MOJ

eISSN: 2574-9773

Natural rubber (NR) from Hevea brasiliensisis is an important industrial raw material. NR possesses excellent mechanical properties, such as high tensile and tear strength, high crack growth resistance, good elasticity, and minimal heat buildup, due to its unique hierarchical structures. This mini-review encompasses the most recent developments in the field of characterization of molecular structure of NR.

Keywords: natural rubber, surface structure, molecular chain structure, terminal groups, abnormal groups

NR, natural rubber; LRP, large rubber particles; SRP, small rubber particles; STORM, stochastic optical reconstruction microscopy; DPNR, deproteinized NR

Natural rubber (NR) obtained from Hevea brasiliensisis is the main commercial feedstock for rubber materials, used in the tire industry and the hygienic and medical sectors.1,2 Fresh NR latex comprises approximately 94% rubber hydrocarbon and 6% non-rubber components.3 The rubber hydrocarbon inside rubber particle is consisting of the initiating group (referred to as ω), 0-3 trans-1, 4 isoprene units, a long sequence of cis-isoprene units and terminal group (referred to as α). The non-rubber components comprise proteins, phospholipids, glycolipids, fatty acids, and so on, which exist in serum and the surface of NR particle.4-6 This unique hierarchical structure is believed to be the origin of outstanding properties of NR. It is noteworthy that progress of structural characterization could provide a theoretical basis for the research on the biosynthesis mechanism and improvement of NR processing technique. In this review, an account of the prospective studies based on characterization of molecular structure of NR will be described.

Structural Characteristics of NR latex particles

The morphology of mature NR latex particles is spherical or pear-shaped. NR latex particles have bimodal size distribution and can be classified into the large rubber particles (LRP) and the small rubber particles (SRP). The mean diameter of LRP and SRP is 0.4-0.75 μm and 0.08-0.2 μm, respectively.7,8 It is widely believed that the NR latex particle is essentially core-shell in structure with the polyisoprene as the hydrophobic core surrounded by a hydrophilic shell of nonrubber components (e.g., proteins and lipids). The proteins and phospholipids surrounding rubber particle surface play an important role in stabilizing the latex particles and in contributing to the outstanding properties of NR.9,10 However, the detailed structure of NR latex particles surface has yet to be elucidated in terms of the spatial arrangement of the proteins and phospholipids. There are two supposed models of NR latex particles surface as illustrated in Figure 1. One is that the NR latex particle consists of a lipid monolayer surrounding the polyisoprene core and protein monolayer facing the outer aqueous medium.11,12 The other is that the NR latex particle membrane is a mixed layer of proteins and lipids without any spatial separation.13,14 Nawamawat et al.15 argue that the mixed layer is composed of 84% proteins and 16% lipids by using phase contrast images of AFM and confocal fluorescence microscopy. Furthermore, they have proved that the thickness of the mixed layer is approximately 20 nm by indentation curve of AFM.15 Recently the spatial organization of proteins and lipids in NR can be directly visualized by two-color stochastic optical reconstruction microscopy (STORM), which providing an advanced analysis method to study structure of NR latex particles.16 However, these approaches are demanding, require chemical fixation and air-drying, and do not provide original morphology of NR latex particles.

Structural Characteristics of NR molecular chain

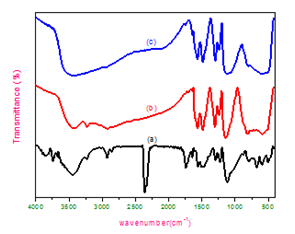

In the previous study, per NR molecular chain has been found to comprise the ω-terminal, 0-3 trans-1,4 isoprene units, 1000-3000 cis-isoprene units and α-terminal by using chemical and biochemical methods, NMR and FTIR. Dimethylallyl is expected to be at the ω-terminal connected to trans-1, 4 isoprene units derived from the initiating groups of biosynthesis.6,17,18 However, no dimethylallyl groups have been detected in NR at the ω-terminal in NMR.19 Meanwhile, the ω-terminal was postulated to be associated with proteins according to the finding that deproteinized NR (DPNR) showed markedly shift of a FTIR band characteristic of peptide at 3280 cm-1 to oligopeptide at 3316 cm-1.20-22 At present, however, there is no direct evidence to confirm the detailed structural characteristics of ω-Terminal. By analyzing the structural change of a rubber chain after treatment with lipase, phosphatase, and phospholipases A2, B,C and D the α-terminal group was postulated to consist of two kinds of functional groups, monophosphate and diphosphate, which are linked with phospholipids via hydrogen bonding some or ionic bonding.23-25 And The molecular weight, gel content and Huggins k′ constant decrease after purifying NR with proteolytic enzyme and transesterification. It demonstrated that branch-points of NR molecular chain have been decomposed after purifying. According to the states above, it is remarkable that the ω-terminal associated with protein and α-terminal associated with phospholipids form network in NR by hydrogen bonding or some metal ions.16,26-28 as showed in Figure 2 In addition to, there are abnormal groups including epoxide group, hydroxyl, aldehyde groups, carboxyl groups and 3, 4- isoprene on NR molecular chain. Recently we have studied contents of those abnormal groups by FTIR and NMR. The results show that the contents of epoxide, hydroxyl and 3, 4-isoprene is 0.14%, 0.07% and 0.36% respectively by the peak area ratio of those groups and 1, 4-isoprene units in NMR spectrogram. And the contents of aldehyde groups and carboxyl groups are 0.11% and 0.01% respectively by the nitrogen atom labeling method and FTIR spectrum. According to the states above, a molecular chain model is established as illustrated in Figure 3.

The present study evidences that NR latex particle is a core-shell structure made up of a hydrophobic core of polyisoprene surrounded either a mixed proteins-phospholipids layer or a lipid monolayer beneath protein monolayer. And the thickness of layer is approximately 10-20 nm. The molecular structure of NR has been found to comprise ω-Terminal, 0-3 trans-1,4 isoprene units connected to long-chain cis-isoprene including some abnormal groups (epoxide group, hydroxyl, aldehyde groups, carboxyl groups and 3, 4- isoprene), α-terminal. The ω-Terminal has been postulated to link a structure similar to dimethylallyl group or protein, and the α-terminal is mono- or di-phosphate groups associated with phospholipids. However, the complete accurate structure of NR hitherto has not been unraveled until the advent of new instrumentations and analytical techniques.

This work was financially supported by the National Natural Science Foundation of China (No. 51363006), Special Fund for Agro-scientific Research in the Public Interest (No.201403066) and Major Science and Technology Plan Projects of Hainan Province (ZDKJ2016020-02).

The author declares no conflict of interest.

© . This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.