MOJ

eISSN: 2574-9935

Research Article Volume 6 Issue 1

1Centro Nacional de Electromagnetismo Aplicado, Universidad de Oriente, Cuba

2Centro Biofísica Médica, Universidad de Oriente, Cuba

Correspondence: Leonardo Mesa Torres, Centro Nacional de Electromagnetismo Aplicado, Universidad de Oriente, Sede Julio Antonio Mella Ave, de las Américas s/n CP 4078, Santiago de Cuba, Cuba

Received: February 22, 2023 | Published: March 7, 2023

Citation: Torres LM, Rodríguez JLG, Cayamo AAB, et al. Design and construction of a Halbach magnetizer for magnetic treatment of fluids. MOJ Sports Med. 2023;6(1):33-35. DOI: 10.15406/mojsm.2023.06.00136

At present, the application of magnetizers (magnetic conditioners) is increasingly booming, in the different branches of socioeconomic work such as Industry, Agriculture, and Medicine. In this work the calculation and design of a magnetizer is proposed; formed by equal permanent magnets type Halbach with rectangular shape, distributed and confined in a non-ferromagnetic structure, circular section in the form of a ring, consisting of an octagonal inner circle, with a magnetic field induction (25,7-42,8) mT and a homogeneity of magnetic field, in the volume of interest, of 1,5 x 10-2 ppm (in a sphere of radius of 0,025 m), in the center of the configuration lines are distributed transversally for different water flow capacities.

Keywords: magnetizer, magnetic field, permanent magnets

In recent years, the use of magnetizers in fluid treatment in various branches of the socio-economic sector has gained more popularity. In the scientific literature, there is a great variety of magnetic devices for fluid treatment. Patent CN202358950U describes a Halbach permanent-magnet array water treatment device. Consisting of an outer casing, a thin-walled, non-ferrous pipe with radial direction of flow.1 However, Chuchai Sronsri (2022) demonstrated the influence of the magnetic field, generated by a laboratory-scale double Halbach magnetizer, on the ultraviolet (UV) absorption of water flowing through three magnetic configurations where the field induction B = (380-580) mT varies.2 In agriculture, the action of magnetically treated water has been reported; to accelerate the growth, germination and nutrient absorption of plants, gaining more momentum, due to its positive action at an experimental and agro-industrial level.3–5 In the industrial branch, the use of magnetism has been reported in sugar mills, derivative plants (distilleries), artificial bagasse wood factories, wax factories, and others. In industry, mainly in the sugar industry, magnetism has been used in vacuum pumps, heaters, evaporators, boilers, tube cooling, mill cooling, inhibition water, and compressors; obtaining good results; due to the antifouling effects and on flocculation and sedimentation. Various types of magnetizing devices have been used in Cuba for the descaling and cleaning of evaporators, boilers, turbo cooling, mill cooling.6 In the oil industry, the use of a magnetic device for fuel oil treatment in a production boiler is described. of steam, decreasing to 60.7%, the emissions of polluting gases (CO)7 In these devices the induction of the magnetic field that is distributed, in the section of the pipe, of the equipment and industrial installations is not uniform, which limits Its use for the treatment of different types of fluids circulating in pipes (water, oil, derivatives) depending on the material of the same. The objective of this work is to calculate and design a magnetizer with Halbach-type permanent magnets, which are distributed and confined in a non-ferromagnetic structure with a circular section, made up of an octagonal inner circle, with an induction magnetic field (25.7-42.8) mT and a homogeneity of the magnetic field of (1.5 x 10-2) ppm in the volume of interest, (0.025) m, that allows the treatment magnetic field of different types of fluids.

The design of a magnetic system depends on the designed configuration, the dimensions and magnetic properties of the material, the fluid flow and the distance between the magnetic poles or gap. The calculation of the magnetic system was carried out according to the following expression.8–10

(1)

where is the magnetic field induction, Br remanent magnetic field flux density, K is constant, depending on the number of permanent magnets; and are the inner and outer radius of the magnetic system configuration, respectively. A computer program was used to calculate the induction and homogeneity of the magnetic field. It was proposed to use material N 42.11–13 The magnetic system is constituted by a ring of 8 Halbach rectangular magnets., confined and distributed, in a non-ferromagnetic structure, of radius R = 0.04 m and thickness 0.005 m; symmetric, with respect to the z = 0 plane, from the center of the configuration.13

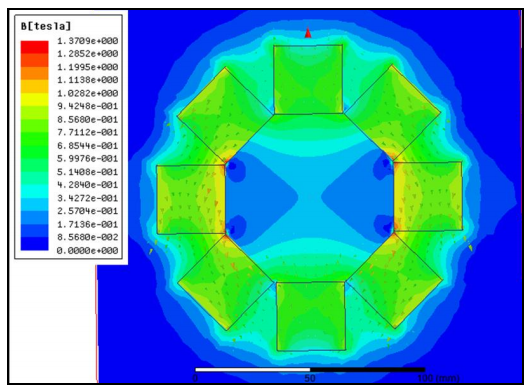

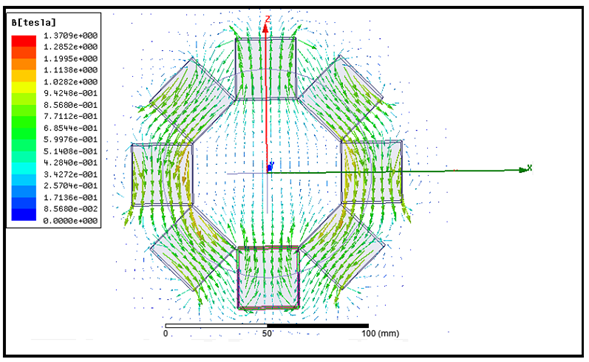

For the configuration design of the magnetizer magnetic system, with Halbach magnets, was made considering account the maps of magnetic induction and magnetic field homogeneity. In Figure 1 the magnetic induction map is shown (B), the (2) the magnetic field vector (B) and the (3) magnetic field magnitude (Mag_B).

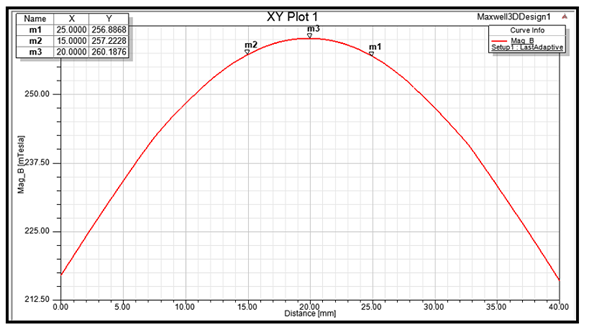

The dimensions of the permanent magnets were: thickness (0.03) m, length (0.05) m and width (0.01) m respectively, in a spherical volume of radius (r = 0.02) m, the center of the configuration. Figure 3 shows the magnetic field magnitude map (Mag_B), in the X, Y planes.

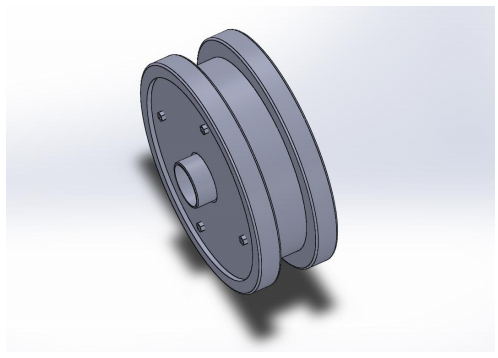

Figure 4 shows the magnetizer for the treatment of different fluids, made up of 8 rectangular Halbach permanent magnets distributed equidistantly and symmetrically with respect to the center of the configuration (sphere with a radius of 0.025) that can be used for pipes of different materials (ferromagnetic and non-ferromagnetic) and Diameters.

In Figure 1, it was observed that the induction of the magnetic field generated by this device in an interval

B = (25.7- 42.8) mT, is effective for the magnetic treatment of water in industrial facilities, for pipe diameter (25≤ d ≤ 50 ) mm, already reduces incrustations by more than 75% and therefore eliminates the use of chemical products in the cleaning and maintenance of this equipment;17 due to the magnetic field induction lines are distributed transversally (Figure 2), with respect to the section of the pipe, which allows for a same that allows In this way, it is possible to test different values of B for the same constructed cylinder and therefore it is applicable for the germination and growth of the plants; not so in the case of pipes with a larger diameter.18,19 It can also be used in the treatment of crude oil, since it reduces the percentage of water in crude oil by more than 52.8%.7,22 Figure 3 shows the magnetic field magnitude map (Mag_B) = (250- 260 ) mT, which favors the use of this technology regardless of the material of the pipe, of the industrial facilities.20,21

Figure 1 Magnetic induction map, B = (25.7- 42.8) mT.14

Figure 2 Magnetic field vector map, B = (34.2-85.6) mT.15

Figure 3 Magnetic field magnitude map (Mag_B) = (250-260) mT in the X Y plane; in a sphere of radius 0.02 m.14–17

Figure 4 Halbach permanent magnet magnetic conditioner.16

Calculations and simulations have shown that the Halbach permanent magnetizer is effective for the intended purposes; because the magnetic field induction is uniform at the center of the configuration, in the volume of interest, which allows to obtain an increase of the values of (B) in a range of B= (25.7- 42.8) mT for the same pipe diameter, which, eliminates and incrustations, the use of products chemical processes for maintenance processes and emissions of pollutant gases from equipment and installations industrials; regardless of the diameter, type of pipe material (ferromagnetic and not ferromagnetic) and flow velocity that positively impacts the environment.

The magnetic conditioner Halbach-type is feasible for the treatment of different types of fluids and various flow capacities; in various industrial and domestic installations; since simulations show that the values increase according to the diameter of the pipe, which makes the magnetic technology a simple, cost-effective and environmentally friendly treatment.

The authors would like to thank the technicians and other colleagues at the National Center for Applied Electromagnetic, the Center for Medical Biophysics and the School of Mechanical Engineering who made this work possible.

The authors declare that there are no conflicts of interest.

None.

©2023 Torres, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.