MOJ

eISSN: 2572-8520

Research Article Volume 4 Issue 3

1Sindh Building Control Authority, Government of Sindh, Pakistan

2Civil Engineering Department, Quaid?e?Awam University of Engineering, Science & Technology, Pakistan

3Chairman Civil Engineering Department, Quaid?e?Awam University of Engineering, Science & Technology, Pakistan

4Head of Civil Engineering Department, Swedish College of Engineering and Technology, Pakistan

Correspondence: Farhan Hussain Wagan, Civil Engineering Department, Quaid?e?Awam University of Engineering, Science & Technology, Nawabshah, Sindh, Pakistan

Received: February 21, 2018 | Published: May 21, 2018

Citation: Rabnawaz juj, Wagan FH, Sand A, et al. Reuse of glass in concrete analysis with minimizing impact of solid waste on environment. MOJ Civil Eng. 2018;4(3):131-134. DOI: 10.15406/mojce.2018.04.00109

This research was conducted to utilize waste glass as a fine aggregate at par ASTM standard for fine aggregates. Waste glass fine aggregates of different sizes rang (1.71 to 1.19mm) were used to partially replace hill sand (fine aggregates). Hill sand was partially replaced with waste glass fine aggregate as 4%, 8%, 12%, 16%, 20%, 24%, 28%, 32%, 36% and 40% by weight in concrete mix with ratio of 1:1.5:3. The concrete cubes were cast and tested for compressive strength, density and water absorption at twenty–eight (standard) days age and these results were compared with same parameters of virgin 1:1.5:3 concrete. It was observed that replacement of fine aggregates at 12% with waste glass achieved strength about 46.162N/mm2 which is better result by using waste glass aggregates. The density of glass concrete also increased about 3.67% at 12% replacement of hill sand as compared to virgin concrete. The water absorption of glass concrete decreased about 1.05 % at 40% replacement of hill sand. The test results show that it is possible to use waste glass as a fine aggregate with same characteristics to those of natural sand aggregate concrete provided.

Keywords: waste glass, fine aggregates, ASTM standard, concrete, compressive strength, density and water absorption.

The Concrete is a mixture of cement, sand, coarse aggregate and water. It is a main building construction material which is the world’s most devouring man– made material.

Glass

It is a hard and fragile material prepares d by melting sand with soda (sodium carbonate) and lime (Ca Co3) and cooling rapidly. Glass was 1st prepared in 3500 BC in Mesopotamia presently Iraq. Glass is broadly used in our daily life in the shape of bottle, utensils, glass sheets, etc.

Waste glass

Like other countries in Pakistan, the main element of solid waste is waste glass. It can be found in many forms including, bulb glass, sheet glass, glass bottles, windows glass and glass containers. It is 100% recyclable material with high performance, and unique aesthetic properties, which makes it suitable for wide appeared uses. The huge volume of yearly disposed waste glass is available in the country.1 The landfill of waste glass is undesirable because it is not biodegradable and not friendly to the environment. The use of waste glass was first reported 50 years ago and with the passage of time research is being carried out to investigate its properties when used for replacement of cement, fine aggregate and coarse aggregate in the concrete mix.

Glass concrete (Glasscrete)

It is a type of concrete which is prepared by addition of waste glass as partial or complete replacement of cement or fine aggregate or coarse aggregate. The use of glass as aggregates in cement has great potential for future high –quality concrete development. When waste glasses are reused in making concrete products, the production cost of concrete will go down, crushed glass if properly sized and processed it can exhibit characteristic applications to that of gravel and sand (Figure 1-4).

Waste material fly ash has been used with glass aggregate to enhance the green environment and durability of concrete and that can be utilized for different transportation function.

From laboratory tests, it can be concluded that the fly ash is helpful against ASR by

By the addition of fly ash, it also decreases the ASR. The Glasscrete has been good for workability, reducing the coefficient of thermal expansion, reducing chloride permeability and absorption of water.2 The hollow blocks which are prepared from clear flat window glass for non–load bearing walls which reduce the water–cement ratio, which depending on the quantity of flat glass present in the mixture. By using flat glass the value of modulus of elasticity decreases, as the unit weight of concrete reduces. The flat window glass has a quality in producing pozzolanic property and its small moisture content property so by this advantage it can used with the ratio of 1:2:4 for load bearing blocks.3 The utilization of fiberglass, this waste achieved from industries and fulfills the requirement fine aggregate as an alternative material. It can be determined that it not only enhances the quality of concrete but also easy and effective disposal of this waste, also decreases the cost of concrete. From the laboratory results, the slump value of glass fiber concrete decreases with the enhance of waste glass fiber percentage.4 Cement can partially be replaced with glass powder in new concrete and to monitor the creep of this concrete. From the laboratory results, it can be found that the waste (Lamp) glass effectively utilizes in a preparation of concrete, thus the reduction of the amount of this waste in and reduce the usage of cement which leads to decrease the amount of carbon dioxide discharge into the air.5 Mixed–Colored waste glass has sufficient chemical composition and reactivity to increase the chemical stability, toughness, and moisture resistance. It is necessary to grind at microscale particle size for enhancing the helpful chemical reaction in concrete. In this research concrete prepared by partial replacement of cement with waste glass. From results it can be found that the waste glass is used as a partial replacement of cement helps in better strength and durability while comparing with standard concrete. Waste glass also has also pozzolanic reaction with cement hydrates to develop the chemical composition and microstructure of concrete. It also plays an important role in development of saving energy, economical and sustainable concrete–base infrastructure system.6 The huge volume of waste glass has been augmenting in few years due to enhancing the development of industrialization and living standard. Unfortunately, as the waste glass present in huge volume, it is not recycled in quantity as desire, hence the cause of definite issues such as waste of natural resources and environmental pollution. This research provides short information and concrete containing waste glass powder which undergoes sulfate attacks.

The utilization of sheet glass powder in concrete which enhances the green environment and decrease s the wastes. The concrete which contains Sheet Glass Powder (SGP) can economize waste disposal, sites and saving natural sand. This paper determined the possibility of utilizing the waste glass powder as partial replacement of fine aggregate in concrete. The test results show the water requirement decreases with the increase of sheet glass powder, The concrete which contain s 100% SGP as replacement of fine aggregate proved good outcome as compared with controlled concrete at 28 days curing and 45 days curing after that the reduction in strength had been observed due to Alkali–Silica Reactions. The density of waste glass concrete was more than controlled concrete. This waste present in huge volume and can be used in concrete to decrease the volume of waste in the environment, 10% utilization of waste glass powder as partial replacement in concrete was at an optimum level.8 Disposal of solid waste to the landfills of used Solid waste which can be used in concrete is a serious issue to be solved for Pakistan EPA. Currently, this industry is facing many challenges, concrete with different proportions to produce concrete more strong than ordinary concrete (especially as a member like Beam) economic and cost effective.9

This research aims to investigate possible utilization of waste glass as fine aggregate in concrete keeping essential properties intact.

The Specific Objectives are:

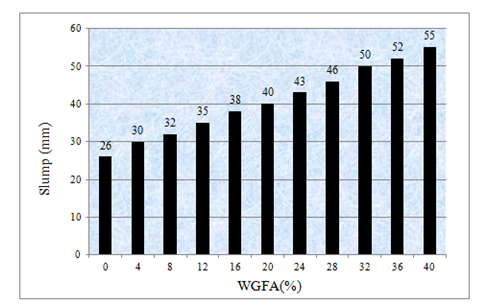

Batch no. |

WGFA (%) |

slump (mm) |

increase %age |

1 |

0 |

26 |

_ |

2 |

4 |

30 |

15 |

3 |

8 |

32 |

23 |

4 |

12 |

35 |

34.61 |

5 |

16 |

38 |

46.16 |

6 |

20 |

40 |

53.84 |

7 |

24 |

43 |

65.38 |

8 |

28 |

46 |

76.92 |

9 |

32 |

50 |

92.3 |

10 |

36 |

52 |

100 |

11 |

40 |

55 |

111.5 |

Table 1 Results of slump test of Glass Concrete for WGFA size passing from 1.71 mm & retained on 1.19 mm sieve

Batch no. |

WGFA (%) |

water absorption (%age) |

Decrease %age |

1 |

0 |

1.9 |

_ |

2 |

4 |

1.64 |

13.68 |

3 |

8 |

1.6 |

15.78 |

4 |

12 |

1.54 |

18.94 |

5 |

16 |

1.45 |

23.68 |

6 |

20 |

1.424 |

25.05 |

7 |

24 |

1.35 |

28.94 |

8 |

28 |

1.31 |

31.05 |

9 |

32 |

1.29 |

32.1 |

10 |

36 |

1.25 |

34.21 |

11 |

40 |

1.05 |

44.73 |

Table 2 Results of Water absorption test of Glass Concrete for WGFA size passing from 1.71 mm sieve & retained on 1.19 mm sieve

Batch no. |

WGFA (%) |

density (kg/m3) |

increase (%age) |

1 |

0 |

2558 |

_ |

2 |

4 |

2605 |

1.83 |

3 |

8 |

2610 |

2.03 |

4 |

12 |

2652 |

3.67 |

5 |

16 |

2580 |

0.8 |

6 |

20 |

2571 |

0.5 |

7 |

24 |

2572 |

0.54 |

8 |

28 |

2570 |

0.46 |

9 |

32 |

2568 |

0.39 |

10 |

36 |

2560 |

0.078 |

11 |

40 |

2511 |

–1.83 |

Table 3 Results of Density test of Glass Concrete for WGFA size passing from 1.71mm& retained on 1.19mm sieve

Batch no. |

WGFA (%) |

compressive strength ( n/mm2) |

increase %age |

1 |

0 |

31.518 |

_ |

2 |

4 |

38.844 |

20.7 |

3 |

8 |

41.954 |

33.11 |

4 |

12 |

45.142 |

43.22 |

5 |

16 |

43.526 |

38 |

6 |

20 |

37.023 |

17.46 |

7 |

24 |

35.963 |

14.08 |

8 |

28 |

33.346 |

5.8 |

9 |

32 |

32.06 |

1.6 |

10 |

36 |

31.675 |

0.48 |

11 |

40 |

29.275 |

–7.11 |

Table 4 Results of Compressive Strength test of Glass Concrete for WGFA size passing from 1.71mm& retained on 1.19mm sieve

Based on the obtained results in this study, it can be concluded that:

By increasing the dosage of WGFA, the density of concrete increased, maximum 3.67% and 3.32% increased as compared to ordinary concrete, at the addition of 12% of WGFA respectively, whereas on further increment of WGFA, the density of concrete decreased.

None.

The author declares there is no conflict of interest.

©2018 Rabnawaz, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.