Advances in

eISSN: 2373-6402

Research Article Volume 5 Issue 2

1Department of Horticulture, Faculty of Agriculture, Al-Azhar University, Nasr City, Egypt

2Horticulture Research Institute, Agriculture Research Center, Ministry of Agriculture, Egypt.

Correspondence: AA Helaly, Department of Horticulture, Faculty of Agriculture, Al-Azhar University, Cairo, Egypt

Received: August 29, 2016 | Published: November 10, 2016

Citation: Helaly AA, Haggag IAA, Shanan SA, et al. Effect of chemical treatments on the quality of fresh–cut globe artichoke (Cynara scolymus, L) during cold storage. Adv Plants Agric Res. 2016;5(2):474-481. DOI: 10.15406/apar.2016.05.00171

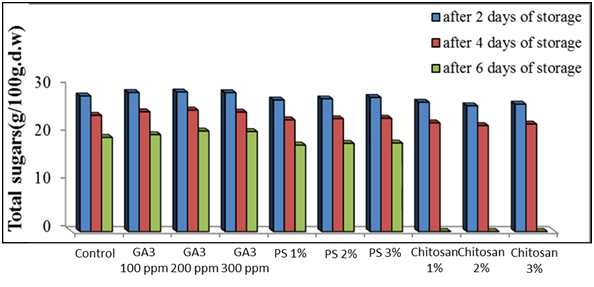

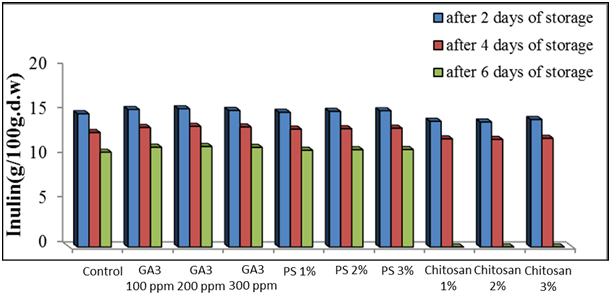

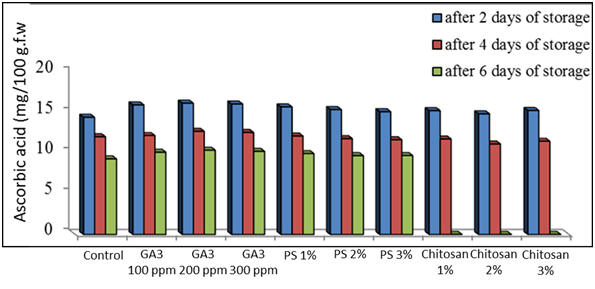

Fresh–cut heads of globe artichoke cultivar "French Hyrious" were dipped in solutions of Gibberellic acid (GA3) at 100, 200 and 300ppm, Potassium sorbate (PS) at 1, 2 and 3% and edible coating Chitosan at 1, 2, and 3 % for 5 minutes then placed in polyethylene trays that covered with polypropylene film which closed thermally and stored at 0ºC and 95% R.H. GA3 exhibited comparatively the most obvious results during storage in lessening the deterioration of loss in weight, unmarketable percentage, T.S.S, inulin beside lowering the activity of polyphenol oxidase enzyme. The maximum T.S.S % was obtained from gibberellic acid at 200ppm, potassium sorbate 1% and chitosan 3%. The application of gibberellic acid led to keep the highest total sugars content at 200ppm followed by potassium sorbate at 1% and finally chitosan at 2%. The maximum inulin content happened due to the application of gibberellic acid at 200ppm followed by potassium sorbate 3% and at least was chitosan at 3%. The highest ascorbic acid was obtained from the application of GA3 at 200 ppm, 3% potassium sorbate and 2% chitosan respectively. Gibberellic acid at 200ppm followed by potassium sorbate 1 % exhibited the least enzyme activity while chitosan at 1 %reflected the highest activity during the various storage periods.

Keywords: globe artichoke, inulin, GA3, potassium sorbate, chitosan, ascorbic acid, polyphenol oxidase

Globe artichoke (Cynara scolymus L.) is a perennial rosette plant grown throughout the world for its large, fleshy heads.1-3 Most of its culture (about 90%) is concentrated in the countries around the Mediterranean Basin mainly in Italy (50 000 ha), Spain (17000 ha) and France (10 000 ha).4 Egypt has the potential to develop an excellent export industry in artichoke. The production areas around Alexandria, Behiera and Giza Governorates have favorable climatic conditions to grow good quality of artichoke for export marketing.3 The edible portions are the fleshy bases of the bracts, the thick, fleshy receptacle on which the bracts are borne, and the flower primordia.2,3,5 Fresh-cut vegetables are ready to use products developed in 1980 to respond to the emerging consumer demand for both convenience and high quality aspects. However, the wounds inflicted during the preparation of fresh-cut vegetables promote many physical and physiological changes that hasten loss of product quality.6 After cutting, the surface of perishable product is exposed to air and to possible damage, being vulnerable to dehydration or change in (color) coloration. Color changes maybe principally due to enzymatic browning or loss of chlorophyll. Some of the damage can be avoided using sharp tools, inhibitors of enzymatic browning, modified atmospheres and active packaging.7,8 During cutting, the surface of product is also exposed to possible contamination with bacteria, yeasts and molds. In the case of minimally processed globe artichoke which falls into the low acid category of horticultural products (pH 5.8–6.0), high humidity and the large number of cut surfaces can provide ideal conditions for the growth of microorganisms.9 Water loss is one of the main causes of the marketability reduce of fresh-cut fruits and vegetables, which represents salable weight loss and reduces profits.10,11 However, without the external protective tissue, the cut products lose weight easily. In contrast, when storing horticultural products inside bags or protected with edible coatings, the relative humidity remains high to keep products from the weight loss.12 Fresh-cut fruits and vegetables release heat from respiration, consequently lose moisture, undergo a rapid softening and decay progress which may detract from their appearance, salable weight, and nutritional quality and also a short shelf-life.13-15 Therefore, any efforts such as effective technologies and facilities that could be done to maintain the fresh-cut fruits and vegetables with high quality after harvest, and during marketing, would be very important. Natural compounds and their derivatives such as GA3 and potassium sorbate have been used to prevent deterioration and browning of fresh-cut fruits and vegetables.16-19 The purpose of this research is to investigate the effects of gibberellic acid and potassium sorbate on weight loss, unmarketable percentage, T.S.S, inulin and polyphenol oxidase enzyme activity of fresh-cut globe artichoke under cold storage conditions. Three chemical substances used in our experiment, i.e., gibberellic acid, potassium sorbate and chitosan to elongate the storage periods of the globe artichoke fresh-cut heads. However, gibberellic acid is a vegetarianism hormone which produced by late leaves and growing caps in the roots and stems. It has many applications on vegetable crops one of them is extend of the storage periods by delaying the senescence. Potassium sorbate is a kind of unsaturated fatty acids compounds which can be absorbed by human body rapidly. It is widely used as preservative in the world showing action against yeasts, molds, and aerobic bacteria beside restrain growth and reproduction of the pernicious microorganisms without restrain useful microorganisms growth.20 It is well known that the preservative efficiency of potassium sorbate is 5-10 times than sodium benzoate.

Chitosan is a sugar obtained from the hard outer skeleton of shellfish, including carb, lobster and shrimp. It is used to treat obesity, high cholesterol, complications that kidney failure patients on dialysis often face, anemia, loss of strength and appetite, trouble sleeping (insomnia), periodontitis and dental caries. In agriculture, chitosan is used for plant defense, yield increase, natural seed treatment, plant growth enhancer, stimulates nutrient uptake, germination and sprouting increase, an ecological friendly biopesticide and photosynthesis increase.21,22

Artichoke marketable heads of the cultivar “French Hyrious" were harvested and shifted to the laboratory of Vegetable Handling Research Department, Horticultural Research Institute, Agricultural Research Center, Ministry of Agriculture, A.R.E. in 2014 and 2015. The heads cooled at 5°C and 95% RH for 24 hours, then peeled and cut by sharp knife into two pieces after which they were immersed in sodium chloride solution for 1 minute. The fresh-cut pieces were dipped in two different anti browning solutions for 5 minutes as follows:

After the heads were removed from the antibrowning treatments, they were placed in polyethylene trays that covered with polypropylene film which closed thermally and stored at 0ºC and 95% RH. The examined samples were subjected to the physical, chemical and biochemical analyses to follow the changes occurred in weight, Unmarketable percentage, total soluble solids, inulin and polyphenol oxidase activity during cold storage. The percentage of loss in weight was calculated by the following equation: Loss in weight % = Loss in weight at the sampling date / the initial weight of the curds X100. While the percentage of unmarketable examined parts was determined from the following equation:

Unmarketable curds (%) = Total number of unmarketable at the sampling date / the initial number of curds X 100. The T.S.S content were determined by abbe refractometer as a percentage.23 The inulin content was determined after the method of24 and the determination of the percentage of the activity of the enzyme polyphenol oxidase took place according to the method of.25

Storage of fresh-cut heads experiment

The marketable heads were harvested and cooled at 5°C and 95%RH for 24 hours, then the heads were peeled and cut by sharp knife into two pieces after which they were immersed in sodium chloride solution for 1 minute. The fresh-cut pieces were dipped in three different anti browning solutions for 5 minutes as follows:

Fresh-cut samples were subsequently removed from the anti-browning solutions and placed in polyethylene trays then wrapped individually with polypropylene film and the edges were sealed with a hot-plate sealer machine then stored at 0ºC and 95%R.H. each package contained about 250 g was weighted and packed in carton box. Three samples of each treatment were used for evaluation at 0, 2, 4 and 6 days from storage at 0ºC and 95% R.H. evaluation included the following:

Determination procedures

The average changes of the heads or the divided cuts were determined by the following procedures:

Visual quality: The visual quality was determined according to the scale of scoring system as explained after Able et al.,26 They were: 9: excellent, 7: good, 5: fair, 3: poor and 1:unsuitable.This scale depends on the morphological defects such as shriveling, loss of compactness and presence of physiological and pathological defects.

Statistical analysis

The obtained data of the first experiment was statistically analyzed by using Goodness of Fit method.29

Good storage of fresh-cut globe artichoke prolongs it's usefulness and in some cases improve its quality. It also checks market glut, provides wide marketing throughout the year, increases financial gain to the producers and reserve the quality of the living product. It is evident that the palatability and taste of globe artichoke is closely associated with the amount and type of the physical nature and the chemical constituents of the commodity to the time of storage. However, chemists have synthesized compounds which function effectively and have achieved some success in controlling the vital processes that led to deterioration during storage. So, this chapter is endeavors to describe in a comparatively way the effect of some chemicals such as Gibberellic acid (100, 200 and 300 ppm), potassium sorbate (1, 2 and 3%) and chitosan (1, 2 and 3%) on the storage ability of the fresh-cut globe artichoke during cold storage.

Physical changes

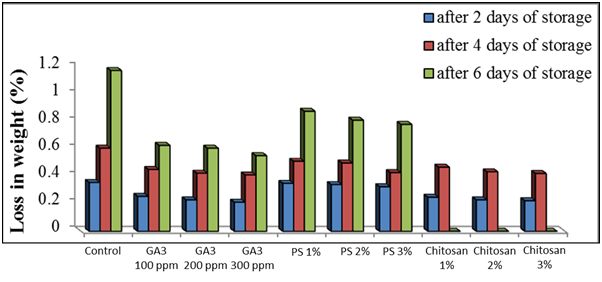

Loss in weight percentage: The effect of the chemical treatments on the fresh –cut artichoke loss in weight percentage during cold storage at 0°C is shown in Figure 1. The obtained results indicate clearly that a continuous gradual loss in weight existed in the stored commodity with extend of the storage periods in all the different chemicals. However, the minimum weight loss during cold storage occurred from the application of all the concentrations of gibberellic acid followed by chitosan then potassium sorbate meanwhile the maximum weight loss was detected in the control. In more detail, the most effective concentration of gibberellic acid was 300 ppm, chitosan 3% and potassium sorbate 3%. On the contrary, the least effective ones came from gibberellic acid at 100 ppm, chitosan at 1% and potassium sorbate at 1%.

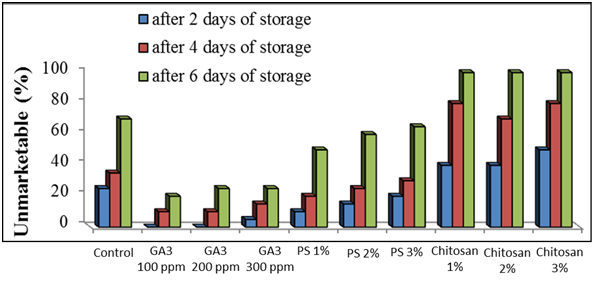

Unmarketable percentage: The results obtained on the effect of the various chemical treatments on the fresh – cut artichoke unmarketable percentage during cold storage at 0°C are presented in Figure 2. The general view for all the treatments throw light showing that the unmarketable percentage in the examined fresh – cut parts increased gradually with the elongation of cold storage periods. However, the lowest unmarketable percentage resulted from the treatments of gibberellic acid followed by potassium sorbate whereas the highest unmarketable percentage obtained from chitosan during all the storage periods. The most preferable concentration of gibberellic acid was 100 ppm, potassium sorbate at 1% and chitosan at 2%. On the other hand, the minimum effect during storage came from the concentration of 300 ppm gibberellic acid, 3% potassium sorbate and 3% chitosan.

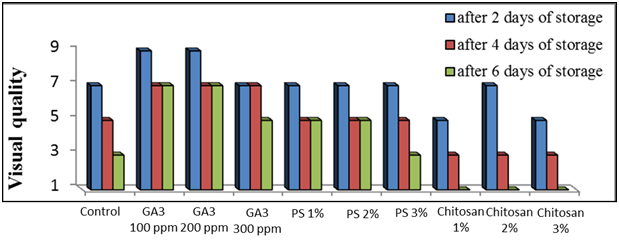

Visual quality: The data obtained on the respond of the visual quality of fresh-cut artichoke to the different chemical treatments during cold storage at 0°C are shown in Figure 3. The existed records from all the treatments indicate that this characteristic decreased progressively and gradually with extended of the storage periods. Nevertheless, the treatments of gibberellic acid kept the highest visual quality during storage followed by potassium sorbate and the least came from chitosan. Hence, the most effective concentrations in this concern are 100 and 200 ppm of gibberellic acid, 1 and 2% of potassium sorbate and 2% of chitosan during all the storage periods. On the other hand, the infelicitous concentrations which appear to sight exerted from gibberellic acid at 300 ppm, potassium sorbate at 3% and chitosan at both 1 and 3%.

The effect of the various chemical treatments on the color of fresh-cut artichoke during cold storage at 0°C is illustrated in Table 1. It was manifested from the table that there was a gradual degradation in color in all the treatments with the prolongation of storage periods. However, the lowest color degradation occurred from the application of the treatment of gibberellic acid then potassium sorbate and control whereas the highest degradation resulted from the use of the treatment of chitosan during the various storage periods. Detailed description showed that the better concentration is 200 ppm of gibberellic acid, 2% of potassium sorbate and2% of chitosan for maintaining the better color during all the storage periods. On the other hand, the low effective concentrations resulted from 300 ppm gibberellic acid followed by 3% potassium sorbate then 1% chitosan.

At 0° C and 95% RH Treatments Control |

Storage periods in days |

(BI) |

(L*) |

(a*) |

(b*) |

(C*) |

(h*) |

|

0 |

44.7 |

79.1 |

-2.9 |

31 |

31.14 |

95.36 |

2 |

60.11 |

73.3 |

2 |

33.42 |

33.52 |

88.8 |

|

4 |

64.18 |

71.8 |

2.11 |

34.37 |

34.41 |

86.74 |

|

6 |

67.56 |

70.26 |

2.83 |

34.65 |

34.7 |

86.56 |

|

Gibberellic acid (100ppm) |

0 |

44.7 |

79.1 |

-2.9 |

31 |

31.14 |

95.36 |

2 |

54.07 |

76.16 |

1.15 |

32.36 |

32.38 |

87.96 |

|

4 |

58.14 |

75.09 |

1.55 |

33.7 |

33.73 |

87.36 |

|

6 |

62.2 |

73.11 |

2.08 |

34.21 |

34.27 |

86.52 |

|

Gibberellic acid (200ppm) |

0 |

44.7 |

79.1 |

-2.9 |

31 |

31.14 |

95.36 |

2 |

51.74 |

77.2 |

1.1 |

31.75 |

31.77 |

88.01 |

|

4 |

56.39 |

75.96 |

1.21 |

33.56 |

33.58 |

87.93 |

|

6 |

60.46 |

73.95 |

1.94 |

33.92 |

33.97 |

86.72 |

|

Gibberellic acid (300ppm) |

0 |

44.7 |

79.1 |

-2.9 |

31 |

31.14 |

95.36 |

2 |

56.97 |

75.31 |

1.51 |

33.16 |

33.19 |

87.39 |

|

4 |

61.04 |

73.61 |

1.83 |

34.13 |

34.18 |

86.93 |

|

6 |

65.11 |

71.34 |

2.44 |

34.42 |

34.5 |

85.94 |

|

Potassium sorbate (1%) |

0 |

44.7 |

79.1 |

-2.9 |

31 |

31.12 |

95.36 |

2 |

54.3 |

72.32 |

0.69 |

31.04 |

31.14 |

88.8 |

|

4 |

63.72 |

70.06 |

0.91 |

33.89 |

33.98 |

88.47 |

|

6 |

70.17 |

68.11 |

1.71 |

35.02 |

35.04 |

87.18 |

|

Potassium sorbate (2%) |

0 |

44.7 |

79.1 |

-2.9 |

31 |

31.14 |

95.36 |

2 |

54.82 |

73.39 |

-1.91 |

33.01 |

33.22 |

92.98 |

|

4 |

63.83 |

69.8 |

1.79 |

33.41 |

33.51 |

87.28 |

|

6 |

68.08 |

68.44 |

2.84 |

33.92 |

34.24 |

85.5 |

|

Potassium sorbate (3%) |

0 |

44.7 |

79.1 |

-2.9 |

31 |

31.14 |

95.36 |

2 |

63.14 |

68.89 |

0.85 |

33.56 |

33.62 |

88.62 |

|

4 |

67.15 |

67.66 |

1.81 |

33.62 |

33.66 |

86.89 |

|

6 |

75.11 |

65.38 |

3.73 |

34.47 |

35.1 |

84.82 |

|

Chitosan -1% |

0 |

44.7 |

79.1 |

-2.9 |

31 |

31.14 |

95.36 |

2 |

73.14 |

67.59 |

2.23 |

35.61 |

35.7 |

86.46 |

|

4 |

89.24 |

60.43 |

3.9 |

36.02 |

36.31 |

83.55 |

|

6 |

-------- |

-------- |

-------- |

-------- |

-------- |

-------- |

|

Chitosan -2% |

0 |

44.7 |

79.1 |

-2.9 |

31 |

31.14 |

95.36 |

2 |

64.82 |

70.7 |

1.28 |

34.47 |

34.51 |

87.89 |

|

4 |

77.9 |

65.25 |

2.72 |

35.79 |

35.9 |

85.74 |

|

6 |

-------- |

-------- |

-------- |

-------- |

-------- |

-------- |

|

Chitosan -3% |

0 |

44.7 |

79.1 |

-2.9 |

31 |

31.14 |

95.36 |

2 |

70.23 |

68.58 |

1.12 |

35.56 |

35.73 |

88.12 |

|

4 |

81.8 |

65.45 |

2.99 |

37.1 |

37.17 |

85.2 |

|

6 |

------- |

-------- |

-------- |

-------- |

-------- |

Table 1 The effect of the different chemical treatments on the color of fresh-cut globe rtichoke head under cold storage

*Visual quality was determined using the following rating score system: Excellent=9, Good=7, Fair=5, Poor=3 and Unstable =1.26

Chemical changes

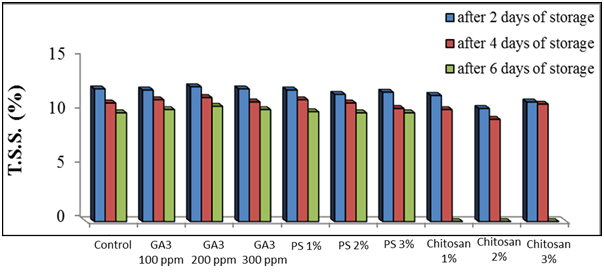

Total soluble solids: The effect of the different chemical treatments on the T.S.S percentage of the fresh-cut artichoke during cold storage at 0°C is illustrated in Figure 4. Generally speaking, the existed figures gave rise to a general gradual decrease in this characteristic in all the applied treatments with the prolongation of the storage periods. On the whole, the use of gibberellic acid shows the maximum T.S.S concentration followed by potassium sorbate and chitosan during the various storage periods. However the most effective concentration of gibberellic acid resulted from using 200 ppm, potassium sorbate 1% and chitosan 3%. On the contrary, the minimum effective ones were gibberellic acid 300 ppm, potassium sorbate 3% and chitosan 2% during the various storage periods.

Total sugars: The effect of the various chemical treatments on the total sugars content in the fresh-cut artichoke during cold storage at 0°C is presented in Figure 5. The obtained results in the whole treatments revealed that there was a progressive decrease in this characteristic with extends of the storage periods. However, the application of gibberellic acid led to keep the highest total sugars content followed by potassium sorbate and finally chitosan. However, the most effective concentrations in this concern was 200 ppm gibberellic acid, 3% potassium sorbate and 1% chitosan during all the storage periods meanwhile the least effective concentrations were 100 ppm gibberellic acid, 1% potassium sorbate and 2% chitosan.

Inulin: The effect of the different chemical treatments on the inulin content in the fresh-cut artichoke during cold storage at 0°C is presented in Figure 6. The results of this characteristic for all the treatments indicate that there was a gradual decrease in this characteristic with the progress of the storage periods. Nevertheless, the maximum inulin content happened due to the application of gibberellic acid followed by potassium sorbate whereas the minimum content resulted from the use of chitosan during the various storage periods. However, the most effective concentration of gibberellic acid which reserved the highest amount of inulin was 200 ppm, potassium sorbate 3% and chitosan 3% during all the storage periods. In contrast, the lowest effective concentrations during storage existed from 300 ppm of gibberellic acid, 1% of potassium sorbate and 2% of chitosan.

Ascorbic acid: The effect of the various chemical treatments on the ascorbic acid content of the fresh-cut artichoke during cold storage at 0°C is shown in Figure 7. There was clear evidence that the contents of ascorbic acid in all the treatments decreased gradually with the elapse of the storage periods. However, the treatment of gibberellic acid during storage kept comparatively the highest ascorbic acid content followed by potassium sorbate then chitosan which exhibited the lowest content of this characteristic. Regarding the used concentrations, it is easy to notice that the concentration of 200 ppm gibberellic acid, 1% potassium sorbate and 1% chitosan hold comparatively the highest ascorbic acid content over the other concentrations. On the contrary, the concentrations of 100 ppm gibberellic acid, 3% potassium sorbate and 2% chitosan reserved the minimum ascorbic acid content during storage.

Biochemical changes

Polyphenol oxidase activity: The effect of the different chemical treatments on the polyphenol oxidase activity in the fresh-cut artichoke during cold storage at 0°C is illustrated in Figure 8. The influence of the various treatments on the fresh-cut heads gave rise to a general trend of increase in this activity with the elongation of the storage periods. The obtained results show that the treatments of gibberellic acid followed by potassium sorbate exhibited the least enzyme activity while chitosan reflected the highest activity during the various storage periods. To give the particulars of the results during storage, it is easy to notice that 200 ppm of gibberellic acid, 1% of potassium sorbate and 1% of chitosan induced the minimum activity in the enzyme meanwhile 300 ppm of gibberellic acid, 2% of potassium sorbate and 3% of chitosan put forth to the highest ones.

The picture took out from the experiment of fresh-cut globe artichoke storage put in sight that the use of gibberellic acid exhibited comparatively the most obvious results during storage in lessening the deterioration of loss in weight, unmarketable percentage, visual quality, color, T.S.S, total sugars, inulin, ascorbic acid beside lowering the activity of polyphenol oxidase enzyme. However, it was evident that the most effective concentration in this concern was 200 ppm. It should be realized that the obtained results for GA3 may be related to a part role played by GA3 in lowering the respiration rate,30,31 it's striking effect in delaying the senescence,32,33 increasing the content of cuticle and sustain the integrity of membranes30,31,34 which reduce the water loss and increasing the cell-wall thickness that protect the fruits from the fungal infection,35,36 delaying the loss of chlorophyll and consequently retarded the appearance of brown color.37-42

Concerning the changes occurred in the chemical characteristics, it is obvious that GA3 kept comparatively the favorite highest contents of T.S.S, total sugars, inulin, ascorbic acid and lowering the enzyme activity of polyphenol oxidase during all the storage periods. These results may be attributed to the depression in moisture loss, respiration rate35,36,43,44 by GA3 and conversion of insoluble solids to simpler forms.45 Considerable attention has been paid to the obtained results of potassium sorbate, where the treatment of potassium sorbate ranked second showing less unmarketable percentage, higher visual quality, less color degradation, higher contents of T.S.S, total sugars, inulin, ascorbic acid and less polyphenol oxidase activity. However, the most effective used concentrations were 1% in unmarketable percentage, visual quality, T.S.S, ascorbic acid and polyphenol oxidase activity and 2% in color and 3% in total sugars and inulin contents. Moreover, it is clear from applying potassium sorbate that this compound play an important role as an effective preservative against yeasts, molds and bacteria and prevent softening of the vegetable tissues by inhibiting pectinolytic enzymes which lead to minimize the unmarketable percentage and hold more visual quality through controlling the browning enzymatic and chlorophyllase activity.46

From another point of view, the treatment of chitosan is ranked the second in less loss in weight percentage after gibberellic acid. However, the most effective concentration was 3%. The role of chitosan is to minimizing weight loss percentage through enables epidermal tissues to control water loss, a physical barrier to water vapor, reducing moisture loss and delaying fruit dehydration47-50 forms a layer of semi-transparent to smooth pericarp surface.51 The picture took out from the experiment of fresh-cut globe artichoke storage put in sight that the use of gibberellic acid exhibited comparatively the most obvious results during storage in lessening the deterioration of loss in weight, unmarketable percentage, visual quality, color, T.S.S, total sugars, inulin, ascorbic acid beside lowering the activity of polyphenol oxidase enzyme. However, it was evident that the most effective concentration in this concern was 200 ppm.

It should be realized that the obtained results for GA3 may be related to a part role played by GA3 in lowering the respiration rate,30,31 it's striking effect in delaying the senescence,32,33 increasing the content of cuticle and sustain the integrity of membranes30,34,31 which reduce the water loss and increasing the cell-wall thickness that protect the fruits from the fungal infection,35,36 delaying the loss of chlorophyll and consequently retarded the appearance of brown color.37-42 Concerning the changes occurred in the chemical characteristics, it is obvious that GA3 kept comparatively the favorite highest contents of T.S.S, total sugars, inulin, ascorbic acid and lowering the enzyme activity of polyphenol oxidase during all the storage periods. These results may be attributed to the depression in moisture loss, respiration rate35,36,43,44 by GA3 and conversion of insoluble solids to simpler forms.42,45

Considerable attention has been paid to the obtained results of potassium sorbate, where the treatment of potassium sorbate ranked second showing less unmarketable percentage, higher visual quality, less color degradation, higher contents of T.S.S, total sugars, inulin, ascorbic acid and less polyphenol oxidase activity. However, the most effective used concentrations were 1% in unmarketable percentage, visual quality, T.S.S, ascorbic acid and polyphenol oxidase activity and 2% in color and 3% in total sugars and inulin contents. Moreover, it is clear from applying potassium sorbate that this compound play an important role as an effective preservative against yeasts, molds and bacteria and prevent softening of the vegetable tissues by inhibiting pectinolytic enzymes which lead to minimize the unmarketable percentage and hold more visual quality through controlling the browning enzymatic and chlorophyllase activity (Monica et al., 2003). From another point of view, the treatment of chitosan is ranked the second in less loss in weight percentage after gibberellic acid. However, the most effective concentration was 3%. The role of chitosan is to minimizing weight loss percentage through enables epidermal tissues to control water loss, a physical barrier to water vapor, reducing moisture loss and delaying fruit dehydration47-50 forms a layer of semi-transparent to smooth pericarp surface.51

In seeking to follow the results in this experiment, we can put in our mind as recommendations for practical work that the dipping of fresh–cut globe artichoke ''French Hyrious'' cultivar in gibberellic acid solution at the concentration of 200ppm for 5 minutes was the best treatment during storage in polyethylene trays which wrapped individually with polypropylene film under cold storage at 0ºC and 95% R.H.

The authors express their gratitude to Prof. Dr. Shamel Ahmed Shanan and Prof. Dr. Abd El–Naem Said Abd El–Rehim Professor of vegetable crops, Department of Horticulture, Faculty of Agriculture, Al–Azhar University. And Prof. Dr. Rawia El–Bassiouny Ibrahim Head of research, Postharvest Section, Horticulture Research Institute, Agriculture Research Center, Ministry of Agriculture for their constructive suggestions, supervision, advice, sincere help and valuable guidance throughout the course of this study.

The author declares no conflict of interest.

©2016 Helaly, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.