MOJ

eISSN: 2641-9297

Research Article Volume 3 Issue 1

Universidad Agraria de La Habana (UNAH), Cuba

Correspondence: Luis Orlando Marin, Universidad Agraria de, La Habana (UNAH), Faculty of Technical Sciences, Agricultural, Mechanization Center (CEMA), San José de las Lajas, Mayabeque, Cuba

Received: February 25, 2020 | Published: March 13, 2020

Citation: Marin LO. Dynamic three-dimensional simulation model of soil interaction estrecha narrow tillage tool using the finite element method. MOJ Research Review. 2020;3(1):1-5. DOI: 10.15406/mojcrr.2020.03.00060

The most of the soil tillage tool interaction studies realized, both experimental and numeric, has shown the influence of the soil conditions (physical, mechanical and dynamics properties, type of soil), operation's parameters of the tool (cutting deep, cutting speed, acceleration) and geometry in the amount of cutting forces. This studies were carried out with and small tool sliding to avoid the distortion, which can to cause convergence problems during the simulation. In this study, a three-dynamic (3D) lineal simulation model of soil˗ narrow tool interaction has been developed by the finite element method (FEM) to analyze the tillage tool movement across of a silt clay soil block (ferralitic). The extended Drucker˗Prager elastoplastic constitutive relation model was used to modeling, which was realized using the Solid Works design software, 2014 version and its complement Simulation. For the better connection between surfaces, both soil and tillage tool were used contact elements and Coulomb's theorem to achieve good soil elements movement on the tool surface. The model predicted the soil movement, soil failures surfaces, stresses' distribution both soil and tillage tool, as well as the draft forces. The results of the simulation model were compared with models and experimental data of the other authors, and good agreement and trends were obtained.

Keywords: 3D dynamic simulation model, soil˗tool interaction, finite elements

The tillage tool-soil is characterized by two phenomena: forces arisen in the soil-tool interfase (draught, lateral and vertical forces) and particles of soil displacement.1 An important part of the researches related with tillage tool-soil interaction has been focused to develop simulation models to predict the cutting forces under different soil conditions, tool geometry and operation parameters.2 Significant effects of these parameters and conditions in draft forces have been experimentally demonstrated in several researches works. Nonetheless, the experimental studies are expensive and its results depend of the precision of measurement instruments. The Finite Element Method (FEM) has been utilized to a great extent at international lever in the soil-tillage tool interaction, because of your potential to describe it in three dimensions process.3,2,4 Many investigations of soil-tillage tool interaction by the finite element method has been realized at international lever, Swick & Perumpral,5 Mouazen & Neményi,6 Abo et al.,7 Brown,8 Bentaher et al.,9 Armin et al.,2,10,11 Elbashir et al.,12 Neisy,13 He et al.14 focused to develop models, in two or three dimensions, both linear and non-linear models; elastic, plastic and elastoplastic models to predict the soil efforts on farming tool, the geometry' influence in cutting forces as well as the energy consumption. The most of these researching was realized at small tool' displacements and lower cutting velocities.

Dynamic simulation models of soil-tillage tool interaction by the finite element method have been developed by5,15,16 keeping into account the cutting velocity, stresses' lever and acceleration. When the soil-tillage tool interaction is analyzed as a dynamical process, is taking into consideration the possible inertia' effects regarding to the influence of soil' mass and deformation grade. In such cases, the time is inside of the constitutive model17 The goal of this study is to develop of the simulation dynamic model 3D of the soil-tool farming interaction process, the tool' moving analysis across the soil, distribution and magnitude of stresses and strain as well as cutting forces.

Soil's model

In this study the soil-tool interaction is modeled by the yield Drucker-Prager linear function, which may be expressed as:

(1)

Where:

are the principal efforts

t: is the deviatory effort and can be calculated by:

(2)

K: is the ratio of the yield stress to the compression yield stress in triaxial test

(3)

Where:

is the internal friction angle of soil

p is the normal effort actuating on the soil, defined as:

(4)

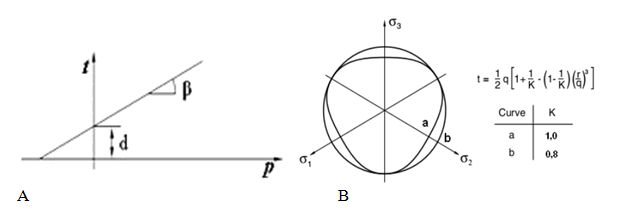

lifting angle referred commonly to material' internal friction angle in the Drucker˗Prager model Figure 1 and may be calculated as:

(5)

Figure 1 Yield criterion of the extended Drucker-Prager model. (A) Southern plane. (B) Principal stresses plane.

Q is the Von Misses equivalent stresses, calculated by:

(6)

is the third invariant of deviatory efforts

(7)

The cohesion d, when the hardening is defined by the same, is calculated as:

(8)

Soil's properties

The soil was classified as red ferralitic according to Second Genetic Classification of Soils in Cuba,18 as Oxisol,19 as Rhodic Ferralsol,3 density 1200kg.m-3, plasticity ratio 36.2% and organic matter content 2.7%. The modulus of elasticity was determined by the slope of a tangential line of a stress-strain curve in straight section. The Poisson rate was determined by:

(9)

The cohesion and internal friction angle were determined by the Mohr graphical solution. According to texture soil triangle20, the soil in study is classified as no much dense. The Table 1 show the properties and parameters of soil required for the FEM model.

|

Property or parameter |

Symbol |

Dimension |

|

Friction internal angle |

φ |

33º |

|

Modulus of elasticity |

E |

5 000 000 Pa |

|

Poisson's ratio |

υ |

0,394 |

|

Flexion stress |

σf |

130 000 Pa |

|

Dilatancy angle |

ψ |

0º |

|

Cohesion |

D |

15 000 Pa |

|

Shear resistance |

τ |

200 000 Pa |

|

Shear modulus |

G |

1 793 400 Pa |

|

Type of soil |

Lineal elastic |

|

|

Traction limit of soil |

σt |

30 000 Pa |

|

Compression limit of soil |

σc |

500 000 Pa |

|

Elastic limit of soil |

σe |

42 000 Pa |

|

Soil humidity |

H |

27% |

Table 1 Properties and parameters required for the FEM model

Finite element model

A 3D dynamic Simulation model in finite elements of the soil-tillage tool interaction has been developed using the Solid Works software design. Is formed by the tillage tool (vibratory curved bent leg) as logarithmic shape, who the vibratory mechanism with swimming masses is added and it’s considered as discreet rigid body .The soil block is deformable in the bent leg interaction, has a length (L) 2m, width (B) 1m, height (H) 1m. The width of the chapped prism by the tool to coincide with the chisel width (b=0,041 m). The working deep of the bent leg (D) is 0, 40 m and the cutting angle is 25 grades (Figures 2&3). The growing of the chapped soil prism dimensions beyond the assigned non affect the cutting forces.22 The soil tool interaction was modeled tangential to the attack surface with contact model surface to surface.

Contact modeling

In the block soil cutting process, the contact modeling is complicated because of any surface (soil prism surface) non exist initially in the model, the same is formed as the process goes by Figure 4. The part of block soil converted in prism is sliding over the tool attack surface, which cause a contact zone with high friction between both surfaces and high stresses. The contact problems are modeled by finite elements using basic contact surfaces.22 With the tool displacement towards block soil, occurs gradually the prism formation, the surface 1 becomes the tilled surface and the surface 2 contact with the surface 3 (tillage tool attack surface). As the surface 3 is formed, the contact element of this surface are activates as a contact surface, which it will displace over the sliding line defined by them, they build up a contact surface between two deformable bodies (Figure 5).

Loads and boundary conditions

The model boundary conditions were established in function of performing loads. On the block soil act the gravidity acceleration (9, 81 m.s-2), the atmospheric pressure (101325 Pa) and has a restricted lateral movement (axis Z) and below part (axis Y). The tillage tool is moving at constant velocity (1, 2 m.s-1) in the positive direction of axis X (Figure 6) and frequency of the vibratory mechanism of 14 Hz. The draft force applied was 15 000 N. The chapped prism is moving over the chisel attack surface.

Mesh of model

The general model mesh was realized with maximum element size (e) of 0.03 m, minimum size of 0.006m and Newton Raphson iterative method was utilized. The surfaces in contact, both tool and chapped soil prism was meshed applying control mesh, with element size of 0,004 m (Figure 7).

The results of the tridimensional simulation model presented provided information regarding cutting forces, stresses, distortions and displacements, both soil and tool. The model was able to simulate the vibratory bent leg's displacement and vibrations with selected frequency and amplitude, as well as the capped soil prism advance on the chisel surface.

Forces in tillage tool

The Figure 8 shows the direction and magnitude of the resulting forces obtained as result the tillage tool- soil block's interaction and the advance of tillage tool across the soil. As can be observed, the bigger values of draft force are on a tip (Fx=-1350 N) and attack surface of tillage tool (Fx=-3890 N), in the direction of tool movement and have a minus sign. This values are similar to obtained by others authors in previous researches.23 The magnitude of resulting forces is determined by the type of soil utilized in simulation.24 The maximum draft force (Fx) is considered as the necessary force to the fault of soil block in front of tool and as the soil resistance when it is chapped.12

Stresses in tillage tool

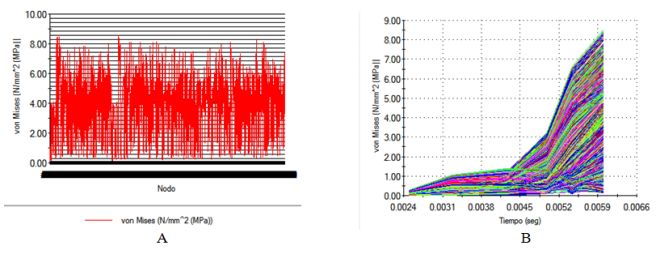

The Figure 9 shows the progress of von Misses stresses when the scarifier bent is tilling the soil. The model is able to simulate the soil-tool interaction process in adequate form. The stresses growing during the contact initial phase between tool and soil and subsequently stabilized, which are in agree with realized studies and experimental data published by other researchers Mouazen et al.,6 Abo et al.,7 Bentaher et al.,9 Chen et al.25,21 These results show the validity of the implemented model.0.12seg, 0.45seg.

Normal stresses in X direction at the tool tip

When the contact with soil start, the normal stresses in X direction at the tool tip Figure 10 have a minimum value of 0.035 MPa, growing an asymptotic mode.6 As the bent move towards the soil block, the stresses reach a maximum value (0.28 MPa), decreasing again until to be stabilized in an average value approximately 0.15 MPa. It is because of, mainly, to oscillating movement of bent and soil resistance.

Normal stresses in attack surface

The normal stresses in attack surface (Figure 11) growing to a minimum value of 0.14 MPa until reach a maximum value of 8.55 MPa, after are stabilized approximately in 3.92 MPa. This stresses average values are bigger than the tool tip because of the great contact area existing between this surface and block soil.

Figure 11 Normal stresses in the X direction in the attack surface of the tool. (A) Statics in nodes. (B) Dynamics.

Model validation

To validate the implemented simulation model was examined the validity of predefined failure surfaces by Abo26 in vertical plane (XY plane) analyzing the strain stresses distribution at zero displacement of the tillage tool Figure 12A and tillage tool displacement of 300 mm Figure 12B. The continuous outline of the strain stresses distribution along the predefined failure surfaces Figure 12B reveal the validity of the same when the gravidity force is applied on the model.

None.

None.

None.

©2020 Marin. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.