MOJ

eISSN: 2574-9773

Mini Review Volume 1 Issue 4

1Department of Physical Chemistry, University of P J Safarik in Kosice, Slovakia

2Department of Physical and Theoretical Chemistry, Komensky University Bratislava, Slovakia

Correspondence: Orinak A, University of P J Safarik in Kosice, Srobarova 2, Kosice, Slovakia, Tel 004210552342321

Received: April 17, 2017 | Published: August 28, 2017

Citation: Orinak A, Orinakova R, Macko J, et al. Functionality of nanopatterned polymer surfaces. MOJ Poly Sci. 2017;1(4):141-145. DOI: 10.15406/mojps.2017.01.00021

The different methods of the nanopatterning of polymer layers, UV laser ablation, plasma depositing technique, electrochemical deposition and soft lithography are discussed as methods of surface patterning. The different surface functionalities are described, especially the effects of increased surface hydrophobicity/superhydrophobicity created by coating substrates with low surface energy material coupled with controlling the polymer surface roughness at both micro- and nano-scale, with many of these hydrophobic layers representing bio-inspired surfaces. Cell adhesion onto nanopatterned polymer surfaces, bacteria and biomolecules immobilization, and cancer cell isolation are discussed as switchable functionalities. A new field is self-assembled monolayers formed from polymers, which can modulate a surface functionality from hydrophilicity to hydrophobicity, forming highly ordered molecular structures to bind different biomolecules and to create stimuli-responsive polymer systems. These polymers have the potential to tune surface wettability to a desired level with a controlled surface structure and smoothness. Examples are described of rotaxenes which are polymeric self-assembled monolayers which can form molecular devices/nanodevices.

Keywords: nanopatterning, polymer, surface, functionality

DBS, dodecylbenzene sulfonate; PDMS, polydimethylsiloxanes; PEG, polyethyleneglycol; PLA, polylactic acid; PLGA, poly (lactic-co-glycoid acid); PNIPAAm, poly (N-isopropy-lacrylamide); PPy, poly pyrrole; PS, poly styrene; PSS, polysodium styrene sulfonate; QAS, quaternary ammonium salt; SAM, self-assembled monolayers; PDMS, polydimethylsiloxane

The aim of this mini review was zoom in the perspective and feasible methods to produce nanopatterned polymers surfaces and to collect their some properties. This has opened new possibilities for making affordable polymer products with functional nanopatterned surfaces.

While a variety of approaches to create hydrophobic/superhydrophobic surfaces have been developed,1–5 there are still restrictions on their widespread use due to the cost, number of processing steps, limits on the manufacturable area, durability, instrumentation required, etc. This has led to the development of inexpensive and reliable techniques for the commercial production of hydrophobic layers. Electrochemical methods have been used to prepare a Ni based nanostructured surface coupled with a polydimethylsiloxane (PDMS) monolayer using spin – coating.6 The surface hydrophobicity increased by about 30% in comparison to the Ni surface only and could be modified to enhance the adhesion of ordered biomolecules or the self-assembly of monolayers. Alternative simple methods included the fabrication of a shark-skin-like patterned PDMS modified with carbon nanotubes to form a polymeric superhydrophobic film.7 A high viscosity paste (comprised of 10 wt % multi walled carbon nanotubes dispersed into PDMS) was placed between two rollers, and the paste was transferred as a smooth film (with less than 300nm roughness) onto the roll with the high rotational speed.7 A spin-coating method has been used to form a biomimetic interface from melanin whose electric signal transduction can be modified.8 High density plasma processing was employed to create a nanotextured superhydrophobic transparent poly (methyl methacrylate) surface.9 By appropriate tuning of the plasma conditions, either random or ordered hierarchical structures of high aspect ratio and surface area could be reproducibly created. Such plasma treated polymeric surfaces have been evaluated as substrates for efficiently controlling the wettability, biomolecules immobilization, and cell adhesion of the surface, paving the way to a wide spectrum of applications. A three-dimensional plasma micro-nanotextured cyclo-olefin-polymer surfaces has been used for biomolecules immobilization because of its environmentally stable superhydrophobic and superoleophobic properties.10 Plasmas could also be used to deposit fluorocarbons on a cyclo-olefin polymer to enhance hydrophobicity11 with good adhesion and effective surface protection reducing plastic deformation. A micro reactive ion-etching method has been used to prepare nanotextured films from PDMS for enhanced cancer cell isolation.12

Slippery liquid-infused porous surfaces show great promise for preventing biofilm formation owing to their low surface energy in combination with their self-cleaning properties.13 Li and co-workers demonstrated a novel hydrophobic liquid-infused porous poly (butyl methacrylate-co-ethylene dimethacrylate) surface with bacteria-resistance in BM2 mineral, which had medium and long-term stability in aqueous environments with Pseudomonas aeruginosa.13

Highly enhanced solid-state thermochromism was observed in regio-regular poly (3-hexylthiophene) when deposited on a superhydrophobic polymer-SiO2 nanocomposite coating without reducing the superhydrophobicity.14 Peng et al.15 have quantified the volume and surface hydrophilicity of a range of water-swollen dense polymer brushes as a function of temperature. They used thermo responsive poly (N-isopropylacrylamide) and poly (di(methoxyethoxy) ethyl methacrylate), strongly hydrophilic poly (N, N-dimethylacrylamide) and poly (oligo (ethylene glycol) methacrylate), and weakly hydrophilic poly (2-hydroxyethyl methacrylate) brushes synthesized by surface-initiated atom-transfer radical polymerization. There were two types of behavior: strongly swollen brushes exhibited a progressive decrease in volume hydrophilicity with temperature, while surface hydrophilicity changed moderately; weakly swollen brushes had a close-to-constant volume hydrophilicity, while surface hydrophilicity decreased with temperature.16 Altering the surface wettability by external stimulation has received great attention recently. Wagner et al.17 have summarized many recent achievements in the field of reversibly switchable polymer films with a focus on changes in wettability. Particularly interesting were light/photo-responsive polymer coatings, which could be used for versatile applications, such as in the biomedical industry or in light emitting diodes, etc. The hydrophilicity of Polylactic acid (PLA) electrospun fibers were modified through the incorporation of polyethylene glycol (PEG) homopolymer and PLA-b-PEG co-polymers of different block lengths by Hendrick.18 The lengths of the blocks were found to influence the maximum amount of PEG that could be incorporated, as well as spin-ability and morphology. Water wettability improved significantly with the addition of PEG to the electrospinning dopes, with PLA-b-PEG co-polymers providing a greater increase than the PEG homopolymer. PDMS films with 2D periodic inverted moth-eye nanopatterns on upper surface were implemented as antireflection layers on a glass substrate for efficient light capture in encapsulated organic solar cells. Inverted moth-eye PDMS films laminated on glass substrates exhibit a hydrophobic surface with a water contact angle of ≈120°C and solar weighted transmittance of ≈ 94.2%.19 Very similar antireflective hydrophobic polystyrene surfaces have been prepared by Kuo et al.20 using the methods of Langmuir-Blodgett deposition and nanoimprint lithography. Ito et al.21 described the superhydrophobicity of the transparent typical polymers, such as polycarbonate and polystyrene patterned with nanorod and hierarchical structure, which combined nanorods with micro convex structures.

Chu et al.22 examined systematic patterned hierarchical structures with dual scale roughness that has been formed using simple and large-scale micro-manufacturing methods. The authors evaluated the apparent contact angles to determine the effect of geometric surface parameters on the hydrophobic properties and found that contact angles of more than 130°C could be obtained without additional coatings. Yu et al.23 prepared surfaces with switchable functionality based on nanopatterned, thermo responsive poly (N-isopropylacrylamide) (PNIPAAm) brushes. They were fabricated using interferometric lithography combined with surface-initiated polymerization. The temperature-triggered conformation changes reversibly modulated the spatial orientation of the polymer chains which leads to the hiding or exposure of molecules that were immobilized in the intervals between the nanopatterned brushes. A biocidal quaternary ammonium salt (QAS) was used to demonstrate the utility of the nanopatterned PNIPAAm brushes to control biointerfacial interactions with bacteria. QAS was integrated into polymer-free regions of the substrate. Above the lower critical solution temperature of PNIPAAm, the polymer chains exposure quarternary ammonium salts that killed attached bacteria. Below the critical temperature, the PNIPAAm chains promoted the release of dead bacteria. Golabi et al.24 studied the physical-chemical properties of polypyrrole (PPy) electrochemically prepared with different dopants (Cl, ClO4, p-toluene-sulfonate (ToS), dodecylbenzene sulfonate (DBS), and poly sodium styrene sulfonate (PSS)) under two applied potentials. E. coli showed greater adhesion tendency to the hydrophobic, rough surface of PPy-DBS, and less adhesion to the smooth and hydrophilic surface of PPy-PSS. Blends of hydrophobic polystyrene (PS) and hydrophilic acrylonitrile butadiene styrene polymers with different weight ratios, modified by avidin, to modify their surface chemistry and topography were prepared by Juvonen and co-workers25 to study the adhesion of Staphylococcus aureus. When the surface coverage of PS component was ~85% the bacterial adhesion was increased and was suitable for using in sensing applications. However, when the surface coverage of PS component was ~55% the adhesion of bacteria was inhibited. This result may open a new way for the development of surfaces with potential anti-microbial properties.

Treatment of polymer surface can be a simple and quick method to produce nanostructured polymer surfaces with anti-bacterial properties. Karahaliloglu et al.26 used alkaline surface treatment to create random nano objects on poly (lactic-co-glycoid acid) (PLGA) membranes, where the nanomorphology of PLGA was affected by the NaOH concentration and exposure time. The most significant results showed a decrease in S. aureus growth, without antibiotics, of up to ~40% after 2 days, following alkaline treatment PLGS (0.5 M NaOH; 10 min) compared to untreated controls. The nanostructured PLGA membranes have a much higher wettability with altered surface functional groups. The newly formed membranes promoted keratinocyte adhesion and proliferation, while limiting fibroblast functions and bacterial growth. Another group27 published bacterial studies showed that nano-PDMS significantly inhibited the growth of S. aureus and E. coli after 48h without using antibiotics, while remaining non-toxic to fibroblasts and endothelial cells.

The combination of colloidal lithography with reactive ion etching enabled Liu et al.28 to prepare PET nanocone arrays with underwater superoleophobicity and anti-bioadhesion properties. The nanocone array with aspect ratio value of 6 had superoleophobicity with oil contact angle of 171.8 °C and had anti-adhesion behavior, when it was used for cell culture cultivation. Sánchez-Salcedo et al.29 tested zwiterionic polymers on ceramic powder and metallic powders for application in bone tissue engineering. The polymers on metal nanostructured surfaces showed excellent inhibition (99%) of the adhesion of E. coli compared to unmodified substrates.

Improving the biocompatibility of biomaterial surfaces by grafting on polymers brings promising effects. Graft polymerization does produce sufficiently grafted polymers, hence leads to nonspecific protein adsorption.30,31 Covalent coupling produced a stable attachment of polymers for long term applications but can be circumvented by modifying surfaces with self-assembled monolayers (SAM) of organic molecules, such as thiols or silanes, which provided covalent interfaces between substrate and polymer(s). This method offered a molecular-level control of material structure, composition, morphology and dimensions, thus enabling the construction of an extensive variety of 1-, 2- and 3D nanostructures.32–35 Efforts have been carried out to elaborate processes able to fabricate organized materials with nanometer resolution, and these have found application in protective coatings,36 molecular electronic devices,37,38 sensors,39,40 robust textiles,41 and biofunctional materials.42 One example is the rotaxanes, containing a pyridine function in the macrocyclic component, which can be grafted onto carboxylic acid-terminated SAMs, giving rise to monolayers or sub-monolayers of rotaxanes. They are attached to the carboxylic acid-terminated surface by hydrogen-bonding between the pyridine group of the macrocycle and the carboxylic acid group of the SAM.43 Several stimuli, such as pH, temperature and even light, can be used to initiate a structural reconfiguration driven by weak hydrogen-bonds.44

The nanopatterning of polymeric surfaces has been shown to be a method for the fabrication of highly or randomly ordered structures at the nano level that have shown good functionality in many fields of science. Methods for the cheaper preparation of such functionalized layers for wide range of purposes are still being developed, including surface hydrophobicity modulation for anti-fouling and cell adhesion, as well coatings with bio-mimetic properties. Despite recent progress it is important to improve the surface ant adhesion properties of medical devices to prevent bacterial colonization.

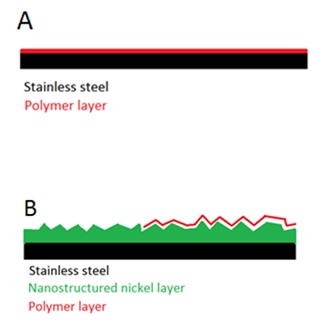

A unique nanohybrid surface with a marked increase in surface hydrophobicity has been observed on the differently polar polymer layers, which have been spin-coated directly on a previously prepared nanostructured nickel surface to form nanohybrids. Nanostructured nickel layers have also been prepared by electrochemical deposition to form a random polyhedral crystalline nanostructure (Figure 1). The hydrophobicity of the surface can be modulated with the roughness of the surface and the polarity of the covering polymer surface. The method is very economical and does not require expensive equipment.6 If PDMS was used as the coating, the nanohybrid surface blocked the adhesion and proliferation of living cells. Similar smart polymer surfaces were also prepared by more expensive methods using laser electron beam lithography.45 However, the mechanical stability of surfaces with PDMS is still problematic. Unpublished results with polyethylene monolayer showed better resistance to abrasion. Such modified surface resulted in a self-cleaning property.

The direct patterning of polymer surface with highly ordered and oriented nanoparticles (nanorods, nano pillars and others) appears to be not commercially viable. Mentioned are also studies that have been carried out to produce artificial biomimetic roughness-induced hydrophobic surfaces.46 To explain effect of nano- or micro- patterning or both on surface47,48 hydrophobicity is also often examined. Self-assembly of random copolymers has recently attracted considerable attention, to prepare nanostructures with different morphologies and nanomaterials that are responsive to single or multiple stimuli. Era of SAM brings exploitation of the molecular devices and nanodevices49 shown in Figure 2.

The ability to pattern functional polymers at different lengths is important in many research fields, including cell biology, tissue engineering and medicinal science and the development of optics and electronics. The interest and capabilities of polymer patterning have originated from the abundance of functionalities of polymers and a wide range of applications of the patterns. This review considers recent advances in the functionality of the patterning of polymers using different methods and self-assembly of block copolymers. The main functions of such prepared surfaces included surface hydrophobicity, adhesion strength and SAM application leading to molecular devices with specific functions. Finally, challenges and future directions are discussed from the point of view of both applicability and strategies for the surface patterning of polymers.

The authors are grateful for the financial support from MS SR VEGA and 1/0074/17 and APVV-16-0029. Authors wish to thank Roger M. Smith for manuscript editing.

The author declares no conflict of the conflicts.

©2017 Orinak, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.