Consider the most important aspects of the problem of static POE fabrication, namely, the conditions needed to achieve high optical efficiency thresholds for a mirror surface. Note that in our first studies4‒9 we obtained only stationary expression for the limiting intensities, leading to the optical destruction of POEs, and the stability parameters of optical surfaces based on them.

Thermal stress state of a body exposed to laser radiation

Temperature field

We considered a strongly absorbing isotropic body, which at the initial moment of time has a fixed temperature. The body surface with the absorption coefficient A is exposed to an axisymmetric radiation flux of arbitrary temporal shape. It is assumed that the intensity distribution in the laser beam cross section obeys the Gaussian law: , where . Energy absorption takes place directly on the irradiated surface. Physically, this means that the skin-layer depth is smaller than the depth of the temperature field penetration in the body under consideration during the characteristic times of changes in the radiation intensity, i.e., , where is the thermal diffusivity of the material.

The problem of determining the temperature field was considered in the linear formulation: it was assumed that all thermal and mechanical characteristics of the materials are independent of temperature and energy loss by radiation and convection was neglected. Provided that the characteristic size of the beam is , where is the characteristic size of the irradiated body, and the energy input time is , in solving this problem one can use the half-space model. The heating of the sample material is described in this case by the heat conduction equation22

(1)

at the following initial and boundary conditions:

,

(2)

where is the finite quantity; is the time function of the laser beam intensity normalised to is the absorption coefficient of laser radiation on a metal surface; is the thermal conductivity of the body material; and is the temperature.

Using the method of successive integral Hankel and Laplace transforms, we obtain the solution to (1)

(3)

where and are the parameters of Laplace and Hankel transforms;; is the image of the Laplace transform of ; and is the zero-order Bessel function.

This expression allows us to describe the thermal state of a solid body heated by laser radiation, whose intensity varies with time in an arbitrary manner.

Thermoelastic stresses

The thermoelastic behaviour of the body is analysed by using the system of equations:22,23

,

(4)

where and are the Lam coefficients;24 is the deformation vector; is the density of the material; is the external force; is the coefficient of thermal expansion; and is the density of volume heat sources.

In considering the deformation of an elastic metal half-space whose surface is exposed to pulsed laser radiation, when the inequalities

,

(5)

are fulfilled, we can pass to the system of equations of the quasi-stationary thermoelasticity theory:

(6)

In this case, from the first inequality we obtain the duration of a single pulse

(7a)

and from the second −

(7b)

We represented the stress tensor components in the general form:21

(8)

where G is the shear modulus; is the first-order Bessel function;

and is Poisson's ratio. Analysis of the expression reveals the nature of the time changes at any point in the half-space.

Thermal deformations

The stress state occurring in a solid body is accompanied by its deformation, its largest amplitude being achieved on the irradiated surface. The expression for the normal displacement of the surface, corresponding to a given temperature distribution, has the form:

(9)

(10)

where The resulting expression allows us to trace the changes in the surface shape during irradiation.

Thus, this consideration has made it possible to describe fully the characteristics of temperature fields, thermoelastic stresses and thermal deformations occurring in solids whose surface is exposed to high-power laser radiation varying with time in an arbitrary manner. In addition, the following relations are fulfilled between the quantities characterising the thermal stress state in the continuous-wave and any other nonstationary regime of energy input into the solid:22,24

(11)

These relations are similar to Duhamel’s integral formula from the theory of heat conduction. It should be noted that the local deformation of the POE surface is the determining factor of the laser impact and the bending deformation component of the POE as a whole can be reduced to zero due to the large thickness of its effectively cooled base. Later, both components of the POE deformation were examined in the book of L.S. Tsesnek et al.25

Continuous-wave irradiation

Temperature field

If the time of laser irradiation satisfies the inequality, a steady-state temperature field can be established in the sample material. The main property of the process of its establishment is described by the expression21

. (12)

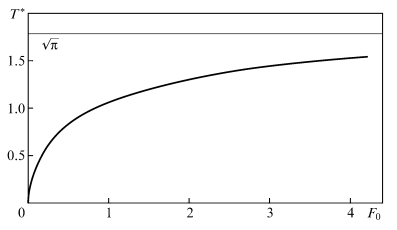

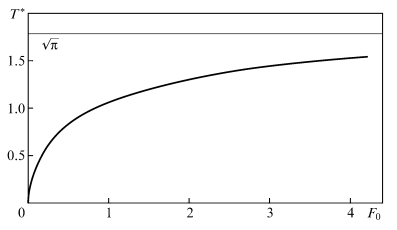

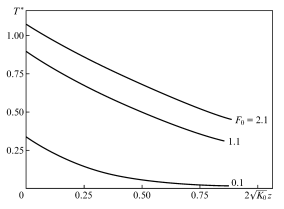

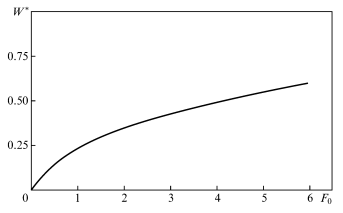

It follows from (12) that for instants of times t, at which , the current temperature is 10% less than the steady-state value. We therefore assume that, starting at time t, at which , a stationary thermal state is established in the sample material (Figure 1).

Figure 1 Time dependence of the sample surface temperature at the centre of the region (number F0) exposed to cw radiation.

The expression for the temperature field in the half-space has the form21

(13)

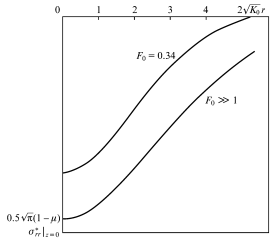

where and From this expression we obtain the locality of the temperature field, the characteristic values of which decrease with increasing distance from the centre of the surface irradiation region and inside the material (Figures 2−4).

Figure 2 Temperature field distributions on the z axis.

Figure 3 Temperature field distributions on the sample surface.

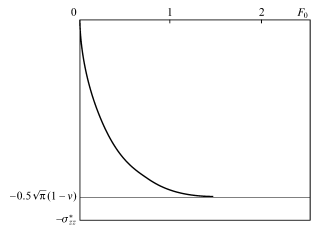

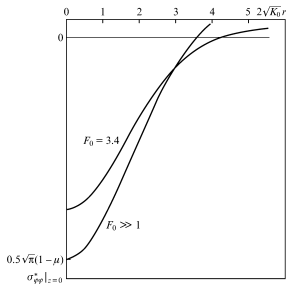

Figure 4 Dependence of the axial stress

on the exposure time of laser irradiation.

Thermoelastic stresses

In the steady-state regime , nonzero are only the components of the tensor of thermal stresses and :21

(14)

where

The maximum values of these components are achieved in the centre of the irradiated region (Figure 5) on the surface of the half-space, where the stationary field of thermoelastic stresses have the form (Figure 6) (Figure 7)

Figure 5 Distribution of the peripheral (

) and radial (

) tensor components on the z axis for different exposure times of laser irradiation.

Figure 6 Stress field

on the surface of the half-space.

Figure 7 Stress field

on the surface of the half-space.

(15)

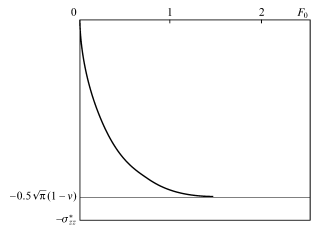

The main property in establishing a steady state for and are characterised by the dependence shown in Figure 8:

Figure 8 Establishment of a stationary strain state on the surface, in the centre of the irradiated region.

(16)

This expression completely describes the characteristics of the stressed state arising in a solid when its surface is irradiated by cw laser radiation.

Thermal deformation of the surface

The expression for the displacement of the reflective surface in the half-space model has the form:21

(17)

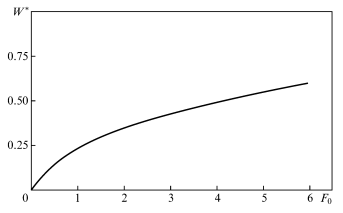

Deformation surface profiles for different exposure times are shown in Figure 9.

Figure 9 Establishment of a quasi-stationary deformation state on the surface, in the centre of the irradiated region.

Pulsed irradiation

Temperature field

In the case of short irradiation times, the depth of the temperature field penetration into the material is proportional to therefore, the radial heat spreading can be ignored, and the temperature distribution over the surface repeats the laser beam intensity distribution profile:26

(18)

where is the Heaviside function; and is the pulse duration.

Thermoelastic stresses

Thermoelastic stresses arising in a solid irradiated by laser light play an important role in the destruction of the optical surface of the POE. Under pulsed irradiation the expressions for the stress tensor components are given by (15), because in this case the propagation of heat in a solid is of quasi-one-dimensional character and the radial heat spreading can be neglected. The depth of penetration of thermal stresses in the material is which follows from the form of on the axis:

(19)

where

The maximum values of the components and are achieved on the surface,

(20)

i.e., the distribution of the components and on the surface repeat the laser beam intensity distribution. The components and on the surface are equal, and the expression for has the form:

(21)

In the case of small irradiation times

(22)

where is a transform variable. The difference in signs of the components means that in the case of thermal deformation of the sample by laser radiation, for tension of a material is realised, whereas for − compression. The maximum value of is achieved on the axis; in this case, i.e., and The component reaches its maximum value at point and

(23)

A distinctive feature of the behaviour of the component is that if the inequality is fulfilled, the position of its maximum on the axis is determined by the spatial characteristics of the laser beam rather than the irradiation time. The maximum of this component is achieved by the end of the laser pulse. This feature is explained by the fact that at the region of thermoelastic perturbations lies on the sample surface and localizes in the irradiation region, because heat due to heat conduction has no time to spread over the sample material. In the opposite case, i.e., at the point of this component maximum is determined from the condition

Thermal deformations

The expression for the thermal deformation of the reflecting surface irradiated by a rectangular laser pulse, whose duration satisfies the condition , has the form:21

(24)

The distribution of thermal deformations of the reflecting surface repeats the laser beam intensity distribution (Figure 10), which we used in our method of the dynamic control of the intensity distribution of laser radiation.27

Figure 10 Deformation surface profiles for different exposure times.

Repetitively pulsed irradiation

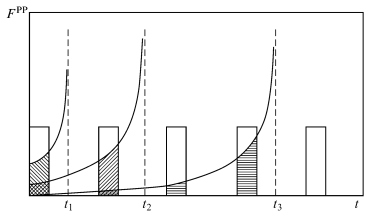

Thermal deformations of a solid body exposed to repetitively pulsed laser radiation were analysed by using the previously derived relations that are similar to Duhamel’s integral formulas. The energy flow was treated as a train of rectangular pulses having a duration period (repetition rate ) and off-duty ratio SQ It was assumed that . The thermal stresses and deformations of the temperature field are expressed in terms of the integrals (typical of the cw regime) that are similar to Duhamel’s integrals:28

(25)

At the initial instants of time, i.e., when repetitively pulsed irradiation is similar to pulsed irradiation. The geometric meaning of (25) is characterised by the area of the integrals in Figure 11. (For the temperature and the components and the value of tend to infinity as at and to zero at for deformation tends to const at and to zero at ) In the case of long irradiation times, i.e., when the temperature and thermal stresses reach their quasi-steady states, i.e., a constant component of these values becomes similar to that in the cw regime of energy input with a reduced intensity SQV. In this case, against the background of this component, along with changes in the laser beam intensity, there will be the characteristic peaks of temperature and stress, which are similar to peaks during pulsed irradiation. A separate ‘pulse’ of thermal deformations of the reflecting surface exists against the background of a ‘stationary component’ tending to infinity.

Figure 11 Geometrical interpretations of Duhamel’s integrals.

Temperature field

The expression for the temperature has the form21

(26)

since for a train of pulses

(27)

is the image of the Laplace transform of and is the number of propagated laser pulses.

In the centre of the irradiation region the temperature reaches a maximum value by the time the next pulse terminates

(28)

where SQV is the off-duty ration of the temporal structure of radiation.

Thermoelastic stresses

Maximum values of the radial and circumferential tangential stress are achieved in the centre of the irradiation region, where they are equal to each other:

(29)

[is determined from (16)]. The field distribution of stresses on the surface by the time when the next laser pulse terminates has the form:

(30)

where and are determined from (16), and − from (21). Because in the steady stress state and are identically zero, their values in the case of repetitively pulsed irradiation are the same as in the case of pulsed irradiation (accuracy ~SQV).

Deformation of the surface

The displacement of a solid-body surface exposed to repetitively pulsed radiation also has stationary and pulse components:21

When the quasi-stationary state is reached

(31)

Criteria for the optical surface stability

Expressions given for the characteristics of the thermal stress state of a solid whose surface is irradiated by high-power cw, pulsed and repetitively pulsed laser radiation allowed us to determine the limiting intensities corresponding to different stages of the optical damage of mirror surfaces.21,29 To this end, the parameters of the optical surface stability include not only the thermo physical and mechanical properties of the material but also the parameters of a Gaussian-like beam, namely the intensity in the centre of the irradiation region, the size of the irradiation region and the duration of a single pulse and, in the case of repetitively pulsed irradiation, − the pulse train off-duty ratio. The stability parameters of the reflector contain the ratio of a maximum value of the thermal stress state characteristic to its value at which the solid material experiences irreversible macroscopic changes – melting, plastic (brittle) or fatigue deformation or achievement of a critical value by the amplitude of thermal deformation of the optical surface, where is the wavelength of the laser used. The thus introduced stability parameters of mirrored POE surfaces made it possible not only to compare different pure metals and their alloys in terms of applicability in power optics but also to create specific types of combined POEs capable of withstanding high-power fluxes of cw, pulsed and repetitively pulsed laser radiation.

Continuous-wave regime

A solid body whose surface is exposed to cw laser radiation is destroyed when the temperature field in the centre of the irradiation region reaches the melting point of the material and the components of the stress field reach the yield point. The stability of the optical surface under cw irradiation is characterised by the parameters

(32)

If and the material will undergo no irreversible changes. The values of these parameters in the case of cw laser radiation at a power density kWcm−2 and >m−2 are shown in Table 1 for Cu, Al and Mo. The main reason for the damage of the optical surface can be determined from the relation

(33)

If the material will be destroyed when the component reaches the yield point, or when the melting point of the material, is reached.

For the materials in question (Table 1), the main reason for the deterioration of the optical surface at lower laser intensities is irreversible plastic deformations of the POE in the centre of the irradiation region. There is another important reason for the deterioration of the optical surface − excess of the critical value by the value of thermal deformation of the optical surface − which is implemented at long exposure times of high power laser radiation and in the range of the parameters corresponding to the elastic deformation of the material. In this case, phase and energy characteristics of the reflected laser beam are markedly impaired. The criterion for the optical surface stability to such changes in the optical characteristics of the reflector is given by parameter

(34)

The value can be reached if use is made of some types of reflector designs with efficient cooling.30

Pulsed regime

The parameters of the optical surface stability under pulsed irradiation by a Gaussian-like laser beam having a duration and intensity in the centre of the irradiation region, determined by the ability to reach critical values and by temperature thermoelastic stresses and thermal deformations have the form:27‒29

(35)

The values of these parameters, found for copper, aluminium and molybdenum at kWcm−2, m−2 and and the heat flow values at which are presented in Table 1. In the cw regime, the optical surface properties are mainly degraded due to irreversible plastic deformations in the centre of the irradiation region. Under pulsed irradiation the behaviour of the thermal stress state is more complicated than under cw irradiation. Thus, in contrast to the stationary thermal stress state, the nonstationary state in the material of a solid is characterised by the presence of the nonzero components and In this case, the highest value is reached by the component on the axis at a distance of from the optical surface. If at some level of these values the component is greater than the strength it is possible to implement the conditions of brittle fracture, at which the surface layer of the POE material will be detached. For this type of destruction the parameter of the optical surface stability has the form:

and the stability parameter defined with respect to plastic deformation, has the form:

(36)

The values of the parameters and their corresponding intensities for Al, Mo and Cu are listed in Table 1.

Parameter |

Material |

Cu |

Mo |

Al |

CW regime |

|

0.74 |

0.8 |

2.3 |

|

1.4 |

1.3 |

0.44 |

|

19.3 |

104 |

38.3 |

|

0.05 |

10-4 |

2.6x10-2 |

Pulsed regime |

|

2.0x10-3 |

1.45x10-3 |

5.4x10-3 |

|

500 |

700 |

190 |

|

0.16 |

55 |

0.28 |

|

6.3 |

1.8x10-2 |

3.6 |

|

0.013 |

4.6x10-3 |

2.6x10-2 |

|

80 |

230 |

39 |

|

2 |

1.6x10-2 |

7.4 |

|

0.5 |

6.3x10-4 |

0.14 |

|

1.8x10-4 |

0.04 |

2.7x10-4 |

|

5.5x103 |

25 |

3.7x103 |

> |

1.2x10-3 |

0.26 |

1.8x10-3 |

|

830 |

3.8 |

560 |

Table 1 Parameters of stability and threshold intensities for Al, Mo and Cu at kW cm−2, cm and

Repetitively pulsed regime

The state of a solid body, whose surface is irradiated by repetitively pulsed laser pulses, combines the characteristic features of thermal stress states implemented under pulsed and cw irradiation. In this case, for the temperature fields, the fields of the components and the stress tensor and the thermal deformation fields the realisable temperature and thermal stress states are a combination of stationary and nonstationary states. In this regard, the stability parameters of the reflecting surfaces, defined by the ability of the temperature to reach the melting point of the material, of the components and to reach the yield point and of thermal deformation to reach the threshold are as follows:21

(37)

Under repetitively pulsed irradiation, a nonstationary, cyclically repeated stress state arises on a solid surface in the material. As a result, the material of the solid body may experience irreversible fatigue damage. The conditions under which the POE surface undergoes macroscopic fatigue fracture can be assessed by Wöhler curves, determining the dependence of modulus of the amplitude of fatigue stresses on the number of cycles of the loading pulses 21‒31

Irreversible changes of the optical surface

Dynamics of the fatigue and brittle fracture is characterised by the emergence and extension of microcracks. Therefore, inadmissibility of destruction of the optical POE surface is dictated by the need to preserve the diffusely scattered component of laser radiation at negligible levels. Moreover, the origin and development of microcracks is accompanied by microstructural and phase transformations of the material, leading to a change in the structural and phase composition of the reflecting surface and, as a consequence-to an increase in its absorption coefficient whereas the adsorption of various substances on the resulting system of microcracks initiating an optical breakdown leads to a decrease in radiation resistance of the reflecting surface. Furthermore, the optical breakdown of air near the target can occur without the segregation of impurities directly in the vicinity of emergence of microcracks, because they become the nucleus of the electric fields, etc. We considered sequentially the basic mechanisms of microstructural and phase transformations preceding the stage of plastic, fatigue and brittle fracture or accompanying these stages, as well as analysed the possible reasons for the change in the optical surface quality. The expressions obtained are important not only for the problems of power optics. They are effectively used today for the analysis of the conditions of fracture of solids of different nature due to excess of limiting stresses for the various components of the stress tensor.