International Journal of

eISSN: 2573-2838

Research Article Volume 9 Issue 1

Department of Electrical and Biomedical Engineering, Shahid Ashrafi Esfahani University, Isfahan, Iran

Correspondence: Hamidreza Shirzadfar, Department of Electrical and Biomedical Engineering, Faculty of Engineering and Technology, Shahid Ashrafi Esfahani University, Isfahan, Iran

Received: December 20, 2023 | Published: January 4, 2024

Citation: Shirzadfar H, Ahmadpour Z, Soltani M. Design and manufacture a syringe pump for intelligent injection of specific doses of contrast medicine in medical imaging applications. Int J Biosen Bioelectron. 2024;9(1):1-5. DOI: 10.15406/ijbsbe.2024.09.00236

The construction of an Arduino Uno based syringe pump with the ability to measure the patient's body temperature during injection and detect the contrast material bubble has not been done so far. A syringe pump is a device that controls the volume and flow of milliliters to microliters for a certain period of time with very high precision, which gradually pushes the injection piston. This use of syringe pump for drug administration has been done for years. The working principle of this system consists of installing two steel rods to push the syringe piston at a set speed, which works through a coupling system. The advancement of technology has made it possible to use a motor as the driving force of the syringe filled with liquid released through the needle, and the electronic system in this tool is used as a controller. The design using a stepper motor based on Arduino Uno is chosen to adjust the flow rate; the research includes two stages of software and hardware construction. The hardware is implemented with the components needed to build a syringe pump with an Arduino Uno as the brain of the system and a stepper motor as a piston pusher.The flow rate in the syringe pump can be adjusted with the keyboard and displayed on the screen. It is also possible to see the patient's body temperature on the screen, and to detect bubbles in the contrast liquid during injection, we also put a sensor in this device that alerts the operator.

Keywords: syringe pump, stepper motor, arduino uno, a4988 driver, temperature sensor, ds18b20, opto counter

A syringe pump is a small injection device used for the controlled administration of small amounts of drugs to a patient or for use in chemical and biomedical research that can precisely administer fluids.1 Especially for the child to prescribe liquid medicine for a long time.2 There are generally two types of syringe pumps: medical infusion pumps and research syringe pumps. A medical infusion pump is a device used to deliver controlled amounts of fluids such as nutrients, drugs, chemotherapy, and blood to patients.3 They are actually used for in-vivo diagnosis, treatment, and for research. On the other hand, a research syringe pump is a device used in research laboratories for applications that can dispense very small portions of liquids or liquid drugs.4 Performance accuracy or efficiency of flow rate control is very important for the application of droplet microfluidic systems.

Cancer is a life-threatening disease that causes loss of integrity and order of normal tissue. Apoptosis or programmed cell death in normal tissues is replaced by uncontrolled cell growth in cancer cells. Cells that grow uncontrollably are called malignant cells and the transformation of a normal cell into a malignant cell. These malignant cells can spread through the bloodstream or lymph flow to any other organ and cause malignancy there, this phenomenon is called metastasis. The main methods used to treat cancer include chemotherapy, drug therapy, immunotherapy, precision medicine or personalized medicine, radiation therapy, stem cell transplantation and surgery. The main methods used to treat cancer include chemotherapy, drug therapy, immunotherapy, precision medicine or personalized medicine, radiation therapy, stem cell transplantation, and surgery. The choice of treatment depends on patient factors, tumor factors and treatment factors. Cancer treatment is chemotherapy,5–8 which uses one or more anti-cancer drugs as part of a regular chemotherapy regimen.

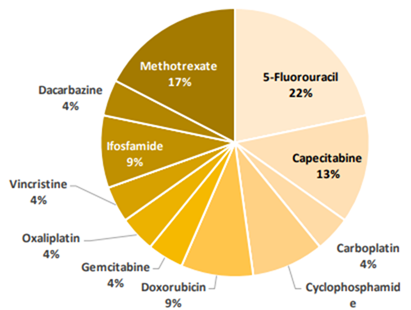

Cytotoxic drugs such as 5-fluorouracil, epirubicin, doxorubicin, cyclophosphamide, cisplatin, docetaxel, paclitaxel, carboplatin, vinblastine, phosphamide, mitomycin C, etoposide, etc. are used to fight cancer. 5-Fluoroura and cisplatin are the most common anticancer drugs that cyclophosphamide can use. Anti-neoplastic agents are also traditionally divided according to their origin or mechanism of action. The main groups are: 16 alkylating and alkylating agents, antimetabolites, antitumor antibiotics, plant alkaloids, miscellaneous agents, hormonal agents. Plant alkaloids bind to microtubule proteins during metaphase and cause mitotic arrest. The cell cannot divide and dies. This group is mainly the cell cycle phase specific to the M phase. Miscellaneous agents differ from each of the major classes of cytotoxic agents. The agents are asparaginase and hydroxyurea. Topoisomerase inhibitors prevent re-alignment of DNA strands and maintain single-strand breaks. Hormonal agents alter the intracellular/extracellular environment. Anti-inflammatory agents are usually prescribed in different combinations of doses and times. The specific regimen is referred to as a protocol. The protocol may use one or as many as five or six different antineoplastic agents. Choosing the right protocol should be based on the type of tumor and its grade. The most common auxiliary drugs used in our study are ondansetron, paracetamol, pethidine, fenargan, pantoprazole, lactulose, ranitidine, and peptard Table 1, 2 & Figure 1.

|

Drugs |

Total No |

Percentage (%) |

|

Pethidine |

47 |

4.75 |

|

Phenargan |

47 |

4.75 |

|

Ondansetron |

69 |

11.38 |

|

Paracetamol |

49 |

8.08 |

|

Pantoprazol |

38 |

6.27 |

|

Dexamethasone |

26 |

4.29 |

|

Ranitidine |

29 |

4.78 |

|

Metoclopramide |

27 |

4.45 |

|

Tramadol |

25 |

4.12 |

|

Ketorolac |

30 |

4.95 |

|

Lactulose |

29 |

4.78 |

|

Ibuprofen |

19 |

3.13 |

|

Betahistine |

13 |

2.14 |

|

Fentanyl Citrate |

4 |

0.66 |

|

Hydrocortisone |

14 |

2.31 |

|

Magnesium Sulfate |

4 |

0.66 |

|

Metoclopramide |

28 |

4.62 |

|

Morphine |

24 |

3.96 |

|

Peptard |

29 |

4.78 |

|

Potassium Chloride |

14 |

2.31 |

|

Eterocoxib |

13 |

2.14 |

|

Rabeprazole |

28 |

4.62 |

Table 1 Auxiliary drugs prescribed per patient9

|

Drug category |

Total N=412 |

In appropriate |

Percentage (%) |

|

5-Fluorouracil |

64 |

5 |

15.53 |

|

Bevacizumab |

21 |

0 |

5.09 |

|

Capecitabine |

36 |

3 |

8.73 |

|

Carboplatin |

27 |

1 |

5.58 |

|

Cisplatin |

19 |

0 |

4.61 |

|

Cyclophosphamide |

26 |

2 |

6.31 |

|

Docetaxel |

18 |

0 |

4.36 |

|

Doxorubicin |

28 |

2 |

6.79 |

|

Etoposide |

15 |

0 |

3.46 |

|

Gemeitabine |

20 |

1 |

4.85 |

|

Oxaliplatin |

16 |

1 |

3.88 |

|

Paclitaxel |

17 |

0 |

4.12 |

|

Vincristine |

22 |

1 |

5.33 |

|

Epirubicin |

17 |

0 |

4.12 |

|

Ifosfamide |

19 |

2 |

4.61 |

|

Dacarbazine |

14 |

1 |

3.39 |

|

Methotrexate |

33 |

4 |

8 |

Table 2 Number of drugs needed by cancer patients9

Figure 1 Pie chart showing inappropriately prescribed drugs.9

Designing and manufacturing stages of electric syringe pump device

In manual liquid drug delivery systems, fluctuations may occur during the work of nurses or hospital staff. Currently, syringe pumps are used worldwide for health care as well as research studies. In this research, a control system in the form of a syringe pump has been developed to control the volume and speed of liquid or solution flow. The syringe pump is made by controlling the speed and pulse width modulation of stepper motors based on the Arduino Uno microcontroller board.10 The tools used are a stepper motor as a syringe driver, an Arduino Uno as a controller, a seven-segment four-digit display and a keyboard matrix designed as input. The syringe pump works by pushing the injection pump, the speed of which is regulated by the flow rate. Flow rate and volume are obtained by adjusting the switching time of the stepper motor using the Arduino Uno PWM pins. The syringe pump has been observed to operate in the flow rate range of 0.10-12.00 mL/h.

Design and simulation

In this study, Arduino Uno board is used to set up the sensors to receive and send data and it is programmed using Arduino programming language (based on wiring) and Arduino development configuration (based on processing).

The schematic of the electrical circuit of the syringe pump to the Arduino Uno board is designed in the Altium Designer software according to Figure 2. The power supply circuit is supplied with a 12V adapter, and then the power supply enters the Arduino Uno board and the A4988 driver to supply the voltage of the A4988 driver motor.

The Arduino Uno board runs the program programmed on it. Keyboard, DS 18B20 sensor and optocounter are also controlled from it. 5V generated by Arduino Uno board is connected to optocounter, display and A4988 driver. The stepper motor is also connected to the A4988 driver for movement. By executing the commands, the display shows the output of the syringe and the patient's body temperature.

Electric circuit board of the syringe pump device

Different syringe pumps are designed and built for smart design Figure 3 shows the PCB of the syringe pump board. But it has no ability to measure the patient's body during injection to prevent unfortunate events for the patient and alert the machine operator if bubbles are detected in the injected substance.

The electrical section of the syringe pump

A4988 Drivers

The A4988 is a dedicated stepper driver that offers adjustable V-Ref and advanced micro stepping capabilities. While the adjustable maximum current solves overheating problems, the A4988 suffers from high operating noise. The noise is very audible while moving and holding the torque. While the motion noise can be reduced by reducing the current and increasing the micro step.

Temperature sensors DS1820

In this method, using the DS 18B20 sensor, a temperature sensor can be measured from -55 to +125 degrees Celsius with an accuracy of ±0.5.11 We can control the sensor from a microcontroller board. DS18B20 is generally used in industrial projects that have the necessary accuracy.

Opto counter

The optocounter module has been used to identify the bubble in the injection hose. Optocouplers are a special type of electrical devices that are designed to pass the signal between two isolated galvanic circuits.12 Optocouplers, also known as optoisolators, photocouplers, and optical isolators, are electrical components that consist of a light-emitting diode and a photodetector. The LED converts the electrical input signal into light, which is then transmitted to the photodetector, which in turn converts the light signal into an electrical output. In this way, Optocouplers provide complete electrical isolation between input and output and separate electrical circuits on different sides. It can eliminate electrical interference in signal transmission and limit the risk. An LM393 chip is used in the structure of this module. In fact, this module is based on an infrared transmitter and receiver that has the ability to count incoming objects. Among the applications of this module, we can mention the use in robotics, production line, counting of incoming objects, etc. The distance between two infrared grooves is 5 mm.

Arduino uno

Arduino Uno is an ATmega328P based microcontroller board. It has 14 I/O pins, 6 analog inputs, 16 MHz quartz crystal, USB connection, ICSP header and reset button, all of which require microcontroller support. The board simply connects to a computer via a USB cable or can be powered by an AC adapter or battery to get started. To execute the program, commands can also be programmed on the microcontroller. The bubble detection sensor and the temperature sensor as well as the stepper motor driver are connected to the Arduino board and take command from it.

Keypad

The 4×4 keyboard is a small and affordable input device that is commonly used in a variety of electronic projects. This keyboard contains 16 buttons arranged in a 4×4 grid and covered with a flexible membrane that protects the buttons and ensures their durability. The 4×4 membrane keyboard pins consist of 8 pins, 4 pins for columns and 4 pins for rows. The pin configuration may vary depending on the keyboard model, but the general idea is that the columns connect to the input pins of the microcontroller or Arduino board, and the rows connect to the output pins of the microcontroller. The 4×4 membrane keyboard pins consist of 8 pins, 4 pins for columns and 4 pins for rows. The pin configuration may vary depending on the keyboard model, but the general idea is that the columns connect to the input pins of the microcontroller or Arduino board, and the rows connect to the output pins of the microcontroller. The electrical part schematic of designed syringe pump is presented in Figure 4.

The mechanical section of the syringe pump

Stepper Motor

A stepper motor is used for rotation. In general, bridge motors work by successive activation coils located in the stator. The rotor contains a toothed iron core, permanent magnets, or both. The stepper we use consists of a toothed permanent magnet. The most important point is to create a state transition diagram for ignition coils based on the optimal performance of the control circuit; when the controller is not active, the modes do not change and thus the motor stops. However, when the controller is active and DIR is low, the modes flip up, causing the motor to move forward. When the controller is active and DIR is high, the modes rotate downward, causing the motor to move backwards. The housing body of the device is designed with Simplify3d software and cut on a plexiglass sheet with a 3D printer. Two shafts are used on the side of the housing for strength and to prevent slipping when the stepper motor moves. Two shafts are used on the side of the housing for strength and to prevent slipping when the stepper motor moves. The syringe is placed in the chamber and starts its injection with the movement of the stepper motor Figure 5.

A plastic syringe containing liquid is placed in the holding part, a tube with a holding set is connected to the patient's vein by a needle. When the liquid flow rate is determined, the stepper motor presses the coupling so that the liquid flows. The injection speed (coupling movement) depends on the diameter of the syringe and the flow rate set for the pump. When the pump is working, the flow rate, volume and liquid pressure are constantly measured, and when an error occurs in these parameters or other parameters, the device alarm will inform the operator. Too much or even too little injection of a certain drug may be very dangerous for any patient. The use of syringe injection pumps is to control the injection fluid pressure and prevent damage to the patient's vein during a possible increase in the injection pressure. High pressure will be associated with the alarm of closing and blocking the injection tube. The unit of measurement is mm/h (ml/h) and typical and common values are from 0 to 250 mm/h. Another feature of this device is bubble detection by optocontrast module; The contrast material passes through the injection hose; The module is placed in the injection path if the contrast material has bubbles; Light has the ability to pass through it, so when the LED of the device turns on, it shows us that the contrast material without bubbles is being injected into the patient. Some injection materials have a temperature difference with the patient's body before injection; To measure the temperature and control the patient's body temperature, we considered a temperature sensor that can be placed under the person's armpit or forehead and shows us the temperature on the monitor. The temperature on the monitor is updated every two seconds.

A syringe pump that injects large amounts of fluids or blood products into the patient's body by programming. The flow rate and speed of liquid injection is controlled by this device. If the liquid has air bubbles, the device's LED lights up and warns us. The temperature sensor for the treatment panel detects the temperature of the solution to prevent the injection of a solution with a large temperature difference with the patient's body. A syringe pump that injects large amounts of fluids or blood products into the patient's body by programming. The flow rate and speed of liquid injection is controlled by this device. If the liquid has air bubbles, the device's LED lights up and warns us. The temperature sensor for the treatment panel detects the temperature of the solution to prevent the injection of a solution with a large temperature difference with the patient's body. Syringe pumps are used in serum therapy, blood transfusion, medicine and chemotherapy. Also, this device is used in all special care departments, especially in the medical imaging department. Other uses of the syringe pump include the syringe pump of liquid food to the patient. Syringe pumps are used in serum therapy, blood transfusion, medicine and chemotherapy. Also, this device is used in all special care departments, especially in the medical imaging department. Other uses of the syringe pump include the syringe pump of liquid food to the patient. Extreme care must be taken when using this device for the amount of injected medicine does not decrease or exceed the desired amount. The inner diameter of the syringe used to inject all kinds of drugs and liquids is fixed, and the settings of the device are made based on this diameter and the desired amount of injected liquid.

None.

The authors declare there is no conflict of interest.

©2024 Shirzadfar, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.