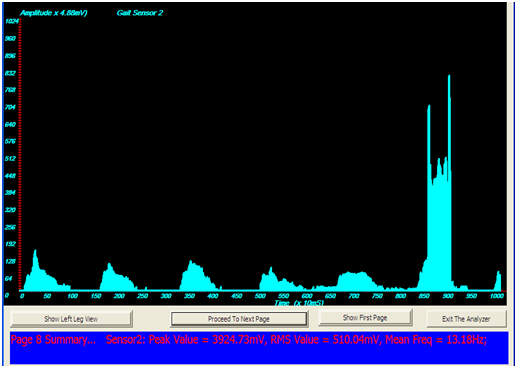

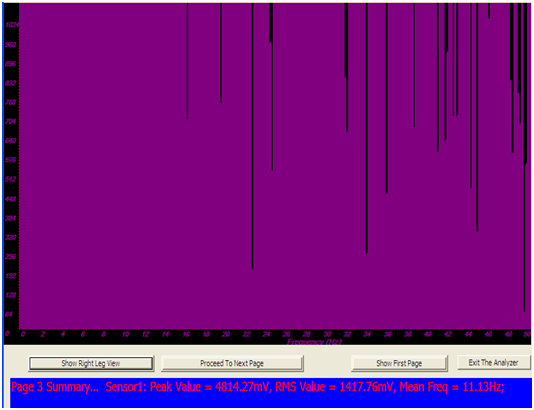

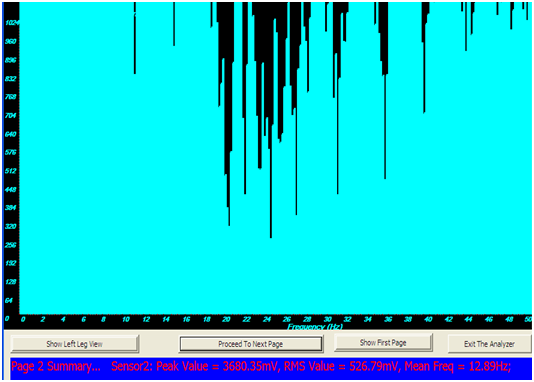

The obtained result from the experiments showed the peak value, the RMS value, and the mean frequency of each sensor for right and left legs. The software interface was designed in such a way that all the corresponding values are clearly shown on the screen. The corresponding waveforms of each sensor could be observed in either Amplitude-Time Plot or Amplitude-Frequency Plot using FFT. Figure 10 & Figure 11 represent samples of the waveforms of the ground-foot reaction force for pathological subjects in amplitude-frequency and amplitude-time modes, for the right and left legs. Each waveform reveals effects of the pressure on the sensor attached to the targeted points where the ground reaction force was measured. This target points could be the heel, metatarsals etc. According to Miyazaki2 it has been shown that the total foot-force is the sum of the forces at the heel and the metatarsals part of the foot. It was also observed that the total foot-force defines two peak points (one on the heel and the other on metatarsal) and a trough, which corresponds to the period when the mass centre of the body is at its highest position. This occurs halfway through of the swing phase.

Figure 10 Graph Sample obtained using Amplitude-Time Plot on an Impaired Subject.

10A) Sample of Graph Obtained Using Amplitude-Time Plot on an Impaired Subject’s leg (Left).

10B) Graph Sample obtained using Amplitude-Time Plot on an Impaired Subject’s leg (Right).

Figure 11 Graph obtained using Amplitude Frequency Plot on Impaired Subject.

11A) Graph obtained using Amplitude-Frequency Plot on Impaired Subject’s leg (Left).

11B) Graph sample obtained using Amplitude Frequency Plot on Impaired Subject’s leg (Right).

The harmonic spectrum of the waveform is shown in Figure 10. It was observed that the spectrum is highly weighted around zero frequency at some frequency points. It could be observed also that the magnitudes of some frequency components were small. The normal human walking speed, according to literature is about 1 Hz which fixes the time to complete a gait cycle to around 1.02 Sec. The harmonic spectrum of the ground reaction force after being filtered, using a 10 Hz cutoff frequency digital filter, was used to represent the gait waveform. This confirms further that the frequencies of comparative magnitude in the impaired gaits were varied and greater than 1 Hz, in most of the cases monitored. Another improvement brought about by this system is the speedy rate of data transfer, carried through the USB driver port, which greatly enhances the speed of data acquisition. The availability of very efficient customized gait analyzed software aids the gait data analysis. The Gait analyzer transformed the discrete time gait data into the frequency data and this was used to determine the relative magnitude of the harmonic content of the gait data. The results of the test and measurement carried out on the system produced high correlation that the system can be used in the analysis of human gait pattern and also can be used to analyze the waveforms, depending on the index of comparison chosen for consideration.

The development of flexible and user friendly application software for the diagnosis of neuromuscular disorder measurement was achieved, with high speed data processing for storage compartment in the gait monitoring system. This research has been able to develop software that can handle qualitative gait analysis; the software was tested to handle the diagnosis of neuromuscular disorder. The result also shows that visual qualitative observation was unable to detect any improvement on the gait of the pathological patients sampled after a period of one week but quantitative observation with the developed software gives improvement or otherwise, though minute, on the gait of the subjects. The slight increase in the peak voltage of the patients’ gaits supports this claim. Adequacy of this research work in monitoring and analysis of human gait is justified.3‒17 Implementation of this research has shown that the developed application software can be use to improve and monitor gaits of stroke patients, military amputee, accident victims and physically impaired people in hospitals and sports facilities.

None.

Author declares that there is no conflict of interest.

©2018 Ajani, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.