eISSN: 2576-4543

Research Article Volume 8 Issue 3

1Centro Nacional de Electromagnetismo Aplicado, Universidad de Oriente, Cuba

2Centro Nacional de Electromagnetismo Aplicado, Universidad de Oriente, Cuba

3Hospital Clínico Quirúrgico, Dpto. Microbiología, Cuba

Correspondence: Leonardo Mesa Torres, Centro Nacional de Electromagnetismo Aplicado. Universidad de Oriente. Sede Julio Antonio Mella. Avenida de las Américas s/n, Código Postal: 90400. GP 4078, Santiago de Cuba, Cuba

Received: June 20, 2024 | Published: July 25, 2024

Citation: Torres LM, Cayamo AAB, Mariño YM, et al. Magnetic treatment of microorganisms in the food industry. Phys Astron Int J. 2024;8(3):138-141. DOI: 10.15406/paij.2024.08.00342

At present, the magnetic treatment of microorganisms in the food industry is gaining more popularity. The aim of this work lies in the design and construction of a magnetic device, which consists of a magnetic system, formed by permanent magnets of rectangular shape, which are distributed and confined in a non-ferromagnetic, annular structure; that contributes: to the growth of lactic acid bacteria (LAB), the pH, the acidity, the morphology of the cells, the symbiotic relationship with an increase in the cell concentration and viability of the yogurt culture to 96%, maintaining the parameters quality of the final product.

Keywords: Magnetic treatment, magnetic device, food industry, permanent magnets, yogurt

New technologies using electromagnetic fields offer mankind immersed benefits; in addition to being used in electrical power transmission, telecommunications, industrial, medical and household appliances. The magnetic device (or magnetostimulator) generates a magnetic field in a certain region of space by means of active and/or passive devices. Active devices (resistive magnets or electromagnets) generate a magnetic field if an electric current is circulated through them, whereas passive devices (permanent magnets and ferromagnetic elements) do not require an electric current to circulate through them for the generation of the magnetic field.1 The use of magnetic processing in the food industry is becoming increasingly popular. In the sugar industry, filtered juices from primary saturation are treated with electromagnetic field (EMF) of (175-188) mT in an exposure time of (30 to 40) min; which improves the quality of raw and refined sugar. Mamatov, 1989 et al., and Petrik et al., 2004.2 describes the use of magnetic water treatment in bread making with a field induction B = (0,8 – 1,2) T and a frequency f = 50 Hz which improves the quantity and quality of raw gluten, final acidity and dough of bread as it controls the activity of enzymes acting on flour (alpha-amylase, protease, lipase, catalase) and accelerates yeast fermentation. In the beverage and liquor industry. Darbinyan et al., 1990, reports the use of magnetic treatment B = (213 - 226) mT for the storage process of: beer, wines, vinegars, fruit juices and tea, for a flow velocity of (1.0 - 1.5) m/s.3-6

In the fish industry, Mogilevskii, 1994 et al. describe the use of magnetic treatment with a magnetic field induction B = (5 - 6) x 10-2 mT and an air heating temperature range T= (35 - 40) oC; to extract essential oils and destroy the surface membrane of sardines.7,8 In Cuba, Anaya et al, 2010, reports the use of B = (0,1 - 0,12) T in the constant flow of beer (15 and 17 L/h) for different stages of the brewing process, in an exposure time of 30 min; which improves the sanitary quality and clarification, without physical-chemical or sensory changes in the samples analyzed, since it allows the stimulation of the brewer's yeast (Saccharomyces uvarum Budvar, S. uvarum 48.1 and S. cerevisiae F-26) m and increases the fermentation efficiency from (12,21 to 93,2)% alcohol with respect to the control, during 15 days of fermentation, which demonstrates the stimulating effect of the electromagnetic field (EMF) on lactic acid bacteria for the preparation of natural yogurt and soy yogurt.9,10 In the dairy industry, magnetic treatment has been used in the reduction of contaminating microflora in cream cheese, improving the quality of the final product. It has also been used to stimulate the cell viability of the bacteria of the Bioyogur culture used in the production of yogurt, obtaining a better quality product with less fermentation time at a low production cost (Mesa et al., 2014). Currently, there are studies to improve the homogeneity of milk and prevent protein losses by controlling the acidity caused by the microorganisms present. For this purpose, fields of (120-180) mT are applied. There are also other systems that use EMF of 120 mT in cheese production where EMF accelerates the syneresis of coagulation and aroma maturation processes, and its durability.9 In addition to proposing magnetic treatment as an efficient and simple technology for the stimulation of microorganisms of industrial interest in the production of different dairy products for the national and international market; therefore, magnetic treatment has been used in the reduction of contaminating microflora in cream cheese, improving the quality of the final production, in addition to proposing magnetic treatment as an efficient and simple technology for the stimulation of microorganisms of industrial interest in the production of different dairy products for the national and international market.11-13 In the dairy mixture of Santiago de Cuba, the low feasibility of these starter cultures destined to the industrial production of yogurt is 86%, with a cell concentration of 5.89 log ufcmL-1, affecting the fermentation and the final quality of the product. In this work, we propose the design of a passive magnetic device, constituted with permanent magnets for the treatment of lactic bacteria (yogurt culture) that allows the implementation of a new technology for the production and quality of yogurt in the national and international market.14,15

The calculation of the magnetic induction (B) generated by active and passive magnetic device configurations is governed by several laws: Gauss law, Faraday and Ampère-Maxwell laws, Biot-Savart up to the finite element analysis (FEA). The design of a disease device is very complex. Here it is taken into account parameters like magnetic induction, and homogeneity which depend on the designed configuration and if he device is active or passive. In the first case, the ampere-turn relationship is taken into account, the shape and cross-section of the conductor, the thickness of the insulation, the distribution of the turns in layers and turns, and the dimensions and separation between the coils that make up the magnetic system. In the second case, the type and dimension are taken into account of the material, magnetic induction and the magnetic gradient of the external field and cylindrical coordinates; as well as the configuration used is discrete (permanent magnet elements) or continuous (bars, ties ferromagnetic) The magnetic field is calculated according to the following expression.16

(1)

where, B is the magnetic field induction, μ magnetic permeability of the material and H magnetic field strength, the divergence andis the gradient of a scalar potential.

It is constituted by a magnetic system, formed by discrete permanent magnets of rectangular (or circular) shape of equal size and magnetic susceptibility confined in a non-ferromagnetic support structure of cylindrical shape. The intensity of the magnetic field of the permanent magnets was measured (magnetometry) with a Hall magnetometer model 5180; belonging to the Laboratory of Magnetic Characterizations of the National Center of Applied Electromagnetism. It was proposed to use material N 42.17 The calculation of the magnetic system was carried out according to the following expression.18

(2)

where, B is the magnetic induction in spherical coordinates, m is the magnitude of the dipole momento, n normal unit vector pointing out of the surface of the magnetized material, p vector from the center of the magnetized volumen, µ =µ0 permeability of the surrounding médium, θ measured from the magnetization axis of the material, Dn material dimensions.19 Because of the complexity of the calculation of the magnetic induction of discrete and continuous configurations of ferromagnetic and ferromagnetic elements, and in order to optimize time, as well as, taking advantage of the potential of this software and the experience in this subject, this software was used to solve a magnetostatic problem that allows the calculation of different configurations of magnetic systems from the magnetic induction and magnetic field homogeneity maps.18 In this study a multifactorial experimental design was performed on 27 yogurt samples with magnetic treatment and the magnetic treatment and the control for 3 days where the means were compared using a Student's t-test, and the normality and homogeneity of variances of the variables of the measurements that allow expressing the values as a function of: BAL concentration, pH and acidity of the treated samples with respect to the control; in 9 experimental runs for each factor with a magnetic induction and exposure time to the magnetic field, as shown in Table 1.20,21

|

Exposure times (min) |

pH |

Acidity index % |

|

|

Measurement |

T1(10) |

2.89 |

0.069 |

|

T2(10) |

2.91 |

0.074 |

|

|

T3(10) |

2.92 |

0.088 |

|

|

T1(20) |

3 |

0.054 |

|

|

T2(20) |

2.94 |

0.117 |

|

|

T3(20) |

2.93 |

0.086 |

|

|

T1(30) |

2.96 |

0.087 |

|

|

T2(30) |

2.95 |

0.067 |

|

|

T3(30) |

2.94 |

0.083 |

Table 1 Shows the experimental analysis of pH and acidity index for different magnetic field exposure times

The data were processed in an Excel table, Microsoft Office version 10, in which the data. The statistical techniques used were implemented in the statistical program Minitab® 14 (Minitab Inc for Windows, 2003, free software, National Institute of Standards and Technology, Pennsylvania State University, USA, https://www.minitab.com/en-mx/products/minitabs).

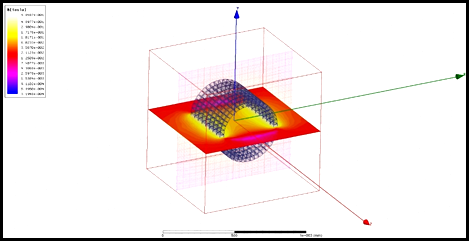

Figure 1 shows the magnetic induction map (B) in a sphere of radius r = 0,1 m.

Figure 1 Magnetic induction map, B= (76,2 to 171,1) mT in a sphere of radius r = 0,1 m. The permanent magnets are 0,03 m wide, 0,01 m high and 0,05 m long.22

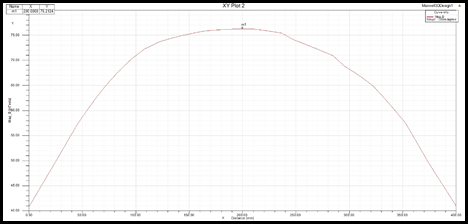

In the Figure 2. The magnetic field magnitude map (Mag_B) is shown, in the X, Y plane.

Figure 2 Magnetic field magnitude map (Mag_B) = (70 to 76) mT and homogeneity H = 6 x 10-3 ppm; in a sphere of radius 0,1 m.23,24

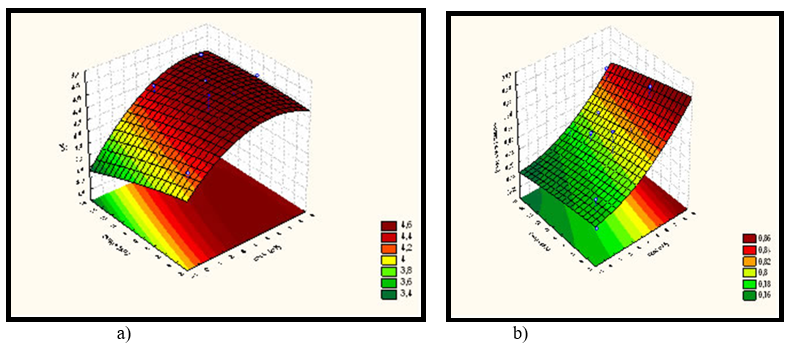

Figure 3a) shows the surface map for pH and Figure 3b) the surface map for acidity.

Figure 3 pH response surface and 3b) Acidity response exposure for a magnetic induction B= (76,2-171,1) mT and magnetic field exposure time (10 to 30) min respectively.25-29

Figure 4 shows the prototype of a magnetic device, with permanent magnets, which consists of several pieces, which are made by different manufacturing processes of materials and are coupled, feasible for the magnetic treatment of lactic acid bacteria.

Figure 1 and 2 showed that the configuration of the magnetic system can be used for the desired purposes since the magnetic induction B= (76,2-171,1) mT and the homogeneity H= 6,6 x 10-3 ppm; in a sphere of radius 0,1 m; generated in the center of the configuration, is sufficient for the desired purposes. In Figure 3a) it was observed that there are statistically significant differences in pH in a range (2,8 to 3)% of the magnetically treated samples with respect to the control and magnetic field exposure time (10 to 30) min, since the magnetic induction generated increases the number of microorganisms on the substrate.20 Figure 3b) It was shown that the values of the acidity indexes show that a behavior similar to pH was obtained; the highest values were obtained for the samples treated with an exposure time to the magnetic field of 15 min, with a reliability of more than 95% with a significant difference p<0,05 because the generated magnetic induction influences the increase in the number of bacterial colonies and inhibits the stimulation of the cell viability of yogurt culture bacteria and decreases the fermentation time, thus obtaining a low production cost and a better quality of the final product.31

The design and simulation of the magnetic device, with permanent magnets, is feasible for the magnetic treatment of lactic acid bacteria since the highest magnetic induction and homogeneity of the magnetic field are achieved in the center of the configuration, which allows an increase in cell concentration, a growth of 10.38 log cfu-mL-1, pH values of 3.80, acidity index of 0.81% and thus improves the viability of lactic acid bacteria. The device is designed to modulate the growth and metabolic activity of acid lactic acid bacteria, which is crucial in various applications such as fermentation processes, which implements a new technology in the industrial production of yogurt because it decreases the fermentation time of the production process and improves the quality of the final product.

The authors thank the technicians and other colleagues from the National Center for Applied Electromagnetism, the Center for Medical Biophysics and the Faculty of Mechanical Engineering who made this work possible.

©2024 Torres, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.